Why you shouldn’t throw away “extra” hardware when changing pads

Brake pads are one of the most frequently replaced consumables on any car. Anyone can change them. However, not even every service technician can do the simple procedure correctly. Every little detail counts in this business. We explain why.

Any driver during the operation of the car at least once, but faced with all sorts of squeaks, squeals or even rattles from the brakes. These phenomena are caused by a variety of factors, and not always by poor quality pads or contamination of the brakes. Usually, the strange noises are just a consequence of inadequate maintenance and the use of improper lubricants.

Of course, we will not deny the presence on the spare parts market of low-quality pads. cheap counterfeit products were, are and will be. Some pads really work with a disgusting squeal precisely because of the composition of the friction linings. And yet, this phenomenon usually occurs for a completely different reason. the pads do not press against the brake discs or are reluctant to move away from them.

In order to understand why this happens, you need to look closely at disc brakes. On all modern passenger cars (with a few exceptions) they are of about the same design. This is a single-piston caliper with a floating bracket. The mechanism works outrageously simple: when you press the pedal, the brake fluid presses on the cylinder which in its turn presses on the inside shoe, which bites a brake disk; from outside the shoe is pressed to the disk by a floating caliper bracket.

Now look closely at the bracket itself: it has special grooves in which the pads move. pressed to the disk and move away from it. From the factory these grooves are fitted with cunningly shaped interchangeable special plates. penny parts made of tinplate with anti-corrosive coating or of more expensive stainless steel. Just these elements are designed to ensure perfect and quiet operation of brake machines.

The tin plates (aka guides) have two important functions at the same time. Being installed on the bracket, they actually act as a bearing for the pads. the movement becomes much easier, especially if the friction pairs are lubricated with a special lubricant. At the same time, these plates increase the pressure area from the shoe to the brace jaw during braking. It allows you to prolong significantly the life of the bracket itself and avoid formation of “corns” on its surface.

Everything would be good, but the service life of guide plates is not long, and new kits of brake pads are often sold without these small, but very important for the proper work of the caliper. Many car owners and service centers don’t want to buy them separately or they forget to do it deliberately. The result is fast wear and contamination of brackets, worsened mobility of mechanisms, and quite often. a lot of people buy them separately. The most hated squeaks and rattle from the brakes.

One more element, not less funny and cheap, but very important, which is often forgotten. anti-vibration plates. These parts are on the back side of the pads and are simply ignored by many service stations and car owners.

In cars with properly designed braking systems there is no need to resort to unnecessary gestures and purchases: anti-vibration (or antiskrip) plates are permanently attached to the pads themselves. just buy a new set and install it, if necessary, lubricating the contact points between the piston and the back of the pads.

But there is a nuance. the cheap, non-original pads may not have any plates. In this case the car enthusiast or service man will have to “glue” a used part or just forget about it.

The anti-squeaking plates are needed to absorb the parasitic vibrations that arise during braking. They also help the pads to transmit the braking force to the disc more evenly when the brake pedal is depressed. The lack of vibration is one of the keys to quiet braking.

That’s why it’s better not to get rid of “superfluous” tins in brakes. All of them are installed for a reason. If you have no new parts, it is better to use used, but relatively “live” elements than to install the pads without them at all.

News of partners

Found a typo? Select the text and press CtrlEnter

All rights reserved. Full or partial copying of materials of this Site for commercial purposes is allowed only with written permission of the owner of the Site. If any violations are found, the guilty persons may be held liable in accordance with the current legislation of the Russian Federation.

