Fuel system repair

A breakdown of the fuel system can be asserted if the engine:

- does not start;

- stalls under load;

- overheats;

- does not function stably at idle.

To eliminate the malfunction, first check the condition of all filters, including air and oil. If they are slightly clogged, blow with compressed air or flush; if they have strong contamination, they are replaced with new ones. Then the carburetor is disassembled, the parts are washed with a special cleaner, the fuel mixture supply valve, the tank and the piston system are cleaned with gasoline. After drying, carefully reassemble.

After the engine is completely assembled, the crankshaft is manually rotated – it is important that the piston moves freely and the valves work flawlessly. Then they pour in fresh lubricant, start the engine and leave it to work at idle. Be sure to check the flow of fuel into the cylinder. Perhaps, after such a repair, the cause of the malfunction will be eliminated, and the tiller will begin to function without interruption..

Ignition system repair

The breakdown of devices for ignition of fuel assemblies can be judged by the signs when the engine:

- starts, but stalls at idle;

- does not start even with good fuel supply;

- works at idle, but with some interruptions.

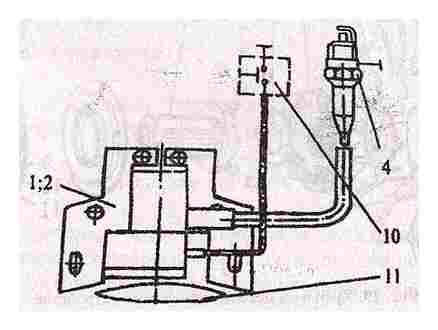

To find out the reason, first check the condition of the candles and, if there is damage to the insulator, replace them. Next, the electrodes are inspected and, if necessary, the gap between them is adjusted. They check the condition of high-voltage wires for oxidation of the tips and insulation breakdowns – the damaged wires must be replaced with new ones. Without such a repair, the spark may completely disappear or it will go through the insulation, piercing the engine case, and will not be able to ensure the ignition of the fuel assembly..

If at this stage a defect with a spark is not found, then perhaps the reason that the equipment does not start or stalls lies in the generator or coil (for models such as Neva, Cascade, it serves to form a spark). To check the generator, a measuring device is connected to its terminals. The tiller starter pulley is scrolled and the readings of the device are recorded – they should be within 12-16 watts. If the indicators are normal, then the reason is contained in the ignition coil, and after replacing it, you can put a load on the engine. Most likely, after such a repair, its performance will resume completely..

Tiller won’t start: reasons for how to properly repair

Owners of tillers, cultivators, motorized towing vehicles and other mini-vehicles sooner or later face a typical problem – their workhorse will not start or start, but stalls when the air damper is opened, starts “shooting”, gasping or “sneezing”. To eliminate the annoying interference, you need to find out the reason for which it occurs, and then carry out proper repairs. This problem occurs on Chinese, Japanese, Korean-made equipment..

Reasons why the tiller won’t start and how to fix them

There are several reasons why motor vehicles do not start when starting. These include:

- damage to the carburetor (in tillers with a gasoline engine);

- malfunction of ignition / glow devices;

- low lubrication level.

When strange changes appear in the cultivator, and its operation becomes unstable, the carburetor is first checked. In this important unit, a fuel-air mixture (FA) is formed and dosing for feeding it into the cylinders of an internal combustion engine (ICE). And if the jets become clogged, the fuel system becomes obstructed, as a result of which the carburetor loses its ability to start the engine. To eliminate the malfunction, the fuel line is repaired: the carburetor is partially disassembled, the pump is washed and the nozzles are blown through the fuel nozzle.

Sometimes the reason that the tiller does not start lies in a malfunction of the spark plugs (the spark is gone), which play an important role in starting the carburetor ICE, or the glow plugs that ensure the start of the diesel engine. If the fuse devices become wet, which happens due to the throwing of their fuel assemblies, then a spark begins to disappear on them. In the absence of sparking, ignition of the air-fuel mixture does not occur, and therefore the engine cannot be started. This problem can be solved in different ways:

- make minor repairs and replace the inoperative candle with a new one;

- “Burn through” flooded candles and use fire to clean them of traces of gasoline.

