Carburetor adjustment

The Husqvarna 240 chainsaw, which can be adjusted by yourself, is a tool that should not be repaired at home. However, you can do the adjustment of the mentioned node yourself, for this you need to learn how to distinguish between the screws. Each of them has a letter designation, the first is for adjusting low rpm, the other for adjusting high rpm, while the third is used for adjusting idle.

Although the factory setting is considered optimal, the screws can be used to tune the engine. This is sometimes required when climatic conditions differ from those recommended by the manufacturer. To increase the speed, the first two mentioned screws must be turned clockwise. The sequence of using the screws is the same as indicated above. If you have some doubts, it is better to contact a specialist, because if the carburetor of the Husqvarna 240 chainsaw is set incorrectly, the engine may be damaged..

Husqvarna 240. And again about the carburetor. Design blooper or what it is?

Chainsaw HUSQVARNA 240 carburetor problem One of the most common diseases of this chainsaw. Excellent

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know how it works and how it works. In fact, everything is not as difficult as it seems at first glance..

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers..

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for restricting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw. At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode..

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems during the operation of the saw can be caused by defects in this particular element. For example, a valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation, it will be necessary to repair or replace the unit..

Three adjusting screws installed in the carburetor body are responsible for setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode:

- screw (L) – adjusts the amount of fuel at low and medium speed;

- (H) – is responsible for traction at high speeds and their number;

- (T) – changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Improper adjustment of the quality and amount of the fuel mixture can cause the engine to stop working or malfunction, leading to rapid wear or even seizure..

How to adjust correctly

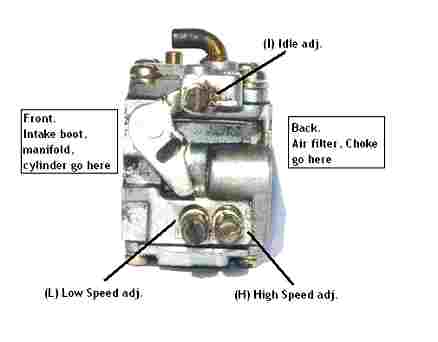

For this, the device has 3 adjusting nozzles. The idle speed screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter of a turn..

- Hold the gas button with one hand for 15 seconds. At this time, we turn the H jet to the right until it stops and reaching the maximum speed. Then we turn it back one and a half turns, or until the “squeal” of the engine disappears.

- With the throttle released, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving..

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture..

If this happens, it is necessary to tighten the jets of the minimum and maximum speed until they stop. Then turn them back one and a half turns and try to start the saw.

Husgvarna 240 chainsaw carburetor repair

This video shows a common cause of a malfunction on chainsaws with an accelerator pump. Be ATTENTION

The device and principle of operation of the carburetor

The carburetor is used to prepare a combustible mixture in a ratio determined by the operator from gasoline and air.

An excessively rich, as well as an excessively lean mixture will lead to unstable engine operation, can cause overheating and accelerate wear of the piston system.

The correct functioning of the device depends on the correct setting and adjustment..

And for this you need to know the principles of the Husqvarna chainsaw carburetor.

Its design consists of the following elements:

- body with clamping bolts and a set of gaskets;

- fuel pump – a device that pumps a gasoline-oil mixture into the carburetor;

- diaphragm – designed to limit the supply of a combustible mixture to the engine;

- float chamber – fuel is collected in it, the level is regulated by the float, as required, the mixture is fed into the main chamber for mixing with air;

- the main chamber – air passes through it, and fuel is injected there, the amount of mixture supplied to the engine is regulated by the throttle valve located here;

- diffuser – section of narrowing of the air supply tube at the place of fuel injection;

- needle valve – a device that regulates the fuel supply;

- jet – screws that regulate the supply of the mixture at high and low speeds, as well as an idle screw.

Also in the carburetor device, in addition to the throttle, there is a damper located at the inlet from the air filter. It artificially reduces the air supply, making the mixture richer for easier cold starting..

The injector valve is responsible for fuel injection into the main chamber, it also prevents air from entering. When adjusting the carburetor on a Husqvarna chainsaw, special attention should be paid to this valve, since its condition has a direct impact on engine performance. Long-term storage may cause the nozzle to stick. This will restrict fuel flow and prevent the engine from starting..

Also, from prolonged use or due to a factory defect, the valve can let air into the main chamber. In this case, only replacing it will help fix the problem..

The carburetor works as follows: the air flow entering the diffuser is mixed with the injected fuel, the resulting mixture is fed into the engine. The amount of the mixture is regulated by the throttle valve. The more mixture, the higher the engine speed.

How to remove the carburetor and whether to do it before tuning

In the event that the chainsaw does not develop speed or, on the contrary, works at excessively high, the carburetor can be adjusted without removing.

But if the chainsaw does not start, the rpm freezes at the same level or it is unstable. Chainsaw carburetor tuning will not change the situation. It must be removed to clean or replace parts. In this case, it is necessary to act in the following order:

- Having unscrewed the retaining fasteners, remove the upper saw casing.

- We remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts that hold it.

Disassembly of the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, be very careful when folding the parts onto the prepared fabric. Due to the small size, there is a risk of losing components during disassembly and flushing..

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Channels, tubes and nozzles are blown out with compressed air, if possible, after rinsing them in an ultrasonic bath.

DIY Husqvarna 240 chainsaw carburetor adjustment

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw..

