The easiest option is the cutting stop

The device is actively used when cutting with a jigsaw.

It works quite effectively, however, it is limitedly suitable for a circular saw. The tire is pressed against the workpiece with a clamp. The bracket protrudes above the work surface both from the bottom and from the top.

As a result, we get restrictions on the length of the cut. The circular motor rests against the clamp, and you have to make a cut in two steps. In this case, the quality of the edge deteriorates, a step may form.

Any master will tell you. a high-quality cut is obtained when the saw moves continuously from the beginning to the end of the workpiece. In industrial designs, the fasteners are placed outside the ruler, and do not interfere with the free passage of the tool.

A self-made guide is made from a ready-made tool of a different profile, which has a low cost. We buy a long aluminum rule (accent on and) for plaster or screed.

His Tool is a profile of complex shape with an even groove on the back for adjusting the position of the handles. Clamping fastening on hex nuts. Not suitable for our tasks.

Make a Simple Circular Saw Cutting Guide | Rockler Skill Builders

As a donor for countersunk clamps, you can use screwless quick-release clamps, which also have a reasonable cost. Their main advantage for our design is the removable upper leg.

We delete it. At the same time, the instrument can be returned to its completeness at any time and used for its intended purpose. Instead of paws, we make and fix runners from a piece of fluoroplastic or polypropylene. The main criterion when choosing a material is strength and a low coefficient of friction.

You can process the workpiece using a router or a metal hacksaw with a fine-toothed blade. In the second case, you will have to, as they say, “finalize with a file”.

We fit the sliders to the groove. Sliding should be without gripping, at the same time, a strong backlash is also not needed. There is no need to try especially, during operation this unit will be fixed.

We fasten the sliders to the top of the clamp tire. The connection must be strong, since there should be no spontaneous release during cutting, this can lead to injury or damage to the workpiece.

We check the performance of the structure. The self-made guide ruler holds securely, there is no backlash.

This design can handle flat workpieces of any size, as long as the length of the ruler is enough. In our case, it is 2 meters. Taking into account the margin at the edges for fixing the clamps. the working length is 1.5 meters. than enough for most household chores.

If your requests are longer, you can use the 2.5 or 3 meter rule. The most reasonable kit is a three-meter ruler. You can saw off a piece of 50 cm long from it, and you will have two rulers. for large-area blanks and narrow boards.

We carry out tests. the cutting line is perfectly straight, nothing interferes with the free passage of the circular saw.

And most importantly, the purchased tool was not damaged during the manufacture of the device. Both the clamps and the rule are returned to their original state at any time and are applied as intended. Labor costs are minimal. in fact, only sliders are made.

Circular saw guide. a must-have accessory that expands the capabilities of the tool

When working with a hand-held circular saw, the question of the straightness of the cut arises. There are two concepts for ensuring a straight line: Fastening the actual circular on the sawing machine (workbench).

In this design, the hand tool is permanently attached to the table, and the workpiece moves along a guide. The quality of the cut is at a height, but there are serious restrictions on the size of the processed material.

The workpiece is fixed permanently, and a guide fence is installed for a hand-held circular saw.

In such a design, the size of the workpiece to be cut can be any, the main thing is to provide a strong attachment for the circular saw attachment. Hand tool manufacturers have taken care of the users and offer a variety of ready-made tools for sale.

Manufactured guides are comfortable and safe. As a rule, they are equipped with an accurate ruler, some allow you to set the angle of inclination of the cutting blade.

The material is selected in such a way as to exclude wedging and backlash during the movement of the tool.

The pair, consisting of a groove and a slider, is protected from the ingress of sawn products and does not need lubrication.

However, all of these kits are expensive, and many DIYers make a rail for a circular saw with their own hands.

Consider the options independently invented and created by home-grown “kulibins”.

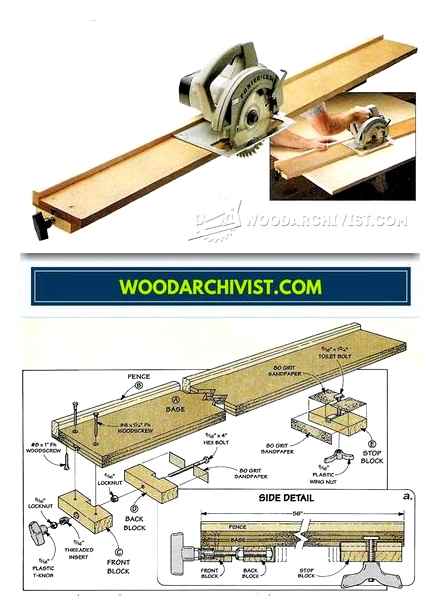

DIY external guide rail for circular saw

While there are many advantages, the previous design has a significant disadvantage. It is necessary to constantly monitor the lateral pressure of the circular body to the ruler. If the width of the workpiece cut off during cutting is too large, the length of the arms may simply not be enough.

