How and how to sharpen the chain teeth

The saw chain teeth are irregularly shaped. They consist of a base, a blade and a depth gauge. At the same time, the blade has a vertical blade and a horizontal blade that falls at an angle. It is thanks to these blades that the chainsaw cuts wood. They work on the principle of a plane, cutting off pieces, and the limiter adjusts their thickness (the difference in height between it and the horizontal blade will be the thickness of the chips). You can sharpen the chainsaw chain manually or using a machine.

PowerSharp System

This system allows the chain to be sharpened in seconds without even removing it from the bar. Includes PowerSharp chain, abrasive bar, guide bar and sharpener. In order to sharpen the chain with them, you will need to take the following 3 steps:

- install the PowerSharp bus and chain;

- fix the bar inside the sharpening device, after which it is installed on the tire;

- the end of the chainsaw is pressed against an object and started for a couple of seconds.

The video below shows in more detail how to sharpen a chainsaw chain with your own hands using this system:

Chainsaw chain sharpening blunt teeth

When to sharpen and how to find out

Problems that may arise due to untimely chain maintenance:

- curves cuts;

- huge pressure;

- increased fuel consumption;

- faster wear of the leading parts of the chainsaw and a shorter service life.

Signs by which you can find out that the chain is dull:

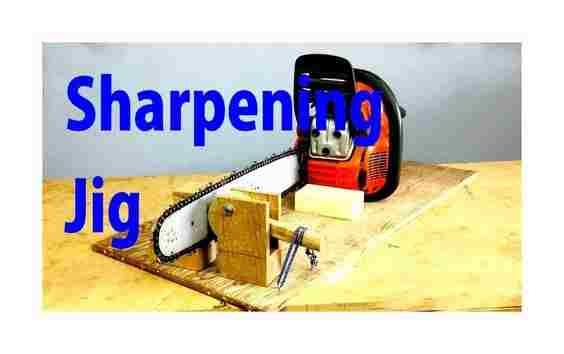

Build a Chainsaw Sharpening Jig. Chainsaw Sharpener

- the tool tries to escape from the hands, gets stuck;

- small shavings are poured, almost dust;

- the saw deepens only with great effort;

- cutting time increases.

In addition, blunt teeth can simply be examined carefully. Signs of dullness will be visible even to the naked eye.

The earlier the chainsaw chain is sharpened, the less metal is grinded, which means that it can last longer.

Sharpening kits

One of the most common methods is with a set of round and flat files, a holder, a stop template and a hook used to remove sawdust. For the correct positioning of the holder, special markings are applied to it, allowing you to determine the correct angle for sharpening. It is installed on the upper part of the tooth and the stop, while the round file remains under it and is located just next to the blade. Thanks to the holder, the file is at the correct height, or more precisely, protrudes 1/5 above the blade. For sharpening the cutting tooth, only round files are used, since the contour of the tooth has a rounded shape.

Kits must be purchased based on the chain pitch. You cannot use the same sharpening kit for different chains.

Before you start sharpening the chainsaw chain at home, the tire must be secured in a vice or with a clamp, the main thing is that the saw does not move during processing. Having installed the holder according to the markings, begin smoothly and without too much pressure, move the file strictly away from you 2-3 times. Similar actions are repeated with all other teeth. The file must be turned over from time to time so that there is no one-sided wear. The force of pressure and the number of movements for all should be the same, this is necessary for uniform sharpening of all teeth. If they are different, then cracks may form in the chain, which will lead to its breakage.

To make it easier to work, the teeth are first sharpened on one side, and after them the saw is turned over and the teeth are aligned on the other.

They start sharpening from the smallest tooth so that the length of all the others is the same with it. After the work on the processing of the blades is finished, proceed to the limiters. A template from the kit is installed on top of the chain in such a position that the stopper is in the hole. The protruding part is grinded with a flat file.

The video shows an example of how to sharpen a chainsaw chain with a file:

There is another set, which, instead of a holder, has one template, both for sharpening the blade and for grinding the stop. Install it so that the chain falls into the holes. Then the round file is placed on top of the rollers and fed under the blade. During sharpening, you need to ensure that it is always parallel to the lateral edges of the template.

There are 2 separate holes for the stopper, labeled Soft for soft wood and Hard for hard wood. The protruding part from the slot, grind with a flat file.

Sharpening is carried out only from oneself and with smooth movements, the number of the latter should be the same for all teeth.

