Hexagonal table for the gazebo

At his dacha recently built a wooden arbor, which is in terms of a hexagon. At first I thought to install a round table inside the structure. But later I decided that it would be most convenient if the countertop is hexagonal in shape. The countertop allows sitting people at a table on a bench to feel more freely and independently. The option of how to make a hexagonal table into the gazebo with your own hands, I chose from several samples of furniture on the Internet. Having made drawings, I started the selection of the right tool and buy the necessary materials.

Since the design should be made of wood, the tool will mainly be needed for woodworking. Here’s what, I used in the manufacture of a hexagonal table with my own hands:

- electrician;

- saw;

- screwdriver;

- chisels;

- a hammer;

- grinder;

- roulette;

- screwdrivers;

- brushes;

- fitting belts;

- clamps.

Materials

In the construction supermarket I acquired all the necessary materials. I made purchases according to this list:

- board 600 x 600 x12.5 mm. 1 pc ;;

- Bay 40 x 40 mm. 12 m;

- Construction plywood 600 x 600 x 18 mm, 0.36 m 2. 1 pcs.;

- Wooden dowels Ø 5 mm. 4 pcs.;

- stain. 0.5 l.;

Tools and materials

You can make a set of shelves in just a few hours, using the remains of wood, which will always be found in a house where they like to independently embody ideas. If you first decide to master the carpentry art, then purchase the wood of the most common breeds in a store or in a warehouse, it is easier to work with it, and costs will be minimal.

- Miter saw.

- Electric grinder and sandpaper.

- Pine boards (you can use lumber of different widths and thickness).

- Glue for wood.

- Maular tape.

- Morilka for wood or paint and soil, protective wax or varnish.

- Hinges for hanging shelves on the wall.

Cut

The design of the shelves consists of 6 identical blanks, in this project the length of one rib is 14 cm, the ends of the parts are cut at an angle of 30 degrees. With this cutting, all parts of the product will be perfectly fitted to each other. The size of the shelves can be proportionally increased, but the angle of cut remains unchanged with any length of the ribs.

Perhaps your bathroom requires two identical shelves and one large design, a huge number options for modeling, choose the most suitable for specific purposes. For example, in this project one of the shelves will have wider ribs than all other designs in the panel.

How to calculate compound cuts

Cut the prepared lumber into exactly the same blanks, count their number. Each shelf will require 6 boards, that is, the number of parts should be a multiple of 6. Pour the prepared details from all sides, pay attention to the ends. Remove dust with a damp cloth.

85% of People Get this Wrong Cutting with a Circular Saw

How to make a hexagonal hole

First, we select a drill of suitable diameter to match the bolt, which needs to be installed in a wooden workpiece. We drill a hole.

After that, install a home.made tool and clog it to the right depth with blows of the hammer. We finalize the hole with a chisel.

Cutting hexagonal corners

Remove a special device from the end saw. Install the table for ending 90 degrees. Measure and mark the wood to cut six parts for one eighth inch, longer than the necessary final length. Place the wood on the table for the end saw and tightly press it to the fence. Run the saw and lower the blade B and through the forest at the marks to make cuts.

Install a special device on the saw table, as shown earlier. Install the table of the end saw 30 degrees from the device. Place the hexagonal side on the table for the end saw so that the edge is adjacent to the fence of the device. Combine the blade with the end of the corner of the workpiece to cut the angle without changing the length of the part. Fix the workpiece on the device. Run the blade and cut the angle into a tree.

Step 3

Turn the end of the workpiece so that the uncircumcised end is facing the end. Comers the blade to cut off the piece, as before, without changing the length of the piece. Fix the part on the device. Run the saw and cut the corner at the end of the tree. Repeat these steps for all six parts.

Check the length of the pieces for accuracy. You can adjust the length of each of them by cutting a very small amount at the end of each piece with a saw.

Production of the roof frame

Of course, you can technically make a roof of any configuration, but the most suitable option will be the roof repeating the contour of the structure, in this case it is necessary to make a hexagonal roof of the gazebo. Structurally, it will consist of such elements as:

Scheme of the rafter system of the hexagonal gazebo. Made of six main rafters and six half, supporting horizontal spacers.

Advice. Pilomaterial for rafters should be one size, have normal humidity and be without large knots. Preference should be given to wood of conifers, such as pine, spruce, larch.

Mauerlat is made from a beam of the same size with supporting racks (or boards of the same size with rafters). In this case, the last option is considered. In order for Mauerlat to be securely fixed and lay on a vertical rack, a groove is made in the “half.core”.

The groove is made on the outer side of the gazebo.

For the most tight fit, the corners of the groove are cut at an angle of 60 degrees

The rafter attachment unit to the Mauerlat is carried out with a groove mount, which eliminates the slide of the rafters when the snow load is exposed.