The way out is the use of a carriage on ball bearings. The design is not so budgetary (at least you need to buy bearings), but its capabilities cover all costs. The principle of operation can be seen in the illustration:

A carriage is made from metal plates and a corner. To adjust the width, you can use the wing clamps installed in the movable grooves.

The profile must ensure that the C-clamp is attached to the inside of the tire. You can purchase a ready-made structure from a matched pair of carriage and guide.

It all depends on the budget of the event. The sole of the hand circular is firmly attached to the carriage.

Such a tire, made by hand, allows you to cut out large-area workpieces. At the same time, the movement of the saw is light and even, the feed can be carried out both by hand and by the guide bar.

Rail miter box for manual circular

The listed designs are well suited for leisurely cutting of single surfaces. In the case when it is necessary to quickly and accurately cut a large number of boards, the work will be done slowly. Then a rail miter box is used.

For manufacturing you will need:

- Two metal corners of the same profile and length;

- Flat base (plywood or chipboard at least 15 mm thick);

- One size bolts and nuts, 4 sets.

At a distance slightly larger than the thickness of the workpiece, guide corners are attached. The board must move freely under the rails, and at the same time, the saw blade cannot be too high.

We use bolts as studs. It is important to observe the parallelism and placement of the corners on the same plane. The photo clearly illustrates the operation of the device:

For free sliding of the tool sole along the guides, fluoroplastic strips can be glued to reduce friction.

But it would be more correct to install wheels. for example, ball bearings. Manufacturing is relatively labor intensive, but the system is very efficient and safe.

If it is necessary to make cuts at an angle, it is enough to screw two screws into the base into which the board will rest.

Still have questions? See the do-it-yourself circular guide rail.

What is the role of the guide

The circular saw bar guides the sliding of the tool along the mowing line of the cut, preventing it from deviating. The correct design of this part determines the smooth cut of the workpieces, the absence of rejects in the places of processing.

An employee, when using a circular, controls the movement process.

To comply with safety regulations, he must:

- securely fix the power saw;

- fix the workpiece.

It is easier to ensure the safety and quality of work in the second way. When the parts are not in the package with the saw, you can make them yourself.

Do-it-yourself circular saw guide rail. detailed instructions

What role does the guide play? How many types of tires do the circular have? Technical features of self-made devices? What is the use of stops?

In production and home workshops, workers use electrical appliances of different purpose. Various elements are used to process workpieces. They provide quality work.

Guide bar for circular saw

So the guide bar for the circular saw serves as an additional device for making an even, accurate cut.

Sometimes the tool manufacturer sells a set of parts accompanying the main mechanism. If there is no tire, it is not difficult to make it with your own hands from improvised material.

What is the use of stops

A self-made guide for a circular saw will save the master from many problems when operating a complex and dangerous tool. The disc operation is not always carried out exactly along the marked line and without chipping. Whatever the reason for the marriage. the lack of locksmith skills or experience with a saw, everyone wants a result without spoiled materials. Arguments proving the benefits of homemade devices:

- It happens that it is enough to attach the plates with clamps, but not always. The saw will touch the clamps.

- If you need to make a single cut, you can apply a painting rule, but you will have to constantly check it to correct the position.

- With a proprietary guide, the direction along the mowing line of the cut is set with accuracy, after aligning the strips, the operation is immediately started. Quality tires have an adhesive tape that protects against chipping. But factory tires are made for limited sizes.

The guide by its name indicates its purpose. to move the saw freely along a given position.

Regardless of what materials the production will be made of:

�� Homemade Track Saw. DIY Guide Rail for Circular Saw

- channel;

- rectangular pipe;

- laminate. it is necessary to create a geometrically correct structure.

Pressed and wooden stops have a significant drawback:

- absorb moisture;

- swell;

- out of shape.

If a loose stop is placed, inconvenient conditions are created with simultaneous sawing and control over the position of the staff. You need to monitor the strength of pressing the rule so as not to spoil the basis.

Preparatory activities

For work, you will need a tool kit with accessories for assembly, cutting a persistent product. You need to prepare:

- wood blanks for processing;

- solid wood from bars, dense plywood, laminate boards;

- fasteners made of screws, self-tapping screws;

- electrical appliances. circular, jigsaw, drill, electric screwdriver;

- clamps.

If manufacturing is carried out in a home carpentry workshop, there should be a primitive furnishings from a table, cabinets, electricity.

How many types of tires does a circular tire have?

The circular saw guide not only serves as a safety feature, it also increases productivity. Devices of different design have been developed, they are:

- bilateral;

- unilateral;

- symmetrical;

- asymmetrical.