Motorized equipment does not start due to the fact that damage to the glow plugs occurs. In a diesel engine, fuel is ignited by contact with hot air, which is heated in the cylinder by compression by a piston. This happens without any problems when the diesel engine has already warmed up and the operating temperature in it is maintained by the heated cylinder walls. But in cold weather, and especially in winter, the engine is warmed up using incandescent devices and, if they are out of order, it will not be possible to start the tiller.

If, when inspecting a carburetor engine or diesel engine, no defective spark plugs were found, but problems remained, and even accompanied by popping into the muffler, you should check the performance of all devices responsible for the flammability of the fuel. A malfunction in them can also be the reason that the tiller does not start. Diagnostics is best done in a service center, where professionals will find the cause of the damage and competently carry out repairs..

Motorcycles will not start even if the level of lubricant in the engine is insufficient. Some models are equipped with special control sensors, which, in the event of a lack of lubrication, do not allow the engine to start. Particular attention should be paid to those machine variants that do not have such sensors. Sooner or later, the level of the lubricant mixture will reach a critical value and, if it is not replenished to the norm, this will soon lead to wear of parts and, as a result, to overhaul of the engine..

Preparing the tiller for launch

It is necessary to study the instructions drawn up by the manufacturer in order to find out which operating cycle the engine has: four-stroke (like Forte, Centaur, Lifan, Bison) or two-stroke. This is important to know, since for models with a two-stroke engine (like the Mole cultivator), a special combustible mixture is needed, consisting in a certain proportion of gasoline and oil. Due to the mismatch of the fuel, the equipment will stall, and the spark plugs and the fuel line may also suffer, which is fraught with the failure of the fuel pump – and this is already a direct path to expensive repairs at the service station. You can determine whether the fuel is suitable for motor vehicles by smoke. If the quality of gasoline is poor, it will have a white color, as is the case with a strong tilt of the car. If you have bad gasoline, replace it to prevent damage..

Fuel quality is also important for a diesel tiller. It does not start in winter or does, but soon stalls if summer diesel is poured into its engine. At low temperatures, it begins to thicken and clog the fuel line. In such cases, the risk of breakage increases. Choose the right fuel in cold weather.

The start-up of motor vehicles both in summer and in winter should be carried out in a certain sequence. For example, to start a Krot brand motor cultivator, the following procedure is carried out:

- open the gas tap;

- put the choke lever in the “Choke” position;

- turn off the ignition and turn the engine several times with a manual start-up starter;

- restart the engine and move the lever to the “Run” position.

Situations often arise when the power unit starts easily, but after a few seconds it stalls. In this case, it is necessary to check the permeability of the sump, perhaps the reason is that the tap is clogged – then it is cleaned with gasoline.

Starting a motorcycle with a diesel engine (such as Bison, Cascade, Centaur, Neva) will be somewhat more difficult than Mole. The diesel engine starts up with “airing” the fuel line, that is, with the release of it from air accumulations. For this:

- open the fuel supply valve;

- untwist the connections of the fuel outlet channel until the fuel appears;

- tighten the connections and blow through the nozzles.

Starting a cultivator after winter or a long downtime also has its own nuances. In order to bring the machine into working condition, the following manipulations are performed:

- open the gas tap;

- check if the power is on;

- check for lubrication;

- give gas, up to about half.

And, of course, before starting motor vehicles, be it the Centaur, Cascade, Neva, Patriot or Bison, they check all connections, including transmission units, clutch, starting mechanisms and, if necessary, adjust them..

DIY Tiller Repair

Unfortunately, any equipment sometimes fails, so its owner needs to be able to troubleshoot on his own. Of course, if the car is under warranty, it is better to take it to a service center, where specialists will carry out warranty repairs for free..

Often, damage to the cultivator or tiller occurs due to improper operation: poor fuel is poured, heavy loads are allowed, or the loss of lubricating fluid is not replenished in time. Then the car starts to stall, “burrow”, it is bad to gain momentum (especially if there is an electric motor on it), or even stops starting altogether. But, knowing the device of the unit and the principle of operation of its mechanisms, you can yourself identify the cause of the damage and carry out high-quality repairs.

