- closed comfortable shoes, preferably with metal edging;

- adjacent, but not hindering movement, clothing;

- non-slip, tight gloves;

- protective goggles;

- helmet or special noise-absorbing headphones.

The Partner 351 chainsaw is operated with only two hands. Using the saw with one hand can cause injury or injury not only to the operator, but also to those around you. Since a gasoline drive generates harmful and toxic fumes, it is forbidden to work with Partner 351 in rooms and poorly ventilated places.

Carburetor setting

The chain saw comes with a carburetor already set at the factory, but after a while you will notice that the saw does not function as well. In order not to carry the tool to the service center, you can try adjusting the carburetor of the Partner 351 chainsaw with your own hands. This procedure may be required only in two cases:

- the chain is idling;

- the saw does not idle.

Read the information on adjusting the carburetor provided in the instruction manual and with video reviews of users in which they carry out this procedure.

Oil and fuel mixture

For the correct and smooth operation of the chainsaw, it must be lubricated. This process takes place automatically, so carefully monitor the presence and level of oil in the reservoir. If there is not enough lubricating fluid, then the guide bar and chain overheat, and, consequently, their rapid wear.

The American Briggs Stratton engine guarantees long and stable operation provided that it is filled with quality fuel. To do this, use a 40: 1 mixture of unleaded gasoline and a special 2-stroke air-cooled oil. That is 5 liters. gasoline is mixed with 125 ml. oils. It is very important to maintain proper proportions to ensure tool integrity and good performance. Avoid Automotive and Marine Oil.

Chainsaw Partner 351. Setting the carburetor. Oil and fuel mixture

Specifications

| Manufacturer | Partner |

| Manufacturing (assembly) | China |

| The birthplace of the brand | Sweden |

| Saw class | Household |

| Power, h.p. (kw) | 1.8 (1.3) |

| Engine volume, cm3 | 36 |

| Chain pitch, inches | 3/8 |

| Chain thickness, mm | 1.3 |

| Number of chain links | 56 |

| Fuel tank volume, l | 0,4 |

| Oil tank volume, l | 0.2 |

| Tire length, cm (inches) | 40 (16) |

| Noise level, dB (A) | 106 |

| Warranty, years | one |

| Weight, kg | 4.7 |

User’s manual

Before starting work with the Partnera 351 chainsaw, you must read the instructions. It indicates the features of the operation of equipment, the nuances of its assembly and maintenance, the rules for adjusting the carburetor of a chainsaw, describes the most frequent breakdowns and ways to eliminate them, and also presents the brands of fuel and oil that are suitable for this model.

You can read and download the instruction manual for the Partner 351 chainsaw at the following link:

Advantages and disadvantages of a chainsaw

This model stands out from the entire range of Partner chainsaws with a powerful professional engine that can withstand even heavy and long loads. Increased safety is ensured by a more sensitive and sharp chain brake that locks the saw chain in emergency situations. The light electric start system guarantees a quick engine start due to the primer, which helps the carburetor to fill with the fuel mixture.

- poor engine tolerance of low-quality fuel;

- lack of visual indicators of the fuel and oil level in the tanks;

- insufficient vibration damping.

Chainsaw “Partner” 351: device, characteristics, malfunctions and repair

Chainsaw “Partner” 351. a worthy representative of the household line of chainsaws from the brand “Partner”. According to its technical capabilities, it is focused on garden work and simple tasks for sawing wood. Simplicity of design, ease of operation and maintenance allowed this model to be on a par with other famous chainsaws from the brands “Stihl” and “Husqvarna”.

Chainsaw device “Partner” 351

Chainsaw “Partner” 351 has a structure typical for other chain saws.

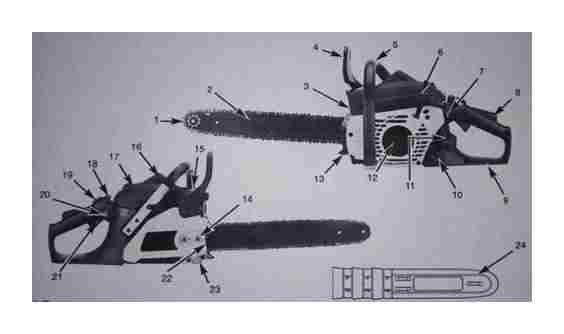

The figures in the figure correspond to:

- chain;

- guide;

- spark catcher;

- safety block;

- lever;

- starter cable;

- ignition system switch;

- crankcase cover;

- fuel tank filling hole;

- starter;

- toothed stop;

- tire mounts;

- muffler;

- candle;

- air filter flap;

- carburetor flap lever;

- throttle valve;

- primer activation button;

- throttling toggle switch;

- screw tensioner for the cutting unit;

- chain catcher;

- protective cover.