In blue, the mounting unit of midpopping was noted, the red raft attachment unit is reduced, and the groove is made in such a way that it overlaps the mounting unit of the vertical rack and Mauerlat. The green units were marked with green, where it is necessary to use mounting corners.

The device of the prince of the hexagonal roof

Bring the rafters in the upper part of the roof in several ways. It is very difficult to give preference to any of them, so it is worth considering the most common ways.

The connecting hexagon for the gazebo is made of trims of the beam interconnected, the size of the edge of the hexagon slightly exceeds the width of the supporting beam, which allows you to regulate during installation. The upper end of the rafters has a small groove that rests on the face of the hexagon. This design works for self.supporting under its own weight and does not require powerful fasteners, it is enough to fix the rafters with one nail.

If tights are used in the design of the hexagonal roof of the gazebo, then at their intersections a mounting stand is installed, to which the upper ends of the rafters are attached

An interesting way to connect rafters. The grooves are cut at a certain angle and consistently inserted into previous rafters. Experienced carpenters are able to perform such work.

Advice. It is recommended to first adjust and collect the roof frame on the ground, mark the details, disassemble, and then make installation on the gazebo. To facilitate the installation process, it is necessary to arrange a temporary rack, which is removed at the end of the work.

Floor

Next, proceed to the floor. For this you will need lags, and they, as you know, can also be done with your own hands. Use 7×3 cm boards or bars 10×5 cm to create lags. Using nails or screws, fix them to all pillars. Then lay the waterproofing. it can be any suitable material, for example, a roofing material sheltered with polyethylene film.

You can lay the floor right on top of the insulation. Use boards or composite materials for this. Do not forget about mandatory treatment with antiseptic and other protective agents! Having prepared the floor, proceed to the partitions. It is worth noting that the hexagonal gazebo can have both solid partitions in the form of dense walls and a railing of meter heights.

Railing

Next, you need to install fences around the entire perimeter of the structure-the height of the railing should be approximately 90-100 cm. In this case, ordinary boards can serve as vertical elements, although if you wish, you can make them figured. for this, pruning with an electric jigsaw.

To make the railing look more decorative, apply two or three layers of varnish on them. Fix all the elements using self.tapping screws, after which install the window board along the upper perimeter of the railing (it must be wide). Using special fasteners, connect this board with vertical elements. Now proceed to the final stage. the construction of the roof.

Preparation of a concrete foundation for wooden gazebo

At the beginning of the construction of a hexagonal gazebo with your own hands, the shape of a concrete base can be made absolutely any hexagonal, square or even round. It does not matter. The main thing is that the site is a little more than the gazebo of the size you plan. And she could fit freely and become on the site.

About how to fill the floor from concrete, I wrote in the article: a professional screed of the floor with my own hands step by step. https: // o-builder.RU/Professionalnaya-Styazhka-Pola-Svoimi-Rukami-Poshagovo/

I think you should not repeat the way the technology is absolutely the same. The only difference is that you will fill the concrete not in the room, but in a pit, with a depth of 15-20 centimeters.

Preparation of the material and marking a hexagonal gazebo made of wood

Let’s start building a hexagonal gazebo for giving from the racks, we should have six pieces of 15 by 15 centimeters. All strictly the same height of at least 200 centimeters. The ends must be chopped at an angle of 90 degrees. We processed all the racks from below so that they pull the moisture from the concrete base less. We painted all four sides with a wax.based pigment, and in the spring we will cover with transparent varnish on top. With the same pigment, we processed all the wooden details of the rafters, a crate and even OSB. True, on the one hand, that which will be to the bottom.

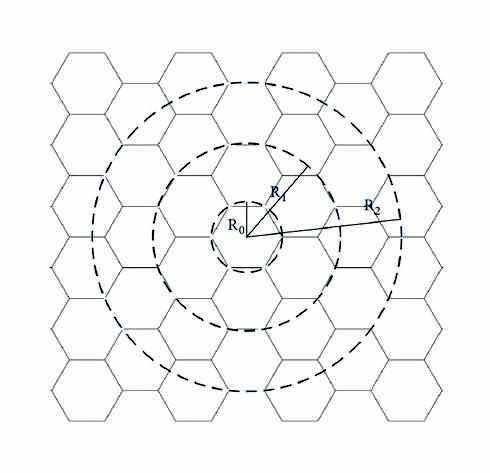

Now, on a ready.made basis, you need to draw a circle of the size that will be our gazebo. And so that the circle comes out to do even, something on the likeness of a large circul. Take two pegs, tie them with a rope. We put one peg in the center of the site and draw a circle the size of our gazebo. To get the right hexagon, it is necessary to measure the distance equal to the radius of the circle from any point of the resulting circle. So we get six points, it will be the very points where we will put the already prepared racks of the gazebo.

