How to connect a headlight to a tiller with your own hands

Many Tillers are sold without factory connection of headlights. But do not be upset about this, because even an inexperienced master will be able to understand how to make a headlight for this agricultural unit.

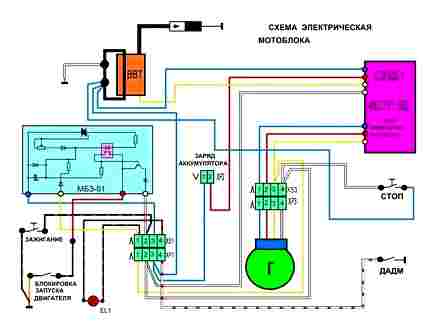

Tiller wiring diagram

Before installing lighting on a tiller, it is worth considering its class. These medium and heavy units are equipped with a generator, which serves as a source of charge for the battery and power for the headlight. On these variants of the mechanism, it is possible to connect several headlights (front and rear for the trailer to the tiller), as well as direction indicators.

The launch of the tiller is provoked by an electric starter and a storage battery, which is installed in a special pallet and firmly fixed to the frame of the mechanism. The battery is powered by a generator. The generator’s power is sufficient to engage all the necessary electrical devices of the mechanism and connect the headlights to the tiller. The manufacturers themselves have foreseen the desire of users to figure out how to make light on a tiller, using generators on constantly rotating magnets with an automatic voltage regulator with a power reserve of about 30%. To connect all sources of electrical power to the generator, it is worth collecting them in a single circuit with double insulated wires. The diagram described above is an ideal picture, but sometimes you have to modify something or figure out how to connect a headlight.

How to make light on a tiller?

Many manufacturers produce this agricultural mechanism without built-in lighting. Here the question arises of how to connect the headlight to the tiller yourself with your own hands.

You can use different kinds of lighting elements:

- Additional lights from a moped, scooter, tractor, car or other vehicle at your disposal.

- You can buy a used headlight on the automotive market at places for disassembling and sorting transport and electrical parts..

- You can choose a new headlight taking into account the color of the mini-tractor itself.

The ideal option is to choose a headlight for a scooter or small motorcycle. In addition, it is worth purchasing the required length of an electrical wire and a toggle switch for switching lighting.

The toggle switch is most conveniently connected to the steering column near the gear lever. The headlight itself can be located in the place of the steering column or on the front of the engine. But the first option will be preferable. On the engine, the headlight will constantly get dirty while the mechanism is moving, especially when it rains..

The next step in connecting the headlight will be pulling wires to it. The mechanism may provide a connection point for the factory headlight. In this case, we just connect a wire to it. If there is none, then the power should be removed from the terminal of the oil pressure warning lamp. We connect the wire to the switch, and then to the headlight. The cord should be attached to the steering column with electrical tape or clips.

Also, many are worried about the question of whether it is possible to make light on a tiller without a generator. It is worth noting that a battery is required, which will be installed using a quick-release mount and recharged in the workshop..

For a tiller, there are wide boundaries of its use, ranging from plowing the land, pumping water to cultivating virgin lands and transporting heavy loads..

Helpful information

tiller is a universal agricultural mechanism that is used to perform various tasks in personal plots, dachas and vegetable gardens. The versatility of the device allows you to use it both for land work and for transporting crops and other goods. Unfortunately, the complete set of many mini-tractor models does not provide for the presence of lighting elements. Therefore, the question of how to make a light on a trailer is relevant for most owners of this compact and practical machine..

Tiller wiring diagram

Before installing lighting on a tiller, it is worth considering its class. These medium and heavy units are equipped with a generator, which serves as a source of charge for the battery and power for the headlight. On these variants of the mechanism, it is possible to connect several headlights (front and rear for the trailer to the tiller), as well as direction indicators.

The launch of the tiller is provoked by an electric starter and a storage battery, which is installed in a special pallet and firmly fixed to the frame of the mechanism. The battery is powered by a generator. The generator’s power is sufficient to engage all the necessary electrical devices of the mechanism and connect the headlights to the tiller. The manufacturers themselves have foreseen the desire of users to figure out how to make light on a tiller, using generators on constantly rotating magnets with an automatic voltage regulator with a power reserve of about 30%. To connect all sources of electrical power to the generator, it is worth collecting them in a single circuit with double insulated wires. The diagram described above is an ideal picture, but sometimes you have to modify something or figure out how to connect a headlight.

Connection by means of an electric generator

The best way to turn on the light on the trailer is to use the generator supplied with the machine. As a rule, standard electric generators for all models of this special equipment have excess power that can be used to operate the lighting fixture. The connection of the headlamp to the energy source is carried out according to the following algorithm:

- using wiring, the lighting element is connected to the generator;

- one of the wires is equipped with a toggle switch, which it is desirable to place at the steering wheel or in another place convenient for the driver;

- after checking the functionality, the electrical wiring is placed in a protective corrugation and fixed on the body of the mini-machine.

If the standard generator has sufficient power, then the lighting will be bright and stable. When, with an increase in the load on the device, the lamp starts blinking and turns off, it makes sense to think about replacing the standard electric generator with a device from any tractor model.

Caution! When using equipment designed for other equipment, it is necessary to provide the tiller with additional support frames, which increase the strength of the fastening..

DIY lighting installation

Manufacturers of special equipment offer spare parts for tillers and ready-to-connect lighting kits, consisting of a headlight, toggle switch and wiring. However, many owners of units prefer to prepare and install lighting equipment on their own to avoid additional costs. Installing lighting on a mini-tractor with your own hands does not require special skills, the acquisition of expensive materials and the use of special equipment. Headlights from various Soviet-assembled vehicles are often used as a lighting device for agricultural machines..

Note! The brightness of the old flashlight may not be enough for special equipment to drive onto the track or perform a large amount of work. In addition, the service life of such a device does not exceed 2-3 months..

Tiller lighting

Despite the rich set of modern tillers, not all of them are equipped with such a useful option as lighting devices. Fortunately, solving this problem is quite simple if you put the headlight on the tiller with your own hands. Moreover, this does not require special skills and extensive experience..

Unit electrical system

Medium and heavy tillers are equipped with an electric generator that charges the battery and powers the headlight. The main function of the battery is to start the engine of the mini-tractor using an electric starter. On medium and heavy tillers, it is possible to connect several headlights (main and rear for a trailer), direction indicators.

The power of the working generator is sufficient for the installation of additional electrical equipment, as well as for the stable simultaneous operation of all electrical devices of the tiller. Manufacturing plants have provided for the possibility of additional installation of electrical equipment and equip mini-tractors with generators with a power reserve of about 30%.

The battery capacity corresponds to the starting current of the electric starter. Most mini-tractor models are equipped with generators without electrical excitation. It will be replaced by constantly rotating magnets. Most often, manufacturers install single-phase generators that produce alternating current..

How can you make a light on a tiller?

How to make a light on a tiller, because most models are not equipped with headlights? tiller (mini-tractor) is a mechanism that is designed for agricultural work (plowing, cultivation, watering, etc.). Many models can be used as a vehicle by means of trailers. In this form, tillers transport people and goods, which makes harvesting easier..

Self-made headlights

Small upgrades to an outdated headlamp will greatly increase its performance. To re-equip the luminaire filling, you need to prepare gypsum, fiberglass and epoxy. The process of alteration of the lantern takes place in several stages:

- the base of the headlamp is freed from the glass and other elements attached to it using plastic clips;

- To create an accurate dummy of the lamppost, liquid gypsum is poured over the entire area of the base of the lighting fixture. After complete drying, the cast is removed from the mold;

- three layers of fiberglass are applied to the finished copy, each of which is treated with epoxy. The mold should freeze for 24 hours under vacuum conditions (you can use a container with a hermetically sealed lid). Then the workpiece is carefully processed with sandpaper;

- the glass for the dummy is made of fiberglass, which is placed on a special platform made of wooden slats in an oven heated to 200 ° C (before that it is very important not to forget to remove the protective layer from the surface of the material);

- as soon as the fiberglass begins to deform, it can be removed and applied to the finished impression. Until complete cooling and hardening, the workpiece is again placed in vacuum;

- at the final stage of the process, the homemade headlight is sanded again with sandpaper and degreased.

The improved lantern can be equipped with one or a pair of halogen lamps or LED strip. After that, the product will be ready for installation on a mini-tractor..

Important! It is possible to install the headlamp on the tiller only after a complete check of the lighting device and exclusion of the possibility of a short circuit. For installation, it is desirable to use a rigid structure with four fasteners.

Light without battery and generator

When deciding how to make a headlight for their tiller, most make the most difficult technical decisions. Making a light without a generator and battery can be simple, fast and inexpensive if you use bicycle lights. This option can be used as the main or alternative light source for any motor vehicle: tiller, cultivator, lawn mower, snow blower. A properly sized flashlight can also be fitted to a motorized dog, towing vehicle or snowmobile.

Bicycle lights have the following advantages:

- no need for wiring;

- minimum financial investments with high efficiency;

- reliability in all weather conditions;

- availability of its own charger for portable batteries;

- the ability to mount on the steering column on the brackets that come with the kit;

- quick removal for manual use or for charging.

It costs two bike lights to purchase. It is advisable to use one for the main beam, the second for lighting directly in front of the unit.

How to make a light on a tiller with your own hands

The question of how to make the light on the tiller has to be decided by everyone who purchased this unit without a standard headlight. Today, most models of domestic and foreign production are designed to work only during daylight hours. And those that have a built-in flashlight do not always provide high-quality lighting. The factory headlight illuminates a narrow sector in front of the car and quickly becomes dirty. Ready-made kits are on sale that can be installed on the Tiller Neva, Plowman, Volgar, Forza and other domestically produced units. With an average quality, such sets are expensive. You can save well if you make a light on the tiller with your own hands. With a headlamp, the cultivator will become much more functional and more convenient to use. Consider the options for how to connect the headlight to the tiller.

Battery lighting

You can make a light on a tiller without a generator by installing a 12 V battery. The battery from a motorcycle, moped or boat is taken as a power source. Don’t give up your car battery. If you put a heavy power source on the cultivator, then you can solve several associated problems – equip the unit with an electric starter and significantly weight its body. In addition, it will be useful to be able to illuminate the area at night without the engine running. This feature can come in handy for a picnic or night fishing..

Installation of a headlight on a tiller using a battery is carried out in the following sequence:

- Arrangement of the frame for the power supply. It is best to use a steel corner for this. The frame should be fixed directly to the frame of the motor cultivator body. After lowering the battery into a niche, it is firmly fixed in it using steel straps.

- Attachment of a lantern and auxiliary lights. The headlight on the tiller is placed so that it illuminates the widest possible sector without dazzling the operator and oncoming vehicles. It is better to choose devices with an adjustable angle of illumination.

- The location of the electric cable in the corrugation along the unit body. Installation and connection of control devices. Checking the correct assembly of the electrical system with a tester.

- Connecting the wire to the battery terminals, leading the wire to the junction box. Connection of wires to the switch, insulation of joints, joints and twists.

In order for the battery capacity to last for a long time, LED lamps must be inserted into the lanterns. They consume negligible amount of energy, creating bright lighting..

If the battery is not located under the standard hood of the tiller, then it is necessary to make a separate casing. To do this, you can take a piece of dense plastic, give it the desired shape and screw it to the homemade racks on the frame..

When deciding to install a battery, you should consider recharging it. To do this, you will need to purchase a charger or install an electric generator on a motor-cultivator..

Using a generator

If the unit is equipped with its own generator, then the solution to the issue of arranging lighting is greatly simplified. You just need to install the flashlight and supply power to it.

To do this, you will need the following tools and devices:

- electric drill;

- soldering iron;

- screwdriwer set;

- spanners;

- nippers;

- stationery knife;

- electrical cable;

- heat-shrink tubing;

- headlight, side and turning lights.

Installation of a headlight on a tiller using a standard generator is carried out in the following sequence:

- The bases of the lighting fixtures are screwed to the body of the unit. It is advisable to put the headlight on the tiller on a separate bracket located on the front part with an elevation above the ground of 100-120 cm.

- On the steering column we install buttons for turning on the lamp, turning and side lights. You should choose devices of increased strength, in a waterproof design. Fixation is carried out with clamps or self-tapping screws for metal.

- The electrical cable is pulled into a corrugated tube. This must be done so that the wiring is protected from moisture, mechanical damage and rodents. The corrugated tube is pulled to the steering column and frame so that there is no sagging.

- The wires are connected to the generator and the terminals of the electrical equipment. The engine is started and the lighting system is tested. After that, all twists and joints are insulated.

When idling and at low speeds, the light dims. To keep the lighting constant, you need to use a voltage regulator or install a powerful generator..

Electric generators from MTZ tractors and ZAZ cars have proven themselves well..

These devices are compact, they can easily find a place on the body of the cultivator. To connect a non-standard generator for a tiller, you will need to make an additional bracket. It is assembled from a steel corner on the frame of the machine (there are many videos available on the Internet with a detailed description of the manufacture).

How to make light on tiller MTZ-09

Tiller MTZ-09, like many others (for example, Neva, Zubr, Agat), is not equipped with a headlamp for working in the evening and at night. If necessary, lighting can be made and installed by hand.

To make a headlamp for MTZ-09, MTZ-09n or any other tiller on your own, you will need:

- electrical wire;

- LED or halogen bulb (optimal power – 5 W with a minimum angle of light scattering);

- a body from a faulty energy-saving diode lamp, or from a small bicycle headlight;

- household switch or toggle switch.

To connect the lighting to the tiller, you can use the algorithms proposed above: through a battery without a generator, or using a standard generator.

Lighting options for vehicles of any class

Although manufacturers create tillers without lighting, they additionally sell ready-made lighting kits for their own products. In this case, there are no questions about the connection and the quality of the systems. If you do your own lighting development, it can be difficult.

How much adrenaline is in your blood

Therefore, it is necessary to think over a number of steps in advance:

- used electrical circuit;

- way of power supply of headlights;

- the right choice of light.

Lighting on the tiller can be done by yourself

From generator

Most manufacturers make tillers with electric generators with sufficient power for the regular operation of equipment and connecting lighting. If the equipment is weak, you can replace the generator with a more suitable type..

