The device of the carburetor of the grass trimmer gasoline

Adjusting the carburetor of a brushcutter is a process that must be mastered for the full operation of the grass trimmer. Grass trimmer is a completely uncomplicated device, which can break down only in a few places and require mechanical repair or replacement of parts. Adjusting the float-type brushcutter carburetor may require some fine tuning. The nuances due to the model and the specifics of its operation will ensure a clear mode of mixing and feeding the fuel mixture.

Champion lawnmower carburetor, how to adjust? It is just a float-type grass trimmer. a common option, designed to mix in the prescribed proportions of air and fuel. The main problems that arise during the operation of the motor, are roughly similar to the problems encountered by the carburetor in the car:

- The engine may shut down as soon as it is started. The reason is that not enough gasoline is being supplied. This is called “poor” fuel;

- Excessive gasoline leads to incomplete combustion, excessive mixture density and uneconomical fuel consumption.

Carburetor Repair

Important! Adjust the carburetor has to be under different circumstances: a change in temperature, octane number of fuel or type of oil, after winter or the end of the running-in period, the load or spontaneous turning of the screws from strong vibration housing. Some owners like to tune the unit before each use to make sure it operates properly.

Major Malfunctions

Faults in the carburetor of a brushcutter or grass trimmer, despite the relative ease of fixing them, sometimes require a long search by the method of elimination. The main reasons are as follows:

The most recurring problem is wear and tear, a ruptured diaphragm. As a consequence, its loose fit. Fuel passages are not sealed at certain stages of the engine cycle. The causes here are as follows:

- You work for too long on your brushcutter or trimmer without stopping;

- low-quality fuel is fueled;

- Exhaust gases enter the impulse line.

A deformed diaphragm carries several bad consequences:

- Not enough gasoline or oxygen in the mixture created;

- The engine starts after 10 or more unsuccessful attempts;

- the engine is knocking, clanking, etc. д.;

- The working piston becomes deformed.

How much citric acid per liter jar of cucumbers

Causes of a clogged strainer are poor quality fuel cleaning, damage to the hose and/or discharge head.

Wear of the contact face of the lever is a consequence of not fully purified fuel, in which grains of sand or particles of clay, metal or other inclusions not soluble in liquid hydrocarbons got into. there appears a problem with fuel injection, the engine works irregularly at no load.

Inlet needle breaks because of metal and rock particles in the gasoline. As a result the inlet needle seat does not seat tightly and the fuel mixture leaks. Too much air in the mixture from the carburetor, causing the engine to “sneeze” while operating. Finally, the needle may stall because of low-quality gasoline, or the unit has been idle for a long time.

Deposits may accumulate in the control compartment. The needle does not close the hole completely, and a lot of gasoline enters the fuel chamber. the engine overflows, possibly flooding the spark plugs. The gasoline-air mixture contains an excessive amount of gasoline vapor because of this. Efficiency drops considerably.

The diaphragm is often deformed (sometimes even torn) due to continuous operation of the brushcutter or grass trimmer for several hours. If you overdo it, diaphragm damage is more likely to occur. New failures will appear from the horn of plenty:

- The piston breaks down;

- The number of unsuccessful engine start attempts will increase dramatically;

- the fuel mixture will contain too little petrol;

- Useful (heat) power will drop down drastically.

Adjustment lever jamming. improper setting of the lever, unintentional bending. The contacting facet will become misaligned. This will interfere with the additional injection of gasoline.

Damper is worn out

Throttle and air damper deteriorate from ingress of dust, metal particles, etc. in the air stream. д. Damaged flaps look like parts that have been blasted with sand. Wear of the flaps lowers the efficiency of the engine and causes malfunctions. The piston and cylinder wear out.

In some cases the filter is simply not compatible with your brushcutter or trimmer model. Eventually the motor shaft will be damaged. pieces of it will get caught in the engine channels, causing the piston to break.

If the adjustment is too rough (no exact setting) it is the fault of the springs on the adjusting screws. The trimmer or grass trimmer manufacturer may have put excessively thick and stiff springs. You can find other ones in shops that repair such equipment, or you can buy them at any dealer or an official representative of the company that produced the motor for your grass trimmer or a mechanical grass trimmer.