Manual and electric machines

If the teeth are severely worn away and the cutting blade has lost its shape, it will take a long time to align them by hand. In this case, a manual machine or an electric one with a sharpening wheel is usually used. The first type of device is in the form of a bow saw with a round file. The machines are stationary and mobile, which can be installed directly on the bus.

To adjust the necessary parameters, start with the smallest tooth. After all the teeth are sharpened and aligned, the round file is replaced with a flat file to sharpen the stops.

The advantage of electric machines is that the disc is fed directly under the blade to be sharpened. In addition, the quality of sharpening in this case is guaranteed and all teeth will be the same size.

The video below shows an example of sharpening a chainsaw with your own hands using an electric machine.

The blades are always sharpened first, and only then the stops.

The sharpening angle can be changed. it depends on the purpose of the application. A smaller angle is used for sawing hardwood, and a larger one for soft. In any case, it should be between 25 ° and 35 °. 10 ° angle is used for chains intended for longitudinal cutting.

The process of sharpening a chainsaw chain with your own hands

The chain is sharpened directly on the saw blade. The arbor is placed on the edge of the cutting tooth, taking into account the angle of sharpening of the chamfer. The sharpening angle is usually 30 degrees or 10.

The most difficult thing in manual editing, sharpening is to maintain this very angle. Here you need to have some practice and feel the direction of sharpening in order to precisely correct in the direction of movement of the round file, and not sharpen your own angle.

Also, when sharpening, you should pay attention to the fact that the movement of the file should be in a perpendicular plane relative to the saw blade. The main difficulty of manual sharpening lies in the fact that all corners must be maintained manually, which will require proper skill and experience from you. The file itself should protrude slightly above the tooth when sharpening it. Sharpening is done in one direction, that is, only in a forward motion, and not in a reciprocating motion.

Further, after sharpening the first tooth, we spin the chain on the shank and similarly proceed to sharpening the second, then the next, etc. After you have “walked” over all the cutting edges of the teeth, it is the turn of the cut stops. In fact, these are projections on a chain that do not have cutting edges. The restraints are located on the same plate with the tooth. Their main task is to limit penetration when cutting. If they protrude strongly, then the chain will slide, and not cut. If they are too deep, the saw will “bite” in the tree.

To edit the cut stops, you need to take a gauge and attach it also to the edges of the cutting teeth. The slotted end strip should be exactly at the level of the stop. If the stopper protrudes from the gauge, then it should be trimmed in size. The stops are leveled with an ordinary flat file, while also working with the file in the plane perpendicular to the saw blade and in one direction.

Chainsaw chain sharpening signs (saws)

Having slightly outlined in the previous paragraph your thoughts about what not to do in order not to start sharpening immediately after 5 minutes of working with the saw, in this paragraph we will talk about the signs of a dull chain, that is, when the sharpening time has already come, it does not matter, how long have you worked. Pay attention to the saw shavings. So with a blunt chain, it will be smaller, in some cases not light, but slightly darker than usual.

Everything is explained very simply, blunt edges cannot remove the proper cutting layer, which leads to chip crushing. and high speeds without proper heat dissipation together with the shavings overheat the wood, from which it burns and darkens.

And of course, the main signs indicating the need for sharpening is a direct visual inspection of the chain. It should not have radii on the cutting edges, there should be no damage in the form of breaks and changes in the shape of the tooth and the cutting edge of the chain.

Otherwise, the chain must be sharpened.

How to extend the period from sharpening to sharpening a chainsaw

Maybe now we will utter common truths, but some neglect them too, apparently in the hope that everything will work out without this, according to the phrase of the hero, the famous cartoon “Vovka in the Thirty Kingdom.” “Oh, and so it will do.”. In no case should you saw with a saw if there are third-party objects in the tree or board, first of all, these are not extracted nails, metal tape. Once you “ride” on a normal nail, of course you will even saw through it, but after that take a look at the cutting edges of the chainsaw chain, because sometimes it is already an irreparable marriage, with chips, plastic deformation of the teeth. In such cases, a hand-held chain sharpening tool may not always help. Before starting work, check the saw site for any foreign objects, the wood must be clean, preferably dry, although this is already how it works. Do not cut on the ground without putting something under the cut. In this case, after the cut, you will have to go deeper into the ground, and this is, oh, how undesirable for your chain. The earth, sand, stones, all this can also quickly and irrevocably disable the chain of your chainsaw, forcing you, after one or two uses of the new chain, to start sharpening it. Make sure that the saw does not “bite” during the cut, so as not to overheat the metal and the saw blade. Watch chain lubrication, oil level in the reservoir. As a result, as you understand, the chainsaw, which seems to be such an “invincible” hand tool, itself needs protection if you want accurate, timely and effective work from it.

