Fuel pump problems

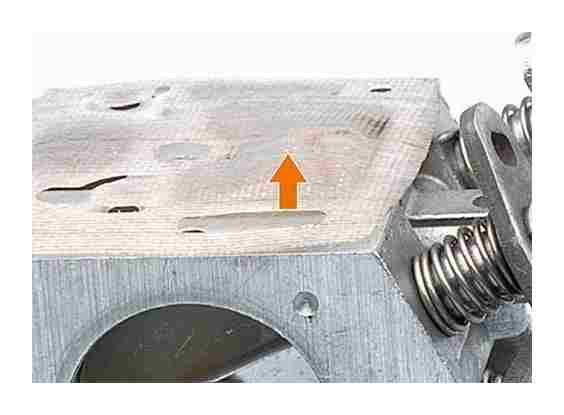

A common malfunction that “pursues” the fuel pump is the deformation of the pump membrane. For this reason, it does not fit properly and the pump passages are not sealed.

The reasons for membrane deformation can be the following:

- long work of the trimmer;

- use of unsuitable fuel;

- ingress of gases into the impulse channel.

As a result, diaphragm damage reduces pump performance and, as a result:

- depletion of the combustible mixture occurs;

- it is difficult to start the engine;

- there are interruptions in the operation of the motor;

- the piston is damaged.

Also, the above-described consequences for the motor can cause clogging of the pump cavity on the impulse side. In this case, dirt enters the membrane through the impulse channel.

To remove the blockage, you will have to disassemble the carburetor and clean the membrane.

Damper wear

The throttle and choke valves are mainly subject to wear due to the presence of abrasive particles in the air. Defective dampers look like they have been sandblasted.

As a result of valve wear, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder coating wear out.

Adjustment lever defective

This breakage occurs when the contact surface of the lever wears out.

The abrasion of the contact surface occurs due to the presence of abrasive particles in the gasoline or due to strong vibration of the engine during operation. This defect in the adjusting lever causes problems with the intake, as well as improper idling of the engine.

Common carburetor malfunctions

Failure of the trimmer carburetor occurs due to the use of poor quality gasoline, a damaged air filter and the accumulation of dirt in the chamber of this unit. Most often, it is quite possible to repair the carburetor with your own hands. Listed below are typical lawn mowers carburetor malfunctions.

How the benzotrimmer carburetor works and works

It is almost impossible to cover all types of carburetors produced by manufacturers of gas trimmers. But, since the design of this module, as well as its principle of operation, is largely similar between different models, a generalized description of the processes occurring in the carburetor can be made. This information will allow the user to understand the principles of operation of the device, eliminate the malfunctions that have arisen and operate it correctly.

The carburetor trimmer is based on a one-piece aluminum body. Below is a diagram of this block.

At the bottom of it, there is a diffuser, which is also called a Venturi nozzle (18). Air is drawn in by the motor through this nozzle.

The smaller this hole, the faster the air flows, and the higher the level of its rarefaction in the zone with the smallest diameter.

The top of the diffuser contains the fuel channels (11,12). Through these channels, the air flow draws in gasoline. The fuel pump itself, jets and the system used to regulate the supply of a mixture of fuel with air can be built-in or installed externally.

The throttle valve (9) controls the amount of air sucked into the carburetor. Its amount affects the power that the engine develops. The damper (7) is used for cold starting. It must be closed if you are going to start the unit. After the engine has started, it must be opened, otherwise, the engine will immediately stall.

The impulse channel (1) connects the impulse chamber of the pump to the engine crankcase, namely, to its internal volume. The piston located in the cylinder, producing reciprocating movements, successively changes the pressure in the crankcase (vacuum or pressure increase). The pressure drops force the diaphragm (4) to move. Therefore, the operation of the pump is synchronized with the operation of the engine.

The suction of gasoline from the tank occurs precisely with the participation of the membrane (4). Gasoline enters the carburetor through the union (2). Further, its path lies through the inlet valve (3), the exhaust valve (5), through the mesh filter (6), the fuel channel (10), passes the needle (14) and fills the chamber (16), which has a control diaphragm (18).

The valve (14) is connected to the diaphragm (18) by means of a lever (17). The cavity, which is located below the membrane, is connected to atmospheric air through the hole (19).

The device functions as follows.