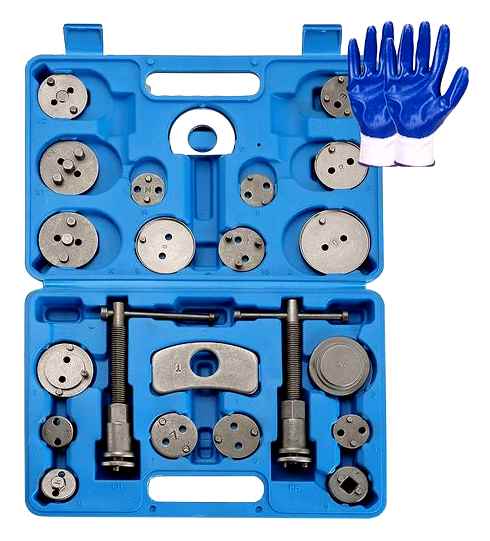

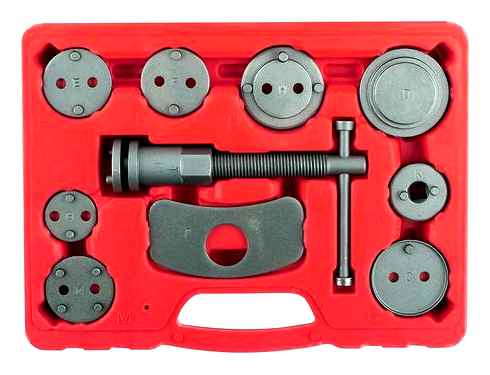

Required tools for brake pad replacement

With your own hands replacement of front and rear brake pads on different makes and models of cars is made by a similar algorithm, so it requires approximately the same set of tools. The only difference may be, for example, the size of the keys and other minor differences. The basic tools required to perform the work of replacing the pads on the car are given in the table below.

To determine if the brake pads need replacing

Brake pad replacement is required in the following cases:

- brakes are getting soft;

- the vehicle veers sideways when driving or braking;

- the wheel is hot;

- the brake pads have been lapped, causing damage to the discs;

- the car brakes badly, even after the pads have run in;

- the handbrake adjustment fails and the handbrake does not hold the vehicle;

- The wheel does not turn well when the car is wheeled out;

- the brakes are completely gone, even if all other parts of the braking system are working properly;

- the steering wheel bounces when the car is stopped or in motion.

Determining if the brake pads need to be replaced

Brake pad replacement is necessary in the following cases:

- brakes are getting soft;

- the vehicle veers sideways while driving or braking;

- wheel is heating up;

- The pads have been lapped and the discs are damaged;

- the car brakes badly, even after the running-in of the pads;

- the handbrake can not be adjusted and does not hold the vehicle;

- In a dislocated state, the wheel does not twist well;

- the brakes are completely gone, if the other parts of the braking system are good;

- the brake pedal is not holding the vehicle;. the steering wheel hits when the vehicle is stopped or in motion.

To change the front disc brake pads with your own hands

You can change the front brake pads according to the instructions below.

- Install the sensor on a new consumable.

- On some vehicles, a number of pads and plates are used. Before installing the pad in its seat, install all elements in the same sequence as they were located with the old expendable.

- If the brake pedal does not hold the vehicle properly, remove the brake fluid. To ensure that the brakes do not become cotton, you need to remove air from the circuit. It is not necessary to do this procedure, but it is advisable. You can pump the brakes at any convenient moment without removing the wheels.

- set the wheel.

- check that the brakes work properly: the intensity of stopping the car is sufficient and the wheels are not jammed during driving.

Replacing rear disc brake pads is done in the same way. The only difference is that because of the handbrake cable you may not need to tilt the caliper up, but dismantle it completely. Note that to prevent damage to the ABS system, the corresponding sensor clamp must be disconnected first.

Replacing Brake Pads on Rear Drum Brakes

The rear brake pads of drum brakes are replaced much less frequently than the more heavily loaded front pads. And although drum brakes look structurally more complicated than disc brakes, replacing them is usually even somewhat easier.

The main thing in this procedure is to remember the location of all the springs and rods in order to install them exactly the same when reassembling, otherwise the brake will not work.

- The first three points of the disc brake replacement procedure are performed. It is important to take the car off the handbrake, which is an integral part of the drum brakes.

- Unscrew the nut fixing the brake drum and if it is “stuck” remove it by tapping and unscrew it.

- Carefully examine the location of springs, clamps and rods.

- Release the handbrake and all springs and rods. Remove the old pads.

- Assemble new pads with tie rods and springs;

- Install the assembled kits inside the brake mechanism.

After installing the new brake pads, always check that the brakes are in good condition.

Checking the brakes after a pad change

When checking the brakes efficiency make sure that the mechanism is assembled correctly, the brakes should work smoothly, without jerks and noise.

This is particularly important with front disc brakes, new pads also require a run-in on the friction surfaces (known as “lapping in”).

If the disc brakes are assembled correctly, the running-in is carried out as follows:

- the first 150-300 km of mileage after replacement use a series of so-called soft (no more than 50% of the maximum force on the clutch pedal) brakes, which are short-lived (to avoid overheating of friction surfaces);

- during the running-in period it is recommended to make at least 30-50 stop cycles with gradual unbraking and each stop for at least 3-5 seconds (to allow the brake mechanism to cool down a little).

Check the quality of the handbrake assembly even before removing the machine from the jack: by tightening the handbrake and trying to turn the wheel. The entire drum brake assembly is evaluated during the running-in process on the move.

It should be borne in mind that the squeaks and noises are not always the result of faulty assembly or poor-quality pads. Such noise may be caused by small stones caught in the brake mechanism or by weather conditions connected with high humidity or formation of condensation.

If the wrong friction lining material is selected and a new pad “dusts”, the noise consequences are much more likely to be detected in a drum brake mechanism than in a disc brake mechanism, since there is simply nowhere for the dust to escape.

Replacing the rear brake pads

But if the rear is a drum mechanism, the replacement of the rear brake pads is more labor-intensive than the disc ones.

Changing the pads on the drum-type rear brakes

Again, the wheel where the brake pads will be replaced is jacked up and removed from the car. To remove the drum, you need to undo the nut fixing the drum and unscrew the nut itself. Then gently pry the drum from different sides, and remove it from the hub axle. When removing, it is important to observe the bearing that is installed in the drum. If there is a parking brake mechanism, it is removed.

Next, you need to carefully remove the coupling springs. that the force of these springs is significant. After removing the springs, the shoe retainer leaf springs are removed, and the pads are removed.

Before replacing the rear brake pads, you need to recess the pistons in the operating cylinder. After that, the pads are put in place. After that they are fixed with clamps, the tie-down springs and the parking brake mechanism are installed on them. Then the drum with the bearing is installed and tightened with the nut, the nut itself is locked. After the wheel is installed. Replacing the rear brake pads of the drum mechanism is made.

It is important to remember that the brake pads should be changed at least in pairs, i.e. if the pads of one front wheel are changed, they must be changed on the second wheel as well. Or better to change the pads on all wheels at once.

Brake Pad Replacement

With intensive exploitation of a car the brake-pads should be replaced more often than it is necessary according to the schedule of car maintenance. If you have never repaired the brakes, the question of how much it costs to change the pads becomes secondary. The mechanics of car-care center S-MOTORS will change a detail quickly and inexpensively.

Car manufacturers do not regulate the frequency of replacement of consumable parts of the brake mechanism. The theory is that the service life of the friction linings is 30,000 to 50,000 kilometers. But with urban operation on Moscow asphalt replacement pads Ford or Subaru may be required after 25000 kilometers.

Increased pad wear is characteristic of extreme operation of the vehicle in the countryside (on dusty roads, country lanes, off-road conditions). Friction linings are quickly erased at an aggressive mode of driving of the owner of a foreign car (in the “gas. brake” mode at every traffic light).

Signs of friction linings wear

The first sign that it is time to change the brake pads is a squeak of friction linings, as they wear, turning into a metallic squeal when braking sharply. With critical wear, brake failure is manifested in wheel wobble, increased braking path.

When examining the brakes even with the naked eye you can see thinning, chipping, friction lining cracks, metal deposits, oily surface, grooves on the brake disc, caliper fixture play. Repair pads (change or rivet friction linings) apply only for rare models of foreign cars, old domestic cars.

Brake Fluid Replacement

The question, how much does replacement of pads cost, is actual for owners of budget cars, Russian Zhiguli and Kalins. At car-care center S-MOTORS the cost of brake pads is not increased by intermediary charges. Car service buys supplies at wholesale and does not apply trade markups when installing.

Take into account that when replacing the brake pads the price of an auto mechanic does not include the cost of the replacement kit. The cost of pad replacement includes operations on disassembly, assembly and adjustment of brake mechanisms.

The price depends on the peculiarities of the brake system of the car, on the complexity of work and technical condition. Knowing car’s VIN number we can tell you exact cost of works and spare parts. Call!

| Type of service | Price in rubles |

| Brake pad replacement, disc brakes | 700 ₽ |

| Front Brake Parts Service per 1pc | 250 ₽ |

| Rear Brake Mechanism Service | 250 ₽ |

| Manual brake pad replacement with removed brake disc 1 side | 500 ₽ |

| Replacing of the front brake discs (set) | 2000 ₽ |

| Replacement of the rear brake discs (set) | 2000 ₽ |

| Brake Hose Replacement | 400 ₽ |

| Brake tube replacement front circuit | 800 ₽ |

| Main brake cylinder replacement | 1200 ₽ |

| Brake fluid replacement | 1200 ₽ |

| Pumping the brake system, bleeding | 1200 ₽ |

| Replacing the front brake master cylinder (disassembling the caliper) | 1500 ₽ |

| Replacement of the rear brake master cylinder (caliper disassembly) | 1500 ₽ |

| Replacement of the front brake caliper | 1000 ₽ |

| Replacing the rear brake caliper | 1000 ₽ |

| Servicing the handbrake mechanism 1 side | 250 ₽ |

| Replacing the handbrake cable 1 side | 1500 ₽ |

| Handbrake actuator adjustment (handbrake)1 side | 400 ₽ |

| Replacement of the anti-lock braking system (ABS) unit ( with adaptation) | 5000 ₽ |

| Replacing Rear Brake Drums 1 Side | 1200 ₽ |

| Replacing the rear brake cylinder with the drum removed 1 side | 500 ₽ |

Correct replacement techniques

Front-wheel drive cars have front brake consumables replaced more frequently, but the procedure from the perspective of experienced mechanics is not difficult. It is more difficult to change rear brake pads, access to which is complicated by the location of the gas tank, drum brake mechanism.

In order to technologically correctly replace the brake pads (usually changed on the same axle in pairs), you need to:

INSTALLING NEW BRAKE PADS

It’s almost time to install new brake pads. But before you can do this, there is one more step to take. You must manually remove the caliper piston.

If you look at the inside of the caliper, you’ll see a cylindrical piston come out. this part presses on the inside of the brake pad. You will see that this piston has adjusted to the worn pads, so you need to reset it before the calipers, along with the new and thicker pads, are in place.

Before you reset the piston in the caliper, it would be a good idea to remove the cover that covers the brake fluid reservoir. If you don’t, you will have to battle with a significant amount of pressurized fluid.

Now that you’ve removed the reservoir cover, there comes a point where you’ll need a C-joint. Place its end with the screw on the piston. If you want, you can use a small piece of cork to protect the surface of the piston. When you turn the end with the screw, the pod will increase the pressure on the piston. Continue to tighten it until you are able to insert the new pads into the caliper and install the caliper with the new pads on the brake disc.

If you find that the piston does not resist retracting, do not put pressure on it. You may be dealing with a caliper whose piston twists when it straightens. If this is the case, you need a special tool that puts the piston back in the caliper. The brake caliper tool. a specially designed tool that allows you to put this type of caliper piston back in place. is available for purchase at almost every auto parts store. If you can’t find it in car dealerships in your city, you can order this tool online, or if you’re lucky you can ask a neighbor if he has one in his garage and he can lend it to you until tonight.

Once the brake caliper piston is back in its original place, you can close the brake fluid reservoir cap. Remember, it’s best not to leave the reservoir open any longer than circumstances warrant. Debris or even water will be able to find its way into your car’s hydraulic brake system. Brake fluid is hygroscopic, which means it absorbs and holds water. Water in the brake tubing leads to serious safety problems and more complicated repairs than the relatively simple brake pad replacement we’re ending up with.

Installing the new brake discs at this stage simply requires you to slip them into place where the old ones used to be. If this process causes any difficulty and you can’t easily insert the new pads with just your hands, you can gently help them with a regular or rubber mallet. Then install the studs or bolts that held the previous pads in place, and the job is almost done.

