Front adapter

The front adapter for the Neva Tiller has one or two attachments to which the attachment is attached. Thanks to the robust design of the wheel axle, the adapter can be used in difficult-to-pass areas of the territory, as well as transport heavy loads. They are of the following types:

- front adapters;

- rear adapters;

- all wheel drive adapters.

On the front adapter, the trailer hitch is located at the rear. The advantage of this type of device is that it is easy to assemble and disassemble, and this allows it to be transported without much difficulty..

Buying such an adapter is the best solution. But if there is no desire to spend money on this purchase, there is an opportunity to assemble it with your own hands. At the moment, there are many ready-made diagrams and drawings that can be useful in this matter. They are all tested and suitable for use. On the Internet, you can always find not only information about adapters, but also about attachments, drawings and instructions for them.

With the minimum number of tools, it will not be difficult to assemble the tiller. We will need:

- A pair of wheels;

- Seating area for management;

- Metal corners;

- Metal profile and pipes;

- Lathe or milling machine for welding;

- Fasteners, etc..

Cutters

They can perform several operations:

- loosen and level the ground;

- crush lumps of soil and mix its layers;

- mix fertilizers;

- weed out.

The set with a tiller usually comes with universal cutters equipped with saber knives. They are comfortable to work on soft soil. For dense and overgrown with weeds, mechanisms are designed, called “crow’s feet”.

High mechanical strength and a special shape of the cutters allow them to loosen neglected areas, pulling out weeds with their roots. In autumn, with their help, they destroy insect pests that have lain in the ground for the winter..

Clutch device

The hitch is responsible for connecting the attachment and the mechanical unit itself. This fastener is defined as one of the most important, therefore it is made of high-strength metals – steel or cast iron.

Building a Hitch to Pull the Tiller

The length of such a device is about 2 meters, the width is 80 centimeters..

Depending on the clutch, the following design options can be considered:

- with movable clutch. Such a device is the lightest. The clutch is located at the front, but the control is more difficult in this case, since it is necessary to deploy the entire power unit;

- with steering. The clutch is firm and the steering is controlled by a mechanical steering assembly. This control is easier to use, but more difficult to manufacture..

Different adapters are intended for tillers of different performance. For mechanisms with low power – with a short mount, for powerful ones – with a long.

Tiller design with adapter

This homemade tiller is simple and consists of only a few components:

- Wheels and wheel axle.

- Adapter Hitch and Tiller Hitch.

- Seating area for control.

In simple terms, the adapter is a trolley with a seat on wheels. When the adapter is connected to the tiller, then we can say that this is already a mini tractor. Of course, the power, its much less, but the functionality is the same. Additional attachments turn such a structure into a multifunctional tiller, expanding the list of possible jobs. Few will refute the dignity and necessity of having such a mini tractor on their site..

Application area

The adapter turns the tiller into a versatile, multifunctional mechanism. Using this equipment, the operator can be seated. It is important to note that it gives the tiller stability and generally simplifies the process of doing the work..

Initially fixed attachment, will not move up or down when driving.

Steering mechanism has great advantages. No need to use tiller pens anymore. Now there is a special steering unit that allows you to reach speeds of up to 5 km / h.

When used together with attachments, you can expand the range of work performed:

- cleaning leaves, snow, territory;

- hilling the soil;

- leveling the ground;

- transportation of goods of different dimensions.

Assembling the device

Having everything you need at hand, we proceed directly to the assembly of the unit:

- It is necessary to prepare a metal sheet 180 cm long.

- Across this sheet it is necessary to weld a smaller sheet, about 60 cm. There will be mounts for wheel struts here. The height of the posts must be at least 30 cm.

- We carry out welding work on the braces, which will be installed to the frame and wheel hubs (their location can be any).

- We weld the beam to a large metal sheet. This will strengthen the frame structure..

- A frame for mounted installations is welded from the channel. In a perpendicular position, we weld another small pipe of 30 cm, which will serve as a blank for the seat. We weld two more smaller pipes on it to make a stand. You can take a ready-made seat and install it on this stand, or use plywood as a seat, having previously covered it with a soft inflated material. Bolted seat.

- The final stage: setting the control lever on 3 knees (35, 55 and 20 cm). To adjust the gain, another lever is installed at 80 cm.All levers must be bolted together.