- A vacuum is generated in the diffuser during the suction stroke. This fact causes air leakage. The position of the throttle valve (9) determines the amount of air entering the carburetor chamber, as well as the engine power and the number of its revolutions.

- At this time, fuel is sucked in from the chamber (16) through the jets (11,12), after which it is mixed with the flowing air. Gasoline, mixing with air, begins to spray. Thus, an air-fuel mixture is created.

- The finished mixture enters the cylinder, where it is compressed by the rising piston and ignited at its highest point from the spark generated by the spark plugs.

- Since the volume under the control diaphragm (18) is connected to atmospheric air through the channel (19), the diaphragm goes up, opening the valve (14) by means of the lever (17). After opening the valve (14), a new portion of fuel enters the chamber (16).

- After the chamber (16) is full, the diaphragm (18) returns to its original position, and the valve (14) closes.

Further, when the motor is running, all the above processes are repeated. A screw (13) is used to adjust the amount of fuel entering the diffuser through the nozzles. The screw (15) is also used to adjust the idle speed. When the regulators are twisted, the fuel mixture is enriched, and when the regulators are twisted, the mixture becomes lean. Also, in some models of carburetors, you can adjust the idle speed of the engine with a quantity regulator. It is usually located outside and, when twisted, abuts against a lever attached to the throttle shaft.

Thus, using 3 adjusting screws, you can achieve maximum engine performance, as well as adjust its smooth operation at any ambient temperature, and even in mountainous areas.

When to adjust

Carburetor adjustment is necessary in the following cases:

- the new engine was run-in (4-5 liters of fuel mixture were used);

- the composition of the fuel has changed (brand of oil and gasoline);

- the weather has changed (it became hot, cold);

- the rarefaction of air has changed (applies to mountainous regions);

- after long-term storage;

- increased load on the engine (after changing tools, etc.);

- due to vibration, the adjustment screws spontaneously unscrewed;

- fuel consumption has increased, the carburetor overflows fuel;

- carbon deposits quickly appear on the spark plug electrodes (while the fuel mixture is prepared correctly);

- the engine starts and immediately stalls or gains momentum poorly;

- no gasoline enters the cylinder;

- large amount of exhaust gases.

Throttle and choke shaft wear

The air and throttle shaft can wear out for the following reasons:

- insufficient and improper maintenance of the air filter;

- the air filter is damaged;

- the air filter is not suitable for this unit.

Due to the ingress of poorly cleaned air, the shaft wears out and can break. Broken shaft parts can enter the combustion chamber or crankcase and cause serious damage to the entire piston system.

To eliminate problems with air purification, it is necessary to replace the defective filter or flush the existing (serviceable) one. The filter must be washed in soapy water and dried.

Principle of operation

The carburetor is a power system module in which liquid fuel and air are mixed before being fed into the engine cylinders. Mixing and flow are adjusted accordingly depending on the tool and its mode of operation.

The carburetor device for lawn mowers is the same for almost all cases. It belongs to the category of float devices. The latter provide stable parameters of ready-made mixtures.

The principle of the module is as follows.

- Air enters the body of the air damper tube. The latter increases or decreases the air flow depending on its position.

- In the area where the hole for the gasoline supply is formed, the tube has a narrowing. a diffuser. Here the flow rate increases.

- Fuel from the float chamber is fed through the nozzle into the tube. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal, and in the tube it is low due to the greater rarefaction of the air, gasoline is sucked in through the nozzle.

- The accelerated air flow picks up the fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through the pipeline.

The more open the air damper in the tube, the higher the density of the air flow, and, therefore, more fuel enters the cylinder. Setting up the carburetor of lawn mowers is reduced to setting such a ratio of flaps at which the density of the fuel mixture becomes optimal.

How does the carburetor for lawn mowers work??

The carburetor device is almost the same as in famous German and Swedish lawn mowers, as well as in Chinese-made tools. This node consists of the following parts:

- Membrane fuel pump;

- Control system with atmospheric membrane;

- Idling system;

- Primer for priming, which makes it easier to start the engine of lawn mowers;

- Elastic plate with two valves;

- Needle valve;

- Dosing system with a rotating rotor;

- Throttle valve.

The carburetors of modern lawn mowers work according to a certain principle. The diagram below shows the movement of air and fuel mixture in the carburetor design.

