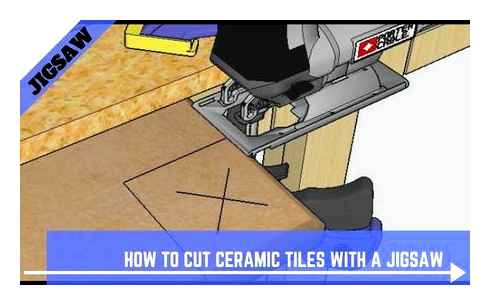

Can porcelain stoneware be sawn with the jigsaw?

Ordinary users who are not engaged in laying tile material skillfully, often ask questions about whether it can be cut with an ordinary electronic jigsaw. The question is pressing, because every skillful owner has this tool.

To work with ceramics is possible, but it is necessary to use special tips and devices that make it very comfortable and excellent.

A Principle: the tiles made of ceramic, porcelain tiles and other varieties of these materials simply prick, forming with all this small splinters, because when working with it need to use personal protective equipment. At least goggles and gloves.

Order of work

Before to start to carry out a cut of porcelain stoneware or porcelain tiles, it is necessary to wear a personal protective equipment. tile, the jigsaw blade needs to be set in the electric jigsaw.

Principle: annotation on the proper installation of the blade can be found in the user’s manual that comes with the jigsaw.

Then the plate should be soaked for 5-10 minutes.

The next step is to mark the mowing line of the cut, then the material is firmly fixed on a special stand of bars. At home, for fixation, you can use an ordinary kitchen table. It is important to fix in such a way that the place of the cut was by weight.

If a block stand is used for clamping, its thickness must be greater than the length of the saw blade. It is necessary so that in the process of work the saw didn’t bump into the base, on which the stand is installed.

Safety precautions at work

In general, the electric jigsaw by its design features is safer than the angle grinder and circular saws. The real danger when working with a jigsaw is to get your hand or other body part under the running saw. It is most likely under the workpiece where the invisible tip of the jigsaw exits.

Read more about the choice and design of jigsaws in this article.

That is why the main rule of safety at work: the hand must not come dangerously close to the working saw during any operations.

Do not saw small workpieces while holding them by hand near the saw. The workpiece must be clamped by any means: clamps, vise, self-tapping screws, clamps, etc.д.

- Sawblade breakage with the sharp piece rebounding to the side in an unpredictable direction. Happens very rarely. often the saw breaks in two parts, one of which remains in the workpiece and the other in the rod. If it bounces, it does so with low force, because the speed of the blade is low, from 500 to maximum 3200-3500 up-down strokes per minute. This is much less than the 12,000 rpm of an angle grinder disc and up to 5000-6000 rpm of a manual circular saw. In this case the jigsaw blade has only reciprocating motion, but not rotation. Which means there is no centrifugal force, which is only generated by rotation and throws the released particles aside.

- Getting sawdust in the eyes. Often the operator leans over the saw to control the alignment of the kerf line and the position of the blade. In this case, the air flow from the motor cooling fan or an accidental draught can bring sawdust into the eyes. To protect against this, the electric jigsaws are equipped with hinged transparent safety covers. Sometimes they interfere with the view and they are thrown away. Then you have to wear safety glasses or at least not lean too close to the working area.

Sawdust that gets into the eyes is a nuisance. And metal, sawdust from sheet metal adhesives, plastic, can hurt your eyes. Therefore, protective guards or goggles should not be neglected.

The operator in the photo, wearing safety glasses, at a safe distance.

Electrical safety rules for jigsaws are the same as those for any electrical appliance.

- Do not use bare wires;

- Plug and socket contact must be tight, no sparks, no heat;

- When working, the socket of the extension cord should not be under your feet;

- it is necessary to exclude the possibility of getting the wire under the working saw.

In terms of fire safety, the jigsaw is also safer than other cutting tools. Does not create a flow of sparks, as when working with a monkey (angle grinder) or an open flame, as when cutting metal with gas/electric welding in the cutting mode.

Preparing the tool

First of all, a saw suitable for the material is selected. Do not use badly worn, bent saw blades with chipped or frayed teeth. With them, the jigsaw is slow, overloading the motor and giving way too much, if at all.

We also recommend reading a useful article about choosing a jigsaw saw.

If the saw is already in place, it is sometimes useful to check the screws are tightened or the auto-clamp is secure. It happens that during operation the webbing becomes loose.