Transmission repair

The following factors indicate a transmission malfunction:

- the working shaft is motionless, and the output shaft rotates;

- the engine speed does not match the speed of the working shaft;

- the engine seems to “choke” from the load.

If at least one of the above reasons manifests itself, they immediately check for the presence of grease in the gearbox. The lubricant in it must be normal, as the lubricant prevents “dry” friction of moving parts and prevents them from overheating.

Then the gearbox is disassembled, the gears are inspected, the chain tension is checked. Whole parts are washed in kerosene, and damaged parts are replaced with new ones. After that, they assemble the structure and make sure that the gears are not skewed..

Before installing the assembled gearbox on the tiller, the shafts are scrolled to make sure that they rotate evenly and without the slightest grinding. The gearbox is filled with fresh lubricant and the motor-cultivator is started. In the absence of a leak under the body, perform simple operations with a rotary tiller or a mounted loader and check the functionality of the tiller. If its working capacity is restored, then all efforts were not in vain, and the repair and maintenance were carried out correctly.

Ignition system repair

The breakdown of devices for ignition of fuel assemblies can be judged by the signs when the engine:

- Starts up, but stalls at idle;

- Does not start even with good fuel supply;

- Works at idle, but with some interruptions.

To find out the reason, first check the condition of the candles: if there is damage to the insulator, replace them. Next, the electrodes are inspected and, if necessary, the gap between them is adjusted. They check the condition of high-voltage wires for oxidation of the tips and insulation breakdowns – the damaged wires must be replaced with new ones. Without such a repair, the spark may completely disappear or it will go through the insulation, piercing the engine case, and will not be able to ensure the ignition of the fuel assembly..

If at this stage a defect with a spark is not found, then perhaps the reason that the equipment does not start or stalls lies in the generator or coil (for such models as the Neva, Cascade, it serves to form a spark). To check the generator, a measuring device is connected to its terminals. The tiller starter pulley is scrolled and the readings of the device are recorded – they should be within 12-16 watts. If the indicators are normal, then the reason is contained in the ignition coil and after replacing it, you can put a load on the engine. Most likely, after such a repair, its performance will resume completely..

What to do if a tiller starts up badly

You should figure out what to do if the tiller does not start well. Another problem that can be encountered when using a tiller is the drop in power, which can be caused by a long storage period with a wet carburetor..

You can cope with this if, with the engine running, the tiller will be inactive for some time (when the engine is idling). Be careful if the motor will get hot. In this case, it is necessary to observe whether the apparatus is firing, whether there is a recoil during exhaust, whether there are interruptions in the operation of the motor. Problems arise if debris gets into the muffler, carburetor, fuel hose, which should be cleaned.

If the tiller smokes, then all the fault is low-quality fuel or a strong tilt of the equipment, which leads to the movement of oil towards the crankcase, and the unit smokes.

How to start a tiller and what to do if it stalls

When using a new tiller for the first time, it is important to first study the instructions and pay special attention to the question of how to start the tiller. Tiller launch consists of a certain number of sequential actions. It is better to know in advance how to start the tiller correctly. This will help you figure out what to do if the tiller does not start, and why such a situation may arise.

If the tiller does not start. Reasons and their removal.

Tiller reanimation after winter and the most common tiller failures.

I tried to start the tiller after winter, but the tiller did not start.

How to start a tiller if it does not start can only be assumed at the beginning, because there may be several reasons:

– wire breakage;

– there is not enough gasoline in the tank and it is not sucked in;

– spark plug dirty.

Transmission repair

The following factors indicate a transmission malfunction:

- The working shaft is motionless and the output shaft rotates;

- The engine speed does not match the speed of the working shaft;

- The engine seems to “choke” from the load.

If at least one of the above reasons manifests itself, they immediately check for the presence of grease in the gearbox. The lubricant in it must be normal, as the lubricant prevents “dry” friction of moving parts and prevents them from overheating.