First, air enters the tube through the throttle valve, and then passes to the diffuser, the narrowing point of the tube, where the air flow becomes especially intense. From the diffuser, air enters the float chamber, where it mixes with the fuel mixture. After that, the air-rich fuel is sucked in by the pipeline and enters the engine cylinder.

Principle of operation

Trimmer Stihl electric

The flow of air into the throttle tube increases or decreases depending on its position. From the fuel chamber, gasoline enters a special tube through a jet.

A float is a device that regulates the supply of fuel, its level determines the volume. Gasoline supplied through the nozzle is mixed with air due to the pressure difference. This is how an air-fuel mixture is obtained for engine operation.

Note! Incorrect fuel composition is due to a lack of gasoline or air. This means that you need to adjust the throttle or float position. The engine may stall due to the jet, but this is already a more serious damage.

Adjusting the carburetor lawn mowers

What is the problem with the trimmer malfunction

Champion lawn mower carburetor, how to adjust? This is just a float trimmer. a common option designed to mix air and fuel in the prescribed proportions. The main problems that arise during the operation of the engine are approximately similar to the problems that overtake the carburetor in a car:

- the engine may stall immediately after being started. The reason is that there is not enough gasoline supplied. This is called “lean” fuel;

- excessively supplied gasoline leads to its incomplete combustion, excessive mixture density and wasteful consumption.

Important! It is necessary to adjust the carburetor under different circumstances: a change in the temperature regime, the octane number of the fuel or the type of oil, after winter or the end of the run-in period, load or spontaneous turning of the screws from strong vibration of the body. Some owners prefer to tweak the module before each use to make sure it works correctly.

The main problems and malfunctions of the carburetor

Mesh filter. With this element, most often there are only two tasks:

In order to find out the cause of the breakdown, the fuel filter cap is unscrewed to remove the strainer. How to properly adjust the trimmer carburetor. On trimmers, in addition to electric motors, gasoline internal combustion engines are installed. If dirt just accumulated on it, then flushing in gasoline or purging will help.

If there is visible damage to the mesh filter, it is imperative to install a new one. There may also be damage to the fuel supply pipe (during repair, they practice checking this element).

The carburetor starter in most cases does not work due to blockages. Use acetone or the same gasoline for flushing.

Blowing out parts of a carburetor with a blockage with compressed air is an acceptable and comfortable repair practice.

The throttle body, the places of the bundles of the carburetor parts, the inlet or outlet pipeline. all of these parts are susceptible to depressurization. You can probably check with a simple method. smear the problem area with soapy foam.

DIY lawn mowers carburetor adjustment

Setting up the module does not apply to repair and replacement of spare parts is not required. In this case, the lawn mowers carburetor repair kit will not be needed.

Three screws are provided for debugging:

- L. is regulated first, since it is responsible for supplying fuel at low speeds;

- H. he is responsible for the supply of gasoline at high speeds, as well as for fuel consumption and temperature;

- T. it is used to debug idle.

There are options, as a rule, this is the carburetor of a Chinese lawn mower, when only one screw remains on the body for debugging. for adjusting the idle speed. This does not mean that the module is configured automatically. it means that it will be difficult to carry out even such a type of repair as debugging. In the photo. adjusting the carburetor of a Chinese lawn mower.

- The module is configured only when the engine is warm: for this, the device is pre-switched on for 10 minutes. If the mowing head rotates at idle speed, then the debugging is started immediately: turn the screw T counterclockwise until the rotation stops.

- Adjustment begins with screw L. The screw is turned to the right and left until it finds such a position at which the idle speed does not become maximum.

- Then the screw is turned ¼ turn counterclockwise. This will be his working position.

- Idle speed must be adjusted by turning counterclockwise to increase the number of revolutions and clockwise to decrease it. Its debugging consists in achieving such a mode in which a sufficient number of revolutions are made before the start of rotation of the mowing head. In this case, the engine must work stably at different positions.

- The position of screw L is determined last. at maximum speed, the trimmer should not work for more than 10 seconds. The throttle opens, the screw turns clockwise, very slowly, until the decrease in the number of revolutions is audible.

- Then, also slowly, the screw rotates counterclockwise until the motor starts to malfunction. Then the screw is turned back clockwise until the engine starts working normally again.

If there is a tanometer, and if the recommended rpm values are indicated in the product passport, the correction can be made more accurate, focusing not on hearing, but on the readings of the device.

