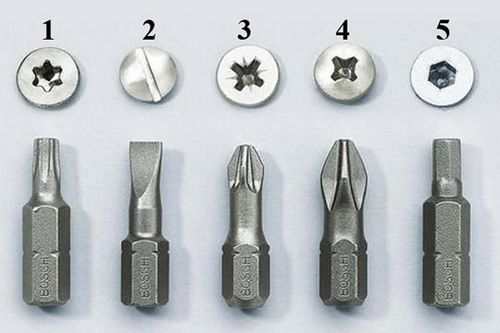

Torx hule

Bits of this type are called asterisks. Provides reliable adhesion to the heads of bolts and screws, eliminating slippage. Used where a lot of force is required to tighten fasteners.

Head bolts of this type are most often found in cars, household appliances.

There are two types of markings, for example Torx8 or T8. Diameter is indicated in mm.

Bits from T8 to T40 are suitable for the screwdriver. In various electronic devices there are also smaller sizes, but working with a screwdriver with such bits will NOT work, you need to use a screwdriver.

Torx hule sprockets may have an inner hole.

PH. Acronym for Phillips

The bit has a cross-slotted, widening near the shank and forming an angle of 55 degrees at the apex, it is clearly and securely inserted into the screw head.

Sizes from PH0 to PH4. The number in the marking indicates the size of the cross. The larger it is, the larger the bit is for the larger self-tapping screw. Bits in size PH0-PH2 are used for the most common screws with a diameter of 2.5-3 mm. PH4 is rarely used, in the repair and installation of large-sized structures, in the automotive industry.

The most popular bits are PH2 and PH3, they are most often used for all types of black screws, including for twisting thin-walled metal profiles. Bedbugs.

The PH standard is universal, fits most other types of self-tapping screws.

SL. Short for Slot

SL standard. Screwdriver with flat straight slot of different width, measured in mm.

Marking, e.g. SL6 or Slot6, means: 6 mm flat-slotted bit.

Sizes from SL0 to SL7.

They differ in the length of the rod. They can be with or without restraints. The limiter is used so that it is not possible to wrap fasteners deeper than necessary, for example, when installing drywall. Bits of this standard are used when screwing fasteners in soft materials when a large torque is NOT required. Cannot provide a secure grip on the head of a screw or screw.

Screwdriver bits: how to choose their types?

- Types and marking of bits

- PH. Acronym for Phillips

- PZ. Short for Pozidrive

- Torx hule

- SL. Short for Slot

- Bit material and coating

Everyone who has dealt with construction, renovation of premises, household appliances, cars, furniture assembly knows how to tighten and unscrew a large number of bolts, nuts, screws, screws and other types of fasteners. This is not an easy business, requiring a lot of effort and time.

A screwdriver is similar to an Electric Drill, only instead of a drill it has a bit.

With the advent of soft-start screwdrivers and drills, the job has become much easier. But a screwdriver without bits. Useless thing.

A huge number of bits from various manufacturers are presented in the building materials markets. They have a different look, shape, size, color, purpose. May differ significantly in cost.

Bit. A nozzle used for twisting and unscrewing various types of fasteners. Each type of fastener uses its own type of bit.

Regular bit. It is a hexagonal metal bar. One part of it. Working, is a screwdriver with slots of various configurations depending on the type of fasteners used. Second part. Shank that fits into an adapter or screwdriver chuck.

Types and marking of bits

PZ. Short for Pozidrive

Bits are used for screwing self-tapping screws with Pozi standard splines and medium thread pitch and universal countersunk (UP).

This is a cruciform bat with 4 large ribs and 4 additional diagonal ribs forming double cross. Apex angle. 50 degrees. This design provides a larger grip area than the PH bit.

The torque transmitted from the screwdriver to the bit and then to the screw or self-tapping screw will be much higher.

Before changing the nozzle in the screwdriver, check if it is disconnected from the mains.

In most cases, PZ bits are used for removing rusted or seized screws.

Bits of this type are indispensable for screwing self-tapping screws into materials with a dense structure, such as hard wood, compressed artificial materials. They can be twisted at an angle. Screw heads and bits are NOT damaged.