Screws for securing saw blade should be tightened firmly, but not excessively, so as not to tear threads or head splines.

It is advisable to make a test cut on an unnecessary workpiece before sawing business material. In this case:

- determine the behavior of the jigsaw, the quality and speed of the cut, the presence of chips;

- The optimum web stroke frequency (motor speed) is selected by means of an adjustment.;

- on the wood the pendulum stroke (swinging of the saw) is switched on with the assessment of how the jigsaw cuts, whether it is better or worse. On metal, laminate, brittle plastics and hard materials, pendulum operation is not included.

after the adjustment and test kerfs the user proceeds to the sawing of the business material, already knowing the capabilities of the jigsaw, the speed and the quality of cutting.

Preparation of the working place

It is more convenient to saw with the jigsaw with the workpiece positioned on the work table. (Except when you saw on the floor). In any case place the workpiece so that it is guaranteed that the saw blade does not touch the floor, the edge of the work table or other foreign objects.

the saw blade for the trimmer must be as close as possible to the support (table top, workbench, floor bars, etc.).д.). If the kerf is too far from the support, the workpiece will jump and vibrate, which is incompatible with a normal straight kerf and can cause breakage of the blade.

It is also risky to position the trimmer blade too close to the edge of the support, because the saw blade can snag the support. Optimal. 5-7 cm for thick bending materials, 2-3 cm for fiberboard, thin plywood, etc.д.

Before you start cutting, check under the workpiece to make sure there are no obstacles in the cut and that the saw blade does not catch on the edge of the workbench.

The workpiece must be secured by any means (screw clamps, clamps, self-tapping screws, stops, etc.).д.) You can not hold it with one hand, as it is unreliable and restricts the operator’s movements, distracting from the main operation. the sawing.

In the photo. the workpiece is properly secured.

When making a long cut, you must consider how the wire will be routed. Can it cut all the way through? Or in the middle you have to turn off the jigsaw and throw, for example, an extension cord socket with a plug on a sheet of material.

The light must fall in front of the jigsaw on the saw trimmer line. If the light bulb hangs behind, it is possible not to see the line for the marking trimmer in the shade. Especially with jigsaws without backlighting.

What materials can be cut

All materials for which saws are available can be sawed with this tool. Its purpose is usually indicated on the cloth by one English word.

Can porcelain stoneware be sawn with the jigsaw??

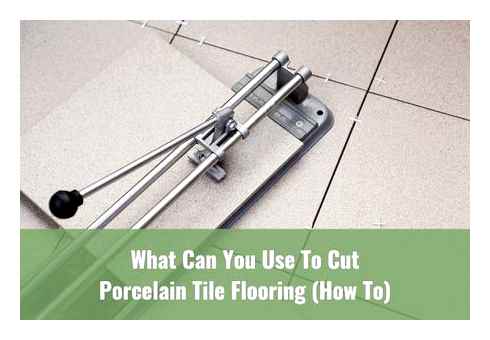

Nevertheless, to cut ceramic and porcelain tiles with a jigsaw is quite realistic even at home, but only if certain requirements are met: The tool must be prepared for sawing porcelain tiles. On the sole glued thin, necessarily soft material, you can paper or rubber.

In its absence, in most cases, an angle grinder is used, which also allows you to cope with the task. But it is necessary to work very carefully, because the angle grinder is a powerful tool, and porcelain tile is a strong material on the one hand, but on the other. fragile. That’s why chipping is possible.

How to cut a tile without using a tile cutter

In the production of various construction works on their own, there is often a need to cut ceramic tiles at home. For this it is not necessary to have a professional tool. a tile cutter. Let’s specify at once: We are not talking about constant work and large volumes, but about small batches or even piecemeal products. In such cases there is no sense to buy expensive tools, you can easily do with improvised means.

Types of cutting

- Cut in a straight line. At the same time, it is necessary to distinguish where the cut goes. If there is less than 2 cm to the edge from the cutting line, such a cut can be considered a shaped cut;

- Round holes in the tiles of different diameters;

- Shaped cuts;

- Mosaic pieces. If there are requirements for precise geometric shapes, this type also refers to shaped cutouts. Otherwise, it is actually crushing the tiles into pieces. Products are placed in a bag and crushed to the desired proportions with a heavy tool (hammer, sledgehammer). The exception may be non-ceramic tiles.

