Converting a screwdriver to lithium batteries. Ni-Cd to Li-ion

Converting a screwdriver to lithium batteries. Almost all models of screwdrivers of the old model worked on nickel-cadmium batteries. This type of battery belongs to low-cost products, but does not have sufficient power for a screwdriver, in addition, it has a memory effect.

It is this property of the battery that contributes to a gradual decrease in its capacity. For this reason, the majority of owners of such an instrument benefit from its conversion to lithium batteries 18650 with a voltage of 12v. Of course, the work with the alteration is not fast and requires some costs, but if everything is done correctly, then the final result is worth it.

The positive and negative sides of the alteration

First of all, you need to clearly understand what we will have as a result of the modernization of an electric instrument by installing Lithium-Ion batteries in it.

The main advantages of Li-Ion batteries:

- significantly increases the working time of the screwdriver from a single charge;

- dramatically increases the speed of charging the battery, to get a fully charged Li-Ion battery, it will take about one hour;

- at least two times greater specific capacity compared to Ni-Cd;

- savings on the purchase of new Nickel-Cadmium batteries due to their short life;

- lithium batteries do not have a charge storage effect;

- the ability to recharge as needed.

Disadvantages of Li-Ion batteries:

- lose effective properties during long-term storage, that is, the possibility of aging;

- difficulty operating at low ambient temperatures;

- the need to use a charger specifically designed for them;

- high price.

Stages of preparatory work

First of all, you need to find out the highest value of voltage for the charge, this is done by calculating the number of elements. In the case of using three capacitors, the most effective voltage will be 12v, and for four. 16v.

Consider a version with a screwdriver designed for a voltage of 14.4v. In this case, it is necessary to apply four capacities, therefore, the difference in volts is equalized and the volume of the capacitance increases. As a result, a tool on a Li-Ion battery can run for a significantly longer time.

Regarding the type of cells, the conversion of the device to lithium batteries is considered more reliable using 18650 batteries. At this stage, you need to determine the capacity of the battery and the discharge current. Under the standard operation of the device, the current consumption is in the range from 5A to 10A. However, in the case of an unexpected sharp decline, its value can reach 25A. In order to protect the batteries from damage when such surges occur, cells with a discharge current of 30A should be used.

Video: Converting a Lithium Screwdriver Charge

18650 format cells with increased discharge current

You can build a lithium-ion battery of eight capacities, for this two banks are combined in parallel. Now these pairs need to be connected in series, the main thing is that eight containers fit in the case.

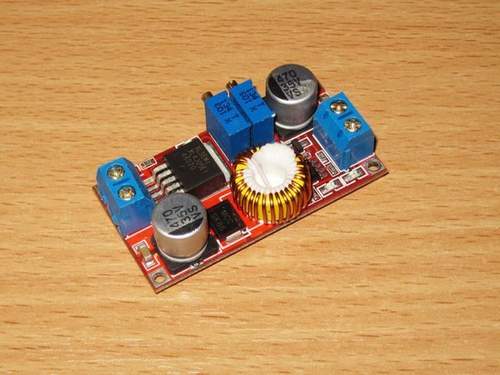

When executed alteration of a screwdriver on lithium batteries, then an important factor is the selection of the controller, based on the operating voltage and discharge current. The battery voltage should be the same with the voltage of the controller, however, the current for discharging relative to the maximum should be two times lower.

For example, this happens as follows: a charge / discharge control device counts on a current of approximately 14A, along with this, the protection function will trigger a sharp jump in current to 30A.

Also, in the process of converting a screwdriver to a lithium battery, do not forget to calculate the size of the protection board in advance. It must necessarily fit freely in the case, if it does not fit, then you will have to increase the space of the case.

Step-by-step installation

When you have all the necessary components for converting a screwdriver to lithium batteries already prepared, you can start the assembly process. In this part of the article we will consider the reconstruction of a screwdriver designed for a voltage of 12v. It consisted of twelve NiCd battery capacities with a voltage of 1.2v each. Our task is to replace them with Li-Ion.

-

1. First of all, we separate the battery case and take out the battery installed there. To perform this procedure, you will need side cutters or wire cutters, while the connector should remain in its slot.

-

2. At this stage, the controller board and thermocouple are installed. These components are mounted in place of the temperature sensor.

Due to the fact that the capacitors are not current, two banks were installed in parallel to ensure their correct operation.

-

3. Now you need to connect all the pairs in series. According to the existing scheme, solder the controller to the board, while remembering that it is necessary to connect balanced points. To complete this step, the circuit has a special connector and wires.

-

4. The final step involves connecting the wires of positive and negative voltage.

If the kit has an original charger, then there should not be any problems with it. Devices of this type are perfectly suitable for Li-Ion batteries. The passage of charge is carried out through the controller circuit. And this, in turn, completely removes the possibility of critical heating of the battery as a result of voltage surges.

If the tool was designed for 12v, then this diagram will be most suitable for assembly:

Based on the fact that new batteries are on sale within three thousand rubles, and the cost of remaking will cost somewhere around 1000 rubles. Therefore, such a modernization of a screwdriver is fully justified.

Converting a screwdriver to lithium batteries

Alteration of the Ni-Cd battery of a screwdriver for Li-ion. Colossal capacity 4400mAh!