Additional drawings of a homemade trailer

Additional materials with a detailed description and diagrams of individual nodes of the trailed device for the tiller will help determine the design and give an idea of the assembly stages.

Tiller trailer drawings

Conventionally, the trailer can be divided into several main units: carrier, frame, body, wheels.

The carrier includes several parts connected by welding. The main load here is taken by the joint of the drawbar with the body of the swivel unit, therefore this place is reinforced with 4 stiffeners.

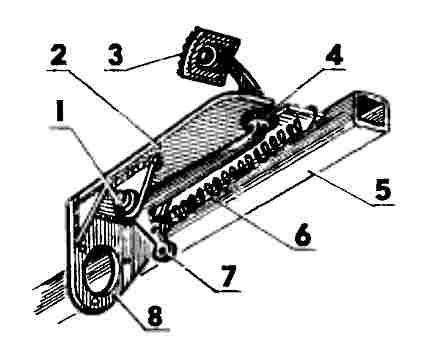

Running node

1 – semiaxis; 2 – bearing 206 (2 pcs.); 3 – an oil seal (felt ring); 4 – semi-axle body; 5 – spacer sleeve; 6 – stopper (screw М8, 2 pcs.); 7 – spring ring, persistent; 8 – trailer axle (pipe 49 × 4.5); 9 – frame.

Brake pedal

1 – axis; 2 – footboard; 3 – pedal; 4 – shock absorber (rubber ring); 5 – drawbar; 6 – returnable spring; 7 – pedal lever; 8 – bracket for fastening the main brake cylinder.

Hydraulic brake drive device: 1 – brake pedal; 2 – brake cylinder, main; 3 – connecting nipple; 4 – pipeline; 5 – tee; 6 – bracket (strip 60 × 14, s2); 7 – rubber bushing.

Trailer to the tiller – starting to manufacture

Trailer for the tiller: 1 – bracket for mounted implements of the tiller “Electronic”, 2 – console, 3 – carrier, 4 – footboard (20mm board), 5 – driver’s seat (20mm board), 6 – frame, 7 – body (20mm board) , 8 – support beam (timber 50 × 50mm, 3 pcs.), 9 – M8 bolt, 10 – thrust ring (pipe 58 × 4), 11 – wheel (from motorized carriage SZD, 2 pcs.). – commonly. View

Homemade trailer to the tiller video compilation

Also, we present a video that shows how to make a trailer for a tiller with your own hands on the experience of people who coped with this matter..

How to make a trailer for a tiller with your own hands?

Having received one more wheel axle, the body and seat of the tiller turns into a universal assistant that can be successfully used all year round.

a trailer with a trailer will successfully replace not only a mini-tractor, but also a truck. And if the trailer has a tipper device, then you do not have to swing a shovel, unloading sand or gravel, black soil or manure.

The factory trailer for the tiller can have a lifting capacity from 300 kg to one ton and different body sizes. It all depends on the technical characteristics of the tiller, so trailer manufacturers adapt their products for light, medium and heavy hand tractors (tillers).

Today, the choice of tillers is very wide, so there are many varieties of cargo adapters for them. The size range of bodies of such trailers is represented by the following options.

For light tillers, trailers with a body width of 1 and a length of 0.85-1.15 meters are usually used. The carrying capacity of such adapters does not exceed 300 kg.. .

For bogies designed to work with medium power tillers (4.8-8 hp), the body size is 1.0×1.5 m or 1.1×1.4 m with a carrying capacity of 300 to 500 kg. The cost of cargo adapters of this class depends on the configuration and the manufacturing company and can range from 19 to 40 thousand rubles.

For heavy machines over 10 hp. use single-axle or two-axle trailed bogies with a body width of 1.2 and a length of 2 to 3 m. They are capable of carrying loads weighing from 500 kg to 1 ton. The price of such adapters ranges from 42 to 60 thousand rubles..

The height of the sides of standard motoblock trailers is from 30 to 35 centimeters. For heavy-duty bogies, frame side fences with a height of 50-60 cm are used.