Methods of cutting tiles

The following methods are mostly suitable for cutting tile at home. But also applicable or limitedly applicable to other types of tiles. You can cut tiles without a tile cutter in the following ways:

Angle grinder (angle grinder)

Generally speaking, this is a universal tool. Just as craftsmen used to be able to cut down a house with a single axe, so now with a single angle grinder they can cut anything. The author witnessed how to cut an even round hole with a diameter of 5 cm.

Note! The method is suitable for straight, shaped types and with minimal skill in handling the tool curved lines of any configuration.

How to cut ceramic tiles in thin pieces (tips and tricks)

- angle grinder. Any power and any kind;

- Cutting wheel (stone or diamond);

- Protective helmet or goggles (mandatory);

- Protective full-body suit and gloves (recommended);

- Respirator (recommended);

- Clamp. Optional in some cases (clamp or vise).

Pre-mark the tile, preferably with scratching the line with any sharp instrument. As a last resort, it is allowed to draw a line with a construction marker. A lot of dust is generated and the marked lines can be rubbed off when it is removed.

Straight small cuts around the edges of the tile can be made by laying the tile on a flat surface on a table or on the floor. First cut a few millimeters into the surface. With this operation, the own gravity of the tile and the friction force is enough to keep the product in place. For deeper passes, the edge of the tile can be stepped on or an assistant can hold the tile in place. For shaped cuts, it is better to clamp the workpiece to the table top or clamp it in a vise, with pieces of cardboard or a thick cloth placed under the jaws beforehand.

Tip! Place a piece of plywood under the workpiece to avoid damaging the table or floor surface.

- On the outer edge, marks are made several times along the entire length. Deepen up to 3 mm in one pass. Repeat the operation until the result is achieved;

- For small cuts, up to 2 cm in length, all at once to the full thickness;

- The marking is applied to both sides. Make a superficial cut on the face (up to 3 mm). Then they cut from the opposite side (up to 3 mm per pass) until they reach their goal. This prevents accidental damage to the face with the cutting tool.

Recommended for difficult cuts: on edges or curved cuts. The point is that with this method there is a lot of dust, cutting blade consumption, time and labor costs. It is possible to cut an ordinary straight line for a trimmer by much easier ways.

If you don’t have a tile cutter or angle grinder, an electric jigsaw may be available. An underappreciated tool by many!

Please note! A manual jigsaw with a stone saw can be used in the same way. But the cutting speed will be much slower.

Sawing in a conventional manner. Sawing too rounded kerf is problematic, the saw gets stuck. Not thick (wall) tiles are good for sawing. Porcelain stoneware is very difficult to saw in this way. For a little relief, it is suggested to pre-soak the material.

Recommended when it is necessary to cut curved sections with large curvature radii.

Glass cutter or any pointed tool

Only tiles can be cut with this method. And only in a straight line. One more limitation. the parts must not be less than 2 cm in width.

- Glass cutter. Any tool with a sharpened cutting edge can be used instead of a glass cutter. Preferably the cutting tool should be made of hard materials: diamond, bobedite, etc.д. As an example of cutting tools: drills, lance drills, utility knife and so on;

- Metal ruler or any straight metal rail. In the extreme case of any material. But then you will need to be very careful to scratch the line for the trimmer cut, because you can cut through the ruler and the scratch will go sideways on the tile.

In order to get a clear cut without chipping or going sideways the scratch must be applied carefully. It is enough to scratch the top, glossy layer.

Tip! Pay attention to the beginning and the end of the scratch when applying the risk. Often, at the very beginning and at the very end, the scratch is not deep enough. It is connected with insufficient pressure and psychology. At the beginning just trying it on and the pressure is loose. At the very end, there is an acceleration and the risk is “blurred. This can cause the break in these places to go sideways.

What to pay attention to before buying

Jigsaw for metal can be identified by a characteristic marking. T118 A (thickness of workpiece up to 3 mm), T224 D (for aluminum) and so on.

Remember that the tool (especially an amateur one) needs a rest. After 20-30 minutes of work it is worth to put the jigsaw aside to avoid overheating it. This is not the case with the professional models. they work for hours at a time. If you feel that the body of the tool is hot (because of the continuous operation of the motor), it makes sense to give the device a rest.

In short, this is all you need to know about jigsaws for metal. If you have something to add, feel free to share your thoughts in the Комментарии и мнения владельцев section.

General cutting principles

Principle 1. All jigsaws give uneven cuts. This is important to understand. The very design of the tool implies several degrees of freedom of the saw, so to get one hundred percent perfect cut will not work, but compliance with a few simple rules will reduce the number of “shoals” to a minimum:

-

do not apply force. No, absolutely no. A small amount of pressure and directional control is all you need for a clean cut. Yes, slow but good;

The Achilles heel of most jigsaws is the pendulum motion system. Its design, in most cases, does not allow a cut to be perfectly perpendicular to the surface. The pendulum mechanism has a big enough backlash, which “takes” the saw away from the vertical and the intended line of the cut, when you apply even a little effort to the jigsaw. Very few professional tools have a different design of pendulum system (assembled directly in the gearbox) and a stabilizing cutting blade that keeps the saw blade in a strictly perpendicular position. To get a guaranteed perpendicular cut, the saw must be as thick as possible (from 1.5 mm).

- only sharp consumables. As soon as the cutting edge becomes a little dull, the saw starts to behave unpredictably. Therefore, if the teeth have “sagged”, it is urgent to change them;

- temperature is everything. It is necessary to monitor carefully the temperature of the cutting surface, not to let it overheat. saw teeth are liable to heavy wear exactly in the moments of overheating because metal becomes softer and can not adequately resist friction forces.

Principle 2. The jigsaw is just a saw drive. Its features (number of steps of pendulum feed, illumination, laser pointer, etc.) are not very important. д.). The really important parameter is the power of the jigsaw. It determines the type and thickness of the material that the jigsaw can handle.

Principle 3. The jigsaw is the main violin in the duet with the jigsaw. There are many types and varieties of these tools. And each is “sharpened” for a specific task or material. The quality of the end result depends on the right choice of cutting attachment.

For example, a fine saw is needed for making curved cuts in the material, and a coarse-cutting saw is suitable for roughing workpieces. Sawing complex, intricate workpieces requires saws with two cutting edges. The front one makes the main cut, and the back teeth trim the workpiece with a small cutting radius, making the blade more maneuverable. In addition, the use of a double-sided blade allows the jigsaw to be run both forward and backward for a short period of time. For example, when sawing the outline of a maple leaf.

It is worth remembering that the cutting blades for jigsaws are available for different material thickness. There are saws for cutting thick and thin material, which differ from each other by their length. Some jigsaws can be up to 250 mm in size, but the jigsaw is powerful enough.

Principle 4. A minimum of three teeth per material thickness of the workpiece to be cut. The thicker the workpiece, the coarser the teeth should be on the saw. This principle gives the best result because there is always room to evacuate sawdust from the place of cutting, the groove does not get blocked and the process goes faster.

Principle 5. All in business. In order to get the smoothest, straightest cut possible, you should not neglect auxiliary devices. A side stop, guide rail, or hastily made jigsaw guide helps to guide the tool as straight as possible, which immediately affects the end result.

A piece of laminate or any other material with a smooth edge, can serve as an excellent guide on which to rest the sole of the jigsaw. The main thing is to set the supporting face correctly and fasten it reliably.

Cutting porcelain tile with a jigsaw. A two-handed handyman

At the end of the twentieth century, a new finishing material. porcelain stoneware. was developed and brought out for the first time.

It is made by dry compressing a mixture of crushed clay, quartz sand and feldspar.

The result is an easily moldable and extremely durable material with an excellent appearance.

Its high strength is causing some problems in processing. porcelain tile is not so easy to cut. Many methods are used for this. from manual to high-tech.

The advantages of porcelain stoneware

Porcelain stoneware has distinct advantages over traditional wet clay fired ceramics.

The extremely durable material has an excellent appearance that is very close to natural stone.

Construction experts formulate the following advantages of porcelain stoneware:

- Toughness and abrasion resistance. Provide long service life with preservation of appearance.

- Resistant to aggressive media and other contaminants. Stains do not form on porcelain stoneware, it is easy to clean.

- Eco-friendliness. Manufactured from natural ingredients without the use of harmful to health and the environment chemicals. The surface slowly reproduces microbes and other microorganisms.

- Forms a smooth edges and cuts. It allows you to accurately cut the material and form seamless surfaces.

Cheap Way to Cut Porcelain Tiles Using Portable Grinder

Most of the advantages are due to the low porosity of porcelain stoneware.

