Air damper

The carburetor choke is installed on the opposite side of the throttle and is responsible for starting a cold engine, it is controlled by the engine control lever. For a cold start, the air damper is completely closed, for normal operation, open.

Frequent breakdown of the Stihl carburetor and how to avoid it

A common reason for the failure of a carburetor on a Stihl chainsaw is a sticking valve in the nozzle. The reason for sticking is a violation of the storage of the chainsaw, or rather the instructions of the manufacturer Stihl 180 for proper preparation for storage.

As follows from the instructions, before long-term storage, it is necessary to drain the fuel from the tank, then start the saw and burn the gasoline from the carburetor. Failure to comply with this elementary rule entails the following consequences. The forsknui valve, being in direct contact with the fuel, sticks to the body, since the gasoline evaporates little by little and only sticky oil remains. It is impossible to replace the nozzle, since they are not in the repair kit, you can only try to knock it out and rinse it, which is not always possible to do without damaging the nozzle.

Dismantling the carburetor Stihl 180

In order to purge, change gaskets or the needle valve, the carburetor must be disassembled. To do this, unscrew 4 screws on the expansion joint cover and one on the fuel pump.

Having opened the case, you should be extremely careful, because if debris gets into the inside of the carburetor, it will make its work impossible. The thickness of the channels in it is comparable to the thickness of a thread or even a human hair.

A video for repairing a Stihl 180 carburetor can be viewed below. In it, the wizard tells in detail about the problems and clearly demonstrates the entire repair process.

Why does the Stihl 180 carburetor overflow and a few typical malfunctions

After we examined the carburetor device, it will not be difficult to determine the reason why fuel enters the combustion chamber in a larger volume. This is due to the wear of the gasket between the compensator cover and the carburetor body. You ask how this might affect?

The answer is simple, by contracting, the gasket releases the diaphragm on top of it a fraction of a millimeter down. She, in turn, will press harder on the rocker arm of the needle valve, it will open more than it should be and the fuel will flow in excess (it will start to overflow).

Another reason is the stretching of the diaphragm itself, this happens as a result of natural wear and tear. It is impossible to prevent this process, but you can solve the problem by periodically changing all the gaskets, carburetor diaphragms, and the fuel pump. There is a repair kit for this.

When cleaning the chainsaw with compressed air, never blow into the fuel pipe, as this can stretch the diaphragm.

Adjusting the Stihl 180 carburetor

The carburetor of the Stihl 180 chainsaw, indiscriminately, can only be adjusted by the number of idle revolutions. It is impossible to increase or decrease the fuel supply in different modes using special screws. The manufacturer restricts access to adjustments and does not install these screws. How to adjust the carburetor to the correct idle speed is described in great detail in the manufacturer’s instructions.

In the event of certain malfunctions, and with experience, it is possible to increase or decrease the fuel supply by increasing the clearance when opening the needle valve.

To increase the flow, the rocker arm of the needle valve in the distribution chamber must be bent up, and to decrease, down. This regulates the stroke of the needle and, accordingly, the throughput of the valve.

It is not necessary to carry out the adjustment yourself, since this must be done very accurately and in case of an error it is almost impossible to return the original position of the rocker arm.