In fact, there is nothing complicated in this design, it is only important to have welding experience. On some of these models, steering is installed. Such a tiller will be convenient to use in arable work.

Harrows

The land overturned by the plow is a “semi-finished product” that requires fine-tuning. For this work, a harrow is used, which breaks up large clods and levels the soil..

There are two types of harrows:

It should be noted that disc structures perform better harrowing and cleaner toothed.

Wheels

There are 2 types of wheels – metal and rubber. The former are used for heavy types of work in the field. The latter are designed for driving on a dirt road.

Plant maintenance equipment

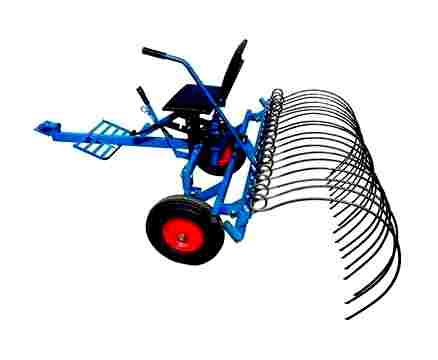

For tedding, as well as raking hay into rolls, a rake is hooked to the mini-tractor. Such equipment is more in demand by farmers and private owners, who have large areas for haymaking. The tedding rake is produced in various modifications. To a mini-tractor with a power of 12 hp. model 9 GL or 3.1G will do. The equipment is characterized by a strip width of 1.4-3.1 m and a weight of 22 to 60 kg.

Cultivators clear the field of weeds, loosen the soil, remove the roots of unnecessary vegetation. The equipment is used after planting germination and during the entire period of their growth. Of the common models, KU-3-70 and KU-3.0 can be distinguished.

Mounted sprayers help control crop pests in fields and gardens. The models SW-300 and SW-800, produced by the Polish manufacturer, are universal. The equipment is suitable for all models of mini tractors. At a liquid solution flow rate of 120 l / min, the jet covers up to 14 m of the treated area.

Making KUHN

To assemble a front loader for a tiller or a mini tractor, you will need to prepare drawings. This takes into account the carrying capacity of the equipment. The walls of the attachments for the mini tractor are made of a sheet of metal (6 mm thick). This will require metal scissors or a gas cutter..

Making Tiller Tines Out of Scrap Metal! DIY Rototiller Blades

Electric welding is used to fix the sheets to each other. The duration of the operating life of attachments for a mini tractor depends on the quality of the seams. The next step is to make the struts and rods. For this, pipes (diameter 50 and 100 mm) are used. Then the hydraulic booster is mounted.

To provide the last element with greater mobility, the bucket diameter should not exceed 30 mm. To secure the posts, a pipe is welded to the front of the vehicle. The structure is reinforced with metal corners. To make homemade tractor attachments turn, a cylinder is fixed to it.

For the independent manufacture of a bulldozer blade, a water pipe is used (section radius more than 70 cm). The width of the device is selected individually in each case. The value of this indicator depends on the parameters of the technique. Experts advise to make a hitch for mini tractors with your own hands from metal 8 mm thick.

An angle grinder is used to cut the pipe lengthwise. At the same time, the distance from the edge is respected (to ensure optimal bending of the bucket). A metal profile is welded below the center of the pipe. If necessary, the attachment to the mini-tractor with your own hands is supplemented with transverse thrust elements.

To attach the blade to the equipment, an A-shaped structure is made. The product is completed with longitudinal beams. A hydraulic cylinder is used to lower and raise the machine. A bracket is used for its installation. The hydraulic cylinder can be removed from the semitrailer 2 PTS-4. Front linkage is required to secure the blade..

Step-by-step instruction

If the hitch for a mini tractor is made in a workshop, then a vise and an anvil will be needed. A sheet of metal is cut out according to the finished pattern (3 mm thick). Then the parts are folded. When performing this work, the maximum accuracy is observed.

To simplify the task, a pipe or cylinder is used. The bottom of the blade and the cutting element are reinforced with a metal band (5 mm thick). To fix it, blind rivets or a welding machine are used. Then the surface is cleaned. A holder is welded on the opposite side (length up to 40 cm). To work the soil at different depths, it is recommended to equip 3-4 holes in the holder.