6 comments on the post Carburetor adjustment and repair lawn mowers

Please clarify. In the adjustment section, item 5, screw L error? Should you read screw A? Thank you.

- prompt the initial position of the screws H L LA

- SHOW START POSITION

- prompt the initial position of the screws H L LA

Thank you very much for the video about the accelerator and didn’t know, but the defect is very important and creates a huge problem that almost everyone is silent about. BRAVO.

Maybe all the same tachometer is a rpm meter, not a tonometer blood pressure meter

The heart of any chainsaw is a two-stroke internal combustion engine.

There was a need to purchase a reliable and reliable mechanical tool.

Gone are the days of Soviet agro-industrial gigantomania. Gig gone.

- The trimmer is not a complex household appliance, so most of its floor.

- Tiller is an economical tractor option for small-volume jobs.

- Tiller Neva is produced today in different modifications, this one is specialized.

About adjusting the carburetor lawn mowers: how to set up and adjust yourself

Carburetor adjustment for lawn mowers is a process that needs to be mastered for full trimmer operation.

A trimmer is a completely uncomplicated device that can break only in a few places and require mechanical repair or replacement of a part.

Adjusting the carburetor device for float-type lawn mowers may require knowledge of certain subtleties. The nuances due to the model and the specifics of its functioning will provide a clear mixing and supply of the fuel mixture.

Carburetor setting lawn mowers with three adjusting screws

Place the mower on a flat, stable surface before starting work. Turn the chain in the opposite direction. Lawn mowers are available with two and three adjusting screws. The two screws are most often equipped with tools made in China. Consider adjusting the carburetor of a lawn mower with three screws.

Carburetor setting lawn mowers with three adjusting screws

The air filter must be rinsed before proceeding with the carburetor adjustment of the lawn mower. Cleaning is carried out with water with the addition of detergent or soap, and, if necessary, a new one is installed. Often, blockages are to blame for poor carburetor performance. As a preventive measure, it is recommended to clean the filter after every 10 hours of tool operation. Do not forget to check the condition of the candle, if there is carbon deposits, you need to clean it. Candles are consumables and have their own resource. To ensure good engine performance, lawn mowers need to be replaced periodically. Next, we evaluate how well the carburetor is attached to the cylinder-piston group. After finishing the preparatory manipulations, you need to start the engine. Let the engine run for 5-10 minutes. Then you need to identify how many adjusting screws on your instrument.

The petrol trimmer has the following adjusting screws:

- Idling adjustment screw;

- Fuel mixture adjustment screw

- Maximum speed limiting screw.

Idle speed adjustment

Following the adjustment of the fuel supply, we take up the idle speed adjustment. To do this, the corresponding screw must be adjusted so that the engine runs slightly accelerated at low revs. But it is necessary to monitor the immobility of the reel with fishing line and knives. Before starting their movement, there should be a few turns in stock. The movement of the spool and knives can subsequently lead to rapid wear of the clutch. Noticing that the engine does not start well, you need to increase the number of idle rpm. As the revs increase, the fuel mixture is saturated with air, which leads to a loss of power.

The main signs of correct idling:

- Stock of turns for the trimmer head;

- Uninterrupted operation of the engine even when changing position (sharp rise or fall of the knife);

- Quiet operation of the engine on a cold run;

- Absence of increased rpm of a hot engine.

Fuel supply adjustment

Adjustment at maximum speed

Further, to fully tune the carburetor, the lawn mowers need to adjust the maximum rpm. It will not be superfluous to look into the instruction manual of the tool and see the maximum value of the revolutions. Most accurately, this number will help determine the tachometer. If such a device is not at hand, we tune it by ear. Having barely determined by ear the maximum value of the rpm, we begin the adjustment. The screw for limiting the maximum speed will help in this matter. Check the operation of the engine at maximum speed. If it is necessary to reduce the speed, it is necessary to loosen the fixing nut and unscrew the screw. If the revolutions are too high, then you will need to screw in the screw. These steps must be done in order to protect the engine from overheating. It is necessary to turn the screw until a clear smooth engine operation is established.

After the work done, if everything is done correctly, the stable operation of the tool is ensured.

This will be understood by the following signs:

- The cutting element will stop rotating when idling;

- Fuel consumption will decrease.