Disadvantages of porcelain stoneware coatings

To properly cut porcelain stoneware, you should also be aware of its disadvantages:

- High cost. Is stipulated by the complexity of high pressure moulding machines. It should be taken into account that the natural stone will cost more.

- High thermal conductivity. The floor will cool your feet. This disadvantage is combated by the device of heated floors.

- Slippery surface. Especially evident in wet rooms, for them tiles with a rough surface texture are recommended.

Features of the material

The main features of porcelain stoneware are

Other features derive from these properties:

- high durability;

- resistance to abrasion;

- resistance to temperature fluctuations;

- resistance to chemicals and fire;

- long service life;

- high hygienic and ecological qualities;

- inability to accumulate static electricity charges.

These features attract the attention of manufacturers and consumers to the material. However, the high strength poses a difficult question: how and what to cut porcelain stoneware?

The best ways to cut porcelain tile

Beginning repair or construction, many home craftsmen are misled by the resemblance of the material to traditional ceramic tiles.

How to cut porcelain tile?

Cutting porcelain stoneware the way they are used to cutting familiar ceramics will not be possible.

Attempts to cut the tough material with a glass cutter, a metal cutting disc, etc. will not cut it.

The productivity of such attempts will be very low or zero.

What to cut porcelain tiles with?

- angle grinder;

- A circular saw;

- electric jigsaw;

- A hand-operated tile cutter;

- electric plate cutter;

- The hydraulic cutter.

you can find an angle grinder in any home repair shop.

This versatile tool, designed for stripping welds, has found a thousand and one uses in the home.

To cut porcelain stoneware, instead of a metal or stone cutting disc, you should buy a diamond-coated disc.

Work with caution:

- use personal protective equipment: goggles (or better. a transparent shield), respirator, tight clothing that does not leave exposed skin areas;

- cut in the open air or in a well ventilated room;

- Do not use open fire and do not smoke: dust explosions are explosive.

It is necessary to accept beforehand with the fact that it will not always be possible to cut without chipping. They will need to be smoothed with a file or a sanding disc.

The tile is placed on a smooth surface and secured with a clamp or clamp.

it is necessary to cut on face side, that chippings and irregularities remain on the back side.

The cut must be made from the far edge toward you, without jerking and in one cut. This will reduce chipping.

Circular saw and jigsaw

The circular saw must also be equipped with a diamond blade.

The safety rules are the same as those described above.

It is necessary to firmly fix the stoneware on the worktable and to hold the platform of the circular saw firmly against it.

The electric jigsaw will also require the installation of a diamond thread instead of the usual saw. It will allow you to cut not only in a straight line, but also in an arbitrary trajectory.

It is necessary to move the tile slowly and smoothly, without stops and jerks. Try to get all the line for the cut trimmer in one go.

This is not easy and requires some skill and forethought, but it is the only way to minimize the number of chips.

Mechanical tile cutter

It is not too easy to cut tiles with a manual tile cutter, but it is quite realistic.

You just need to make sure that it is designed to work with tiles of great thickness and size.

It must have sufficient leverage, a strong and wide frame, a long and sturdy handle.

If you see that the tile cutter doesn’t cut, but only slightly scratches porcelain tiles, you should sharpen the cutter or even replace it with a carbide cutter of good tool steel.

The procedure when cutting porcelain tiles with a tile cutter is as follows:

- Draw the line for the cut trimmer.

- Set the tile on the bed so that the rollers of the device rest on it.

- Moving the lever away from you, make the cut.

- Lowering the lever to break porcelain stoneware along the cut line.

Cutting porcelain stoneware with a jigsaw. A master at both hands

At the end of the twentieth century a new finishing material was developed and for the first time produced: porcelain stoneware.

It is made by dry compacting a mixture of crushed clay, quartz sand and feldspar.

The result is an easily moldable, extremely strong material that has an excellent appearance.

High strength comes with some machining problems. porcelain stoneware is not easy to cut. Many methods are used for this. from manual to high-tech.

The advantages of porcelain stoneware

Porcelain stoneware has distinct advantages over traditional ceramics, which are obtained by wet clay firing.

The extremely durable material has an excellent appearance, very close to natural stone.

Construction experts formulate the following advantages of porcelain stoneware:

- Durability and abrasion resistance. Ensure a long service life whilst maintaining appearance.