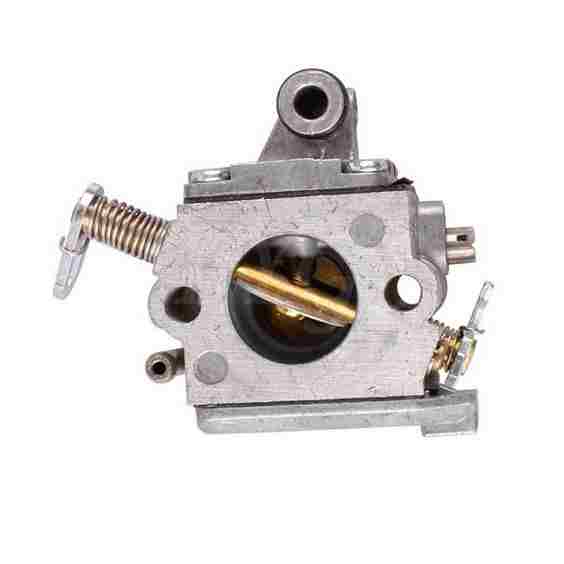

Stihl 180 carburetor device

So, the Stihl ms 180 carburetor is developed and manufactured by a subsidiary of Stihl, called Zama. Original carburetors, on their body have a company logo that guarantees product quality.

Throttle flap

The throttle valve is installed in the carburetor body and is responsible for increasing the supply of the fuel mixture directly to the engine cylinder. At the moment of pressing the gas, the throttle valve opens slightly, thereby increasing the throughput of the channel and fuel from the carburetor cavity, rushes into the cylinder in a larger volume.

Combustion of a larger volume of fuel increases the amount of generated energy, which affects the power and speed of the processes. The damper is installed on the shaft passing through the entire carburetor body. At the exit of the shaft from the body, a mount for the gas cable is installed, next to it is a cone-shaped adjusting screw responsible for adjusting the idle speed. By tightening the screw, you can slightly adjust the position of the shaft and the damper installed on it, thereby increasing or decreasing the idle speed, slightly opening or vice versa closing the damper.

Nozzle

The fuel injector is mounted in the carburetor body in such a way that it is a connecting link between the distribution chamber and the cavity in which the throttle valve is installed. Simultaneously with the fuel, air is supplied to the nozzle and an air mixture is formed. The nozzle has a check valve that blocks the flow of air in the reverse sequence, that is, from the throttle chamber to the distribution chamber.

Signs of imbalance

Debugging the carburetor must be done during the manufacture of the device. As a rule, the owners will find out about the need to adjust the fuel supply with their own hands only after serious enough breakdowns, in the process of correcting which, the module was removed and, for example, cleaned.

The following are the symptoms of a configuration failure:

- starts, but the engine immediately stalls. since the engine can only work when a certain amount of gasoline is supplied, with too “lean” fuel, that is, blocking the supply channel, the engine will stop;

- too high fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the mixture. In this case, on the contrary, there is too much fuel and the mixture is too dense.

The carburetor for lawn mowers Stihl, Makita, Husqvarna and others is adjusted using the adjusting screws. Sometimes the reason for the malfunction is a violation of fixation. due to vibration or damage to the protective cap. Such a breakdown can be detected by simply trying to turn the screw slightly: if the fixation is not rigid, it is worth checking the setting.

Principle of operation

The carburetor is a power system module in which liquid fuel and air are mixed before being fed into the engine cylinders. Mixing and flow are adjusted accordingly depending on the tool and its mode of operation.

The carburetor device for lawn mowers is the same for almost all cases. It belongs to the category of float devices. The latter provide stable parameters of ready-made mixtures.

The principle of the module is as follows.

- Air enters the body of the air damper tube. The latter increases or decreases the air flow depending on its position.

- In the area where the hole for the gasoline supply is formed, the tube has a narrowing. a diffuser. Here the flow rate increases.

- Fuel from the float chamber is fed through the nozzle into the tube. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal, and in the tube it is low due to the greater rarefaction of the air, gasoline is sucked in through the nozzle.

- The accelerated air flow picks up the fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through the pipeline.

How to clean, adjust, and fix common carburetor problems on a Stihl FS90 trimmer weedeater

The more open the air damper in the tube, the higher the density of the air flow, and, therefore, more fuel enters the cylinder. Setting up the carburetor of lawn mowers is reduced to setting such a ratio of flaps at which the density of the fuel mixture becomes optimal.

