What is it for?

Many saw owners ask a reasonable question, why does this tool need oil. The answer is simple. this tool is used as a lubricant for the chain, so that the levels of the impressive force of friction between the individual parts. Due to the presence of oil, important elements of the device DO NOT suffer from excessive heat, in contact with each other.

With a good and timely oil application, the saw will work Not only more efficiently and lighter, but longer. Equipment deprived of such maintenance is subject to very serious breakdowns. She will hardly serve for a long time.

There are several options for chain saw oil on the market today. These formulations can be mineral, synthetic or semi-synthetic based. It should be borne in mind that the latter contain both synthetic and mineral components. Another category of modern chain oils for electric dust from different companies is represented by products based on raw materials of vegetable origin. Of course, each group of oils has its own advantages and disadvantages.

If we consider the properties of all oils from the point of view of stability and the ability to operate effectively in rather difficult conditions, then, of course, synthetic products come out on top. They are capable of providing electric dust operation even in very cold weather (up to 40 degrees). However, these types of oils also have one important drawback, which must be taken into account. they are expensive. This is why many consumers are abandoning their purchase in favor of more affordable options.

As for the popular mineral oils, they are much cheaper than the synthetic ones. However, their performance characteristics are very inferior to those of the above compositions.

Semi-synthetic oils are a cross between synthetic and mineral products. These types of oils are produced for both electric and gasoline devices.

Champion

Champion adhesive oil is usually used for work with a rather wide temperature range. This grease is sold in containers of 3 and 10 liters. The product is inexpensive, it is also easy to use.

Usage tips

Choosing the right saw oil is not enough. You also need to know how to properly pour it into such a technique.

So, modern saw models are equipped with a special well-thought-out system for the automated supply of lubricant to the necessary units, where friction occurs during the operation of the tool.

If your toolkit contains such a technique, then you will NOT have to invent anything superfluous. You just need to carefully pour the selected suitable oil into a specially designated container. After that, it is worth letting the device run for just a few seconds, but without load (the saw should operate “idle”). During this operation of the technique, the lubricant will “disperse” as evenly as possible along the entire length of the chain.

Let us use brushes or a grease gun to lubricate an important tool assembly. Compositions in special aerosol-type packaging are most suitable for such purposes, they are very convenient to use.

Forest plus

This oil is in great demand and has excellent adhesion properties. Forest plus is characterized by the fact that it can be operated if the temperature outside the window is at least 15 degrees.

Popular brands

As mentioned above, there are many brands of modern saw oils. Among them there are both Little-known and very popular ones. If you decide to purchase high-quality and reliable saw oil, then you should familiarize yourself with the list of the most popular models.

Can I use engine oil?

Whether engine oil can be used as a saw lubricant is another common question from tool owners.

It should be borne in mind that such compositions are suitable exclusively for specific dust models. The fact that the tool can be lubricated with engine or transmission oils must be indicated in the technical documentation attached to the equipment.

Ordinary vegetable oils are not suitable for lubricating the chain mechanism. Of course, they will have a short lubricating effect, but it is worth remembering that such compositions have a characteristic property. they dry out. Subsequently, this can lead to the fact that the chain will move very badly in the mechanism, with a delay. Because of this, the performance of the saw as a whole will noticeably deteriorate, so it is not recommended to experiment with vegetable oils in relation to this technique.

Choosing and using saw oil

Electric saw oil is hardly the most important and necessary consumable. It is he who has a positive effect on the operation of the instrument. Good oil greatly simplifies the operation of this device. With it, the cutting blade better contacts materials with different structures. In addition, thanks to this consumable, the tool can last much longer.

Let’s figure out how to choose the right oil for your electric saw.

Bio Plus

The company’s products called Bio Plus are plant-based. Oils of this company, when penetrating into the soil, very soon begin to decompose. Not every oil can boast of such a distinction. It is permissible to use this product at temperatures up to 15 degrees, like the previous version.

Husqvarna

The name of this world famous brand inspires trust. Husqvarna Saw Oil is the most profitable and economical solution for lubricating electric saw mechanisms. These products are characterized by moderate consumption and high efficiency.

How to fill a hydraulic jack

The next factor influencing the choice of the optimal oil is its viscosity. The viscosity grade of hydraulic oils is indicated by the abbreviation VG (Viscosity Grade), which has a numerical value ranging from 5 to 150.

- Low viscosity: 5. 15

- Average viscosity: 22. 32

- High viscosity: 46. 150

When choosing a fluid for a hydraulic jack, one should focus on the average viscosity, which is close to the lower VG values. With a high value of this indicator, the oil will thicken more in the cold.

The hygroscopicity of oils is the ability of these to absorb water, which impairs the lubricating characteristics and entails many other undesirable consequences. It is not recommended to pour a solution with this feature (for example, brake fluid) into the jack. Despite the complete isolation of the liquid, when the pump rod and piston are extended, it will receive its dose of moisture over time.