Adjusting the carburetor trimmer

lawn mowers have long been included in our lives as a very useful tool and a great alternative to the usual scythe. lawn mower and lawn mower are the same tool. And trimmers are gasoline, and there are electric. In this case, we will focus on gasoline. This unit is quite simple to operate, but it has its own characteristics. lawn mowers are equipped with an internal combustion engine. The carburetor for lawn mowers is a very important part of the tool. The main task of the carburetor is to ensure the flow of air-enriched fuel into the engine cylinder. The most important thing here is to maintain the balance of fuel and air. The article will tell you about the signs indicating the need for adjustment, how to adjust the carbrator on the trimmer.

It is allowed to adjust the trimmer carburetor yourself, having previously studied the unit design. As a rule, a detailed description of the constituent assemblies of the tool is in the instruction manual. An experienced craftsman is able to even determine by ear that there are shortcomings in the work of lawn mowers. The sound of the motor, when properly tuned, should be perfectly smooth. If you can clearly hear screeching sounds, then the mixture is oversaturated.

Cases indicating the need for adjustment:

- If a fuel mixture of a different composition is used;

- With a long break in operation (the lawn mower lay idle for a long time, and even before the new season after winter);

- After completion of the equipment break-in process (usually after using 4-5 liters of fuel)

- When weather conditions change (this item is relevant for);

- Poor engine starting

- If fuel consumption has increased sharply;

- An increase in the amount of exhaust gases;

- Slow set of revolutions by the engine;

- If the fuel mixture does not flow.

Carburetor setting lawn mowers with two adjusting screws

Adjusting the carburetor for two-screw lawn mowers is much easier than described in the first option. However, it is worth noting that this setting is less accurate. Before starting the setup, you must memorize the factory parameters of the lawn mowers. After a while, the engine starts and runs for several hours. Although on some instruments, 10-15 minutes of work is enough to set the necessary parameters.

Carburetor setting lawn mowers with two adjusting screws

First you need to start the engine at low speed. If, during operation, the chain moves along the bus, then this is not the norm. You need to adjust the screw so that the chain stops moving.

Next, you need to go to medium speed. After which the engine can smoke. The adjusting screw will also help eliminate this nuisance. By tightening it harder, the fuel mixture, which is less enriched, will begin to flow into the engine. After that, the smoke will disappear. But the turnover will increase. Adjustment must be made until smooth, precise operation without jerking is achieved.

After all the necessary settings have been made, it is necessary to let the trimmer work in real conditions for more than one hour. After a while, it would be good to check if all the components are working correctly. If deviations are found, they need to be eliminated.

An indicator that the adjustment has been completed successfully will be residual combustion of fuel and a slightly brownish color of the plug. The color of the carbonized candle is darker.

Adjusting the carburetor for lawn mowers is a very important preventive measure that must be carried out every time such a need arises. As described above, such a need may arise quite often. By the way, screws that have loosened from vibration can also serve as a reason for tuning. In order for the tool to serve for a long time, you must always follow the instruction manual for the lawn mowers, use the correct fuel mixture.

The main problems and malfunctions of the carburetor.

Mesh filter. There are often only two problems with this element:

- Blockage.

- Breaking.

In order to find out the cause of the breakdown, the fuel filter cap is unscrewed to remove the strainer. If dirt just accumulates on it, then flushing in gasoline or blowing will help.

If there is visible damage to the mesh filter, it is imperative to install a new one. There may also be damage to the fuel supply pipe (during repair, they practice checking this element).

Blowing out carburetor parts with compressed air is an acceptable and convenient repair practice.

The throttle body, the places where the carburetor parts are connected, the intake or exhaust pipe. all of these parts are subject to depressurization. You can check for sure in a primitive way. smear the problem area with soapy foam.

The principle of operation of the carburetor lawn mowers

The throttle valve determines the amount of air to be supplied, and the engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the choke in the carburetor. The fluid then flows through the pump inlet and outlet valves. Filtered by the grid. Moves through the needle valve into the diaphragm chamber.

Hidden Adjustment Screw on Walbro Style Carburetors

Step-by-step operation of the device:

- Air supply to a tube with an air baffle (damper). The baffle regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a constriction. A float chamber adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with a constriction it is already low. Due to the differential pressure, the fuel penetrates through the nozzle.

- The acceleration of the air flow facilitates the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air / fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a lawn mower is about creating an optimal fuel mixture through the correct air supply.