Do-it-yourself chainsaw sharpening (saws)

Having bought a chainsaw once, you should not think that it will always work as efficiently as on its first day. The initial apparent ease of woodworking can fade over time. An inexperienced saw owner may not immediately understand or notice that the saw is dull. As a result, this can no longer lead to sharpening the chainsaw chain as a preventive one, but to its restoration in special service centers, using machines for sharpening the chain, or even worse, to its complete replacement with a new one. In the same article, we wanted to tell you exactly about timely maintenance, chain sharpening. When, how and by what means it is necessary to carry out such procedures so that you can cut without problems, and your saw can work efficiently and for a long time.

Negative consequences in case of untimely sharpening of the chainsaw chain

If you still continue to saw, despite the fact that the chain is dull, then this will primarily affect your productivity and possibly the nervous system, which does not accept such an ordeal. It will also affect the life of the electric or chainsaw, due to the fact that the engine will overheat. On increased consumption of gasoline and electricity. It will also affect the shank, along which the saw will pass many more times, in order to cut the same thickness, compared to a sharpened chain. The chain may come to such a state that it will have to be adjusted with a machine in a specialized center or, even worse, replaced, we have already talked about all this

Chainsaw chain sharpening in specialized centers, on the machine (features and cost)

If your chain is in a completely depressing state, or you feel that you are not able to skillfully sharpen yourself, then contact a specialized center, or purchase a chain sharpening machine that minimizes the influence of the human factor when sharpening the chain. In this case, the chain is removed from the bar and installed on the machine guide. Further, it is tightened by a roller and a ratchet that holds it by the cutting tooth. The sharpening angle is set according to the protractor on the machine. Then the abrasive wheel is lowered and literally a few tenths of a mm is removed, that is, the chain is straightened, sharpened. Then the chain is rearranged to the next tooth, etc.

This sharpening allows you to meet higher requirements for the size of the cutting part of the chain and its shape. The downside is also obvious that here you will have to buy an expensive machine, which is not always advisable for one-time sharpening of the chainsaw chain.

An alternative option for a private trader will be to use a manual machine, it is somewhat cheaper than an electric one, but the processing speed will also be slightly lower, although the accuracy is commensurate with the machines used in the service.

Now knowing about all the alternatives when sharpening the chain, you yourself can choose what you think is the most suitable option.

How to sharpen a chainsaw chain with your own hands: 3 proven methods

The quality of sawing wood with a chainsaw largely depends on the sharpness of the chain. How to sharpen a chainsaw chain with your own hands at home? We will tell you about three good ways.

The speed and quality of sawing wood with a chain saw depends on the sharpness of the chain. It needs to be sharpened from time to time. How can this be done? We will tell you about three reliable ways in which you can sharpen a chain with your own hands. One of them allows you to sharpen the chain right in the field, while the other two require a special tool and electricity.

Method 1

We install the chainsaw on the table, and clamp the tire with a vice so that it does not move during operation. We set low revolutions on the angle grinder (if there is only smooth adjustment, then slightly press the start button). We direct the disc at an angle of 30 ° relative to the plane of the tooth and tilt it slightly (as shown in the photo). Press on the tooth with light, soft movements.

With this method, the main thing is not to overheat the tooth and not to grind off too much metal. Ditching teeth, sharpening in this way, is much easier than with a hand file, but the sharpening speed increases significantly.

Saw chain sharpening methods

There are three ways to sharpen your saw chain effectively:

- File.

- Angle Grinder.

- Sharpening machine.

Chain design

The saw chain consists of the following elements:

- Left cutting tooth.

- Right cutting tooth.

- Cutting depth stop.

- Leading link.

- Rivet.

In order for the chain to saw well, it is necessary to sharpen each tooth on the left and right sides. However, in order not to spoil the sharpening, it is important to know what shape our teeth on the chain are. There are two common forms of saw teeth:

- Chipper. This is the more common tooth shape and is found in almost all chains. Here the profile is somewhat rounded, so it is much easier to sharpen it with a round file. In practice, however, the chipper dulls a little faster than the chisel.