Despite the manufacturer’s Swedish origin, the Partner 351 chainsaw is assembled at factories in China.

Chainsaw “Partner” 351 does not start: causes and remedies

Difficulty starting a chainsaw can be the result of:

- piston-cylinder wear. weak compression, piston ring cracks or seizure. These faults are eliminated by replacing worn parts with new ones;

- weak or no spark due to plug or ignition coil failure, spark plug filling, and improper ignition coil-to-flywheel clearance. It will help to fix the breakdown by replacing the failed parts;

- the use of low-quality fuel mixture;

- defects in the fuel supply system. To solve this problem, it is enough to replace the gas tank primer, fuel filter or hoses and reconfigure the carburetor mechanism.

Functional and technical characteristics of the “Partner” 351 chainsaw

Advantages:

- double filtration system CCS;

- ergonomic design;

- special vibration-damping shock absorbers;

- side screw-tensioner;

- double-acting emergency brake;

- lubrication of saw blades in the “Automatic” mode.

Performance properties:

- Traction. 1.4 kW;

- Carter. 200 ml;

- Gasoline tank. 0.38 l;

- Guide. 350 (410) mm;

- Chain. 56 links 3/8 ” pitch

- Weight. 4.7 kg.

Instructions for turning on the chainsaw “Partner” 351

If you purchase a new chainsaw or start the device after a long period of inactivity, you must:

- screw on all accessories or check the tightness of the connections;

- adjust the chain tension with a screw on the side of the housing;

- check the oil level and fill the saw with a freshly prepared fuel mixture;

- put the device on a flat horizontal plane and press it with your foot;

- open the flap;

- move the control lever to the on position;

- 5 times pump up gasoline with primer and pull the starter;

- let the saw warm up for a minute and start working.

Faults of the Partner 351 chainsaw and repair features

- disregard of the manufacturer’s recommendations for the use, care and storage of the saw;

- purchase of low-quality consumables and spare parts;

- unqualified technical support, incl. users who use the saw for the first time.

The main breakdowns that can occur during the use of a chainsaw are:

- muffler clogging. the saw does not work well under load, smokes during operation. The repair begins with dismantling the muffler, after which it is washed, dried and installed in place;

- problems of the cylinder-piston group. it will be difficult to fix them with your own hands: you will need special equipment and new parts;

- gas contamination of the crankcase, which was the result of wear on the piston ring. a spare part that should always be in stock;

- disruption of fuel supply. the result of contamination of the fuel filter, which can be washed at home;

- clogging of the carburetor or resetting factory settings. to stabilize the operation, you will need to reconfigure and clean it.

Adjusting the carburetor of the “Partner” 351 chainsaw

The process consists of the following stages:

- adjust the idle speed with the screw T. it must be tightened until the saw unit stops rotating;

- jet L rotates a quarter of a turn;

- at the final stage, you will need a tachometer. The H jet, which is responsible for work under load, is turned by a quarter, a tachometer is connected: with the correct setting, it should show the value declared by the manufacturer in the data sheet.

Feedback

Device

In terms of the structure and location of the working units, the Partner 351 chainsaw does not differ from other models and consists of:

Diagram. Partner 351 device Description for the diagram Partner 351 device

Specifications

The Partner 351 saw good performance and performance, despite its compact size and weight of 4.7 kg:

- motor power 1400 W (1.9 hp);

- tire 35 cm. It is possible to install a tire at 41 cm;

- 56-link chain with 3/8 ” pitch;

- spark plug. Bosch WSR 6F;

- fuel tank capacity 380 g;

- oil tank for 200 gr;

- noise level just over 100 dB.

The CCS air filter significantly reduces fuel consumption. The double air purification system increases the engine resource of the Partner 351 chainsaw. The chain operates at high speeds.