- Resistant to aggressive media and other contaminants. Stains do not form on porcelain tiles, they are easy to clean.

- Environmental friendliness. Manufactured from natural ingredients without the use of harmful to health and the environment chemicals. Microbes and other microorganisms multiply slowly on the surface.

- Forms flat edges and cuts. This allows to cut the material precisely and form surfaces without joints.

Most of the advantages are due to a small porosity of porcelain stoneware.

Disadvantages of porcelain tiles

To properly cut porcelain stoneware, you should also be aware of its disadvantages:

- High cost. Is caused by the complexity of high-pressure pressing machines. It should be taken into account that natural stone is more expensive.

- High thermal conductivity. The floor will keep your feet cold. This disadvantage is combated by the device of heated floors.

- Slippery surface. Especially manifested in wet rooms, for them we recommend tiles with a rough surface texture.

Material Features

The main features of porcelain stoneware are

From these properties arise other features:

- high durability;

- abrasion resistance;

- Resistance to temperature fluctuations;

- resistance to chemicals and fire;

- long service life;

- high hygienic and ecological qualities;

- inability to accumulate static electricity.

These features draw the attention of producers and consumers to the material. However, their high strength poses a difficult question: how and with what to cut porcelain stoneware?

The best ways to cut porcelain tiles

Beginning repair or construction, many home craftsmen are misled by the similarity of the material with traditional ceramic tile.

How to cut porcelain tile?

It is not possible to cut porcelain stoneware the same way they are used to cutting ceramics that they are familiar with.

Attempts to cut a durable material with a glass cutter, or cut with a cutting wheel for metal, etc., will fail.

The performance of such attempts will be very low or zero.

What to cut porcelain stoneware with?

- an angle grinder;

- A circular saw;

- An electric jigsaw;

- A tile cutter with a manual drive;

- Electric tile cutter;

- hydraulic cutter.

Angle grinder can be found in any home repair shop.

This versatile tool, designed to strip welds, has found a thousand and one uses in the home.

To cut porcelain tiles, instead of a metal or stone cutting disc, a diamond-coated disc should be purchased.

It is necessary to work with caution:

- Use personal protective equipment: goggles (or better, a face shield), a respirator, tight clothing that does not leave exposed skin;

- Cut outdoors or in a well ventilated area;

- Do not use open fire and do not smoke: dust explosions are dangerous.

It should be accepted in advance that it will not always be possible to cut without chipping. They will have to be smoothed out with a file or sanding disc.

The tile is placed on a smooth surface and fixed with a clamp or clamp.

You need to cut on the front side so that chips and irregularities remain on the back side.

The cut should be made from the far edge towards yourself, without jerks and in one go. This will reduce chipping.

Circular saw and jigsaw

You will also need a diamond blade on your circular saw.

Safety rules are the same as those described above.

It is necessary to securely fasten the porcelain stoneware on the work table and press the circular saw platform firmly against it.

An electric jigsaw will also require a diamond thread instead of the usual saw. It will allow you to cut not only in a straight line, but also along an arbitrary trajectory.

Move the tile slowly and smoothly, without stopping and jerking. The entire cutting trimmer line should try to go through in one go.

It is not easy and requires a certain skill and prudence, but only in this way you can minimize the number of chips.

Mechanical tile cutter

Cutting porcelain tiles with a manual tile cutter is not too easy, but quite realistic.

You just need to make sure that it is designed to work with tiles of great thickness and size.

It should have a sufficient stroke of the lever, a strong and wide frame, a long and sturdy handle.

If you see that the tile cutter does not cut, but only slightly scratches the porcelain tile, you should sharpen the cutter or even replace it with a carbide, made of good tool steel.

The procedure when cutting porcelain tile with a tile cutter is as follows:

- Drawing a fishing line for a trimmer cut.

- Set the tile on the bed so that the rollers of the device rested on it.

- Moving the lever away from you, make the cut.

- Lowering the lever to break the porcelain stoneware along the cut line.

Correctly to cut porcelain tiles in domestic conditions not so much difficult, but rather troublesome. In order to deal with a lot of abrasive dust, you have to use paper bags and filters if the cut is made on a table or workbench. Besides, a vacuum cleaner is necessarily needed, it is rather uncomfortable to cut hard porcelain tiles at home without collecting dust.

Discuss the article on a forum