- Chisel. The cutter profile in this case looks like a seven. Such a cutter has a rather small contact area when it comes into contact with wood, so it encounters less resistance. For this reason, in one cut, it makes a greater depth of cut, which means that the speed of cutting a log will be higher (in comparison with a chipper). But sharpening it without damaging the edge is much more difficult.

Sharpening the chain with a file

This type of sharpening can be used directly in the field. It requires a round file, a holder for it (clamp) and a vise for clamping the tire.

To sharpen with a file, you need to perform the following manipulations:

- Clamp the tire in a vice. If you are in landing and did not take a vise with you, then you can clamp the tire by resting it on the log.

- Place the clip with the file on the chain so that it creates an angle of 30 °.

- With light movements forward (away from yourself), we sharpen the tooth. With a new file, it is enough to make 5. 7 movements. If the file has already been used several times, then more movements will be required.

- After the tooth has been sharpened, remove the file with a clip and scroll the chain to the next tooth. After passing all the right teeth, turn the saw (or change the position of the file) and sharpen the left teeth.

Some file holders have a filed template on which the turning angle is already indicated. So you do not have to “figure out” this angle. But from experience we will say that you need to practice well until it turns out to sharpen the chain perfectly smoothly with a file.

Method 2

In this case, it is the angle grinder that needs to be fixed immovably. Can be clamped in a vise or screwed to a workbench with a bracket. Sharpening is done as on a conventional grinding wheel. We hold the chain with our hands and turn it so that the tooth sharpens at an angle of 30 °.

With this method, hands are less tired, since you need to hold the chain, and not the angle grinder. However, the chance of getting injured increases dramatically. We recommend using this method infrequently or not at all, since safety is still more important than speed or quality of sharpening.

Chain sharpening angle grinder

If you have an angle grinder, you can sharpen your chainsaw chain much faster. It is best to use a small, 125-disc angle grinder. Sharpening is done at low speeds. There are two ways to sharpen an angle grinder.

Using a file

Sharpening the saw blades with a file is the best solution for a beginner. For this procedure, you need to prepare an appropriate set of tools:

- 2 types of files. round and flat;

- holders;

- calibration template;

- chip remover.

Structurally, all devices may differ, but functionally they must perform the necessary operations.

The choice of the diameter of the round file depends on the dimensions of the saw blades:

- at step 1.3, a file with a diameter of 4 mm should be used;

- pitch 1.6. 5.2 mm.

Sharpening of the cut limiter is carried out with a file with flat edges.

In order to properly sharpen the chainsaw chain with a file, you should adhere to the following sequence when working:

- The chain brake is pre-activated, the tire is secured in a vice. A well-clamped tire is the key to high-quality sharpening.

- The template is installed so that the guide of the risk is directed towards the free end of the bar. The chalk marks the tooth from which the procedure was started. This is required in order not to go on the second circle to sharpen the sawing elements.

- Sharpening is carried out with a suitable file pitch in accordance with the factory cut indicating the maximum angle.

- In addition to the cutting itch, there are stops on each link. Sharpening of this element is carried out as needed. Editing it is required if, as a result of sharpening, the tooth height of the saw segment decreases. The limiter is straightened after 2-3 sharpening of the teeth.

The advantage of this method is the ability to carry out work in the field. The disadvantages include a large waste of time for the operation and the rapid wear of the file. For the procedure, it is better to choose files from a good manufacturer.

How to sharpen a chain on a chainsaw with your own hands?

The procedure for sharpening a saw chain with your own hands is not very difficult. A chainsaw chain at home can be sharpened in several ways, using various tools and sharpening devices for this purpose.

- Sharpen Chainsaw Chain Angle Grinder.

- To carry out such a technical procedure, use a special file.

- Use Powersharp technology.

- Sharpen a chainsaw chain with a machine.

Each of the above sharpening methods has its own nuances that must be taken into account when carrying out the operation.

How often do you need to sharpen the chain on a chainsaw?

With the operation of even high-quality equipment, the cutting element is worn out, it loses its original factory sharpness, and sharpening is required.