For the manufacture of the body, a rectangular steel pipe is used. The length of the hull should fluctuate within 0.5-1 m (taking into account the number of the hinged structure). A flange is mounted on one side of the pipe (for fixing the frame to the equipment). On the opposite side, the working part of the plow is mounted on bolts.

If a heavy plow is being made, then two wheels are provided. They are positioned relative to the mowing line of the axis so as to ensure the balance of the plow during operation and reduce the load on the mini tractor..

During the operation of any attachments for a mini tractor, it is recommended to observe safety precautions.

Planting equipment

This type of equipment includes potato planters. There are several models of planters, with 1 and 2 rows. They also have different tank sizes for planting tubers. Different agricultural enterprises and individual owners can choose for themselves tanks of different sizes.

Homemade potato planters for a mini tractor are a versatile unit. They cut the furrow and throw the planting material, that is, the potato tubers, at an equal distance. After that, the planting is automatically covered with soil. All these operations are performed while the mini-tractor is moving around the site. If it is standing, then planting potatoes is impossible..

Power of katofel planters – from 24 horsepower and more. Weight – about 180 kg.

Important! The potato planter should only be used on large scale farms. The use of attachments in summer cottages and household plots is ineffective and impractical.

A hiller is an equipment for filling the planting site with soil. Plants are processed in rows. Works the same as a seeder.

Manufacturing of the trailer adapter

The design of this apparatus includes:

- metal frame;

- coupling;

- transverse bar;

- braces;

- racks, axle, wheels;

- management tools;

- trailer or cart;

- space for the operator and connection of additional mechanisms.

The frame is made of pipe (length – from 1.5 to 1.7 m). A hitch is welded at one end, a bar is welded at the other. Racks for wheels are attached to the bar, brace.

Levers are used to control the devices. By switching them, you can set the optimal position of the attachment. An additional lever is installed to adjust the applied force.

The length of the drawbar depends on the power of the tiller. Engine power affects wheel size. Additionally mounted hydraulics.

A hitch for a mini tractor, internal combustion engine and other units is easily done independently. It is suitable for almost all agricultural equipment, greatly facilitates and reduces the cost of all work in the country or on the farm. Correct use of the equipment will prolong the life of the tiller.

Do-it-yourself mini tractor attachment

Harvesting equipment

This type of equipment includes potato diggers. Conveyor and vibration models are mainly used. For a homemade mini-tractor, diggers are often made on their own. The easiest to manufacture is the fan design. There are also drum-type and horse-drawn diggers. From the factory-made models, DtZ-1 and WB-235 can be distinguished. Any potato diggers are connected to the rear hitch of the tractor.

Equipment for preparing soil for planting work

The plow is responsible for preparing the soil. A mini-tractor with attachments of various designs is working. One- and two-body plows are used with equipment with a capacity of up to 30 liters. from. Their plowing depth is adjustable from 20 to 25 cm. If the unit is equipped with an engine of more than 35 liters. with., then you can pick up a four-body plow, for example, model 1L-420. The plowing depth is already increasing to 27 cm.Such models are called reversible or plow-moldboard and are most often used by private owners for giving.

There are also disc plows used for heavy soils and virgin lands. In farms, soil preparation can be carried out with rotary models.

Before planting work, the soil must be prepared. Disc harrows are responsible for this front of work. Depending on the design, their weight is in the range of 200–650 kg, and the ground coverage is from 1 to 2.7 m. Different models differ in the number of discs, as well as in the harrowing depth. For example, 1BQX 1.1 or BT-4 cultivate soil up to 15 cm deep.

Making a plow

Before making this attachment, it is necessary to prepare drawings. In them, you can designate the main nodes. share and blade. For working elements, 3 mm steel should be used, but first, experts advise working on a removable share. The most suitable material for it will be a disc borrowed from a circular saw. In the absence of, you can use ordinary steel that has not been heat treated.

The cutting part will be the working element of the scythe, which beats off on the anvil. A mounted plow should also have a blade in its composition, you can start making it after you finish with a share. As a material for this, you can use a 50 mm pipe, the thickness of which will be 5 mm. The blade can be blank using a gas torch. To begin with, a template is cut out, at the next stage, the workpiece can be brought on an anvil, and then on a grinder.