A workpiece with a non-standard shape is processed with a universal device. With such a guide, you can work with a circular and hand saw.

Specialized tires are used when performing professional tasks.

When the crossbars are cut at an angle, a textolite or plywood limitation is made of bars. Before installing the supports, a check is carried out:

- the reliability of the clamps;

- tire surfaces for deformation;

- for the conformity of the workpiece materials with the guide.

Thrust rails are made of metal or wood. It is important that they are resistant to mechanical stress. They did not change their shapes and sizes. Products are used for production from:

- profile;

- rail;

- corners;

- bars.

- self-tapping screws;

- screws;

- bolted.

There is another stubborn tool. a ruler.

It is quite simple to make it from a plywood strip. In width, the fragment is taken 20 cm more from the working area. And the base is fixed with fastening hardware. Before work, you need to check with test cuts:

- tool behavior;

- vibration;

- level of physical effort to perform the operation.

Reliable safe execution of actions depends on the mountings:

- clamps;

- clamps;

- movable carriage;

- retainers.

These elements fix the workpiece in the required position. The installed limiter prevents the sharp cutting part from deviating from the perpendicular arrangement of the wood fibers.

Technical features of homemade devices

The factory guide for the circular saw does not allow for all production tasks. The manufacturer sets its dimensions, which are often not suitable for the master by the length of the board or other technical characteristics.

If a self-made emphasis is placed during work processes, take into account:

- the size of the workpiece;

- saw feature;

- how often the tool is used.

- slice lengths;

- performance and specificity of the application of technology;

- the width of the grooves;

- by directions of cuts;

- density of materials.

The carpenter must correctly evaluate the workpiece in terms of size and material of production.

The correct tire will make it easier to perform precise cuts

Instruction for production

Different materials for the production of guides require the same attitude. When a laminate is used for creation:

- cut off 2 parts according to dimensional marks;

- the edge is milled;

- fixed to the base with a self-tapping screw;

- measure the groove in width with a sheet of paper, screw it to the device;

- a tire is attached to the sole of the saw, it will serve as a side stop;

- the guide is pushed to the maximum so that the sole protrudes onto it;

- sawn off from the laminate along the edge markings.

The circular can be equipped with an outrigger carriage

Such a device is not difficult to create, but it absorbs the cutting depth.

Limiters are also made from the painting rule. A design with grooves and handles is suitable for this:

- the handles are removed from the building model for installation of spring clamps in these places, after their removal, the clamp is fixed on the rule;

- for adapters, propylene is used, parts are cut out in a special shape to insert into the grooves of the handles;

- hollow recesses are cut out at the base of the adapter for screwing the screws;

- place an emphasis on the surface, firmly fix it with a fastening element.

Fixation is carried out to the sheet with grooves located below, so as not to create obstacles for the saw to slide, only the size of the rule can limit the work.

The production of a rail miter box will allow you to cut:

- boards;

- bars;

- small workpieces.

- metal corner;

- plank or plywood base;

- hardware.

Marking is made along the length of the tire with fixation points. For dimensions, conditions must be provided:

- free movement of the board under the tire;

- not high arrangement of the saw blades.

They fasten the structure with bolts with a parallel arrangement of the corners so that the base of the circular slides freely. This is achieved by sticking fluoroplastic strips, which reduce friction and reduce the force acting on the saw.

Create a device from a finished aluminum profile

Metal lasts much longer than wood products. In addition, it holds steadily without distortions. For installation you will need:

- profile fragment;

- fasteners;

- plywood sheet.

As additional tools, you will need preparation:

- electric drills, drills for metal;

- wrench;

- measuring items.

- take 2 profiles;

- aluminum is attached to plywood on both sides for rigidity, chipboard is used;

- cut off excess.

When combining all the work carried out, the setting is carried out:

- a profile with a smaller cross-section is installed in the rail, the height of which should not absorb the main profile;

- fix the structure with thumbscrews on the bottom of the circular parallel to the disc circle;

- the saw should be on top of the guide;

- the edges of the tire are directed to the line of the marking, fixed.

Such stops provide smooth sliding of the cutting device, create ease of control of the saw.

The simplest fixture can be made from plywood.

For correct production, you need to make markings and strictly follow the dimensions without deviations. For this:

- measure the gap between the inner edge of the saw and the guide groove in the longitudinal cut, it is located on the support base of the mechanism;

- cutting the plywood strip along the width less than the measured distance with the arrangement of the fibers on the material in the longitudinal direction;

- with self-tapping screws, the obtained segment is fastened to the base with the alignment of the ends to form the working edge of the guide;

- take a caliper to determine the width in the longitudinal cut, the remaining strip should fit here, parallel to the first plate, ensuring a gap between 2 sheets.

A soft cloth is glued to the finished tires to protect the working material from damage.