Sizes from PZ0 for self-tapping screws with a diameter of 2.5 mm to PZ4 for self-tapping screws with a diameter of more than 4 mm and anchor bolts. The most popular sizes are PZ2 and PZ3.

Help in determining the best screwdriver bits

Thus, it is easier to navigate in the variety of types of attachments and choose the most robust, practical, tuned for a long period of action.

Things to consider when choosing bits

Industrial bit sets can be purchased separately at retail outlets, but the standard sets offered for the Screwdriver already contain sets of bits of various formats.

Neglect of such requirements will lead in the future, when working with a power tool, to the constant breakdown of the bit and its scrolling into the screws.

Small-format parts and their big role

Construction and installation processes have been simplified due to the emergence of a huge amount of fasteners. Modern electric screwdrivers or screwdrivers allow quick connection of elements using fastening parts.

Nails, which were mainly used as the only existing fasteners in the old days, have now faded into the background. Everyone, from hobbyists to professional craftsmen, prefers to use screws and screws. These fasteners are extremely popular today.

However, for their even arrangement and rigid attachment to the mounted surface of sheet material or other connected elements, good attachments are needed.

In other words. Bits. Without them, any screwdriver, even the most practical, becomes useless.

Hence the conclusion, it is necessary to have an idea of the existing types of nozzles in order, if necessary, to make the right choice.

Basic materials of manufacture

The second important factor when choosing bits for a Screwdriver is the type of metal used to make them. The main role is assigned to the working parts of the nozzles.

As they are made in combination with various specialty solders, it is worth knowing Top priority alloys.

There are the following alloy types for quality bits:

- Molybdenum combined with chromium;

- Vanadium with the same chromium;

- Molybdenum and vanadium;

- Silicon-magnesium heat (win).

Where is the best place to buy quality attachments

Bits for a screwdriver how to choose

Additional parts for a power tool are qualitatively important as well as the tools themselves. A good result in the course of the drill-screwdriver, for example, is achieved when using high quality bits.

Summary of the article:

- Small-format parts and their big role

- Help in determining the best screwdriver bits

- Things to consider when choosing bits

- Where is the best place to buy quality attachments

- Basic materials of manufacture

- The most practical bit types

- Photo of the best bits for a screwdriver

How to evaluate the quality of bits for a screwdriver

So that in the process of work there are no difficulties in the choice of consumables, you should approach responsibly.

Therefore, it is recommended to know in advance how to evaluate the quality of the bits before purchasing.

Types of bits and their purpose

Bits for a screwdriver differ in the shape of the working part, on which their purpose depends.

All types of products can be purchased as a set, which is much cheaper than buying them separately.

But before that you need to make sure the quality of the bits.

To make the right choice, you need to know the types, sizes, bits, their main differences and the material from which they are made.

How to choose bits for a screwdriver

To make it easy and convenient to work with a screwdriver, you just need to choose the right bits.

At the same time, it is desirable to choose high quality products, even if their cost may be a little overpriced.

Before buying, you should study the recommendations for choosing bits from specialists.

Spring and magnetic

Bits with a spring clip or a magnetic tip are designed for working on ceilings or other hard-to-reach places.

Retainers are designed to hold the bits in the adapter.

The magnetic tip allows you to securely fix the bit in the screw grooves.

It is also able to prevent slipping of the screwdriver nozzle during operation and allows you to screw the self-tapping screw deeper than a simple nozzle.

The spring nozzle is a special.

It allows you to work with fasteners that are at different angles and in hard-to-reach places.

Most often it is a slot and a base, which are connected with a flexible spring for fastening: you need to fix the slot of such a nozzle manually, insert it into the notches on the screws, while the spring can be bent at any angle, even more than 90.

Screwdriver bits

Bits for a screwdriver are almost always necessary for repair and construction.

It is difficult to imagine repair work without screwing in screws, screws and other similar parts.

When the number of fasteners is large, a special electric tool is used, but its functionality largely depends on whether the bits for the screwdriver are correctly selected.

With anti-vandal slots

The bat with anti-vandal slots is called by the master “snake eye”, since K. It has a socket for a fork wrench.

How to use screwdriver bits correctly?