Sophisticated ergonomics and reliable vibration damping system allows you to use the tool for several hours without interruption.

The chain brake is instantly responsive, making working with the chainsaw even more comfortable and safe.

In the segment of non-professional chainsaws, Partner 351 (Partner 351) takes its rightful place. Lightweight, powerful and reliable, the saw allows you to perform a wide range of wood sawing tasks at the household level.

The chainsaw is ideal for working in a summer cottage. It copes well with felling small fruit trees, pruning branches. It can be used to work in the forest with small diameter trunks. Partner 351 is suitable for construction work.

Carburetor setting

The Partner 351 chainsaw has several working mechanisms that require periodic inspection and maintenance. One of them is a carburetor.

It is not recommended to repair the carburetor of the Partner 351 chainsaw with your own hands, but it is possible to make a small adjustment. There are two main breakdowns that can be eliminated by adjusting the carburetor with your own hands:

- Spinning the chain while the engine is idling. To eliminate the malfunction, you must use the adjusting screw. First, turn it fully clockwise. Then do 4.5 turns counterclockwise. The malfunction should disappear.

- Incorrect supply of the fuel mixture. There may be several reasons. From misalignment of adjusting screws to breakage of carburetor parts. In any case, the adjustment takes place according to the same scheme.

There are three adjusting screws for adjusting the carburetor: L. for high revs, H. for low revs, T. idling of the Partner 351 chainsaw.

- The adjustment starts with screw T. To do this, start the saw, and turn the adjusting screw counterclockwise until the chain stops.

- Then screw L is turned counterclockwise a quarter of a turn. During idle adjustment, there should be the largest turns.

- Turn screw H a quarter of a turn counterclockwise.

After carrying out these manipulations, a tachometer is taken, and the revolutions are checked. They should correspond as much as possible to the rpm indicated in the passport of the Partner 351 chainsaw. If you nevertheless decided to adjust the carburetor of the Partner 351 chainsaw with your own hands, we recommend reading the article about adjusting the carburetor on a chainsaw. The article is of a general nature, contains all the necessary information and will greatly help you in this difficult process.

Carburetor adjusting screws

Chainsaw starting instructions

The Partner 351 chainsaw works on the same principles and has a similar structure as other tools with gas engines:

- Before the first use, all components of the Partner 351 chainsaw are securely screwed on, the integrity of the body is checked.

- The chain tension is checked before each start. If necessary, the chain is tensioned or relaxed using the adjusting screw.

- The amount of oil is checked before each start.

- The chainsaw can only be started from a hard surface. The foot should firmly press the tool to the ground.

- Before starting, the damper is placed in the “open” position.

- The start button is moved to the “on” position. after which it is necessary to press the primer 5 times and start pulling the starter cord. The main thing is to start the chainsaw smoothly, without jerking.

- After starting, the engine should idle for 60 seconds. Then you can start working by adjusting the power with the throttle.

Starting the Partner 351 XT chainsaw

DIY repair and basic faults

During the operation of the Partner 351 chainsaw, various breakdowns and malfunctions may occur. Some of them can be corrected by hand, without contacting service centers and repair shops.

- When the engine is running, a lot of black smoke is emitted, does the chainsaw stall at high revs? Most likely, the muffler is clogged. To fix the problem, remove it and remove all debris and carbon deposits. Over the long years of operation, the muffler of the Partner 351 chainsaw, and not only, is heavily clogged with carbon deposits. Dry the muffler after wet cleaning. During the repair, the inlet from the muffler is closed with a piece of cloth.

- Fuel not flowing? There may be several reasons:

- Fuel filter or fuel tank hole clogged. To fix it, you need to remove and clean the fuel hose or breather.

- Problems with adjusting the carburetor, including clogging of its channels and membranes. The carburetor of the Partner 351 chainsaw consists of many small parts. For repair, it is better to contact the service center.

- Lack of fuel in the tank. To fix it, you need to pump up fuel, and fill the tank.

Cylinder. piston group Partner 351

You can learn more about solving problems with idling and starting the engine from the video on repairing the Partner 351 saw.

The Partner 351 chainsaw, despite its low cost, copes well with its tasks. It is indispensable for working in the garden, on the personal plot. Most of the faults can be corrected by hand without resorting to the services of repair shops.