Do-it-yourself lawn mowers carburetor adjustment

A lawn mower carburetor is a unit in the power system. In it, like any carburetors, there is a process of mixing air and fuel (gasoline) for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which the carburetor is regulated.

Lawn mowers carburetor device

The basis of the carburetor for lawn mowers is an aluminum body. It contains a diffuser (hole with inner contours). Air is blown through this hole. The flow rate of oxygen (air) depends on the cross-section (orifice) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn in from them using the air flow.

Outside the carburetor is installed:

- fuel pump;

- jet system;

- a system for adjusting the mixture of fuel and air;

How to adjust the carburetor on a lawn mower

Before adjustment, you must thoroughly clean the filters according to the maintenance instructions in the instructions.

Further adjustment of the carburetor of the lawn mowers with their own hands is carried out with the adjusting screws. There are three of them:

- right;

- left;

- lower.

Right (L). adjusting the fuel mixture for low rpm.

You need to find the maximum idle speed. To do this, slowly unscrew the screw (L) to the right and left.

To adjust, turn the screw a quarter of a turn, be sure to counterclockwise.

Lower (T). responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

For the correct adjustment of the idle speed, it is characteristic:

- stable operation of a cold engine;

- not overestimated speed of a hot engine;

- a large reserve of turns for the trimmer head;

- stable operation of the engine when changing position (sharp lifting or lowering of the knife).

Left (H). mixture adjustment at high rpm. (The screw is adjusted last).

The left screw (H) determines the overall adjustment of maximum speed, engine power, temperature and gasoline consumption.

Setting up the carburetor for lawn mowers with the last screw is done as follows:

- Open the throttle to full, at the same time give full throttle. Turn the screw clockwise until the speed drops (in this case, orientate by ear).

- Turn the screw counterclockwise as slowly as possible until the engine runs unevenly.

- Then turn back quite a bit, barely hearing a stable, even operation.

- For a more visual use of skills, it is more convenient to consider the work of an experienced user:

Interestingly, from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not only by the speed and stability of the engine.

Correct adjustment of the carburetor with your own hands in this case. combustion of the fuel mixture without residue, the color of the candle should be light brown.

Adjusting the fuel level of the carburetor k126

K126 fuel level adjustment

Check the fuel level with the engine off of a vehicle installed on a horizontal platform. When pumping fuel using a manual pump drive, the fuel level in the carburetor float chamber should be within the range marked by marks (tides) “a” on the walls of the inspection window. If the level deviates from the specified limits, make adjustments by removing the cover of the float chamber. Adjust the level by bending the tongue 3 (see fig.). At the same time by bending the stopper 2, set the stroke of the needle 5 of the fuel supply valve to 1.2. 1.5 mm. After adjusting, check the fuel level again and, if necessary, make the adjustment again. Considering that during operation, due to wear of the float mechanism, the fuel level gradually rises, set it when adjusting to the lower limit. In this case, the fuel level will be within acceptable limits for a longer time.

Note. When adjusting the fuel level in the carburetor float chamber, do not bend the float tab by pressing the float, but bend it with a screwdriver or pliers.

A little about the repair of the K126 carburetor

The K 126 carburetor, like all other carburetors, has its weak points. A very weak point in the carburetor k126 is the attachment of the lower part of the carburetor to the middle one, in this place the fasteners are over time exposed to heat from the engine side and in these places, with a strong constriction of the carburetor fastening, and at an increased operating temperature of the engine, the fastenings of the carburetor halves were deformed, as as a consequence, a gap appears between the lower middle part of the carburetor k126, the transition channels of the idle system begin to suck in air and it becomes almost impossible to adjust the idle, this applies to almost all carburetors of the k 126 family.

Checking the plane of the carburetor flange

You can check the flange plane using a straight ruler, as shown in the figure (Solex carburetor is shown, the principle is the same). To eliminate this problem it is necessary to disassemble the carburetor completely, remove the large diffusers from the middle part, and grind both halves, replace the intermediate spacers with new ones and assemble the carburetor. After the engine has warmed up to operating temperature, adjust idle speed and mixture quality.

Adjusting the idle speed of the K126 carburetor

Adjustment of the minimum idle speed is carried out in the following sequence:

-warm up the engine to operating temperature;

Checking the results of the adjustment is carried out by abruptly pressing the gas pedal, the engine should not stall, there is a smooth drop in revolutions

The screw 15 of the toxicity limiter adjusts the limit value of carbon monoxide (if equipped with a gas analyzer).