Without a generator and battery, you can connect the lighting yourself

Step-by-step installation instructions:

- connect wires to the generator contacts, and one of them must be connected via a button;

- conduct wiring from the generator and switch to the lighting fixture and check the operation of the system;

- fix the headlamp to the frame and use protective elements to prevent moisture and damage.

You can independently connect the lighting without a generator and battery, but this will require a headlight with an independent power source.

From ignition

An alternative version of the light on the tiller with your own hands without a generator is to connect to the ignition contacts. Each time after starting the engine, power will appear and the installed headlight will light up. The main disadvantage is the inability to turn off the equipment until the tiller dies.

When considering options for how to put a headlight on a tiller from the ignition, they think about the convenience of using lighting. It is necessary to consider additional elements that will allow you to turn off the light when parking, regardless of the state of technology.

Connecting to the ignition contacts – an alternative version of the light for the tiller

How to make a light on a tiller?

Many manufacturers of tillers produce equipment designed for operation during the daytime, therefore lighting elements are not provided. To cope with the problem, the owners install the lighting themselves, extending the life of the electrical equipment. Below are the details on how to make the light on the tiller, the features of mounting the headlights, as well as the difficulties that arise and how to solve them..

Necessary tools for the job

Before starting work, it is necessary to prepare all materials, including wiring, headlight, corrugation, and also assemble a set of tools:

- soldering iron;

- screwdrivers and wrenches;

- nippers and stationery knife;

- electrical tape and heat shrink tubing;

- electric drill and fasteners.

Electrical diagram

The headlight connection diagram is quite simple and consists of only three main elements:

- a power source, including an ignition, generator, or battery;

- power switch – a simple button that breaks and turns on the power supply circuit for the lamp;

- lamp holder to which wires from a power source are connected through a switch.

A fairly simple diagram for connecting a headlight to a tiller

For greater reliability, all wires are placed in a special corrugation. The material protects the electrical wiring from damage and allows you to fix the equipment in such a way that it does not interfere with the use of the tiller.

With your own hands

Almost all owners of tillers resort to using headlights from Soviet light vehicles as lighting equipment. This is one of the easiest ways to solve the problem..

But do not forget that such a light will not be bright enough, and it is unlikely to please you with a long service life..

Therefore, the best option is considered to be the independent manufacture of such electrical equipment. You do not need to purchase expensive sources and equipment. All you need is the same headlight from a Soviet car. You will only replace the inside.

So, to begin with, the outer glass and other elements, fixed with plastic clips, are removed from the headlight. The next step is to make a dummy body of the lighting device. It is made of plaster. Liquid gypsum is poured into the base of the fixture and spread evenly over the entire base. Wait until the plaster is completely dry, then the impression must be carefully pulled out.

Please note that experts do not recommend artificial drying, so it is better to wait until the gypsum hardens naturally..

Three layers of fiberglass should be applied to this template. Be sure to apply epoxy between coats. It is inexpensive, on the market it .

After all the steps taken, your workpiece should lie at room temperature in a hermetically sealed container, without air penetration. Wait until the dummy is completely dry. Next, you will need to grind the product so that there are no irregularities on it..

Now comes the most important step – you need to make glass. To do this, you need to heat the oven to a temperature of 180-200 C. Buy thin slats in advance and make them a stand. The manufacture of such a structure will require about 10 rails. Then attach the fiberglass to it. Remove the protective layer of the material. Otherwise, the workpiece will absorb all the dust. You can send the workpiece to the oven.

Open the oven periodically and check the product. As soon as it begins to deform, you can take it out and apply it to the material that was prepared a few steps above. All this is again sent to a sealed container with a tight-fitting lid. Wait for complete hardening.

The resulting headlamp is carefully polished. For these purposes, you can even use sandpaper. Next, we treat the surface with a solvent and wait until it dries. The next step is to install an incandescent lamp with a buffer gas. One halogen lamp in Russia costs about 700 rubles. Instead, you can use LED strip as a more budgetary replacement..

Do not immediately install the lighting fixture. Previously, it must be checked several times for short circuits, and only after that the headlight can be attached to the tiller. Do not use a suspended structure to install it. Such a light source must be fixed in at least four places..

Without generator

Another method of connecting lighting is widespread among operators. Here it will be possible to do without using a generator. You will need a 12 volt battery and LED strip.

There is no need to specially purchase a new battery. For this purpose, you can use an old electric scooter battery..

In addition to the source code, you must think in advance where this device will be mounted. If you are the owner of a large vehicle, then the ideal solution would be to mount a battery between the gearbox and the engine..

Step-by-step actions:

- Using welding and an iron angle, you need to make a stand for your gel battery. It is attached to the frame of the mini tractor.

- A battery is installed from the inside, which is clamped by a pair of bolts and a metal insert.