Checking the spark on the spark plug and eliminating the causes.

The first step in finding the reasons why the gasoline saw won’t start is to check the spark on the spark plug. There are many factors that affect the performance of this element. However, the main ones at the initial stage of instrument troubleshooting are:

- Incorrect carburetor adjustment;

- The presence of more than it should be, the amount of oil in gasoline;

- Clogged air filter.

All of them contribute to the formation of carbon deposits on the spark plug electrodes. In 50 cases out of 100, the saws do not start on a cold one due to the absence of a spark due to carbon deposits on the electrodes and their corrosion. As a result, the gap either decreases or increases.

Checking the spark plug with an idle chainsaw

It is quite easy to check for a spark. This will require:

- Remove the tip of the high-voltage wire;

- Unscrew the candle;

- Put the tip back on;

- Lean the candle with a skirt against the cylinder;

- Start with a starter.

If a good spark is observed between the electrodes at the time of starting the engine of the chainsaw, then everything is in order with the ignition unit. If it is not there, then it is worth cleaning the element itself and checking the gap of the electrodes. If necessary, use a special probe to adjust the distance between the contacts.

Ремонт бензопилы PARTNER 351. Нарезка резьбы для крепления карбюратора.

For candles from different manufacturers, the distance between the electrodes may fluctuate. For some, it may be equal to 0.5 mm. Others have 0.2 mm. Therefore, carefully study the manufacturer’s recommendations.

There may be no spark on the spark plug for other reasons. Of the main faults affecting the poor start of the chainsaw and the unstable operation of the internal combustion engine at idle, from which the tool can stall, the following can be attributed:

- Overflow of the spark plug channel with fuel;

- Lack of contact between the high-voltage cradle and the tip of the candle;

- Failure of the ignition unit.

How to start a cold chainsaw if the spark plug channel is constantly flooding with gasoline? To eliminate the problem while starting the tool, you can use the following algorithm:

- Unscrew the candle with a special key;

- Wipe it with a clean and dry cloth;

- Dry for 20. 30 minutes;

- Remove carbon deposits with a file and adjust the gap between the electrodes;

- Drain the remaining fuel from the spark plug channel and dry it;

- Collect everything and try to start the mechanism.

As a rule, these measures are enough to start the chainsaw and get the job done. However, this extreme measure does not eliminate the main reason why the engine does not start or stalls. improper operation of the carburetor, which needs fine adjustment.

If there is no spark and poor contact of the high-voltage cradle with the spark plug tip, check the connection. The check can be done using a conventional tester. If a defect is found and it is eliminated, the chainsaw should start without any problems.

If the check showed that the contact is reliable, and the saw does not start further, look for the cause in the ignition unit. As a rule, a faulty unit cannot be repaired and restored. A complete replacement is required here.

What breakdowns can occur

Chainsaw malfunctions can be conditionally divided into groups:

- Malfunctions of the engine (ignition, exhaust and cylinder-piston systems, fuel supply).

- Failure of components such as clutch, chain brake, lubrication system or tire.

Chainsaw engine failure is more common than others. Most of the time is spent on its detection and repair. As a rule, it boils down to such manifestations when the engine is unstable or completely stalls, the engine does not start, does not develop power.

Before you start repairing a chainsaw, first check for all possible causes of violations in its functioning, and even better, watch the video. Fortunately, today on the Internet you can find any material of interest.

Then you have to prepare the necessary tools for repairing breakdowns:

- device diagram (should be included in the delivery set);

- keys, including spark plugs.

What to do if the chainsaw won’t start further?

If the initial inspection did not give anything or the defects were eliminated during the search, and the chainsaw does not start further, then you need to look for more serious reasons. It is best to identify and eliminate such breakdowns in a service center. However, with experience, you can find and eliminate them yourself. What to diagnose and check?

- Compression in the cylinder;

- Compression in the crankcase;

- Carburetor operation.

In the first case, checking the compression in the cylinder will allow you to find out the state of the cylinder-piston group (CPG) of a chainsaw that does not want to start cold. For this you need a compressometer. The device is screwed into place of the spark plug and the engine is idle. Measurement of readings allows you to judge the state of the CPG. In the absence of a compression gauge, the compression in the cylinder can be determined offhand as follows:

- Place your finger on the candle hole;

- Try to start the chainsaw engine.