1) Exact match of screw head and bit. In any master, if the beloved bit, and that lives in a screwdriver for a long time, when buying hardware, try to choose screws or screws for it. There are a lot of configurations of heads, there are many, sometimes you have to work with such crap in this case, keep an inexpensive set of bits on hand, you can even make it in China.

2) Don’t forget the ratchets. Screwing the dowel nails onto jerk, just in case, set the ratchet limit just above the maximum force. If the self-tapping screw rests against the concrete, this will not allow the splines to be ripped off. When working with drywall and metal profiles, the ratchet will protect the surface of the gypsum board from ruptures when the screw head is overly immersed.

3) Grease for self-tapping screws or screws. Before screwing in, lubricate the working surface, this will significantly reduce the effort and, as a result, unload the screwdriver and the bit will live much longer. If you screw in a self-tapping screw forever and ever for example, when stretching the floorboards of a wooden floor, it is better to lubricate it with water, then it is very difficult to unscrew such a screw. But if it is supposed to later Unscrew the screw, then you can grease it with soap, kerosene or WD-40. Such a grease will dry quickly and will NOT affect the quality of the fastening, but it will screw in like a knife into butter.

4) keep the angle! Banal advice, but most often the slots break down precisely for the reason unsteady hand or haste. The bit must fit into the head tunic in tunic, without backlash. If possible Use spring-loaded bits, this slows down the work, but only in the beginning, over time your hands will do everything right and quickly.

5) get a box for old bits

After the completion of large volumes of work, bits remain tired, little backlash or worn out. These can be folded for future use, and later this box will help you out more than once. These bits are still useful for unscrewing. I have a powerful magnet in this box, besides the fact that it can magnetize any bit, it often helps out in hard-to-reach places. If they ask me which beat is my favorite. This is a ph2x50 graff screwdriver bit from Phillips.

How to choose bits for a screwdriver

The right bit for a screwdriver or drill. Significantly speeds up the work, for example, when pulling the floorboards of the plank floor, they use long self-tapping screws (80-100mm), which are simply unrealistic to screw in with a screwdriver, hand dry up. Here is the place for a good screwdriver or electric drill! But without a high-quality bit, work can turn into torture, screw slots break off, overheated self-tapping screws break. And to disassemble a laptop or a dishwasher, you need special, curly bits. The latter simply cannot be promoted. It seems to be a trifle, but you need to figure out which bits to use for what and which ones are better to choose.

Bit set for BOSCHE screwdriver. Top left. Collet bit adapter

Double Sided Bits

Combination bit set

Combination bits have 2 different types or sizes of working parts at both ends, for example slotted and crosswise. They are usually longer than normal bits. For comfortable and fast work, it is important to choose the right bit fixture. This is easiest to do empirically, so when buying a bit, you must have a sample of fasteners with you.

Special and Combined Bits

Special Hex Bits

Special bits are used to work with specialized fasteners, for example, repairing household appliances, cars, industrial equipment. Let’s take a look at the three-sided bits separately, they are similar to the PH, but with three faces. And the bits are double pin, with two protruding in the shape of horns. From Special bits in everyday life, bits for working with drywall can come in handy. The limiter does not allow the screw to be screwed in too much and spoil the surface. Specialized bits include spring-loaded bits, which allow you to tighten screws or self-tapping screws at an angle of up to 30 degrees, which is very convenient when working in narrow, hard-to-reach places.

Additional attachments for screwdriver bits

You cannot get everywhere with a screwdriver without a nozzle, in the work of the master there are places where you cannot even look. For this case, there are several accessories on sale that make it easier to use a screwdriver or electric drill in hard-to-reach places. Bit adapters also fall into this category. Not all adapters for a screwdriver are produced of proper quality, there is outright junk, so let’s start with it:

Flexible bit shaft

Or as it is also called flexible bit, designed to work in hard to reach places. Available with or without a magnetic bit head. Theoretically, such an extension adapter copes with its functions, but in practice, the effort is far from every screwdriver will turn the flexible shaft bent at the desired angle. How many times I tried to adapt to working with this mega-device, I never found a use for it. When screwing in a self-tapping screw 6 × 60 per tree. The flexible shaft heats up perceptibly and my NOT weak shura hums at the limit.