Trailers with a lifting capacity of more than 350 kilograms are equipped with a mechanical brake. This is required by safety regulations. When driving down a steep incline, you will not be able to extinguish the inertia of a loaded trailer with one tiller brake. Therefore, when choosing a trailer for a heavy hand tractor, be sure to pay attention to the presence of this option..

The standard tipper trailer for light and medium-sized trailers does not have a lifting hydraulic cylinder. The body is installed in it in such a way that the center of gravity of the load is on the pivot axis. This central balancing makes manual tipping much easier..

To increase the convenience of loading and unloading, some models of trailers, in addition to the rear, also have two side opening removable sides.

Trailer bodies are most often made of painted galvanized sheet, painted black steel sheet or impact resistant plastic. The first option is the highest quality and most durable, albeit the most expensive..

DIY trailer for a tiller

A trailer for a tiller, a necessary thing, and sometimes even necessary in a private household. In this material, we will consider how to make a trailer for a tiller with our own hands, focusing on the drawings and descriptions for them.

In the diagram below, a homemade trailer for a tiller, capable of carrying a load weighing more than 400 kg, but first things first. The trailer is equipped with a driver’s seat, it is unpretentious in operation and quite easy to manufacture.

Control device

The work of a home-made tiller or motor-cultivator, like any machine, must be controlled. The control devices for such homemade products are usually handles – they are attached directly to the frame of the frame. They are made from two thick-walled pipes that are bent to give a comfortable shape (the video demonstrates this well).

At their ends, throttle levers and clutches are installed, removed, for example, from an old moped.

The KP and kickstarter levers of the motor cultivator are made of a metal bar with a diameter of 10 mm. The kickstarter on a homemade product is taken back, closer to the operator, thereby making it easier to start the diesel engine. Also, in a convenient place, the brake levers and gearshift levers are fixed..

In a self-propelled tiller, you can make a convenient steering adapter instead of handles. A car steering column with a bipod or removed from a tractor is ideal for this. In such a mechanism, the bipod acts as a hitch, combining the cart with homemade products. In the assembly of the steering adapter, a ball joint is used – it allows you to make the hitch independent. The whole process of preparing a homemade hitch is better seen in the video.

Self-propelled rake

Despite the presence of a factory rake, many farmers prefer to make them themselves, taking into account the characteristics of their economy: the size of the meadow, the relief.

As materials for the rake, metal pipes and hardened rods are used. Alternatively, you can use the factory manual forks by welding them to the base. For the convenience of work, it is advisable to install small wheels or paws-skis at the edges, which will relieve the load on the entire structure.

The expediency of homemade products

Despite the fact that there is a wider variety of attachments on the market, it may not always be suitable for certain tasks. And the price-quality ratio sometimes leaves much to be desired. Therefore, many gardeners make the necessary accessories for tillers with their own hands. To do this, it is enough to have a drill, an angle grinder and a welding machine at hand, as well as to have the skills to work with them..

Only in some cases, when more accurate calculations and turning work are needed, do you have to turn to narrow-profile specialists.

A plus in the direction of homemade products is the fact that at any disassembly you can easily find the necessary unit or assembly from an old car, suitable for construction.

Field sprayer manufacturing

A homemade sprayer for a tiller is necessary in cases where the area of cultivated crops exceeds 20 acres. It is very difficult to do such work manually, it can take a whole day. Mechanizing this process will save a lot of time and effort..

To manufacture a sprayer you will need:

- welding machine;

- Angle Grinder;

- level;

- electric drill;

- soldering iron for polypropylene pipes;

- shaped or round water pipes;

- plastic or steel barrel with a capacity of 80-100 liters;

- wide pneumatic wheels;

- plastic pipes;

- rubber hose;

- nozzles or nipples from wheel tubes.

The assembly of a homemade sprayer is carried out in the following sequence:

- Frame manufacturing. Its dimensions are adjusted to the size of the container. The chassis is attached to the frame. For good cross-country ability, at least 4 wheels are required. In the absence of wheels, wide skids are made of aluminum.

- The container is installed and fixed on the frame. For this, spacers and ties are used. Holes are made in the tank for the supply of high pressure hoses. The filler neck is sealed.