The primer is broken

Primer is a mini hand pump for forcing fuel into the carburetor. You may need to pump 20 ml of gasoline manually to get your motor running successfully.

Technical features and special features

With a manual fuel pump, you can easily pump fuel into the carburetor. Especially important if the lawnmower is idle for long periods of time. Constant feeding of fuel will quickly start the device even after a “long vacation.

Protection glasses and the mowing head are supplied with the machine. With the manual on our website you can understand the mechanics and specifics of the machine.

Other useful information can be found in the following document:

The STIHL FS 38 boom with curved handle is worth a look. This design makes it easy to clean an area, even in narrow or confined spaces.

All controls are located on a handy handle, so you don’t have to look for a long time to find where and what to switch. This is a decisive advantage when working, because it allows the operator to control the machine without having to take his hands off the mower and without having to move it unnecessarily.

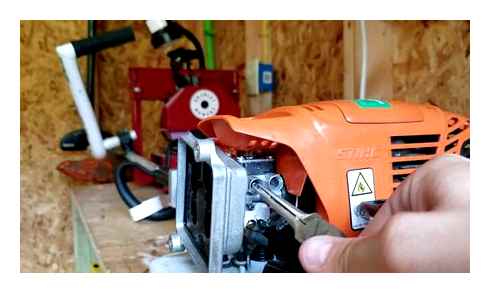

Adjusting the carburetor on the STIHL FS 38

All the procedures are straightforward, but you have to be serious and willing to do the job. And many owners note that you can independently conduct not only the adjustment of the carburetor, but also the replacement parts. The following diagrams are excellent tools for this task.

How to adjust the carburetor on the STIHL FS 80 weed trimmer

While STIHL makes every effort to factory-tune the equipment it manufactures, different environmental conditions may require adjustments to the unit’s idle speed and power output. If your STIHL FS 80 trimmer is not performing as it should, you may need to adjust the carburetor settings. STIHL supplies an adjustment tool for every FS 80 that is designed to help you with this task.

Turn the high-speed screw clockwise to fine-tune it for use at higher altitudes. Keep turning it until there is a noticeable increase in engine RPM. Do this with the motor running.

Turn the high-speed screw counterclockwise to fine tune it for use at sea level. Continue turning it gradually until there is a noticeable increase in engine speed. Carry out this task with the motor running.

Adjust the idle speed screw by turning it clockwise or counterclockwise until the cutting head.

How to adjust the carburetor on a chainsaw

Before adjusting, the filters must be thoroughly cleaned according to the maintenance in the manual.

Further adjustment of the lawnmower carburetor with your own hands is done with the adjustment screws. There are three in total:

Right (L). fuel mixture adjustment for low revs.

Find the maximum idle RPM. To do this, turn the screw (L) slowly to the right and left.

How to adjust the carburetor on a STIHL 55 trimmer.

To adjust, turn the screw a quarter of a turn necessarily counterclockwise.

lower (T). responsible for engine adjustment at idle speed.

It is the idle speed that is characteristic for proper adjustment:

- stable operation of the cold engine;

- not over-running the hot engine;

- for the trimmer head is a large RPM margin;

- stable engine operation during changes of position (sudden upslope or downslope).

Left (H). adjusts mixture at high rpm. (The screw should be adjusted last).

The left-hand screw (H) affects the overall adjustment of maximum rpm, engine output, temperature and gasoline consumption.

Adjustment carburetor lawnmower with the last propeller is performed as follows:

- Open throttle to full throttle and give off full throttle. Turn screw clockwise until rpm drops (in this case turn it by ear).

- Turn the screw as slowly as possible counterclockwise until the engine is uneven.

- Then turn back just a little, barely hearing a stable, smooth operation.

- For more obvious application of skills it is more convenient to consider the work of an experienced user:

It is interesting that from the point of view of the author of the video, the adjustment (its correctness) is determined by the color of the candle, and not only by the revs and engine stability.

The correct adjustment of the carburetor with their own hands in this case. combustion of the fuel mixture without residue, the color of the candle should be light brown.

Technique of performance

Before adjusting the carburetor on your STIHL chain saw, carry out maintenance. It involves cleaning the engine as well as the carburetor. Replace the spark plugs, check the chain tension and work on cleaning the air filter. The engine should be preheated and the idle speed adjusted.