Adjustment and repair of the carburetor lawn mowers

The trimmer does not belong to complex household appliances, therefore, most of its breakdowns are mechanical in nature and are quite successfully eliminated with their own hands. Even if the engine fails for serious reasons. damage to the piston ring, for example, repairs are reduced to replacing a part.

But even with a relatively simple design, such a part of the device as a carburetor needs to be adjusted.

DIY lawn mowers carburetor adjustment

Setting up the module does not apply to repair and replacement of spare parts is not required. In this case, the lawn mowers carburetor repair kit will not be needed.

Three screws are provided for debugging:

- L. is regulated first, since it is responsible for supplying fuel at low speeds;

- H. he is responsible for the supply of gasoline at high speeds, as well as for fuel consumption and temperature;

- T. it is used to debug idle.

There are options, as a rule, this is the carburetor of a Chinese lawn mower, when only one screw remains on the body for debugging. for adjusting the idle speed. This does not mean that the module is configured automatically. it means that it will be difficult to carry out even such a type of repair as debugging. In the photo. adjusting the carburetor of a Chinese lawn mower.

- The module is configured only when the engine is warm: for this, the device is pre-switched on for 10 minutes. If the mowing head rotates at idle speed, then the debugging is started immediately: turn the screw T counterclockwise until the rotation stops.

- Adjustment begins with screw L. The screw is turned to the right and left until it finds such a position at which the idle speed does not become maximum.

- Then the screw is turned ¼ turn counterclockwise. This will be his working position.

- Idle speed must be adjusted by turning counterclockwise to increase the number of revolutions and clockwise to decrease it. Its debugging consists in achieving such a mode in which a sufficient number of revolutions are made before the start of rotation of the mowing head. In this case, the engine must work stably at different positions.

- The position of screw L is determined last. at maximum speed, the trimmer should not work for more than 10 seconds. The throttle opens, the screw turns clockwise, very slowly, until the decrease in the number of revolutions is audible.

- Then, also slowly, the screw rotates counterclockwise until the motor starts to malfunction. Then the screw is turned back clockwise until the engine starts working normally again.

If there is a tanometer, and if the recommended rpm values are indicated in the product passport, the correction can be made more accurate, focusing not on hearing, but on the readings of the device.

The adjustment of the carburetor of the lawn mowers in the video was carried out by ear.

8 comments on the entry “Adjustment and repair of the carburetor lawn mowers”

-

Dmitry Pavlovich 07/04/2016

Please clarify. In the adjustment section p. 5, screw L. error? Should you read screw A? Thank you.

prompt the initial position of the screws H L LA

SHOW START POSITION

prompt the initial position of the screws H L LA

Thank you very much for the video about the accelerator and didn’t know, but the defect is very important and creates a huge problem that almost everyone is silent about. BRAVO….

Maybe all the same tachometer is a rpm meter, not a tonometer blood pressure meter

and I have L, H, LA, it’s LA instead of T?

The video shows some kind of tightness, so you need to be able to chew snot.

Fuel ratio

I read somewhere that if different mixing ratios are indicated in the operator’s manual for the lawn mowers and on the oil canister, the proportion indicated in the manual should be used.

For a long time he did this. excess oil flowed from the engine onto the gas tank and carbon deposits were constantly formed on the candle, since the manual indicated the proportion for the run-in engine 1:25, and on the canister. 1:50. After switching to a ratio of 1:50, the appearance of oil drips stopped. The candle continued to burn, but at a lower intensity (the carburetor was not yet adjusted).

Until now, some users of gasoline-powered tools determine the proportion of the fuel mixture “by eye”. If during the preparation of the mixture the amount of oil is underestimated, after a while an extraneous sound may appear immediately after starting the engine, gradually disappearing during warming up, and the engine stops with a sharp jerk. Continued use of the trimmer in this mode will lead to its failure.

Adjusting the carburetor lawn mowers, trimmer

Increased fuel consumption and the rapid formation of carbon deposits on the spark plug when using a properly prepared fuel mixture indicate the need to adjust the carburetor. Here’s how to tune trims with carburettors with one fuel adjusting screw.