- A bracket for the pump is being manufactured. A model is selected that works from a power take-off shaft (belt drive) or from electricity (tiller generator).

- The watering system is being assembled. A durable holder is made of steel profiles. Plastic pipes are attached to it with clamps or plastic ties. Overpressure relief valve and nozzles are being installed.

- All parts are connected together, the quality of the fasteners is checked, the tightness of the joints. The tank is filled with water, the unit is tested in various modes, the final adjustment and adjustment is performed.

A self-made sprayer will fully justify the effort invested in the first season. Thanks to this device, spraying and watering of the garden will be carried out quickly and efficiently..

Very often, the acquisition of a tiller is due to the performance of a single task, but over time, its owner has a desire to make his technique universal. Many people wonder what can be done from a tiller to improve it. In fact, there are a large number of craftsmen who can adapt anything for other tools: the main thing is to have certain technical skills for this, combined with creative ingenuity..

Tiller blade

The dump is a necessary device that is needed at any time of the year. The front knife is used to clean snow, plan the area, dig holes and move bulk materials. Such equipment for the Neva tiller is of good quality, but not everyone can afford it. Do-it-yourself dumps require minimal financial investment. By installing the front knife on the Neva tiller, you can solve many household tasks. With levers and hydraulics, a homemade shovel can also be used as a loader..

To make a blade, you will need the following tools:

- roulette;

- welding machine;

- electric drill;

- Angle Grinder;

- spanners;

- acrylic paint;

- barrel 200 l;

- reinforced rubber;

- sheet steel 5 mm;

- profile pipe 40×20 mm;

- paint and brush;

- bolts and ties.

Before making a dump, it is necessary to calculate the correspondence of the power of the tiller to the size of the bucket. Excessive loading leads to rapid wear of parts and mechanisms of the unit. Depending on the weight and power of the machine, shovels are made 60-100 cm wide and 20-30 cm high.

Do-it-yourself snow removal homemade products for the tiller are made in the following sequence:

- Marking the barrel, sawing it into 3 identical parts vertically. Cutting 1 piece into strips 5 cm wide.

- Bonding 2 blanks with bitumen and rivets. Aligning the edges of the product. Bucket reinforcement with transverse struts.

- Fastening of sheet metal strips along the edges of the shovel. This is done with welding or bolts..

- Drilling bolt holes. Attaching a rubber strip to the bottom of the bucket.

- Shovel hitch making. It is done by attaching a piece of pipe and a semicircle of sheet metal to the blade by welding. Holes are made on the sector to adjust the angle of attack. A self-made snow removal device is attached to the tiller bracket with an adapter from a profile pipe.

The finished product needs to be cleaned and painted. All bolted connections must be lubricated regularly to prevent corrosion..

Inexpensive device with great functionality

A home-made tiller or a motor-cultivator is an economical and very useful motor unit in the household. He is able to perform all kinds of agricultural operations, thereby freeing a person from tedious physical labor. In the video below, you can see all the functionality of this wonderful machine..

Such homemade products are applicable not only as an assistant in agricultural work. They are successfully used when cleaning the local area, and in winter – for clearing snow. If you make a high-quality homemade tiller or motor-cultivator, then the operating parameters of the homemade product will be no worse than that of an expensive factory analogue.

Homemade products for the tiller are invented and manufactured by almost all owners of this technique. The purpose of these actions is to expand the functionality of the unit with minimal financial investment. In the basic configuration, the cultivator has extremely limited capabilities. Installing various options on it can turn a small car into a full-fledged mini-tractor. Often, homemade devices are in no way inferior to factory-made counterparts. In order to improve the tiller with your own hands, a set of tools that are available in every workshop of a country house or summer cottage is quite enough. The materials you need can be found in a junkyard, in a barn or at a scrap metal collection point.

Mini bulldozer

You can turn the tiller into a miniature bulldozer capable of leveling small areas or removing snow and debris by installing a shovel blade on it. To do this, use sheet metal with a thickness of at least 3 mm. The lower part of the shovel should be slightly bent forward in relation to the general plane, fix a strip of dense rubber on it for snow removal or sheathed with tin (for earthwork). To strengthen the entire structure at the back, it is necessary to weld several stiffeners from a metal corner.

DIY trailer for a tiller!

If you have a desire to make a trailer yourself. then the article below is for you! If you have a desire to purchase from us, call. 097 564 04 05!

A trailer for a tiller, a necessary thing, and sometimes even necessary in a private household. In this material, we will consider how to make a trailer for a tiller with our own hands, focusing on the drawings and descriptions for them.

In the diagram below, a homemade trailer for a tiller, capable of carrying a load weighing more than 400 kg, but first things first. The trailer is equipped with a driver’s seat, it is unpretentious in operation and quite easy to manufacture.

Tiller trailer

Trailer for the tiller: 1 – bracket for mounted implements of the tiller “Electronic”, 2 – console, 3 – carrier, 4 – footboard (20mm board), 5 – driver’s seat (20mm board), 6 – frame, 7 – body (20mm board) , 8 – support beam (timber 50x50mm, 3 pcs.), 9 – M8 bolt, 10 – thrust ring (pipe 58×4), 11 – wheel (from motorized carriage SZD, 2 pcs.). -Total View

Conventionally, the trailer can be divided into several main units: carrier, frame, body, wheels.

The carrier includes several parts connected by welding. The main load here is taken by the joint of the drawbar with the body of the swivel unit, therefore this place is reinforced with 4 stiffeners.

Carrier: 1 – body of the swivel unit, 2 – drawbar (pipe 49×3, L1850), 3 – footboard frame (corner 25x25x4), 4 – stop (pipe 58×4), 5 – stiffener (s4), 6 – pad (strip 25×4).

The frame is made of steel elements: pipes, rectangular and circular sections, angles and bars. They are welded together, and form a structure (frame), the design features of the frame are due to the countryside, where, when driving, the road is replete with irregularities, holes, etc..

For the wheel axle, a steel rod with a diameter of 30mm is used, which is connected by welding, gussets with the side members and the body of the longitudinal hinge, and corner supports. The length of the rod is 1070 mm, the length is chosen so that the wheels do not protrude beyond the body contours.

Trailer frame: 1 – brace (corner 21 x21 xZ), 2 – seat frame (corner 21x21x3), 3 – riser (pipe 50x25x4), 4 – seat racks (corner 40x40x4), 5.14 – front struts (pipe 50×25), 6, 15 – longitudinal side members (corner 40x40x4), 7, 8 – right wheel axle supports (corner 32x32x4), 9,16 – rear struts (pipe 50×25), 10 – reinforcing cross member (corner 40x40x4), 11 – body of the longitudinal hinge ( pipe 58×4), 12 – wheel axle (bar 0 30), 13.17 – transverse spars (angle 40x40x4), 18 – kerchiefs (s4).

The trailer body is made of boards, 20mm thick, for greater strength, at the corners it is reinforced with metal plates. The body is attached to the frame with three support frames made of 5050mm timber and bolts.

This cart is mainly intended for the transport of goods in bags, so its sides do not fold back..

The wheels in this trailer are borrowed from the SZD motorized carriage, the wheels come with assembled hubs, and the axle is turned to fit the bore diameter.

The trailer connects to the tiller with a console, the console is made in such a way as to fit the standard tiller hitch for attachments. The upper part of the console is an axis around which the carrier pivot unit rotates, in two bearings. The bearings are covered with anthers, and the space between them is filled with grease.

The carrier is connected to the frame of the trailer, pivotally, i.e. The drawbar is inserted into the tubular body of the longitudinal hinge, all this is fixed with an M8 bolt and a thrust ring. On uneven roads, this allows the trailer wheels to be independent of the tiller wheel position.

Carrier swivel assembly: 1.console, 2 – anthers, 3.6 – bearings 36206, 4 – housing, 5 – spacer sleeve, 7 – distance sleeve, 8 – washer, 9 – M20x2.5 nut, 10 – oiler, 11 – drawbar.

Seeder for tiller do it yourself

Making a universal seeder for a tiller with your own hands does not take much time. This structure consists of several main parts:

- a pair of wheels;

- sowing roller;

- two bearings;

- seed box;

- handles with bracket;

- pairs of brackets for fixing the opener.

The seed box is made of planks (up to 15 mm). The structure is closed with steel overhead bottoms. Longitudinal and transverse walls are fastened with self-tapping screws, steel corners and spikes. At the bottom of the walls, 15 mm thick wood strips are attached.

Semicircular cutouts are made in the linings and on the walls. They are designed to fit the seeding roller. Mounting brackets are pre-mounted on them..

In the inclined bottoms, rubber plates are fixed for dropping seeds from the cells.

The diameter of the wheels of the universal seeder for the tiller is 200 mm. The size of the hubs is 60 mm, holes are provided in them equal to the diameter of the roller.

To create the opener, 1.5 mm steel is used. It is fixed to the brackets.

The planting depth of the seeds is adjusted by re-securing the opener in the holes on the bracket.

Another bracket is fixed to the back of the seed box. It provides a connection of a homemade construction with a tiller. For a better understanding of the algorithm for making a seeder with your own hands, see the drawing.

Seeders for a tiller: how to make a planter with your own hands

Many farmers ask how to make a tiller seeder. In modern agriculture, motor-cultivators are increasingly used, which are supplied with various devices and designs. These tools include tiller grain seeders..

The tiller seeder is designed to evenly distribute cultivated seeds in the ground. The type and type of structures resemble those of a tractor, only several times less.

How seeders work

The chain transmission system is aggregated with the rear wheels of the equipment. The seed hopper holds the crop volume over several rows or beds. Some models have a separate container for each row. Often the seeds are mixed with some kind of filler or fertilizer..

The vegetable seeders are equipped with special brushes that loosen the seeds. There is a disc at the exit from the container, which opens the hole for the exit of the culture.

Designs, as a rule, are suitable for almost any cultivator, for example, the tiller Neva, Oka, etc..

Tiller seeders are quite convenient in the sense that the speed of planting the crop can be adjusted in advance. This is a big plus for planters for motor cultivators and other units. Another plus is that this tool can be installed on any type of tiller.

For planters, there is a classification of sowing methods:

- privates;

- nesting;

- square-nested;

- dotted (exact);

- scattered.

For different types of seeds, different models are used: vegetable, grain, universal. But for some cultures, there is still an exception. These are the seeds of sunflower, corn and beans. Most often they use a bunker system, but sometimes they resort to vacuum ones, which are used as mini-pneumatic planters..

Vacuum seeder – it is pneumatic, precision seeder, dotted. The vacuum seeder for the tiller is SVTV 4-8. Its purpose is to sow vegetables and grains. Initially, the design is designed for 4 rows, but it can be converted into an eight-row one without drastically changing the unit.

Pneumatic seeders are used to work with weighted tillers. The set includes 4 removable drums that can sow 2 rows each. You can plant both small grains and large ones, for example, corn. Sowing depth – up to 10 cm, row width – up to 70 cm.

Homemade garlic planter for tiller is used for planting bulbous species (garlic, tulip, onion). Farmers also use this seeder for vegetables. CTB is an excellent garlic planter. SV-6, SVTV 4-8 – these models are vacuum. There is a special garlic planter specifically for garlic. The design includes small spoons that pick up the onion and guide it directly into the furrow, which is prepared in advance.

But on some models there are no plates with which the wheels burrow into the soil and compact it. However, this attribute can be made by hand..

DIY garlic planter for a tiller

In order to make a garlic planter for a tiller with your own hands, you will need:

- wooden boards (metal tools add extra weight to the unit, making the tiller‘s work heavier);

- brush wheel (driven by a chain drive);

- a shaft with a chain attached to the front wheels of the cultivator;

- metal layer.

It is necessary to build a box from the boards, which will later be a bunker. A wheel with seeds is installed at the back of the box. It can be adjusted to fit the seeding size.

A metal plate is attached to the bottom frame of the garlic planter, which plows the ground under the rows. The plate digs trenches for planting garlic. This type of planter can be considered universal..

The homemade version of the garlic seeder for the tiller is quick and easy to assemble. But for the accuracy of the assembly, you need to use drawings and diagrams. They indicate the exact dimensions and diameters of the unit, and this will increase the accuracy of sowing..

Step-by-step instructions for creating a garlic planter for a tiller with your own hands are presented in the video. Tiller seeders have occupied an honorable place among agricultural equipment for many years. With their help, row planting of garlic, wheat, corn, rye, lentils and other crops is carried out..

It is advisable to use a manual seeder in medium to small areas. For a large plot of land, it is advisable to use a self-made seeder for a tiller. Any of these devices optimizes the sowing process, and improves the uniformity of seedlings..

Depending on the plants that are planted, there are several groups of seeders:

- Combined. Have special devices for applying fertilizers to the soil.

- Universal. For planting various crops.

- Special. Sowing certain plants.

Having studied the algorithm of actions according to the presented drawings, you can make sure that it will not be difficult to make a seeder yourself. The use of this agricultural device will save the strength of the gardener, increase labor productivity and improve the quality of sowing..

Seeder for tiller SM-6

This seeder is used for row planting of small grains and vegetables. Number of planter rows – 6. CM-6 can also plant corn. Seeder for tiller CM-6 plants crops accurately enough. Achieve maximum accuracy from this tool by using double regulation.

Homemade tiller extension for my suzuki outboard

You can change the number of seeds when sowing, the depth and width of the sowing. For a better harvest, it is advised to combine planting with sowing cereals, bran, and other small seeds. The corn seeder CM-6 is suitable for the tiller Neva, which is the most common cultivator.

The self-made seeding planter is connected to the tiller with the machine in several ways:

- Using the AM-2 adapter, the machine can handle up to 10 hectares.

- With the help of one motor-cultivator, it is able to sow more than 10 acres.

- With manual pull. But such a unit can sow only 5 acres.

Above, the mechanisms for planting garlic are disassembled: the principle of operation, how to assemble it with your own hands. But there is no detailed description of a planter for a tiller of a crop such as corn. Seeders are an add-on tool for attachments. That is, it will be enough to add a grain metering hopper to the main hitch, and the seeder is ready to the tiller with your own hands..

You can use a potato planter as the main hitch. Its principle is based on an exact fit in several rows, it remains only to add a hopper with rotating discs that open a hole for grain.

Do-it-yourself planter for a tiller is not particularly difficult to assemble. You just need to be smart and open the drawings, choosing the necessary dimensions for the equipment.

Dear summer residents, and which home-made design of a seeder for a tiller seems most convenient to you?

Do-it-yourself trolley trolley: dimensions, drawings, video

Equipment such as a tiller is an excellent assistant when working in the field, garden, country house or farm. To expand the capabilities of the equipment, you can attach a trailing device to it and transport soil, garbage, crops, tools and other heavy or oversized loads. You can make a trailer for the tiller with your own hands, spending just a few days on it. The result is an irreplaceable assistant that will facilitate further work..

Trailer mechanisms

You need to think over everything to the smallest detail, so that during the assembly of equipment there are no difficulties. To do this, you need to understand:

- screwing, riveting or welding will connect non-separable units and parts;

- how axles, bearings, bushings, hinges will be connected;

- which seat is better to install (simple or rotating);

- from what to make an emphasis on the legs for the parking;

- Do you need a tipping body, to which you will have to add a mechanical tipper or a self-dumping unit with a special handle;

- which unit of attachment to the tiller to select (on bearings, bushings or articulated).

Having dealt with all these questions, you can start preparing a list of necessary materials and calculating the approximate cost of the future trailer.

Do-it-yourself multifunctional trailer for a tiller: stages of work, video instruction

Having decided on the dimensions and sketching the drawing, you should calculate how many meters of rolled metal and how many channels will be needed to make a homemade trailer. This is necessary in order to protect yourself from unnecessary costs for the purchase of unnecessary parts and fasteners..

Required materials and tools:

- welding machine;

- steel corners 40×40 mm and 50×25 mm;

- timber measuring 50×50 mm;

- boards 20 mm thick;

- cutting pipes of round and rectangular cross-section;

- complete wheels with hub.

The future trailer will consist of four main units connected by welding.

- The frame is assembled from scraps of pipes and corners of 40×40 mm and 50×25 mm and the frame is connected by welding.

