When moving the chainsaw chains in the groove of the tire due to friction, a large amount of heat is released. If oil does not enter the chain of the chainsaw, it is necessary to stop operation and take all measures to eliminate the malfunction of the lubrication system. The combination of high loads and overheating of the headset is accompanied by its accelerated wear and premature failure.

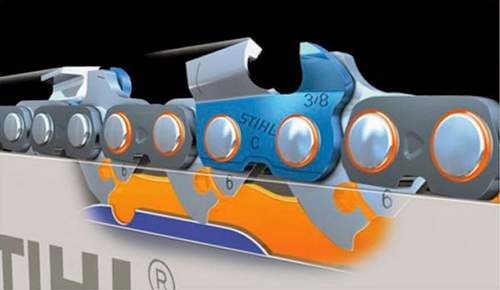

- Without exception, all chainsaws and their electrical counterparts are equipped with the systems of the same type by the principle of operation, through which the lubrication of the tire, the saw chain and its drive parts is realized.

- The standard composition of this device includes a tank from which the chain oil is supplied to the pump inlet with a fixed or adjustable capacity.

- Next, the working fluid in a metered amount enters the groove of the tire, in which the shanks of the saw chain are evenly distributed over the entire headset and the working surface of the crown of the drive sprocket.

Tires for product sets from 400 mm in length are equipped with a driven sprocket. Periodic lubrication of the bearing is carried out individually, after 6-8 hours of operation.

Symptoms of a lubricant system malfunction

The correct choice of consumable lubricant and the excellent operation of the system contribute to complete lubrication, efficient cooling of the saw equipment and the full development of its resource.

There are several external signs that the chain on the chainsaw is not lubricated. First of all, it is:

- constant oil level in the tank;

- increased engine load;

- accelerated wear of the cutting edges of the saw links;

- characteristic smell of overheated wood.

In the simplest version, the cause of oil starvation may be clogged with sawdust oil channels. This disadvantage is typical for budget headsets that do not have convenient access to problem areas.

Reasons for decreasing system performance and efficiency

Video: Chinese Chainsaw Chain Oil Adjustment

In the right amount, oil is not supplied to the chainsaw chain for several reasons. Of the most characteristic failures, we can name:

- clogging of the filter located in the oil tank;

- mechanical failure of one of the elements of the worm pump drive;

- in winter, the performance of the discharge device is reduced due to filling the system with too thick oil.

In the latter case, the drive and all pump parts operate at increased loads, initiating serious mechanical damage.

Advantages of premium class oil pumps

The maintainability of collapsible pumps is sufficient to restore the operability of the unit at home.

The gears of the drive of the pumps of budget chainsaws are mostly polymer. Advanced in terms of technical equipment branded models with adjustable performance are equipped with drive mechanisms made of non-ferrous metals. The cost of such systems is offset by an economical, up to 50%, flow of working fluid.

Self-help troubleshooting feature

A full-fledged independent repair of the chainsaw chain lubricant, all conditions being equal, requires knowledge of the interaction of all elements of the system, the availability of tools and locksmith skills.

The restoration of the operating parameters of many chainsaws provides for partial or complete dismantling of the component equipment. To perform complex repair work it is better to use the capabilities and technical potential of service workshops.

Parts with torn threads and damaged splined joints, as well as non-separable structures that complete the lubrication system of the popular Stihl 180 chainsaws and other similar models, must be replaced.

If, when the tank is filled, oil does not enter the headset design, the reason should be sought in the pump itself. Dismantling and disassembling the mechanism will help to identify defective parts and eliminate the malfunction by replacing them.

Checking the system for oil output and performance

Oil filter contamination results in a significant decrease in pump performance. Checking this option is easy. To do this, you need to hold the headset of the working revolving saw over a clean sheet of paper.

By the density and size of the oil strip, you can confidently judge the condition of the system and the complexity of the upcoming repair.

When asked why the repaired lubrication system works, but the right amount of oil does not go to the chain, there is no definite answer. The cause of failure may be errors made during assembly, malfunctioning of standard adjustments, inconsistency of the density and viscosity of the selected composition with the declared characteristics.

Headset oil starvation is possible when installing on a household saw with an unregulated pump a longer production tire, which is equipped with professional-grade chainsaw equipment.

The specifics of repairing Chinese chainsaws

A significant share of the imported chainsaw range is made up of Chinese-made chainsaw equipment. Many models with more or less success are copied from the best European developments.

The main advantage of Chinese products of the budget segment is a high level of interchangeability of spare parts, components and systems. For the repair of Chinese chainsaws, in some cases, you can use accessories from models of other manufacturers identical in power and purpose.