How to understand that everything is done correctly

After setting up, you need to start the chainsaw. Check the stability of idling. In this case, the chain must not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At minimum and maximum rpm, the Husqvarna 350 should run stably, free of extraneous noise. At the time of operation, there should be no sharp loss of power or shutdown..

How to adjust the carburetor on a Husqvarna 240 chainsaw?

Any technique is subject to breakdowns from time to time. The main malfunctions of the Husqvarna 240 chainsaw are associated with the repair of the carburetor, other components of the fuel system, and malfunctions of the oil pump. If the oil pump breaks down, the chain for the Husqvarna 240 chainsaw stops rotating due to lack of lubrication. Also, damage to the gas tank or fuel hoses can be the reason why gas is leaking out of the saw. If the saw has completely stopped starting, first of all you should make sure of the quality of the fuel mixture, check the spark plug spark. If necessary, clean the spark plug or replace it with a new one, adjust the carburetor.

Adjustment of the carburetor is also required in cases where the chainsaw began to start poorly, stall under load, and also if the type of fuel or operating conditions have changed. It is worth adjusting the carburetor after pre-cleaning the air filters and warming up the engine.

Then proceed according to the following algorithm:

- Screw L turns to the maximum. Then immediately return the screw a quarter of a turn back..

- While holding the throttle grip, turn screw H a quarter of a turn.

- Release the throttle and turn the screw T clockwise until the chain starts to move. Then immediately turn the screw back until the chain stops..

The location of the corresponding screws is shown below:

How To Actually Tune A Chainsaw!

Adjustment carburetor

Chainsaw “Husqvarna 240″, carburetor setting that you can do yourself. it is a tool that cannot be repaired at home. However, the configuration of the mentioned assembly can be performed independently, for this it is necessary to learn how to distinguish the screws. Each of them has a letter designation, the first. for adjusting low rpm, another for adjusting high rpm, and a third. to adjust idle speed.

Although the factory setting is considered optimal, the screws can be used to adjust the motor operation. This is sometimes necessary when climatic conditions differ from those recommended by the manufacturer. To increase the speed, the indicated first two screws must be turned clockwise. The sequence for using the screws is as indicated above. If you have any doubts, it is better to contact a specialist, because if the carburetor chainsaw “Husqvarna 240” is not adjusted correctly, the engine may be damaged..

Chainsaw specifications Husqvarna 240

At the heart of the Husqvarna 240 is a 2-stroke engine with carburetor. Works on a gasoline-oil mixture. The service life has been increased due to improvements in the crank assembly and a special coating of the cylinder. Fuel economy is reduced by 20% thanks to the innovative X-Torq system, which also reduces the harmfulness of exhaust gases. Capacious fuel tank and low fuel consumption extend the operating time of the tool, without interruption for refueling.

The rest of the saw has the following technical characteristics:

- productivity – 2 liters. from.;

- chain pitch – 3/8 inch;

- fuel tank capacity – 300 ml;

- oil tank – 200 ml;

- tire length – 40 cm;

- weight – 4.7 kg.

Adjusting the carburetor of a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw..

Ignition adjustment after carburetor adjustment

If cleaning and adjusting the carburetor did not correct the existing problem, you need to check the spark plug and tune the engine. It is worth acting in the following order:

- The candle is unscrewed and a visual inspection is carried out. If it is dry with light brown carbon deposits, it can be considered intact..

- If traces of gasoline are found on the spark plug, readjust the carburetor. This is because it supplies an excess amount of fuel to the internal combustion engine, filling it.

- If the candle looks normal, check the electrical equipment. First of all, the cable that supplies current to the candle. The end of it is brought a short distance to the radiator grille of the cylinder and the starter is turned with a cord. A spark should slip through. If not, the cable is checked with a tester and, if necessary, replaced..

- If the cable is in good condition, the ignition coil is tested. If the inspection does not reveal singed or broken wires, the coil is called with a tester, comparing the data with the accompanying documentation. If deviations are found, the block must be replaced with a similar one..

After replacing the coil unit, the magneto gap should be set. The gap between the ignition coil and the flywheel should be between 0.2 and 0.4 mm. To set the gap, you need a set of probes or you can use foil of a suitable thickness. The probe is clamped between the coil and the flywheel at the time of installation, and then pulled out.

Husqvarna 240 Carburetor Adjustment At Home

Design and scope of use

Your Husqvarna 240 chainsaw goes beyond standard firewood functions. With its help, you can easily clear a large area of shrubs and old trees, form the crowns of ornamental plants in the garden, use it in construction for cutting boards. Sufficient power and length of the bar allow you to cut wood both along and across.

The classic design of the brand is combined in this model with high technical characteristics and ease of use. The Husqvarna 240 saw is in the household class, but its performance is not much different from professional tools. Manufacturers have provided in this saw such necessary functions as easy start, double air purification, vibration reduction. Ergonomic control levers and handle provide maximum comfort during operation and reduce operator stress. The main components of the mechanism are located in such a way as to speed up and simplify access to them in case of repair.

Part 3 How to Tune Carburetor Husqvarna 235e Chainsaw

If you follow the operating instructions and regularly carry out preventive inspections of the chainsaw, repairs can in most cases be avoided. But even in the event of a breakdown, the tool will not cause you significant inconvenience – original spare parts can be easily purchased and replaced. The detailed structure of the Husqvarna 240 chainsaw is shown in the diagram below: