How the saw is set and what is it

The setting of the saw is the bending of the teeth in different directions by a predetermined amount. This is done so that the saw does not jam in the material during processing, it goes easily and effortlessly. The more the teeth bend, the less the risk of the blade getting stuck in the wood. However, a set that is too wide will have a negative effect on the cutting process. The maximum value should not exceed 2 mm.

If a dry material is cut, then the width of the wiring should be 0.3-0.5 mm, if raw wood is processed, then the bend should be 0.5-1.0 mm.

You can use special pliers for routing. The required bend size is set on them, after which the tool is set up. The process is carried out quickly and efficiently, but ticks are not cheap. Therefore, many people use adjustable plates that have a stop and manual adjustment.

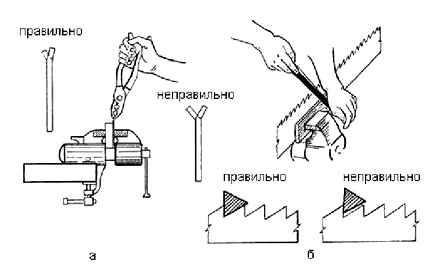

Before bending, the saw must be securely clamped in a vice. The teeth are processed through one: first one side, then the other. In this case, the bend must be made from the middle of the cutter, and not from the base. Otherwise, it may break.

What to Consider: Professional Tips

- When buying a new saw, many craftsmen make a template on cardboard, which later helps to sharpen the hacksaw with high quality and correctly.

- When sharpening, the file should cling tightly to the metal and remove the chips. If it slips, then the tool does not fit and must be changed to another.

- Do not route with pliers, as the tool will not provide an even angle of inclination.

- To prevent the hacksaw from losing its sharpness quickly, it is necessary to store it correctly. The saw is hung on the wall on a hook, during transportation it is placed in a case.

General requirements for sharpening

The following requirements are imposed on manual sharpening of the teeth of a hacksaw for wood:

- for work it is necessary to use high-quality files (needles);

- files should only be used for sawing;

- there should be an equal number of passes for each tooth, regardless of the shape of the tooth;

- it is forbidden to change the angle of inclination of the file and rotate it during sharpening;

- the file must be moved only in one direction, away from you;

- the edge of the tooth should be matte, if there is gloss, it is necessary to repeat the sharpening;

- during operation, the blade must be securely fixed in a vice, while the teeth should protrude slightly and be at the same height;

- the workplace should be well lit.

How To Sharpen A Crosscut Hand Saw

Instructions: how to sharpen a hacksaw yourself

Before carrying out the process, you need to know that hacksaws for wood from hardened steel cannot be sharpened. The material can be distinguished by its black color with a characteristic blue tint.

It is important to remember that the teeth must be diluted before sharpening.

To sharpen a wood hacksaw with your own hands, you need to decide on the necessary tool. Files are most often used as a sharpening device, less often an angle grinder.

The process of restoring the sharpness of the cutting edge depends on the type of hacksaw. Crosscut saw processing is carried out as follows:

- The blade is clamped in a vice at an angle of 45 ° in relation to the table.

- The left edge of the even cutters is sharpened.

- The blade flips.

- The left edge of the even teeth is sharpened.

- Sharp cutting edges and sharp tops of incisors are formed.

For processing, a triangular file with a fine notch is used.

wiring; 2. chisel; 3. saw blade; 4. bars; 5. wedge; 6. support; 7. triangular file; 8. square

To sharpen a universal saw or a rip saw, the blade must be clamped in a vice at a 90 ° angle. For processing, you should use a diamond file. The tool is held in the hands parallel to the work table. Otherwise, the process of processing the cutting edge is the same as sharpening a hacksaw for cross-cutting.

After processing all the teeth, burrs may remain on the edges, the size of which depends on the thickness of the saw blade. They are removed using a fine file (with a “velvet” notch), or an abrasive bar of fine grain.

Sharpening quality can be determined in 2 ways. When checking by touch, the sharpness of the teeth should be felt, the absence of burrs. Or check the cutting edges by color: when illuminated, there should be no glare on them.

Additionally, a test cut is carried out: during processing, the hacksaw should go smoothly, without being pulled to the side; the cutting surface must be smooth, without torn wood grain.

You can sharpen the saw with an angle grinder. For this, the power tool is attached to the work table. The saw is moved along the guides manually so that each cutter is fed to the emery disk in the same plane. In this case, it is necessary to install a sharpening depth limiter, which allows maintaining the same cutter height. First, the faces of an odd row of teeth are processed, then an even one. After processing, deburring with a file or a touchstone is also required.

How to sharpen a hacksaw at home. step by step instructions

A hacksaw for wood is a tool that every owner has. However, over time, the saw loses its sharpness, which affects its performance and cut quality. Sharpening a hacksaw at home is quite simple, without much effort.

Why sharpen the canvas with a hand hacksaw, and when to do it?

A hacksaw is subjected to various loads during operation, as a result of which the teeth become dull. In addition, they change their position. All this leads to the fact that:

- the efficiency of using the tool decreases;

- more time and effort is required for the sawing process;

- the accuracy and quality of the cut deteriorates (notches are formed);

- there is a danger of using a blunt instrument.