Choosing a place and a drawing of a building

One of the main collaterals of a cozy gazebo is the choice of the right place for the future structure. Not only the convenience of its operation depends on this, but also the rationality of the use of the entire site. The ideal place for building should be located in the shade. Therefore, the most commonly selected territories near one or more large trees. If a small reservoir or fountain is erected on the site. The gazebo should be located as close as possible to them.

It is important for the gazebo and the base, it is best to choose a small hill for construction. This will prevent flooding of the foundation during heavy rains or spring thaw. In addition, in order to avoid soil subsidence, when operating the structure, it is not recommended to build it on arable substrates. Dense sandy and clay soils are best suited for this, which were previously involved in economic activity at a minimum.

The next stage of planning future construction is the drawing. When creating it, it is necessary to at least schematically depict a general gazebo plan. as well as the layout of each of the faces and sides of the future hexagonal structure, including the shape of the base. It is also necessary to calculate the shape of the roof, as well as to clearly plan all the places of its attachment to the walls and other nuances. In this case, be sure to not forget to determine the place for the entrance and window openings.

Examples of drawings of hexagonal arbors:

Step.by.step construction

In most cases, the average summer cottage arbor is a wooden structure based on a solid concrete base. This combination allows the maximum to use all the positive properties of each of their materials, while creating comfort and comfort inside the gazebo. At the same time, for its competent exhibition, one should adhere to a step.by.step principle of fulfilling all stages, observing a strict order.

Helpers marking

In order to mark the perfectly even foundation of the future structure, 6 wooden flags and the same number of installation rails will be required. 6 blanks of equal length should be created from it, according to the size of the previously planned faces. The resulting segments must be laid out in the form of an ideal hexagon, while the evenness of all sides should be checked using the construction level.

Further, in the corners formed between the segments of the rails, you need to install wooden pegs, pulling a strong nylon thread or twine between them. After that, the installation rail can be removed, in the future, the main role of the markings will be played by pegs and a thread stretched between them.

Bookmark of the foundation

The main task of the foundation is to create a perfectly even and strong base, which will further keep the entire building.

To make the foundation base correctly, it follows:

- At the site of the installed pegs to dig holes with a diameter of about 20 cm and a depth of at least 30 cm.

- Install metal reinforcement in each hole.

- Pour the liquid concrete of a brand at least M150 into the holes.

- After the mixture dries, a small brick column should be built on each concrete base, up to 30 cm high. To do this, use red or silicate brick brand M100 or more.

Lower strapping

After the construction of foundation pillars, they must be tied to each other. This will evenly distribute the entire load of the future structure between the concrete foundations. The strapping is performed using 6 wooden bars with a section of at least 100 × 100 mm.

They are laid overwhelmed, between each individual column, according to the so.called principle “in half.ceremony”. On contacting bars, you should create interconnected grooves, which are additionally fastened with self.tapping screws. To a concrete basis, the strapping is attached using anchors or metal rods.

Installation of pillars

As soon as the base is ready, then the main frame should be built. Its installation begins from the installation of vertical wooden pillars at the site of the faces of the base. Their size should be equal to the necessary height of the ceiling, and the cross section is selected relative to the binding beam.

The vertical bars are attached to the base with the help of metal corners. After that, in the upper part, the pillars are connected with each other with the help of the same timber. All coal compounds are fixed using the oenic plates of metal.

Paul flooring

For floor flooring, almost any type of construction tree that exists in the modern market is used. The traditional version is considered a pine or spruce board with a thickness of 40 mm or a special floorboard with a groove. A more expensive but reliable option is considered to be coated from specially processed larch.

Put the floor covering with all kinds of ways, but only two are considered the most popular. It is laid an excessive, parallel to one of the faces or divided the floor into 6 separate sections, and then the coating is laid alternately in each of them. At the same time, to enhance the strength of the floor, it is recommended to divide the entire area of the base using wooden bars into separate compartments.

Production and installation of the roof

The construction of the rafter system begins outside the roof, still on the ground. This will make the design to the maximum strong, without the cost of unnecessary efforts. It begins to assemble it from the installation of the hexagonal base, then at an angle of at least 15 °, oblique bars are installed on each edge at an angle of at least 15 °, connecting them among themselves approximately in the center.

Thus, the rafter system should acquire the shape of the correct cone. The assembled structure manually or using the equipment is installed on the base and attached to it on both sides using metal plates.

Before laying the roof on the roof, you should create a supporting crate between each vertical rafter beam. It will evenly load the rafter system under the pressure of the snow, as well as avoid shedding the roof in some places.