Then the gearbox is disassembled, the gears are inspected, the chain tension is checked. Whole parts are washed in kerosene, and damaged parts are replaced with new ones. After that, they assemble the structure and make sure that the gears are not skewed..

Before installing the assembled gearbox on the tiller, the shafts are scrolled to make sure that they rotate evenly and without the slightest grinding. The gearbox is filled with fresh lubricant, and the motor-cultivator is started. In the absence of a leak under the body, perform simple operations with a rotary tiller or a mounted loader and check the functionality of the tiller. If its working capacity is restored, it means that all efforts were not in vain, and the repair and maintenance were carried out correctly..

Possible reasons

Tiller starts and stalls? Why is this happening? There may be several reasons why motor vehicles do not start at start-up. These include:

- damage to the carburetor (in units with a gasoline engine);

- defect in ignition and heating devices;

- low base lubrication level.

When unusual changes occur in the unit, and its operation becomes unstable, first of all, the carburetor is checked. In this essential unit, the formation of a fuel-air mixture (FA) is performed and its dosage for feeding into the cylinders of an internal combustion engine (ICE). And if the jets become clogged, an obstruction of the fuel system appears, due to which the carburetor loses its ability to guarantee the engine start. In order to eliminate the defect, the fuel line is repaired, which involves a partial analysis of the carburetor, flushing the pump, purging the nozzles through the fuel connection.

If the tiller Neva does not start, the reasons may also be different. Sometimes the problem is hidden in the malfunction of the spark plugs, which play an important role in starting the carburetor ICE, or the glow plugs, which ensure the start of the diesel engine. In the event that the fuse devices are made wet, which happens due to the throwing of their fuel assemblies, a spark begins to disappear in them. In the absence of sparking, the ignition of the fuel-air mixture does not occur, and, therefore, the engine does not start..

You can solve this problem in different ways:

- carry out minor repairs and replace non-working candles with new ones;

- “Burn through” flooded candles and use a flame to clean them from traces of fuel.

The equipment does not start due to the fact that a defect in the glow plugs appears. In a diesel engine, fuel is ignited by contact with hot air, which heats up in the cylinder when compressed by the piston. This happens without complications if the unit is already warmed up, and the heated cylinder walls keep the operating temperature in it. However, in cool weather, the heating of the motor is performed using incandescent devices, and if they break down, it will not work to start the tiller.

If, when inspecting a carburetor engine or diesel engine, no defective candles were found, but difficulties persisted, and even accompanied by pops into the muffler, it is necessary to check the functionality of absolutely all devices responsible for the flammability of the fuel. A defect in them can also be a prerequisite for the tiller not starting. It is more correct to carry out diagnostics in a service center, where specialists will find the cause of the damage and professionally carry out the restoration.

Motorcycles will not start even if there is a lack of lubricant in the engine. Certain modifications are equipped with special control sensors, which, if there is a lack of lubrication, do not allow the engine to start. Particular attention should be paid to those variants of machines that do not have such meters. Sooner or later, the degree of the lubricant mixture will reach the limit value, and if it is not compensated to the norm, this will soon lead to wear of the elements and, as a result, to the overhaul of the motor..

There is no spark on the tiller – we understand the problem

Another common reason that the tiller does not start is a malfunction in the ignition system of the unit. Malfunctions can be lurking in the hood, magneto, spark plug, or in the high voltage wire of the agricultural machine..

When inspecting the ignition system, first of all, you need to carefully check every part for blockages. If a spark has disappeared, then the reason for this is often the ingress of moisture or dirt on the elements of the ignition system. Also, an agricultural machine often does not start due to the lack of the ability to form a spark – the reason for this is poor contact between the center electrode and the spark plug cap..

If you did not find dirt and moisture in the ignition system, and the tiller does not start, then be sure to check the integrity of the electrodes and the gap between them. As a rule, a special probe is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove carbon deposits from the insulator and metal elements of the ignition system.

If the unit does not start, and none of the above procedures helped, then you will need to replace the tiller spark plug. The cost of replacement parts is low, however, when buying, we advise you to give preference to more expensive candles – they will last many times longer than cheaper counterparts.

All of the above methods are suitable for repairing the Mole, Neva MB-1 and MB-2 tillers, as well as Kaskad, Zubr, Agro and Salyut.

Difficulty starting

Difficulties in starting indicate a malfunction of components and elements. The success of repair work depends on the accuracy of the diagnosis. If deficiencies are found, they are engaged in repairing the diesel tiller. Service and minor repairs can be done on our own. You will need a set of keys, a locksmith mechanism and skilled hands.

At the stage of fuel preparation, the following incidents are likely:

- light filter does not let air in;

- the hole of the tank lid is boarded up;

- the fuel supply channel is littered;

- broken carburetor.

After a series of unsuccessful starts, it is advisable to unscrew the plug. The working part can be filled with fuel. In this case, dry the element, then pump the cylinder through the hole. We twist the candle and start it up again.

If the candle is dry, it means that no fuel enters the combustion chamber. Let’s perform several operations in turn to resume the feeding system:

- drain old gasoline;

- wash the tank;

- clean the special filter from dirt;

- clean the fuel supply hose;

- clean the carburetor jets;

- fill the tank with the cleanest fuel;

- open the tap;

- clean out the airway in the tire.

Why the diesel tiller won’t start – popular reasons and their solution

In the spring, people begin to actively engage in land work, so they often choose specialized technical devices as their assistants. Diesel Tillers are considered the most versatile and practical devices that are easy to operate and multifunctional. The relative cheapness of fuel is also one of the reasons for the increased interest in the unit, so it is not surprising that many agronomists choose the specified tillers among all the variety..

But sometimes after winter, not very pleasant situations arise, and it becomes quite difficult to start the device. Naturally, a person wants to independently deal with the causes of the breakdown and fix the problem with his own hands..

Why the diesel tiller may not start?

Due to the storage of the device in a damp room, the contacts are oxidized, the carburetor jets are clogged, the insulation of the wires is broken, the oil and the fuel itself are flooded. It is worth noting that before starting the tiller, you should carefully inspect it and check the clutch cable, gas, reverse, etc. An important point: not every person can carry out high-quality home repairs, so people who are not particularly versed in mechanical engineering should go to a service center. Those who know how to properly handle a diesel engine and other mechanisms can try to repair a diesel tiller, guided by their own knowledge and skills..

Among other causes of problems with the functionality of the device, the use of old oil, lack of lubrication, which can cause damage to the piston group, an insufficient amount of the same oil, poor fuel quality is also reflected in the productivity and service life of the unit, so you should not save and give preference to yourself quality.

Why does a diesel tiller start badly??

| Cause | Solution to the problem |

| Low room temperature | You need to pour hot water (not boiling water) into the radiator itself |

| Clogged nozzle | It is necessary to replace or clean the nozzle |

| Frozen fuel | It is advisable to heat it up or even replace it with a higher quality and fresh one. |

| Dirty carburetor | It should be removed, cleaned and adjusted. |

| Clogged muffler with combustion products | The owner must disassemble the muffler, inspect it, rinse it in fuel and clean it with a special scraper. |

| Low injection pressure | Adjust pressure to normal level |

| Engine overturns too quickly and easily by starter |

In any case, you should carefully study the instructions and follow the specified rules, because such care for your “assistant” can improve productivity and save the owner’s time, who in the near future will no longer be engaged in repair work and the purchase of additional parts.

Starting a diesel engine

How to start a car that runs on diesel fuel:

- Open the fuel cock.

- Unscrew the duct connections until fuel starts to flow.

- The parts are screwed in and the nozzles are blown with compressed air.

How to prepare a tiller for launch

What to do first when the tiller won’t start? Regardless of the modification of agricultural machinery, first of all, the owner must familiarize himself with the operating instructions, and then carefully check all devices and connections. Also, we must not forget about checking the level of the lubricant in the internal combustion engine..

The manual contains the necessary information for the repair, such as a description of the engine. The motor can be two- or four-stroke.

For models from the first category, you will need a special flammable liquid, which contains gasoline and engine oil. If you use the wrong fuel, then the engine will work intermittently..