The main signs that it is time to sharpen the chain on a chainsaw are:

- the tool loses stability in work, strong vibration appears, and the saw breaks out of the hands;

- the chainsaw begins to produce fine shavings;

- there is no slight deepening of the tire of the equipment into the wood; to perform the cut, it is required to apply force to sink its cutting part;

- when cutting, a curved cut is formed;

- there is a rapid heating of the gasoline engine;

- there is an increased wear of the cutting element;

- fuel consumption increases.

It is required to check and sharpen the chain if any of the listed signs of a malfunction of the tool appear.

The chain must be sharpened at regular intervals, which depends on the intensity of use of the tool.

How to sharpen with an angle grinder?

Sharpening the chain angle grinder is considered by professionals to be a primitive work. When using this tool, there is a high probability of damage to both the saw elements and the bar.

The process looks easy on the surface, but it requires a lot of skill. During the procedure, the chain remains on the bus.

Sharpening an angle grinder chain consists of the following steps:

- A metal cutting disc with a thickness of 1.5-2 mm is fixed to the angle grinder. For this purpose, it is recommended to use not a new disc, but with a worn edge.

- An obstacle is placed in front of the bar and chain.

- Sharpening is carried out at the desired angle.

With a professional approach, the number of sharpenings in this way can reach 7 times.

It is better not to use this method for a beginner, as there is a high probability of damaging not only the saw segments and the bar, but also parts of your body.

The advantages of the method are fast implementation, low cost and minimal expenditure of physical forces. Disadvantages of the technique. the need for a person to have special skills in handling tools and strict adherence to safety precautions, violation of which can provoke injury.

Powersharp system

Powersharp is Oregon’s patented self-sharpening saw chain system. This is the only technology in the world that allows an employee to make sawing elements on the tool as new directly during the working process without the use of additional tools and fixtures.

The technology is based on 4 elements, the use of which allows self-sharpening in a short time and anywhere.

To use this technology you will need:

- The original PowerSharp chain. Its peculiarity is the presence of super-sharpened cutters and minimal vibration during operation. Due to the use of special profiled connecting links, the operation of this element of the chainsaw is of higher quality, and an excellent removal of the formed chips is carried out.

- PowerSharp special abrasive stone. The bar is original in terms of the composition of the abrasives used. It is installed inside a sharpening tool, which is designed for use over the life of 1 chain. Its replacement is carried out simultaneously with the chain.

- Oregon Power Sharp guide bar. A special feature of this element is that it is specially designed for sharpening. Due to the presence of holes on the bar, which are created to secure the chain under a special sharpener, high-quality and accurate tension calibration is carried out when working on a sharpening device.

- Sharpener PowerSharp. It is a high-quality block made of high-strength plastic, inside which an abrasive bar is installed. On the back of the device there is a stop handle.

To sharpen a chain using the PowerSharp system, you will need:

- Attach the sharpener to the guide bar.

- Support the sharpening device with the stop handle on a hard and stable surface.

- Run the saw at maximum speed for 3-5 seconds.

The use of this system allows you to keep the tool always in good condition, even in the absence of experience in sharpening.

Sharpening machines

Grinding machines are available in 2 types: electric and manual.

Electric units are equipped with special adjustment options that help to position the saw blades at the desired angle. These functions make it possible to accurately and accurately drive the blade to the saw teeth. There are models of machines that are equipped with autos. They are started when the disc approaches the sharpened edge. This equipment is characterized by a high degree of functionality.

Structurally, the equipment with a manual drive resembles a bow saw, in which the blade has been replaced with a round file. This machine can be used for the procedure of sharpening and dressing the teeth while adjusting the proportionality of the edges of the teeth to the minimum size.

The mechanism of such equipment makes it possible to fine-tune all the required technical parameters. After the adjustment, the sharpening procedure is carried out using 2-3 movements, after which they move on to the next tooth. If it is necessary to sharpen the limiter, the round file is changed to a flat file.

HOW TO SHARPEN A CHAINSAW CHAIN PROPERLY.

The advantages of using this equipment are fast and high-quality sharpening of saw links without significant physical costs. The use of machine tools allows you to restore the operation of teeth that have lost their original shape. The disadvantage of this method is the impossibility of using electrical equipment away from power grids.

How to sharpen a chainsaw chain with your own hands

Correct use and care affects the quality and performance of your chainsaw.

One of the most common brands of gasoline powered tools is Stihl. For comfortable operation, it is required to sharpen the chainsaw in a timely manner. A dull saw chain can be handed over to specialists or sharpened independently, especially since the process is not particularly difficult.