A saw with dull teeth must be sharpened. You can determine that it is time to process the tool by the following factors:

- when working, the hacksaw makes a characteristic sound (with constant use, it is easy to determine its change);

- the tips of the teeth are rounded;

- the tool has lost its former efficiency and cut quality.

When these situations arise, tool sharpening is required.

How to sharpen a hacksaw

The question “How to sharpen a hacksaw with your own hands?” does not lose its relevance, despite the presence of a modern power tool in every home.

The saw is needed on the farm, irreplaceable on vacation, used for cutting boards, logs, chipboard.

It is also necessary for construction, carpentry and installation work; in the garden and workshop.

In the city, in the country or in the garage. everyone has this time-tested tool.

Set of teeth of a hacksaw

The movement of the blade must be free, for which the saw teeth are set by the same amount.

To reduce the coefficient of friction and the clamping of the hacksaw in the cut, its width must be greater than the thickness of the working blade, otherwise the metal heats up and expands, which leads to the saw to jam.

The setting of the hacksaw teeth is performed by bending the cutters to the sides.

Using pliers does not allow you to get the same angle of inclination. such a tool can only cut firewood.

To spread the cutters evenly and get an even, neat cut, use a homemade setter.

To make it, you need a metal plate of arbitrary shape with a thickness of 2-3 mm.

In a simple version, several slots are made to indicate the thickness of the blade.

The prong is gripped into the hole and bent back until it reaches the selected stop.

In the second version, a cut is cut in the bar with a metal file, and two holes are drilled to install the limiter.

Turning the sector to the sides allows you to adjust the bend angle.

The figure shows a simple model and wiring with an emphasis.

The device circuit is intuitively easy to manufacture and use.

It should be noted that the bend width has its own parameters.

Requirements for setting the teeth of the hacksaw

Bending the cutters through one on both sides of the blade, observe a certain value, which can be set on a homemade device.

The width of the wiring depends on the type of wood.

Soft and damp wood requires a higher incline angle than dry wood.

Generally, hand tools work effectively with an average of 0.2-0.3mm.

At the same time, the total value should not exceed the width of the web.

In addition, the same bend pattern is observed on each side.

The hacksaw set is checked visually or with a vernier caliper.

Pay attention to the size of the tooth. the height of the incisor is especially important.

Checking the height of the hacksaw teeth

Check the height of the teeth before sharpening the tool.

To do this, lay a sheet of plain paper on a hard and even surface, and press the cutters tightly until a clear print is obtained.

If there are teeth protruding from the general row, traces from them will be reflected in the print.

If there are higher teeth, they are carefully cut with a flat file to the general level.

How to sharpen a hacksaw with your own hands

How to properly sharpen a hacksaw yourself, if the need arose?

First you need to decide what material the working blade is made of.

Ordinary steel can be corrected independently, and teeth with victorious solders can only be processed on specialized industrial machines.

How to Sharpen a Hand Saw | Ripsaws

Some craftsmen, at their own peril and risk, undertake to sharpen a hacksaw with an angle grinder. but this is an unreliable and dangerous way.

To tidy up an ordinary hand-held hacksaw at home, you need to determine the shape of the teeth, prepare everything you need, and be sure to observe safety precautions.

Why sharpen and when

With constant use, the teeth lose their sharpness, the cutting edges wear out, deteriorating the quality of the cut and increasing the time to complete the task.

Buying a new one will not correct the situation for a long time, and it will take no more than half an hour to restore the old canvas.

Timely sharpening of the hacksaw will restore the cutting ability of the cutters, and will allow you to always have a working tool at hand.

It is worth correcting the sharpness of the cutting edges at the first signs of wear, which may touch local areas and the entire working surface.

The dimensions of the set of the cutters also change, and this leads to jamming during operation.

How to sharpen a hacksaw with a file

The use of a file is still relevant today, so let’s try to figure out how to properly sharpen a hacksaw at home.

It must be fixed, as already mentioned above, in a clamp or vice.

The vise cheeks must be made of wood, with a jaw width of at least 200 mm.

The movement of the file should be uniform, and the pressure on the teeth is made only when moving “forward”.

It is necessary to move the hand with the tool to the starting point freely, without effort on the incisors.

In one working pass, an even layer of metal is removed, this will preserve the step, height and profile of the edge.

The sharpness of the cutter can be reduced by the formation of burrs on the surface and irregularities after the passage of the abrasive.

A file cannot perfectly sharpen a hacksaw, but you can get high quality. after sharpening, the smallest file or a file and a touchstone will come in handy.

Burrs are removed by selective cleaning with a fine abrasive, and the edges are smoothed with a wet donor along the side base of the blade.

Having set a goal to sharpen the hacksaw correctly. pay attention to the preservation of the tops of the teeth.

The same cutter height, correct setting affect tool wear resistance and cut quality.