To determine the appropriate fuel, attention must be paid to the outgoing smoke. When using good quality gasoline or diesel, it will be white. Also, the engine does not work if diesel fuel intended for warm weather is poured into it in winter..

How to start a tiller after winter

If the motor unit is started after a long idle period or in the summer after winter, then the following actions are carried out:

- They open the tap where the fuel comes from.

- Check if the ignition is on and the presence of engine oil.

- Gas up to about half.

My Tiller won’t start!

In addition, before starting, it is necessary to check all connections, clutches, mechanisms and assemblies. Next, we will talk about what to do if the tiller does not start..

Why the tiller won’t start

Often, the owners of agricultural machinery are faced with various malfunctions. For example, the tiller does not start and fires. To eliminate a breakdown, first of all, you need to determine its cause..

After that, they independently engage in direct equipment repair or contact a service center. In this article we will tell you about why the tiller won’t start and how to fix it..

How to start a gasoline engine

Starting a gasoline mini-tractor is carried out in a specific order:

- Open the fuel cock.

- On the carburetor, the choke lever is moved to the Start position..

- Turn off the ignition and turn the motor a couple of times using a mechanism with a special cable.

- Start the engine again, then put the lever in the Run position.

Causes and remedies

Tiller does not work – reasons:

- insufficient amount of engine oil;

- malfunctions in the performance of glow and ignition devices;

- malfunctions in the power supply system unit of the internal combustion engine of a mini-tractor with a gasoline engine.

Often, the reasons that the tiller does not start are due to improper operation of the spark plugs or glow plugs. This is due to the fact that the spark has disappeared from the spare parts due to excessive moisture. It occurs as a result of throwing a fuel assembly.

If there is no sparking, then the tiller engine will not start. How to solve the problem:

- repair or replace the damaged part with a new one;

- “Burn through” flooded candles, thus clearing them of fuel residues.

If the diesel tiller does not start, and the glow plugs are still functioning properly, then check the operation of all devices that are responsible for the flammability of the combustible.

Manufacturers recommend passing diagnostics at the service center so that the masters determine the cause of the malfunction and carry out a full repair..

DIY Tiller Repair

Agricultural machinery, like other devices, breaks down periodically. Therefore, it is important for the owner to be able to repair the equipment, based on the dimensions of the tiller, with his own hands. However, if the warranty has not expired, it is better to contact the masters at the service center, since they will carry out the repair completely free of charge..

The fuel system is damaged if the engine:

- stalls at the slightest load;

- overheats a lot;

- does not work when the clutch is fully depressed.

To repair the tillers, first check the condition of the air and oil filters. If there is little clogging, they are washed or blown out with compressed air. If there is strong dirt on the parts, then the old parts are replaced with new ones..

At the next stage, they are engaged in the analysis of the carburetor, rinsing all the components with a special cleaning agent. Also thoroughly clean the fuel cock, tank and piston system with gasoline..

When all parts are well dry, they are installed in the reverse order..

Next, the crankshaft is screwed on, while the piston should move freely, and the valves should function smoothly. Then they refuel with new engine oil, start the engine and leave it to idle for some time. It is important to check if the flammable substance is flowing to the cylinder..

Why not turn on the tiller?

Despite all the reliability of modern tillers, sooner or later they fail, which is why the unit cannot be started and continued to work on the site. We offer you to study the most common breakdowns of agricultural machines, as well as do-it-yourself methods for eliminating them..

Why not start a tiller – understand the reasons

Before the start of the season, both the gasoline and diesel tiller need preparation. To do this, the owner of the unit must make sure that the design of the unit contains all the parts necessary for operation, and each of them “sits” tightly in its proper place.

Often, many Tillers equipped with a Subaru engine or motors from other well-known brands refuse to work after a long winter standstill. At the same time, the incorrectly chosen storage conditions of the agricultural machine also affect – if it stood in a cold, damp room, then, most likely, it will not start before the start of spring work. This is due to a number of such malfunctions:

- Oxidation of contacts in electrical wiring;

- Violation of the integrity of the insulation of the wiring;

- Oil and fuel watering;

- Accumulation of debris in the carburetor jets.