- Wires are laid from the battery to the power button. All joints must be soldered and insulated with heat-shrinkable tape.

This kind of lighting will turn out to be very bright. However, this method of installing headlights has one negative side: a full charge of the battery is enough for literally a couple of hours of operation, after which it will need to be recharged again. This is a very significant disadvantage for those who work intensively with a mini tractor..

Power generator

After you have built the main part of the light source, you need to connect it to the generator. You can use any standard electric generator from a mini tractor. For this purpose, many trailer manufacturers produce vehicles with excess capacity. This power is just spent on lighting and installing a car signal..

Such an electric generator is more than enough for a given light source..

To equip the tiller with lighting, just follow the steps below:

- First of all, route the wiring from the generator to the headlight.

- Install the power button near the steering wheel, or in another place convenient for the driver. A wire is also removed from it and connected to the headlamp. Check the quality of lighting and the operation of the power button.

- If all is well, then disconnect all wiring. The wires should be protected with a corrugation. Otherwise, you could accidentally pick them up and damage them. Also, without protection, the possibility of water ingress and short circuit is not excluded..

If the generator is powerful enough, you get very bright lighting with a high beam. The low power of the generator may be indicated by the constant flashing of the headlight at high loads on the tiller. If you are faced with just such a situation, then a reasonable solution would be to replace the standard unit with an electric generator from any tractor made in Minsk. Its power will definitely be enough for you.

Do not forget that if you are installing a third-party electric generator, then standard mounts will not work for it. You will have to cook additional ones. Lighting coil is used for connection.

After successful installation, check the wiring. Get in the habit of checking your contacts every time you work with a tiller. Otherwise, moisture may get in, which will affect the operation of the tiller as a whole..

How to make a light on a tiller?

- With your own hands

- Power generator

- Without generator

- From ignition

In the modern world, all mini tractors are very well equipped. Despite this, not everyone has lighting equipment. However, solving this problem will not be difficult. Everyone can put a headlight on a tiller without having any knowledge of electrical engineering. Everything is done very simply and according to the instructions..

From ignition

This is the easiest way to create a light source. You need to route the wire with one end to the ignition and the other to the headlight switch. Such a light source will work stably. This connection method also has a disadvantage: with the ignition off, you cannot turn on the headlight.

All of the above lighting installation options are compatible with absolutely any brands of tillers and mini tractors manufactured both in Russia and abroad..

To learn how to make light on a tiller, see the video below..

Power generator

After you have built the main part of the light source, you need to connect it to the generator. You can use any standard electric generator from a mini tractor. For this purpose, many trailer manufacturers produce vehicles with excess capacity. This power is just spent on lighting and installing a car signal..

Such an electric generator is more than enough for a given light source..

To equip the tiller with lighting, just follow the steps below:

- First of all, route the wiring from the generator to the headlight.

- Install the power button near the steering wheel, or in another place convenient for the driver. A wire is also removed from it and connected to the headlamp. Check the quality of the lighting and the operation of the power button.

- If all is well, then disconnect all wiring. The wires should be protected with a corrugation. Otherwise, you could inadvertently pick up and damage them. Also, without protection, the possibility of water ingress and short circuit is not excluded..

If the generator is powerful enough, you get very bright lighting with a high beam. The low power of the generator may be indicated by the constant flashing of the headlight at high loads on the tiller. If you are faced with just such a situation, then a reasonable solution would be to replace the standard unit with an electric generator from any tractor made in Minsk. Its power will definitely be enough for you.

Do not forget that if you are installing a third-party generator, then standard mounts will not work for it. You will have to cook additional ones. Lighting coil is used for connection.

After successful installation, check the wiring. Get in the habit of checking your contacts every time you work with a tiller. Otherwise, moisture may enter, which will affect the operation of the tiller as a whole..

Without generator

Another method of connecting lighting is widespread among operators. Here it will be possible to do without using a generator. You will need a 12 volt battery and LED strip.

There is no need to specially purchase a new battery. For this purpose, you can use an old electric scooter battery..

In addition to the source code, you must think in advance where this device will be mounted. If you are the owner of a large vehicle, then the ideal solution would be to install a battery between the gearbox and the engine..

Step-by-step actions:

- Using welding and an iron angle, you need to make a stand for your gel battery. It is attached to the frame of the mini tractor.

- A battery is installed from the inside, which is clamped by a pair of bolts and a metal insert.

- Wires are laid from the battery to the power button. All joints must be sealed and insulated with heat-shrinkable tape.

This kind of lighting will turn out to be very bright. However, this method of installing headlights has one negative side: a full charge of the battery is enough for literally a couple of hours of operation, after which it will need to be recharged again. This is a very significant disadvantage for those who work intensively with a mini tractor..

How to make a light on a tiller?