It is possible to adjust the idling system of the carburetor k126 without a gas analyzer.

This is how this procedure is described in the book of N.N. Tikhomirov. “Carburetors K-126, K-135”:

In the absence of a gas analyzer, almost the same control accuracy can be achieved using only a tachometer or even by ear. To do this, on a warm engine and with the unchanged position of the “quantity” screw, find, as described above, the position of the “quality” screws at which the maximum engine speed is ensured. Now use the “quantity” screw to set the speed to about 650 rpm “1. Check with the “quality” screws whether this frequency is the maximum for the new position of the “quantity” screw. If not, repeat the entire cycle again to achieve the required ratio: the quality of the mixture ensures the maximum possible speed, and the number of revolutions is about 650 min. ”1. Remember that the “quality” screws must be rotated synchronously.

After that, without touching the “quantity” screw, tighten the “quality” screws so much that the rotational speed decreases by 50 minutes ”1, i.e. to the regulated value. In most cases, this adjustment meets all the requirements of GOST. Adjustment in this way is convenient in that it does not require special equipment, and can be carried out every time the need arises, including for diagnosing the current state of the power system.

In case of inconsistency of CO and CH emissions with GOST standards at increased speed (Nпов “, = 2000100 min” ’), the impact on the main adjusting screws will no longer help. It is necessary to check if the air jets of the main metering system are dirty, if the main fuel jets are enlarged or if the fuel level in the float chamber is too high.

Adjusting the carburetor K126

Carburetors K-126 are very simple in design, moderately reliable and require minimal maintenance if used correctly. Most malfunctions occur either after unskilled intervention in the adjustment or in the case of clogging of the metering elements with solid particles. Among the types of maintenance, the most common are flushing, adjusting the fuel level in the float chamber, checking the operation of the accelerator pump, adjusting the starting system and the idle system.

Consider the carburetor adjustment to 126 using the example of K 126GU.

K126 carburetor device, adjustment and repair

You will familiarize yourself with the device of the K126 carburetor, learn how to adjust it, find information on the principle of operation of the carburetor.

The K 126 carburetor has many modifications, below I will give the information that I managed to find:

K126G, K126GU. UAZ;

K126GM. Volga 24;

K126I. GAZ 52-03;

K126E. GAZ 52-04.

Differs in tops, parts, soles, diffusers, calibrations, etc.

Carburetor device K126

Consider the device of the carburetor k126. The k126n carburetor has a similar structure. Carburetor K-126. emulsion, two-chamber, with a falling flow, with sequential opening of the throttle valves and a balanced float chamber.

The carburetor has two mixing chambers: primary and secondary. The primary chamber operates in all engine modes. The secondary chamber is activated under heavy load (after about 2/3 of the throttle stroke of the primary chamber).

To ensure uninterrupted operation of the engine in all modes, the carburetor has the following metering devices: a primary chamber cold running system, a secondary chamber transition system, main metering systems of the primary and secondary chambers, an economizer system, a cold engine start system and an accelerator pump system. All elements of dosing systems are located in the body of the float chamber, its cover and the body of the mixing chambers. The body and cover of the float chamber are cast from zinc alloy TsAM-4-1. The mixing chamber body is cast from AL-9 aluminum alloy. Sealing cardboard gaskets are installed between the body of the float chamber, its cover and the body of the mixing chambers.

Carburetor device K-126

The body of the float chamber contains: two large 6 and two small diffusers 7, two main fuel jets 28, two air brake jets 21 of the main metering systems, two emulsion tubes 23 located in the wells, a fuel 13 and air jets of the idling system, an economizer and guide sleeve 27, accelerator pump 24 with delivery and check valves.

The nozzles of the main metering systems are led out into the small diffusers of the primary and secondary chambers. Diffusers are pressed into the body of the float chamber. In the body of the float chamber there is a window 15 for monitoring the fuel level and the operation of the float mechanism.

Viewing window k126

All channels of the nozzles are fitted with plugs to provide access to them without disassembling the carburetor. The idle fuel jet can be turned out from the outside, for which its body is brought out through the cover up to the outside.