Idle speed adjustment

We start adjusting low speed. The screw limits the return movement of the throttle lever. by turning it, we increase the idle speed, unscrewing it, we decrease it. Adjust so that the engine runs confidently at low revs and even slightly accelerated (for better starting), but so that the line reel or knife does not rotate, and there is a sufficient reserve of revolutions before they start spinning. If the engine starts poorly, increase the idle speed even more.

Carburetor adjustment

Flush the air filter before adjusting the carburetor. It is recommended to rinse it after every 10 hours of operation. After that, you can start adjusting. The photo shows the PRORAB-8406 petrol trimmer carburetor as an example. The numbers indicate the adjusting screws that we will use.

PRORAB-8406 petrol trimmer carburetor adjusting screws

The purpose of the adjusting screws:

- Fuel mixture adjustment screw.

- Idle adjustment screw.

- Maximum speed limiting screw.

Start a lawn mower and wait for it to warm up.

From personal experience

Spring may interfere

My first attempt to adjust the carburetor of the lawn mowers did not work, as the spring of the screw for adjusting the fuel mixture interfered with. The factory spring turned out to be too thick in the compressed state and did not make it possible to reduce the fuel supply to the required level. I had to pick up another spring and continue adjusting after replacing it.

Fuel mixture adjusting screw with spring

In the photo above the factory spring, below the adjusting screw with the matched spring. I am writing about this because I’m not sure if this is an isolated case, and someone else may face the same situation.

Maximum speed limitation

After adjusting the fuel mixture and low speed, check how the lawn mower engine will run at maximum speed. If necessary, limit the maximum speed to the required level using the hollow screw. Loosen the fixing nut and screw in the screw to decrease the maximum speed or turn it back to increase it. Tighten the nut after adjustment. The maximum RPM setting is necessary to protect the trimmer motor from overheating and to be able to use the start key lock to reduce right hand fatigue.

In the future, it may be necessary to readjust the trimmer carburetor. For example, if the engine starts to rev poorly when running at full load, loosen the screw another quarter turn. If starting is difficult, increase idle speed. Both weather conditions and the quality of the fuel mixture can affect the operation of lawn mowers. Vibration can cause the adjusting screws themselves to turn.

lawn mower or trimmer

A trimmer is a broader concept than a lawn mower (lawn mower), as it can also be electric. A petrol trimmer and a lawn mower are one and the same.

Some authors claim that the trimmer is a weaker tool than a more powerful lawn mower, which can be used for mowing shrubs. Personally, I have a tool with a maximum power of 1.7 kW and capable, as stated in the instructions, to mow small shrubs up to 10 mm thick. The user’s manual is called “Petrol trimmer.”.

Adjustment diaphragm damaged

The membrane often deforms (sometimes breaks) due to the continuous operation of the lawn mower or trimmer for several hours. If you abuse this “shock” mode of operation, membrane damage occurs more often. New breakdowns will sprinkle like a cornucopia:

- the piston will break;

- the number of unsuccessful engine start attempts will increase dramatically;

- the fuel mixture contains too little gasoline;

- useful (thermal) power will sharply drop.

Checking the correct Husqvarna carburetor setting

The engine quickly, steadily and steadily picks up speed, and quadruples a little at maximum speed, the T-35 trimmer head at idle should not rotate.

How to adjust the carburetor on a lawn mower

Before adjustment, you must thoroughly clean the filters according to the maintenance instructions in the instructions.

Further adjustment of the carburetor of the lawn mowers with their own hands is carried out with the adjusting screws. There are three of them:

- right;

- left;

- lower.

Right (L). adjusting the fuel mixture for low rpm.

You need to find the maximum idle speed. To do this, slowly unscrew the screw (L) to the right and left.

To adjust, turn the screw a quarter of a turn, be sure to counterclockwise.

Lower (T). responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

DIY make your own Stihl Carb Adjustment Tool in a pinch. Lawn Care

For the correct adjustment of the idle speed, it is characteristic:

- stable operation of a cold engine;

- not overestimated speed of a hot engine;

- a large reserve of turns for the trimmer head;

- stable operation of the engine when changing position (sharp lifting or lowering of the knife).

Left (H). mixture adjustment at high rpm. (The screw is adjusted last).

Setting up the carburetor for lawn mowers with the last screw is done as follows:

- Open the throttle to full, at the same time give full throttle. Turn the screw clockwise until the speed drops (in this case, orientate by ear).

- Turn the screw counterclockwise as slowly as possible until the engine runs unevenly.

- Then turn back quite a bit, barely hearing a stable, even operation.

- For a more visual use of skills, it is more convenient to consider the work of an experienced user:

Interestingly, from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not only by the speed and stability of the engine.

Correct adjustment of the carburetor with your own hands in this case. combustion of the fuel mixture without residue, the color of the candle should be light brown.

Principle of operation

The procedure for pumping and filtering fuel in the engine of the lawn mowers is as follows.

- The throttle valve controls the amount of air supplied to the diffuser. The more air is supplied, the more oxygen the gasoline needs to burn, and the more power is generated in the form of heat. Heat energy is further converted into mechanical.

- The diaphragm pump delivers the required amount of gasoline.

- Next, the gasoline passes through the engine choke.

- Fuel flows through the intake and exhaust valves.

- Fuel filtration is carried out using a mesh filter.

- Through the needle valve, it also enters the chamber with the membrane.

The staging of the carburetor is as follows.

- Air enters the duct with an air damper. The damper sets the required air flow rate.

- In the gasoline injection unit, the diffuser is narrowed. this is necessary to give a higher air flow rate.

- The fuel passes through the compartment with the float and passes the nozzle, enters this narrowing of the tube. The float chamber doses the supply of gasoline. In this compartment, the pressure is in equilibrium. In a narrowed tube, it goes down. Due to the difference in both pressure values, gasoline and passes through the jet.

- The accelerated flow sprays gasoline, converting it into aerosol vapors. The resulting gasoline-air mixture is ready for ignition in the combustion chamber.

- Having passed through the fuel line, this mixture is in the carburetor cylinder.

Conclusion: in order to set the required power, first of all, you will adjust the rate of fuel combustion using the air damper. If the gap is too small, and oxygen in such a mixture is less than 10%, the fuel does not burn, therefore, the engine will not start or will immediately stall.

In the case of buying a Chinese trimmer, it is worth considering that it differs little from European ones. the same 2- or 4-stroke engine and drive.

DIY trimmer adjustment

Damper worn out

The throttle and air damper become unusable due to the ingress of dust, metal particles, etc. with the air flow. Damaged dampers are similar to parts that have been blasted with sand. Due to wear on the dampers, the efficiency of the motor decreases, and breakdowns are detected. Piston and cylinder wear out.

In some cases, this filter is simply not suitable for your lawn mower or trimmer model. In the end, the motor shaft will suffer. its pieces fall into the engine channels, causing the piston to be broken.

Carburetor device

lawn mower (lawn mower) contains a base. a body made of aluminum, which houses the rest of the parts, working harmoniously as a whole. There is a diffuser in the carburetor body. a stroke with internal channels through which air is pumped.

Channels branching off from the diffuser stroke deliver fuel, with which the forced air mixes, entraining gasoline vapors with it. Outside the main carburetor compartment are located:

- jets;

- mini fuel pump;

- unit regulating the mixing of fuel with air.

The latter forms the very explosive mixture ignited in the carburetor combustion chamber.

Strainer clogged

Reasons for blockage of the mesh filter. poor-quality fuel cleaning, damage to the hose and / or delivery head.