Framed

The gang saw is a tool commonly used in sawmills. It serves for longitudinal cutting of wood into boards and beams. Its peculiarity is that the saws are rigidly connected in the form of a frame.

The undoubted advantage of the design is its high performance. When sharpening, it is necessary to take into account the parameters of the teeth, which are usually selected for interaction with a specific material.

Sharpening gang saws is considered more difficult than conventional similar tools for wood.

Extra strong material must be used. The automatic machine copes well with the task at hand, the grinding wheel moves at a certain interval. It is important to maintain the correct angle and avoid mechanical damage.

The width of the set of teeth for sawing fresh coniferous wood should not exceed 0.8 millimeters, the same figures for oak or beech. 0.6 millimeters. The operation is carried out industrially, the grinding material is corundum.

At the end of the work, grinding is carried out. Sharpening gang saws is more difficult because the thickness of the material to be ground is not the same for different teeth. Both the front and back of the teeth are sanded.

Sharpening signs

The first sign that a regular saw needs to be set and sharpened is to move away from the mowing line or to clamp it in the material. A sharp chain saw allows for effortless cuts, while high heat combined with too small chips signals the need for adjustments. Experienced technicians can determine the need for sharpening by changing the sound.

Circular saws also heat up, build up carbon deposits and become more difficult to move.

The chain saw dulls extremely quickly after hitting the ground. Its further use leads not only to an increase in muscle efforts, but also increases the load on the units of a gasoline or electric saw.

The chain may vibrate, fuel consumption will increase, and overall efficiency per unit of time will be significantly reduced. The size of the detached shavings will resemble flour.

The appearance of smoke during the operation of a circular or circular saw and heating of the protective casing, chips and irregularities along the edges of the cut indicate the need to sharpen.

Deformation of the teeth can be determined visually. Thus, the urgency of the operation will be indicated by a general decrease in labor productivity, a decrease in accuracy, a change in the nature of the sound, rounding of the tops of the teeth, the withdrawal of the tool from the mowing line, and the use of large physical efforts.

How to sharpen a saw correctly?

- Sharpening signs

- What tools are needed?

- How to sharpen correctly?

- saw

- By wood

- Framed

- Helpful hints

How to sharpen correctly?

The tool sharpening process is quite simple. The blade is clamped in a vice and the teeth are sharpened alternately. First, this is done on one side, and then, turning the canvas over, the manipulations are repeated. Movements should be extremely accurate and monotonous.

Sharpen the saw from the inside towards the set. Naturally, in this case, it is necessary to observe precautions by wearing special gloves. It is recommended to evaluate the result with the help of “control sawing”. The difference “before and after” should be significant: the resulting cut is smoother, much less effort is made.

Each saw tooth can be viewed as a small knife, and in the case of a chain saw, as a small plane that enters the material at different angles depending on the technological purpose of the tool.

Teeth can be straight and oblique, trapezoidal or conical. Oblique. the most common, conical, as a rule, perform auxiliary functions, in particular, they are used for cutting laminate.

In any case, the result should be the same: the hand tool at each point moves with equal efforts the same number of times. Burrs are removed with a very fine cut file. For suburban construction or major repairs at home, you can use compact machines.

Before sharpening round discs that are used for working on aerated concrete, you need to clearly understand what kind of alloy we are talking about. Not every abrasive material will cope well with the task: the harder the metal, the more difficult it is to sharpen it.

The wear of the stone and the cleanliness of the processing depend on the correspondence of the abrasive material to the metal, including the grain size. When using machine tools, the speed of rotation also affects the efficiency of sharpening.

The cutting tool can be tipped and carbide tipped. In this case, experts recommend using abrasive wheels with diamond chips or products made of CBN and silicon carbide. Circular saws sharpen from the side of the rear working surface that is in contact with the material.

saw

An electric or gasoline chain saw uses the chain as a contact cutting surface. It is sharpened in workshops using industrial equipment or do it yourself using a template. In the latter case, round (cylindrical) files with a small diameter are used, which are selected depending on the marking of the sharpened product.

In particular, the Stihl MS brand chain from 180 to 250 will require a file with a diameter of 4 mm, for MS 290 and further up to 440, a tool with a diameter of 5.2 mm is required.

The round file only moves forward and nothing else. Direction perpendicular to the chain plane. In addition, when sharpening chains, a flat file and a template are also used, after installing the template on the tooth, the cutting surface is sharpened.