In the cover of the float chamber there is an air damper 11 with a semiautomatic drive. The air damper drive is connected to the primary chamber throttle valve axis by a system of levers and rods, which, when starting a cold engine, open the throttle valve to the angle required to maintain the starting engine speed. The secondary throttle valve is tightly closed.

This system consists of an air damper actuator lever, which acts with one shoulder on the choke axle lever, and with the other through a pull on the idle lever, which, turning, presses the primary chamber damper and opens it.

A float mechanism is mounted in the carburetor cover, which consists of a float suspended on an axle and a fuel supply valve 30. The carburetor float is made of 0.2 mm brass sheet. The fuel supply valve is collapsible, consists of a body and a shut-off needle. Valve seat diameter 2.2 mm. The cone of the needle has a special sealing washer made of fluoride rubber compound.

Float chamber k126

The fuel entering the float chamber passes through the 31 mesh filter.

In the housing of the mixing chambers there are two throttle valves 16 of the primary chamber and the secondary chamber, an adjusting screw 2 of the idling system, a toxicity screw, channels of the idle system, which serve to ensure the coordinated operation of the idle system and the main dosing system of the primary chamber, opening 3 of the vacuum supply to a vacuum ignition timing regulator, as well as a secondary chamber transition system.

The main carburetor systems operate on the principle of pneumatic (air) fuel braking. The economizer system works without braking like an elementary carburetor. The idle, booster pump and cold start systems are available only in the primary chamber of the carburetor. The economizer system has a separate spray nozzle 19, which is led out into the air pipe of the secondary chamber. The secondary chamber is equipped with a transitional idle system.

The carburetor idle system consists of a fuel jet 13, an air jet and two holes in the primary mixing chamber (upper and lower). The lower hole is equipped with a screw 2 for adjusting the composition of the combustible mixture. The idle fuel jet is located below the fuel level and is included after the main jet of the primary chamber.

Fuel jets of the carburetor k126

The fuel is emulsified with an air jet. The required performance of the system is achieved by the idle fuel jet, the air brake jet, as well as the size and location of the vias in the primary mixing chamber.

The main metering system of each chamber consists of large and small diffusers, emulsified tubes, main fuel jets and main air jets. The main air jet 21 controls the flow of air into the emulsion tube 23 located in the emulsion well. The emulsion tube has special holes designed to obtain the required system performance.

The idle system and the main metering system of the primary chamber provide the necessary fuel consumption at all main engine operating modes.

The economizer system consists of a guide sleeve 27, a valve 23 and an atomizer 19. The economizer system is put into operation for 5-7 until the throttle valve of the secondary chamber is fully open.

It should be noted that, in addition to the economizer system, the main metering systems of both chambers operate at full load and very little fuel continues to flow through the idle system.

The accelerator pump system consists of a piston 24, a drive mechanism 20 for the inlet and discharge (outlet) valves, and a spray nozzle 12, which is brought out into the air pipe of the primary chamber. The system is driven from the primary chamber throttle axis and works when the vehicle is accelerating.

Accelerating pump k126

On the axis of the throttle valve of the primary chamber, the drive lever 4 is rigidly fixed. The link of the link 25 is also rigidly fixed on the axis. The link is freely installed on the axis of the damper 16 and has two grooves. In the first of them the leash moves, and in the second. the finger with the roller of the lever 26 of the drive shaft 8 of the secondary damper fixed on it.

K126 second chamber throttle actuator

The flaps are held in the closed position by springs attached to the primary chamber axis and the secondary chamber axis. The link 25 also constantly strives to close the shutter of the secondary chamber, since it is acted upon by a return spring fixed on the axis of the primary chamber.

When the lever 4 drives the axis of the primary chamber, the leash of the primary chamber lever first moves freely in the groove of the link 25 (thus only the damper of the primary chamber is opened), and after about 2/3 of its travel, the leash begins to rotate it. The rocker 25 of the secondary flap drive opens the secondary throttle valve. When gas is released, the springs return the entire lever system to its original position.

Scheme of the carburetor to 126

Instead of a conclusion

A feature of the K-126 carburetors is that the adjustment is not particularly difficult and does not require the cost of tools and special tools. It is for this reason that the production of carburetor k126gm cars continues, which are used under difficult conditions, remote from car service services. Compliance with the frequency of maintenance will make it possible to operate the car for a long time without critical breakdowns.

Video about the device and repair of the carburetor k126.