Its step is chosen relative to the roof, which will be applied in the future. For slate, metal tiles and corrugated board, a distance of not more than 40 cm is suitable, when the soft roof is arranged, it is made continuous (from moisture.resistant wood boards).

Step.by.step instructions for the construction of external coating:

- The roof installation begins by fixing on the roof of waterproofing materials (hydraulic floods, roofing material and t. D.).

- In places of joints of the faces, a metal comb with a reverse roller is installed (when installing a soft roof, the action is not performed).

- After that, they begin to skin each fuel line.

- The installation of the roof is completed by fixing the external crests on the faces, as well as the cone top (in the case of a soft roof, the coating is made holistic).

At the end of the installation of the roof along the perimeter of the roof, the drainage is fixed. They do this with special fasteners with a recess for gutter, perform installation so that the edge of the roofing material is directed approximately to the center of the gutter.

The entire structure is attached under a small slope, about 2-5 mm/linear meter. The waste of wastewater is made in places of adjacence of the sides, while it is permissible to make both one common vertical drain and several, located in parallel.

Preparation for work

The choice of building material

At this stage, you need to decide on the building material. The most popular options are wood and metal (profile pipe). In the case of a tree, you can use a beam of 100 per 100 mm, and metal. a pipe with a section of 60 by 40 mm.

If you prefer reliable brick, then the entire erection technology will be noticeably different. It will be necessary to fill in a reliable foundation (strip or monolithic type), and then engage in brickwork. There is no special special constructive here, it will be enough to lay out the walls in six faces.

Drawings with sizes and explanations

If you do not fully understand the device of a hexagonal gazebo, then I propose to study the drawings below. They clearly show the sizes of potential buildings, area, size of the rafter system, connection in the joints of the name of the components.

The above projects are enough for you to definitely have an opinion about a similar form. In the drawings, perhaps the trim of the roof that is done to lay soft tiles is not shown, we will talk about this later.

Construction on their own

Hang.up

The first task that will need to be solved is to determine the size of the arbor and make the marking of the right hexagon (hexagon). To do this, we need roulette, pegs and six identical bars of the lower binder.

- We make 6 bars strictly the same size.

- We spread them on a surface in the shape of a hexagon in the shape of a hexagon in advance (figure below).

- In places of joints we score pegs.

- Remove the bars and prepare for laying the foundation.

Foundation

For the foundation, it is cheaper to use foundation blocks that you can buy in a store or make yourself. If you work “for conscience” at all, then there is a more expensive, but very reliable version of the foundation with brownish piles.

The main task is to create a flat (in level) plane, on top of which the lower binding will go.

Connections in the lower binding

For attaching the lower binding, you can use two methods:

Corners in most cases are enough to fix the beam tightly. But if you want to do everything for centuries, then you can do cutting out and add additional fastening. The photo is higher, which shows the base from the blocks, this connection is presented in all its glory.

Installation of pillars

It is necessary to install six vertical pillars and fix them at an angle of 90 degrees. It is most convenient to work with a partner who will hold the pillar while you are attached to the lower binding.

By analogy with the strapping, we use metal corners and screws. In the photo below, you can clearly see the finished result.

If you are not enough metallic corners, then for additional reliability you can use the connection using a spike and nest. work is noticeably added, but the stability of the pillar will increase significantly.

Shipping connection Fixing the pillar to the lower bandage on the corners

For the floor, you can use any type of boards that will withstand people and furniture inside. The classic option is a forty.knit on pine tree. A more expensive option. larch. There are several ways to lay the floor:

Continuous flooring with a beautiful floor

Roof erection

A little secret: the rafter system is best collected on Earth. It is much simpler and more reliable. Then it will need to be raised to vertical pillars and fixed. This technique is used everywhere, so I recommend it to you too.

The rafter system consists of six bars (the beam is most often used 150 by 50 mm), which are mounted in the center with each other using a wooden spire and a metal apron, as well as in each angle separately to the upper binding.

The roof collected on the ground (without a crate) is a rafter system (top view) of the rafter system (below)

Choosing and laying the roof

When choosing a roof, it is necessary to proceed from whether you are ready to engage in the lining of the roof of the OSP plates.

By installing a rafter system and a crate, you can lay, for example, corrugated board or metal tiles. If you want to lay soft tiles (such as shinglass), then you must additionally sheathe the roof with slabs, on top of which roofing will already be laid.

Soft tiles Ondulin six.slot

Step.by.step instructions with photos

Below is the construction of a hexagonal gazebo of 13 steps. Each photo is signed and describes the process that took place. The next paragraph will show a video in which this process is shown even more clearly.