By placing your finger on the spark plug hole and pulling the starter, you can check the compression in the cylinder.

If you feel that your finger is pulling strongly into the candle channel, then everything is in order with the compression. The absence of vacuum in the chamber indicates a malfunction. The cylinder-piston group needs a more detailed inspection, which will give an idea of the condition of the piston and cylinder, piston rings and bearings.

The chainsaw may not start on a cold one due to the lack of compression in the engine crankcase. The main reason for this is damage to the gasket placed between the cylinder and the crankcase. It is quite easy to detect the lack of compression:

- Disconnect the upper tube from the carburetor;

- Pour gasoline into a regular cork;

- We immerse the removed tube in the fuel;

- We pull the starter several times.

If the fuel is sucked from the cap when starting the chainsaw starter, then everything is in order with the compression. If not, see the gasket.

If the fuel is drawn in, then everything is in order. the gasket is intact. Otherwise, you will have to purchase a repair kit and replace it. How to do this watch the video, why the Chinese chainsaw does not start:

Starting the tool can be complicated by improper operation of the carburetor or its breakage. It often happens that during the sawing process, the fastening screws are loosened and air is sucked into the cylinder. Check that the carburetor is securely fastened. Inspect it for fuel leaks. There can be a lot of reasons for the malfunction. It is possible to pinpoint the malfunction, eliminate it and fine-tune the carburetor only in a service center.

After going through the step-by-step troubleshooting of the chainsaw engine, you can find the malfunction, fix it yourself and successfully start your working tool. Do not take on jobs that you are not sure about. Entrust the troubleshooting to specialists from the service center.

Malfunction of the ignition system

When the engine refuses to work, but there is a spark on the spark plug, and fuel is supplied, the ignition should be checked.

It is not at all difficult to check it: unscrew the candle, and adjust the gap between the contacts, connect it to the wire and press it against the cylinder body. After that watch out for the spark.

Chainsaw outlet check.

One of the reasons that a chainsaw does not start well may be a clogged exhaust channel or its muffler. At the same time, a drop in power is noted in the process of sawing sawn timber and logs. This is most often due to resinous deposits on the spark arrestor or muffler channel, which are formed during the combustion of a poor-quality mixture of gasoline and oil, which impede the removal of exhaust gases.

Resonator clogged with carbon deposits can cause poor starting of the gasoline saw.

Eliminate the reason for the poor start of the chainsaw, in this case, you can remove the accumulated combustion products. To do this, perform a number of manipulations:

- Remove the muffler by unscrewing the screws;

- Remove the cooling panel and gasket;

- Remove the spark arrestor;

- Disassemble the resonator housing;

- Wash all elements from carbon deposits with a detergent;

- Let them dry completely;

- Collect everything in reverse order;

To prevent dust and sand from entering the cylinder when cleaning the muffler, cover the outlet of the chainsaw engine with a clean rag.

Determine the availability of fuel and its supply.

First you need to make sure that there is a fuel mixture in the tank of a chainsaw that does not want to start, and it regularly enters the carburetor. With a full tank, we check how the mixture is fed through the gas line. Disconnect the fuel system pipe from the carburetor and try to pump it up. In the case of a complete order, when pumping up, gasoline will be supplied in jerks in accordance with the norms set by the manufacturer. Poor or no fuel supply may result from:

- The fuel supply channel is clogged;

- Debris-clogged fuel filter.

Often the reason for a poor start of the chainsaw can be a tank that is too full. In this case, you should pay attention to the presence of smudges under the saw case cover. If present, see the connection of the gasoline feed pipe to the carburetor. Most often, it is squeezed out by pressure when the tank cap is screwed on, which is filled under the very neck, which prevents the engine from starting.

The quality of the fuel mixture can also be one of the reasons why the chainsaw does not start. If, after completing the work, the remaining gasoline is not drained, and the tool is left for long-term storage (more than 2 weeks), then the processes of resin formation and polymerization of the components will begin to occur inside the tank. What can cause carbon deposits on the piston, rings and cylinder liner. Therefore, always prepare the mixture only in the required amount before work.