Then, install the caliper in its place on the brake disc. Make sure it fits snugly, and tighten the bolts that hold the caliper in place. Make sure everything is back in place, and then push the brake pedal inside the car a few times to make sure everything is back to normal. You may need to press the pedal a few times to get all the components of the brake system back into place.

The rest of the repair is the easiest part. Reinstall the wheel, tighten the nuts, lower the car to the ground with the same jacks. Don’t forget to fully tighten the wheel nuts when the car is down on the ground.

Also, don’t forget to give the car a little test drive to make sure that the pad replacement job was completed successfully. Repairing the brakes is one thing, but making sure it was done properly is another thing entirely.

Removing the old pads.

The caliper is put on the brake disc as a clamp, and its task is to squeeze the brake disc with the pads using hydraulic pressure. That’s how you apply the brakes.

The calipers usually come in one-piece or two-piece construction, attached by two or four bolts from the inside of the wheel to the caliper brackets.

Spray the caliper bolts with WD-40 to make them easier to unscrew. Allow the grease to work for about 5 to 10 minutes, then you can unscrew the caliper guides.

If there are retaining clips, you need to remove them with a small screwdriver. Many cars have pad wear sensors, so carefully disconnect the connectors.

Check the pressure on the caliper. Take a large screwdriver and squeeze the pads a little, pushing the cylinder. This makes it easier to remove the old pads.

The caliper of the car in a resting state should move back and forth a little. If not, the caliper is under pressure and may come off when the bolts are removed. Check to see if there are any shims or working washers installed between the caliper mounting bolts and the mounting surface. If there are, remove and inspect them, if necessary replace them with new ones.

Brake caliper guide bolts

Many Japanese cars use a two-piece sliding caliper, which requires the removal of only two guides with heads 12-14 mm. You do not have to remove the entire caliper.

Changing the front brake pads with your own hands

Now remove the caliper or move it aside if you only unscrewed the guides on one side.

Hang the caliper carefully on a wire or rope to the wheel or spring of the shock absorber strut.

Replacing the front brake pads with your own hands

Attention! The caliper is still attached to the brake line, so secure it in such a way that it does not pinch or pull on the brake hose.

Pulling the brake pads out of the calipers. Clean seating surfaces of pads with a metal brush or screwdriver.

Replacing the front brake pads with your own hands

Be sure to check the guide pins. the dusters should be intact, and the guides themselves walk smoothly and easily in the grooves.

Warning! Clean and lubricate the caliper pads every time the brake pads are replaced. This procedure is not time consuming, but it will prolong the service and improve the reliability of the brakes.

Use a special high temperature lubricant to lubricate the guides. Lithol, the old fashioned way, should not be used. At some manufacturers of pads you can find such a grease in the set with the new pads.

Installing new brake pads.

All necessary preparations are made. let’s proceed to assembly.

The first thing to do is to press the brake cylinder fully in. Squeeze the caliper cylinder with the brake caliper piston press tool. Changing the brake pads with your own hands, and if still in the field, to compress the caliper piston you can use a cylinder wrench, a clamp wrench. You can also make a special tool with your own hands use a large bolt and an old pad. There are many variants, the main thing is to take into account the principle of action of the original tool and use your ingenuity.

how to depress the brake caliper piston without using tools in the field

Warning! Some pad equivalents may be slightly different in shape. For example, the ears of the pads may be longer than the slots in the brake calipers, and the part will not fit in the grooves. In this case do not panic, but check: does the shape and design of the shoe match the other parameters. Yes, it is. grind down the unnecessary protrusions to the size of the old pad.No, it does not. there are significant differences. you need to pick up other pads. Do not try to make the wrong pads into the right ones, it may cause the brakes to jam or malfunction.

Putting on new pads and sliding the caliper. Apply some copper grease on the threads to prevent corrosion.

Change The Brake Pads in Your Car Step 9 Version 6.360p

Reassemble the caliper like you did it and put the tire on.

Important! Before you go on your trip, check the brakes after replacing the pads. Press the pedal all the way down. Push the pedal all the way in and brake. Repeat this a couple of times. It’s OK? Re-brake at a higher speed. Make sure there is no grinding or other discomfort.