- With your own hands

- Power generator

- Without generator

- From ignition

In the modern world, all mini tractors are very well equipped. Despite this, not everyone has lighting equipment. However, solving this problem will not be difficult. Everyone can put a headlight on a tiller without having any knowledge of electrical engineering. Everything is done very simply and according to the instructions..

With your own hands

Almost all owners of tillers resort to using headlights from Soviet light vehicles as lighting equipment. This is one of the easiest ways to solve the problem..

But do not forget that such a light will not be bright enough, and it is unlikely to please you with a long service life..

Free energy generator with light bulbs very easy – free energy 100%

Therefore, the best option is considered to be the independent manufacture of such electrical equipment. You do not need to purchase expensive sources and equipment. All you need is the same headlight from a Soviet car. You will only replace the inside.

So, to begin with, the outer glass and other elements, fixed with plastic clips, are removed from the headlight. The next step is to make a dummy body of the lighting device. It is made of plaster. Liquid gypsum is poured into the base of the fixture and spread evenly over the entire base. Wait until the plaster is completely dry, then the impression must be carefully pulled out.

Please note that experts do not recommend artificial drying, so it is better to wait until the gypsum hardens naturally..

Three layers of fiberglass should be applied to this template. Be sure to apply epoxy between coats. It is inexpensive, on the market it .

After all the steps taken, your workpiece should lie at room temperature in a hermetically sealed container, without air penetration. Wait until the dummy is completely dry. Next, you will need to grind the product so that there are no irregularities on it..

Now comes the most important step – you need to make glass. To do this, you need to heat the oven to a temperature of 180-200 C. Buy thin slats in advance and make them a stand. The manufacture of such a structure will require about 10 rails. Then attach the fiberglass to it. Remove the protective layer of the material. Otherwise, the workpiece will absorb all the dust. You can send the workpiece to the oven.

Open the oven periodically and check the product. As soon as it begins to deform, you can take it out and apply it to the material that was prepared a few steps above. All this is again sent to a sealed container with a tight-fitting lid. Wait for complete hardening.

The resulting headlamp is carefully polished. For these purposes, you can even use sandpaper. Next, we treat the surface with a solvent and wait until it dries. The next step is to install an incandescent lamp with a buffer gas. One halogen lamp in Russia costs about 700 rubles. Instead, you can use LED strip as a more budgetary replacement..

Do not immediately install the lighting fixture. Previously, it must be checked several times for short circuits, and only after that the headlight can be attached to the tiller. Do not use a suspended structure to install it. Such a light source must be fixed in at least four places..

From ignition

This is the easiest way to create a light source. You need to route the wire with one end to the ignition and the other to the headlight switch. Such a light source will work stably. This connection method also has a disadvantage: with the ignition off, you cannot turn on the headlight.

All of the above lighting installation options are compatible with absolutely any brands of tillers and mini tractors manufactured both in Russia and abroad..

To learn how to make light on a tiller, see the video below..

Connecting the headlight to the tiller generator

Installing the light on the tiller with your own hands is quite simple if you use a standard electric generator of an agricultural machine for this. Especially for this, many equipment manufacturers produce tillers with generators, the power reserve of which is slightly increased specifically for mounting lighting. Thus, the power of the node is quite enough for uninterrupted power supply of lighting devices and sound signal.

To install the headlights on the tiller, and connect them to the generator, you need to proceed in this order:

- Connect the generator by means of a wire to the switch, which must be fixed near the steering wheel or in another place convenient for the operator;

- Dissolve the wiring from the switch and connect to the headlamp, then check the operation of the lighting device;

- Then disconnect the wires and place them in a dense corrugation that protects the wiring from moisture and mechanical damage..

If the generator has a sufficient power reserve, then the headlight will shine uninterruptedly and brightly. If the unit is not powerful enough, the headlamp will flash every time the engine goes into operation at low rpm. In this case, it is best to change the standard tiller generator to a unit from MTZ tractors. It should be remembered that to install a new generator in the tiller structure, additional support frames will need to be welded, and a lighting coil must be used to connect the node..

After connecting, regularly check the integrity of the wiring contacts, otherwise, if moisture gets on them, a short circuit may occur in the tiller’s power supply.

Tiller lighting

Despite the rich set of modern tillers, not all of them are equipped with such a useful option as lighting devices. Fortunately, solving this problem is quite simple if you put the headlight on the tiller with your own hands. Moreover, this does not require special skills and extensive experience..

Headlight to tiller – self-production

Many owners of tilers use headlights from domestic and imported cars to install on their units. This method is the simplest, however, it should be remembered that the old headlight on the tiller will not emit bright enough light and will last no more than several months..