Saw set

Sharpening a hacksaw for wood begins with a procedure such as setting the teeth. The setting of the hacksaw teeth is performed for such purposes as ensuring the free movement of the blade without jamming. The setting is the bending of the teeth in different directions, alternately, by one amount. This leads to the fact that the kerf width increases, which means that during the sawing process the chip removal process is accelerated.

It’s important to know! The wider the tooth setting, the less chance of blade jamming.

The size of the set of teeth depends on the thickness of the blade, and is usually equal to 1.5-2 mm. To bend the teeth by the same amount, you will need to use a special device. This device is a metal plate with a special slot. The blade is clamped in a vice so that the links protrude slightly. After that, the process of bending the teeth is carried out. Sharpened teeth must also be bent to the same distance.

Why and when to sharpen

The tool in question is subjected to various loads during operation, which leads to dulling of the teeth. If you cut with a saw whose teeth are dull, the result will be much less effective than a sharp one. In addition, using a saw with blunted teeth is not recommended for the following reasons:

- Decreased tool performance. Not only the powers of the master will be spent, but also his time.

- Decreased accuracy of work. It is impossible to smoothly cut wood materials with a blunt-toothed hacksaw, and even more so to do it neatly.

- Danger of using the tool. During work, the saw will get stuck, jammed, come off the mowing line of the cut, so such work can be dangerous for the master.

A sharp hacksaw is not only easier to work with, but also much safer. To determine that the time has come for sharpening the saw blade for wood, you should pay attention to the following factors:

Saw Blades & Router Bits Sharpening Jig

- The canvas emits a characteristic dull sound. If the master often uses a hacksaw, then it will not be difficult for him to determine such a sound.

- The tips of the teeth are rounded.

- Saw when trying to cut wood, refuses to do its job.

These factors indicate that the time has come to sharpen the hacksaw on wood with your own hands. But before you take up the file, you should determine whether these links are subject to sharpening.

Purpose and device of the saw

The hand saw is used for sawing various wood materials. It is a blade with teeth at the bottom. On one side, the tool is equipped with a handle, with which the master holds it during sawing work. The convenience and comfort of working with the saw depends on the quality of the handle.

The number of manufacturers of hacksaws for wood is quite large, but they all differ not only in names, but also in quality. All of them are intended for sawing wood, chipboard, logs, laminate, as well as tree trunks. Hacksaws are subdivided into such types as: classic, circular, bow, as well as with butt and reward. The thickness of the blade plays an important role in the selection of the tool. After all, a thin blade can break during sawing wood, and it is quite difficult for a thick one to work.

Important! Wood hacksaws should be sharpened periodically. Sharpened saw blades include those that have not gone through the hardening stage. If the links of the canvas are hardened, then it is impossible to sharpen them.

How to sharpen a hacksaw on wood

To sharpen a hacksaw on wood, the blade should be fixed in a vice in the same way. Needle files or triangular files with a fine cut are used to sharpen the saw links. Not many people know how to properly sharpen a file on wood, so you should pay as much attention as possible to this process.

- Initially, you need to pick up a file. A file with a fine cut should be used, which should be held with one hand by the handle and the other by the tip of the instrument.

- The sharpening angle is determined, which usually ranges from 15 to 30 degrees. The angle is usually determined by eye, but if this is difficult to do, then you can use special home-made devices, for example, a wooden block. To do this, the bar is turned until it has the shape of a right-angled triangle with angles of 30 and 60 degrees.

- The most important thing when working with a file is pressure on it. To ensure uniform sharpening, the same number of file passes on each tooth must be performed. With experience, you will learn how to remove the top layer of metal evenly.

- With the help of the prepared device, the sharpening angles are controlled. The process is carried out in the same way on the back of the web.

Now you know how to properly sharpen the teeth of a hacksaw blade for wood. But the process does not end there yet, as it will be necessary to align the teeth in height. If they have different heights, then the uniformity of the cut will be disturbed. If there are links that are higher than the others, then they are shortened using the same file. Checking is carried out using a sheet of paper, to which the blade should be applied with the teeth down. After that, the sizes are compared, and the shortening procedure is repeated.

How to sharpen a hacksaw on wood yourself

For sawing building materials from wood, as well as trees, a tool such as a hand saw is used. Despite the fact that electric and even gasoline saws, jigsaws and circular saws have long been developed, a hand saw for wood remains an indispensable assistant in the arsenal of every craftsman. With the active use of this tool, it becomes necessary to sharpen the teeth. How to sharpen a hacksaw on wood yourself at home, we will consider in the material.

How to sharpen a saw: practical recommendations

When carrying out work on sharpening a hacksaw, you should adhere to the following recommendations:

- The device is tightly fixed on the working surface in a vice.

- Providing good lighting for the workplace.

- For sharpening the links, files and needle files with various notches are used. The smaller the notch, the better. It all depends on the degree of dullness of the teeth.

- Metal removal is carried out only when the file moves away from itself in one direction.

- After the work is done, you need to check the quality. To do this, you need to look at each link in the light. If the tooth shines, then it is sharpened correctly, as in the photo below.

In conclusion, it should be noted that many craftsmen do not consider it necessary to sharpen a hacksaw. This is wrong, since the efficiency of the work depends on the quality of sharpening.