- The body is made of 20 mm planks, the nodes of which are then sheathed with steel corners.

- With the help of three supporting beams, the role of which is played by wooden beams, the body is mounted on the trailer frame.

- Wheels are installed on the structure. Before this, it is necessary to sharpen the ends of the axle rod so that its diameter matches the dimensions of the hub bearings. It is necessary to follow the length of the rod. When assembled, the wheels must not protrude beyond the rims of the body..

- Through corner supports and gussets, the rod is welded to the body of the longitudinal hinge and side members.

- The trailer will be attached to the tiller using a do-it-yourself console. The lower part of this element is the axis around which the pivot unit rotates. The upper part should be made so that it follows the contours of the hiller holder. The console is attached to the attachment bracket.

- In order for the trailer wheels to work independently of the wheels of the tiller, and to make the equipment easy to operate, it is recommended to insert the drawbar into the body of the longitudinal hinge and secure with thrust rings.

The tiller trailer is ready. Now you can fix the footrest and the driver’s seat, from which the equipment will be controlled.

Preparatory work

First of all, you need to think about what size the trailer should be so that it fits a certain tiller, and it is convenient to use it. After that, you will need to sketch a drawing or a sketch of the trolley, on which to display the structure from different angles, put down all the dimensions and draw the nodes.

Simple trailer for the “Neva” tiller

To start making a cart with your own hands, you need to prepare the following materials and tools:

- duralumin sheet with a thickness of 2 mm;

- steel sheets with a thickness of 0.8 mm;

- springs and wheels;

- steel pipes 25×25 and 60×30 mm;

- channel;

- fasteners;

- screwdriver;

- welding machine;

- jigsaw;

- Angle Grinder.

The trailer frame will be a one-piece structure mounted on a frame grille. For its manufacture, two traverses of 25×25 mm must be made transverse and pipes 60×30 mm must be attached to them so that the result is a lattice.

Two longitudinal pipes are welded to the finished lattice, on top of which a 25×25 mm strapping is attached by welding. The material for the sides will be steel sheets, which are cut to the required size and welded..

The turn of the beam has come, for the manufacture of which two channels will be needed. The elements are inserted into each other, after which the wheel axles are put on one of the ends of the resulting part.

Tiller mount Homemade row maker / Bed shaper!

The spar is connected by means of springs, the end of which should be put on the beam axle and the shackle axle. Then, the central part of the springs must be welded to the same beam with stepladders..

Last but not least, you need to make a drawbar with your own hands from 60×30 mm pipes. They should be docked and, by welding, one part should be connected to the trailer, and the other to the side members..

A simple tiller trailer is ready. I would like to note that experts recommend using a welding machine to connect its parts. Such a mount will allow you to operate the structure for a long time..

Homemade trailer to the tiller from car parts

Having drawn up a drawing in advance and prepared the necessary materials and tools, you can assemble such a trailer with your own hands in 1-2 days.

For work you will need:

- front axle shafts from Zhiguli or Moskvich;

- channel 65 mm along the body length;

- corners 60×60 mm;

- two pipes 2 m long;

- one pipe 60×40 mm, 3-5 m long;

- welding machine.

The bearing part of the structure will be the axle, which is made from a channel. Its length depends on the length of the future trailer. On both sides of the channel, the axle shafts from the car are attached by welding. Profile pipes are installed on top:

- One pipe is centered. She will act as a drawbar. Its length must be selected in accordance with the dimensions of the hitch..

- Two-meter pipes are laid along the edges of the channel, in the place where it meets the ends of the axle shafts. As a result, the channel joint must divide each pipe in half..

- Short pipes are laid parallel to each other and fastened perpendicularly with corners.

To ensure the structure of strength and rigidity, from the front corners of the trolley, profile corners or pipes should be pulled. Joints can be bolted or welded.

The trailer frame is ready. Now you can install on it a simple wooden body made with your own hands, a seat and attach it to the drawbar.

After watching the video instructions and studying the article, you can understand that in order to make a trailer for a tiller with your own hands you do not need to be a designer or mechanic. To implement the plan, you will need a drawing, the necessary tools, materials and a little desire and free time.