Before starting the tiller, its owner must carefully inspect all the connections in the unit design. It is necessary to check the course of the throttle, reverse and clutch cables – it should be soft. If during inspection you find clamps or twisting of the cables, then you cannot start the tiller.

Before starting the chiller for the first time, check the oil level inside the crankcase. If there is no lubricant, this will lead to severe damage to the piston group. Judge for yourself: at a crankshaft rotation speed of 1400 rpm, it will take a fraction of a second for it to form a few burrs on the cylinder surface.

The oil remaining for the winter is one of the main reasons for the unstable operation of the unit motor. It is quite simple to make sure that the tiller does not start well for this very reason – after starting for a few seconds, white smoke will fall from the exhaust pipe of the car, after which the unit will stall. Do not forget that both diesel and gasoline tiller will not start well due to insufficient amount of oil. Some models of units are equipped with low level protection, owners of other machines should independently monitor the volume of oil inside the tank.

Another important factor is the gasoline you use to refuel the tiller. If you regularly fill in fuel of a different brand than the one recommended by the car manufacturer, then this can also cause it to not start..

Do-it-yourself breakdown elimination

Success in self-repair of a tiller largely depends on how correctly you diagnose the unit. The reasons why the tiller won’t start can be hidden in the following:

- Due to blockages, air does not pass through the air filter;

- The hole in the fuel tank cap is clogged;

- Debris has accumulated in the fuel supply channels;

- Breakage of the carburetor.

Each of these faults can be easily and quickly eliminated by hand. If this is not the cause of the breakdown, and the unit still does not start, then you should unscrew the spark plug and check if there are oil stains on it. If you find oil or thick carbon deposits on the candle, then the part must be cleaned and dried. In addition, drying will also be required for the tiller cylinder – for this, you need to sharply pull out the starter cable several times.

Top Reasons Tiller Engine Won’t Start — Tiller Troubleshooting

It is often difficult to start a tiller due to the lack of fuel in the combustion chamber. In this case, the candle will be completely dry. If the cause of the breakdown is this, then the following measures will need to be taken:

- Drain the old fuel completely;

- Rinse the fuel tank thoroughly;

- Clean the air filter from clogging;

- Blow out the fuel supply hose with compressed air;

- Blow out the carburetor jets;

- Pour fresh gasoline into the tank;

- Open the fuel cock;

- Purge the airway inside the fuel tank cap.

Before restarting, you will need to manually pump fuel by pressing the primer of the fuel pump several times. After starting the engine, be sure to give it time to warm up, after which you can start working with the tiller.

If all the above steps did not help, and the tiller still does not start, then check the inlet and outlet valves – if they do not fit tightly to the seats, then the parts will need to be adjusted by turning the corresponding screws clockwise.

Also, if the tiller does not start, we advise you to pay attention to its muffler – after long-term operation, carbon deposits accumulate on its walls, which must be regularly removed with compressed air..

There is no spark on the tiller – we understand the problem

Another common reason that the tiller does not start is a malfunction in the ignition system of the unit. Malfunctions can be lurking in the hood, magneto, spark plug, or in the high voltage wire of the agricultural machine..

When inspecting the ignition system, first of all, you need to carefully check every part for blockages. If a spark has disappeared, then the reason for this is often the ingress of moisture or dirt on the elements of the ignition system. Also, an agricultural machine often does not start due to the lack of the ability to form a spark – the reason for this is poor contact between the center electrode and the spark plug cap..

If you did not find dirt and moisture in the ignition system, and the tiller does not start, then be sure to check the integrity of the electrodes and the gap between them. As a rule, a special probe is used for this. Ideally, the gap should be 0.8 mm. If necessary, remove carbon deposits from the insulator and metal elements of the ignition system.

If the unit does not start, and none of the above procedures helped, then you will need to replace the tiller spark plug. The cost of replacement parts is low, however, when buying, we advise you to give preference to more expensive candles – they will last many times longer than cheaper counterparts.

All of the above methods are suitable for repairing the Mole, Neva MB-1 and MB-2 tillers, as well as Kaskad, Zubr, Agro and Salyut.