Recommendations for the implementation of the coupling unit

If you decide to make attachments for the tiller with your own hands, then you should familiarize yourself closely with the instructions for making the coupling assembly. The simplest design will be a 15-centimeter pin that fits into the hole in the drawbar of the tiller‘s towbar. The disadvantage of this option is a rather quick wear, because under the influence of a rotating trailer, the holes for the hitch are broken. The hitch can be lengthened to reduce the wear rate..

Plow assembly

Attached homemade equipment in the next step can be put together. To begin with, you should use the option of assembling the layout, which is made of thick cardboard. Parts are glued together, while you need to adhere to the required angles. After finishing the blade, share and auxiliary parts, a 2 mm square steel sheet with a side of 500 mm can be prepared. An indent of 40 mm is made from the edges, then a ploughshare is applied and spot welding is done on both sides.

The stand guard should also be docked with the share, the joint should be in a vertical position. The guard must be positioned slightly higher than the share blades. The offset is necessary for cutting the soil. It is important to tightly dock the share with the blade, there should be no gaps. As a result, the structure should turn out to be almost cast. Between the upper edge of the shaft and the share blade, an angle must be set within the range from 6 to 8 ° С.

Assembly Instructions for Simple Tiller Adapter

Do-it-yourself attachments for a tiller can be made by almost any home craftsman. If you want to make an adapter, then it can be a steel frame made of pipe. To do this, you need to take the one that has a rectangular section, while the length should be 1.7 m.

To one of the ends, it is necessary to weld a pipe perpendicularly, the length of which is 0.5 m. This part will become the basis for fixing the struts under the wheels. The height of the struts from the axle to the top point will be 0.3 m. At the next stage, it is necessary to fix the braces to the central tube and the wheel hub. The length of the products will depend on the slope and angle.

The square frame can be of any size. In this example, the following dimensions will be considered: 0.4 x 0.4 m.If you decide to make such attachments for the tiller with your own hands, then you need to strengthen the channel to the rear end of the frame, the length of which will be 0.4 m. a single design is possible with bolts. To be able to adjust, a lever should be welded to the frame, which should have three knees, their length will be as follows: 20, 30 and 50 cm, respectively. In order to increase the applied forces, the arm should be supplemented with a 75 cm arm. The hitch assembly can be purchased or manufactured by yourself. The duration of the operation of the attachment will depend on the quality of the coupling. It is necessary to fix the seat on a metal support, which is welded to the central tube. On this we can assume that you managed to make attachments for the tiller with your own hands. Its advantages are low cost and simplicity of construction..

Solution to the problem

Do-it-yourself attachments for the tiller. Drawings, assembly instructions

If you have a land plot, then you are familiar with how difficult it is to work on digging, loosening and hilling. It takes a lot of time and effort. In order to facilitate the solution of such problems, you can purchase auxiliary special equipment, it can be a tiller. Using this equipment, you can perform a wide range of works. This can be the cultivation of the land, cleaning the site, as well as the transportation of crops and any other cargo..

Making a mower

A do-it-yourself mower for a tiller can also be done. It is used for lawn care, mowing grass for hay. For work, you should prepare the chains from the chainsaw gearbox, as well as a couple of discs borrowed from the grain seeder. The knives can be made from hardened metal, and you need 4 knives per disc. Drill holes on the discs with a diameter of 6 mm. The knives should be reinforced on the disc using shanks. The gap between the knife and the shank should be 2 mm larger than the thickness of the knife.

When making a do-it-yourself mower for a tiller, the knife attachment axes can be made of carbon strong steel, the diameter of which is 8 mm or more. The axle must be tightened to the stop with the disc so as not to impede the movement of the knives..

Seat installation recommendations

You can draw up drawings of attachments for the tiller yourself. From them you can learn that the adapter is attached to the equipment using a single hitch, which consists of two parts. The first is required to connect the equipment, while the other is an adjustable adapter between the equipment and the hoist..

To increase the number of implements used, the adapter can be supplemented with a universal double hitch. Such equipment is also suitable for the Salyut tiller. However, in order to read the instructions, it is important to ask how the seat is installed. With a step 80 cm from the front edge, the seat must be secured to the backbone frame. In this case, you need to use bolts. After the entire system is assembled together, it must be checked for operability..