When adjusting the carburetor on your STIHL chain saw the screws H and L should be turned clockwise. The equipment should be turned off. Both screws are then turned out one turn. Then the machine starts and warms up. Give full throttle and then use the first screw to increase the maximum rpm to 14,000. This can be checked on the tachometer. This is the engine speed counter.

When adjusting the STIHL 180 with your hands, do not hold the carburettor for more than 10 seconds. To the stop of the idle speed with the LA screw you have to make the chain start moving. This screw is then turned a quarter of a turn counterclockwise. After this you may notice that the idling speed is not stable.

The chainsaw may not run fast enough. This indicates that the L screw should be turned anticlockwise. The equipment will pick up speed for a short time and therefore work well at idle. The LA bolt should be adjusted after that, and idle speed should be 2800 per minute.

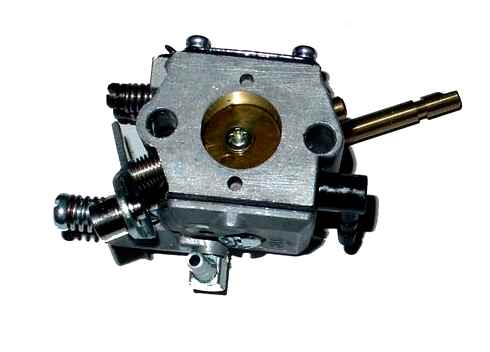

On the structure of the carburetor

The carburetor serves for mixing the fuel/air mixture in the proportions determined beforehand. If the exact doses are not respected, the malfunction of the engine is endangered. When during the mixing of the component receives a lot of air, and not enough fuel, then such a mixture is considered “poor. Do not allow and supersaturation, because when a large amount of fuel compared to the air is also likely to malfunction or wear the engine. STIHL 180 chain saw repair with their own hands. 142, 240, 365 with their own hands. video. Adjustment of the carburetor is needed not only before initial implementation, and when any differences in its operation are identified. Before starting your chainsaw, don’t forget to run it in.

The design of the carburetor contains a standard set of parts, but may vary slightly depending on the manufacturer. Components:

- The base. Adjusting the carburetor with your own hands on. It is a special tube, which visually resembles an aerodynamic design. Air passes through it. There is a flap in the middle of the tube in a transverse direction. Its position can be adjusted. The more it extends into the aisle, the less air gets into the engine.

- diffuser. This is the narrowed part of the tube. With its help, it increases the rate of air flow exactly in the segment where the fuel comes out.

- Channels for fuel supply. The fuel mixture is contained in the float chamber, then passes into the nozzle from which it flows into the atomiser.

- Float chamber. Is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain an optimal level of fuel fluid in front of the inlet to the channel, where the air comes from.

Not sure which chainsaw to choose? Read our article.

Looking for cheaper models, but reliable and time-tested? Pay attention to chainsaws made in Russia.

Or study foreign chainsaw manufacturers, such as STIHL.

Problems and remedies. repair with your own hands

But what to do if you suddenly could not avoid the mechanism failure? We will not get into the causes of this, but it will not be superfluous to consider possible problems that may arise with the mower, as well as methods of their elimination with their own forces.

The engine won’t start. If you face this problem, then initially you need to assess the amount of fuel in the tank, maybe the problem is not as such, and you only need to add fuel and continue to work. By the way, the fuel used by the mower is worth special attention, because its quality determines the durability and quality of life of the mower. Experts recommend gasoline AI-92, not lower.

Stiga robotic lawnmowers are an innovation in the agricultural industry that has managed to win the hearts of many farmers and gardeners.

Makeshift circular sawmill. easy and simple, thanks to the detailed instructions you will find on this site.

Wondering “How to choose a professional saw, not having any experience with this tool?”If you do not have access to a water supply, please go here //machinspec.com/lesozagotovitelnaya/benzopila/kak-vybrat.html.

Another reason for an unstable engine could be a clogged fuel filter. It should be inspected carefully and cleaned if necessary. If the filter can not be repaired by yourself, you should replace it with a new one.

Do not forget about the air filter, clogging which can also lead to failure of the tool. To avoid this, the part should be removed and washed in water and detergent or in petrol if you do not have access to a water supply.