It is much better to make your own farm vehicle lighting. This does not require the purchase of expensive materials and equipment. You will need the same old headlight, the filling of which you will replace with new parts in the future. The order of work is as follows:

- Remove the existing glass surface and other elements from the old headlight that are attached to the base with plastic clips;

- Next, make a plaster cast based on the headlight frame. To this end, pour the still liquid material into the headlight base along its entire perimeter. After the final drying of the gypsum mass, it must be carefully removed;

- Apply 3 layers of fiberglass to the impression. There should be a layer of epoxy between each of the tiers. Place the workpiece in a vacuum and wait at least a day – during this time the impression will completely solidify. After that, align the workpiece so that even the slightest chips do not remain on it;

- Start making glass for your homemade headlight. To do this, preheat the oven to 190 ° C, make a stand of 8 battens fastened together and fix a glass fabric sheet in it. Before putting the mold in the oven, do not forget to remove the protective film from the material, otherwise it will be covered with dust particles;

- As soon as the material sags in the stand, remove it from the oven and apply it to the previously made workpiece. The product must be placed and kept under full vacuum until it hardens..

After hardening, the manufactured headlamp will need to be carefully sanded, degreased and dried. Further, 1-2 halogen lamps or LED strip are placed inside it. Installation of the headlight on the tiller is carried out after a thorough inspection of the lighting fixture. To put the headlight on the tiller, be sure to use a reliable frame and at least 4 fasteners.

How to make a light on a tiller without a generator?

There is another way that allows you to connect the light on the tiller without a generator. It requires a 12 volt battery and LED strip. It is not necessary to buy a new battery – an old gel cell from an electric scooter will work fine.

In addition to the materials, you will need to determine in advance the location of the battery installation. Since it has a small size, it is best to place it between the engine and the tiller’s gearbox. The further work plan is as follows:

- From a steel corner, make a mount that will match the size of the battery used;

- Position and fix the bracket on the frame of the unit;

- Install the battery inside the mount, fix it with a steel plate and two bolts;

- Route the wiring from the battery to the switch and headlight. Fix the connection points with soldering and insulate with tape. To get acquainted in more detail with connecting the headlight on a trailer without a generator, the video will help.

The light from the battery-powered headlight is intense and bright enough. However, this method has one significant drawback – the battery capacity will last no more than a few hours of continuous operation, after which the power source will need to be charged..

In this case, you can make a light on the tiller from the ignition. To do this, one end of the wiring must be connected to the ignition system of the unit, the other end to the switch, and from it to the headlight. The lighting device connected in this way will work only when the ignition of the tiller is turned on..

All of the above methods of manufacturing and connecting the headlight are suitable for Neva, MTZ and agricultural vehicles produced by other domestic and foreign manufacturers..

How to make a light on a tiller without a generator?

It is quite possible to connect the light on the tiller without a generator. You will need an LED lamp and a 12-volt battery. You can use a rechargeable battery (battery) from a car, a gel battery that is installed on e-scooters / e-bicycles.

It is important to choose the right place for installing the battery. It is often compact in size, so you can use the area on the frame between the engine and the gearbox..

The installation of the battery is carried out as follows:

- Steel fasteners are being prepared. They should be sized to fit the battery;

- The ready-made fasteners are screwed to the frame with four bolts to securely fix them;

- The battery itself is installed, for which you will need two bolts, nuts and a metal plate;

- The electrical wire runs from the battery to the switch, then to the electrical equipment (headlight on the tiller). All sections of the connection of wires are fixed by soldering and are qualitatively insulated.

As a rule, a headlight connected to a battery shines evenly and intensely. The battery charge will last for a couple of hours of continuous operation, but periodically it will need to be recharged from an electricity source. Therefore, it is worth trying to make the light on the tiller from the ignition. The wire connects directly to the ignition system, toggle switch and headlight. So the lighting is switched on only during operation of the unit..

Connecting lighting to the tiller

A large number of different types of tillers are presented on the agricultural machinery market. But not all models have standard lighting. This problem can be solved with the help of simple modernization manipulations..

How to carry out lighting on motor vehicles from a generator?

The easiest way to make a light on a tiller with your own hands is from a “native” electric generator. If the manufacturer provides for such a possibility, then the installed generator has a certain power reserve. It will be enough for the normal functioning of the key electrical appliances of the tiller and power supply of the additionally installed electrical equipment (turn signals, headlights, sound signal).

The algorithm for connecting light from an installed electric generator does not differ in complexity:

- Connect the power generating device to the switch on the steering column using a wire;

- Dissolve the wiring system from the switch to the electrical equipment (on the tiller, this is the headlight);

- Place the wires in a corrugation to protect them from mechanical damage. So they will not dangle and interfere when working on the unit..

If the generator has a high enough power level, then the lighting will be good. When the light goes out at low speeds, it is necessary to change the installed electric generator to a device from a tractor or machine.

You can install a generator from “Zaporozhets”. The device is small in size, therefore it is easy to fit in the area between the motor and the gearbox. Installation is simple. Fasteners are preliminarily made to fasten the generator and fix it on the frame: strong metal slats are welded to the frame, after which the clamp is attached.