Before starting work, the tire is clamped in a vice. However, the use of the machine in such a case is still preferable, although there are opposite opinions. If the wear is small, the matter can be corrected in manual mode, but we must not forget about the geometry of the cutting part.

With heavy wear, machine tools are necessary. Complex equipment has a tuning system that allows it to work automatically.

It must be borne in mind that different chains differ in the shape of the teeth, so the tool used must comply.

As a general rule, the teeth are first sharpened in one direction through one, after which the saw turns in the opposite direction and the operation is repeated.

For manual sharpening of chain saws, the tool is sold in sets. Choosing it, you need to understand well which chains will have to sharpen. If in the course of solving the problem you have to choose between the engine power and the sharpness of the chain, the latter should be preferred.

By wood

Any wood saw works very efficiently if it is regularly checked and sharpened. Manual model can be sharpened by hand.

By the way, this way you can sharpen not only a hacksaw or a chain saw, but also a circular saw, which has found wide application in woodwork.

The machine is a good solution, however, if only a manual version is possible, the procedure will look like this. First you need to fix the product on a stand that will rotate. Mark the corners with a marker. The template can be a standard disc, taken “on the side” or previously purchased in pairs. If there is none, you will have to take care of your own hardboard template in advance.

What tools are needed?

Various types of saws make their own adjustments to the list of tools used for sharpening. For a regular hacksaw, a triangular file is required, needle files are also used.

In addition, you will need a clamping device, for example, a vice, or you will have to make a special device yourself. In this case, bonded plywood sheets are used, between which the canvas is clamped. In this case, the teeth should protrude slightly above the surface.

A circular saw will require a pair of wooden blocks, self-tapping screws, a marker, a screwdriver, a jigsaw or a hacksaw, a ruler.

An industrially manufactured machine is used if the process is more complicated, for example, when sharpening chain, frame cutting surfaces or if there are several saws. A grindstone is used as a working tool.

Chainsaw attachments are used in conjunction with a special bar, which is used to sharpen while rotating. Sharpener, rhombic stone, circle, disc. these are the forms and types of sharpening tools.

Machine tools, in turn, are divided into electrical and mechanical, the latter are driven only by muscle power. The most sophisticated and expensive electrically driven options allow the operation to be carried out automatically, turning the grinder into a regular machine operator.

Helpful hints

- The part to be sharpened, as a rule, is always rigidly fixed, the place of work must be well lit.

- The parts to be processed must be the same in height and shape, which can be checked at the end of the work by placing the product on a sheet of white paper. If the result is not achieved, additional reworking using a file is required.

- The more often the saw is sharpened, the longer it serves.

- An important aspect during the work is compliance with safety measures, full concentration of attention and the absence of distractions are required.

Parts can be manipulated only when the machine is off, otherwise the user risks serious injury.

- Sometimes the fine-tuning of a sharpened tool occurs with fine sandpaper.

- The teeth should always be brought into the same form, even if only a few are dull. No gaps and precise adherence to technology is the key to success.

- In the event that the saw is not sharpened independently, this operation should be entrusted to a “narrow specialist”, and not to a “general-purpose grinder”. If sharpening is done independently, it should be noted that using a vice will greatly facilitate the solution.

- The quality and quantity of sharpening for a product depends on a number of factors. It is necessary to take into account the hardness of the alloy, the future working material and its volume.

- Naturally, one should take into account the time elapsed after a similar operation.

- It is impossible to demand the impossible from circular or chain saws, they are used only as much as declared by the manufacturer, it will be more expensive to deceive yourself.

- Removal of the metal layer depends on the degree of wear. The more you remove, the less the resource will be.

- Handicraft work always differs in its effectiveness from the results of the efforts of a specialist using a machine.

Thus, we highlight a number of general rules that should not be forgotten when sharpening saws.

- Satisfactory fixation is required. It is provided with the help of devices, including those made by hand.

- Workplace lighting and distraction-free.

- Quality tool.

- Uniformity, smoothness and compliance with the rules of grinding.

- Deburring with a file or a file with a very fine cut.

- Checking the lack of gloss on the cutting edge and the correct geometry of the tooth. If it remains rounded, we can assume that nothing has worked out.

- “Control” cut will show everything. Changes must be substantial.

For information on how to sharpen the saw correctly, see the next video.