STIHL lawnmower

The filter should then be thoroughly rinsed and dried, paying close attention to structural integrity. Before installing the part in the mower, it is necessary to lubricate it with a small amount of oil. However, if you do not want to bother with cleaning the machine, then we suggest you familiarize yourself with the mower with the mulching function, because it will not only mow the lawn, but also prepare further fertilization.

The spark plug can also affect the performance of the engine. It is necessary to unscrew it and check its condition and if necessary replace it with a new one.

If after all the manipulations done, the engine still does not start, you can resort to the advice of experienced craftsmen who have used them in practice.

It is necessary to adjust the revolutions by means of the carburetor screw. The mower is laid in such a way that the fuel hits the bottom of the carburetor. To do this, the tool is placed so that the air filter is on top.

Take it off and put a little bit of fuel in the carburettor and put all the parts back. The engine should start.

You can pull the starter grip and close the carburettor choke. Then open it and pull the starter a couple more times. This is a fairly universal method, proven over the years.

These tips are not a panacea, but they are quite effective and useful.

Mower stops shortly after starting. The main reason for such a malfunction is improper adjustment of the carburetor. It is easy to spot the problem, you will feel the vibrations. You can correct the problem yourself by consulting the manual, which describes the problem and how to fix it.

Pay extra attention to the fuel line, because it is often the reason why the tool stops. Check it regularly and get rid of any dirt.

Lawn mower characteristics

Various small parts, such as the cable or the fuel intake hose, can affect the stable operation of the tool. So you need to monitor their condition, check for cracks and small punctures.

Lawnmower carburetor construction

The basis of the lawnmower carburetor is an aluminum housing. It contains a diffuser (an opening with internal circuits). This is the port where the air is forced in. The cross-section (orifice) of the diffuser determines the flow rate of the oxygen (air).

The diffuser is equipped with fuel channels. Fuel is sucked out of these with a stream of air.

Many might be put off by the relatively high price of a STIHL fuel system, but is it more important to consider whether reliability and good value or economy of scale against quality?? But if you set the goal to save money, then we offer you a variant of the lawnmower with your own hands, collecting the device with your own efforts you will know all the nuances and structure of the tool.

Of course, you can choose cheaper Chinese analogues, but then no one can vouch for the result of the final work and for the lifetime, which can be very short in such models. That’s why it’s better to buy a STIHL lawn trimmer from a reputable company once and enjoy stable operation for years of use.

Grass trimmer specifications

In addition to good build quality, the STIHL FS 38 lawnmower is also designed and built to the highest standards from the factory.

The list of the most important features of the garden tool includes:

- factory engine power. 0.9 l. с. at 9500 rpm;

- Fuel tank capacity of 330 ml;

- maximum fuel consumption. 320 ml/h;

- coverage when mowing with a blade/blade. 38/25,5 cm;

- The acoustic impact on the operator is 97 dB;

- weight 4.2 kg.

STIHL grass trimmers stand out from the competition because of their modest dimensions. Length of the brushcutter is 147 cm with the cutting attachment removed.

How to change the spark plug correctly?

As you can see there is nothing very complicated about this procedure.

A new spark plug for the two-cycle combustion engine of a petrol grass mower is installed to replace an old part that has failed

Operating recommendations

It is necessary to take temporary breaks in operation. To prevent the engine overheating and early mowing. For recreational models, there is a break every 20 minutes for the same amount of time. For professional mowers, it is necessary to interrupt work every 50 minutes, in which case the downtime should be at least 10 minutes.

Keep an eye on the fuel tank. If you do not plan to use it for a certain period of time, it is best to drain the fuel from the fuel tank. This will help avoid damage to motor parts.

Rules of Usage

Advantages and disadvantages

For mechanised mowing in confined spaces, the STIHL FS38 is the right mower for the job. Clean and neat cuts, mobility, lightness and high performance are huge advantages over a handheld mower.

Of malfunctions, owners often note that immediately after starting the STIHL lawnmower can simply stall. In this case check the fuel line for blockages. Another reason could be an improper carburetor adjustment, which can be easily corrected according to the service recommendations.

The STIHL FS38 mower is priced at around 9,000 €. Of course, on the market you can buy cheaper, often short-lived analogues.

A well-known brand guarantees the reliability of certified products, as the owners of the equipment point out.