The presented diagram will help you understand the correct attachment of the device to the tiller..

An electric generator from an old or new car is able to provide normal lighting for the tiller. It is also possible to solve other problems with the connection of various electrical equipment..

How the headlight is connected to the tiller?

Not all Tillers come with a headlight. Therefore, making lighting on the tiller with your own hands,

you need to decide on a suitable part:

To make a headlight, you will need some elements: the body of an old or burnt housekeeper, a small piece of electrical wire, a toggle switch (switch) or a simple switch.

You can connect the headlight to the tiller by adhering to the following scheme:

- Secure the toggle switch. Its location must be practical and reliable. Optimally – the steering rod of the unit near the shift lever;

- Put the headlight on the tiller. For this, the manufacturers have provided a special place in front of the engine or on the steering column. The stationary lighting element in front of the engine can quickly become dirty, and the light from it is directed only to the ground. Therefore, a moving headlight is more suitable, in which the light can be directed in a certain direction;

- Pull the wire. This is often done from the nearest power source. For example, a 12-volt oil pressure warning lamp, which is located on the steering unit;

- The wire is located as follows: from the power source to the switch, from the toggle switch to the headlight on the tiller. All wiring must be carefully tied to the handle bar with electrical tape or secured with special clamps.

Halogens can illuminate the tiller, but their drawback is rapid overheating and failure. It is optimal to use light sources of 5 W with a small dispersion angle, they economically consume electrical energy, shine brightly and at a long distance.

The proposed videos will help you understand the features of providing lighting for motor vehicles.

The described methods allow you to make light and install headlights on the most popular brands: Neva, MTZ, Centaur, Bison and others. After all, most of them are without regular lighting..

Headlight for tiller

Magneto device and principle of operation

Magneto is a source and distributor of high voltage current used in carburetor engines to ignite the working mixture. Its principle of operation is shown in Figure 59. When the pole pieces of the rotating magnet (rotor) 5 are located against the shoes of the magnetic circuits 4, almost all magnetic power mowing lines are closed through the core of the transformer 15. If the rotor turns 90 ° (neutral position), the magnetic power mowing lines closed through an air gap between pole pieces and shoes.

When the rotor turns to the neutral position, the magnetic power of the mowing line crosses the turns of the primary 14 and secondary 13 windings of the transformer, as a result of which an electromotive force (e.m.f.) is induced in them..

17.07.2018

Magneto circuit

With closed contacts 1 and 2 of the breaker under the action of e. etc. with. a current flows in the primary winding, which creates its own magnetic flux around the transformer core. At the moment of opening the contacts, the current in the primary circuit disappears and the magnetic field is sharply reduced. In this case, e is induced in the secondary winding. etc. with reaching 10-25 thousand volts. Since at this moment the movable electrode of the distributor is opposite one of the fixed electrodes, a high voltage current will flow in the secondary circuit along the following path: the secondary winding of the transformer 13, the spring contact 12 of the distributor, the air spark gap between the movable 11 and the fixed 10 electrodes of the distributor, the high voltage 9, the electrode of the spark plug 8 and the spark gap of the spark plug, the mass of the engine and magneto, the primary winding 14, the secondary winding.

At the moment of opening the breaker contacts, the magnetic power of the mowing line also intersects the primary winding of the transformer and therefore e. etc. with. self-induction. Its voltage (200-300 V) is sufficient to break through the air gap between the opening contacts, so a self-induction current can pass in the primary circuit for some time. It slows down the disappearance of the magnetic field, and, consequently, reduces the e. etc. with. in the secondary circuit. In addition, sparking in the contacts of the breaker leads to their burning. To avoid this, a capacitor 16 is connected in parallel to the contacts of the breaker, thanks to which, at the moment of opening the contacts, the self-induction current does not pass in the form of a spark between the contacts, but goes to charge the capacitor.

The current passing in the primary circuit will reach its greatest value when the rotor turns from neutral to a certain angle. It was at this moment to get the greatest e. etc. with. in the secondary circuit, the breaker must open the primary circuit. The angle of rotation of the rotor from the neutral position to the moment the breaker contacts open is called the magneto outline. Its value for various types of magneto ranges from 8 to 18 °.

Magneto

Types of tractor engine magneto

Depending on the direction of rotation of the rotor, magneto are distinguished:

According to the number of sparks that a magneto can give in one revolution of the rotor, magneto are:

How to Build an Engine/Alternator Generator 2/2 Putting it Together

- single spark

- two-spark.

By size, magneto is usually divided into two groups:

- small-sized

- with normal dimensions.

Tractor magneto with normal dimensions is intended for engines with at least four cylinders. Temporarily this type of magneto was used on the D-14 and D-24 engines..