When operating the jack in warmer conditions, you can use less frost-resistant industrial mineral mixtures: I-12A, I-30A, I-40A or I-50A. With a strong desire and limited financial resources, you can fill the jack with used engine oil, previously passed it through a fabric filter.

Why exactly oil

Not all liquids have a positive or at least neutral effect on the metal of which the tool is composed. Water, acids, alcohols and many other liquids cause a natural oxidation reaction, and as a result, corrosion and rust. Some compounds react faster, others more slowly. Some can corrode at all, either metal or rubber or Teflon gaskets and seals. When choosing which oil to pour into the hydraulic jack, you should be careful, since even in this category of substances there are unwanted mixtures (more on this below).

In essence, a properly selected oil will not only not harm the system, but will also protect its components from abrasion and oxidation. Working in such a liquid, the mechanism retains its original qualities for many years. With regular maintenance, even the most budgetary tool can easily last longer than an expensive one if the latter is NOT maintained.

What kind of oil to fill in a hydraulic jack: examples for all occasions. Hydraulic jack device

It is best to start identifying mixtures that are harmful and useful for the jack, it is best after a meaningful, albeit quick acquaintance with the internal system that will be filled with this liquid. Perhaps this knowledge will not help much in choosing an oil, but it will convey the importance of this process, and an understanding of the operation of the mechanism will be very useful during repairs. If you do not have time or desire for this kind of information, scroll down a little, and for now we will go over the following scheme and tell you how the liquid circulates in it.

When the lift is not in its best working condition, its stop is lowered to the zero position, and practically all the liquid is in the oil reservoir. In order for the stop to be pushed up, the fluid must move from its compartment to the cylinder block, being under the piston cup. The oil pumping operation is performed by a pump and 2 valves (suction and delivery).

When the pump piston rises, a vacuum is created in its chamber, sucking liquid from the oil reservoir through the Corresponding valve. On the contrary, when the piston is lowered, pressure is created to push the oil out of the chamber through the discharge valve. The liquid cannot leak back, since the ball on the spring (valve) allows it to flow only in one direction and under pressure, blocks the round hole, tightly pressing against it. Thus, the volume of liquid in the working cylinder gradually increases, pushing out the piston and raising the stop with the load.

When the oil jack has completed its task, the piston must be lowered, moving the fluid back into the Primordial Compartment. This task is effectively performed by a shut-off valve, the rotation of which unites the working cylinder and the oil reservoir, allowing oil under pressure to flow from the first to the second. A classic hydraulic lift functions according to this simple principle.

How often to change the fluid

Having studied all the possible options, and having analyzed in detail what to fill in the hydraulic jack, it remains to clarify the frequency of this procedure. It is worth noting that there is an exact fluid change interval, and these periods depend on the intensity of use of the jack, storage conditions, operation, as well as the initial purity of the oil. It is better to change the working off 2-3 times more often, in contrast to pure mixtures.

Nevertheless, it is necessary to establish at least an approximate time, Based on certain situations. If you use the jack for seasonal tire fitting on one car, doing it carefully and in a clean garage, the fluid can not be changed for more than 2 years. With more intensive use, from 2 to 4 cars, you should devote time to this once a year. When working in a workshop, where the jack is constantly in operation, the oil should be changed once a month, or even more often (depending on the cleanliness of the room). When using the lift in construction, where it is constantly in contact with dust and dirt, the procedure for changing the oil should be carried out once every 1-2 months (depending on how often it is used).

Types of transmission fluids

All lubricants for a manual transmission are classified according to the degree of viscosity, performance and the type of base from which they are made. It is the last subdivision by the type of basis that is predetermined when choosing a transmission oil among most motorists. They are divided into three types of bases: mineral, semi-synthetic and synthetic.

Mineral gear lubricants for manual transmissions are the most popular in the Russian market. This is primarily due to the fact that the price of lubricants with a mineral base is lower than oils of the second types. Mineral lubricants are inferior in properties to synthetic transmission and semi-synthetic oil fluids.

Semi-synthetic lubricants are more effective than mineral lubricants, but they are inferior in properties to synthetics. When choosing how to choose a gear oil for a manual transmission, it is best to focus on synthetic lubricants, and not the “cheapest” analogues.

The rating of gear oils for manual transmissions is led by synthetic lubricants. But they have a price higher than in semi-synthetic and mineral analogues. The best properties of transmission oil for manual transmissions, in products based on synthetic base.

Division of oils according to their performance

In addition to the SAE viscosity grading, API markings can be found on lubricated bottles. They will divide oil fluids according to their performance properties and quality:

- GL-1. mineral grease without additives;

- GL-2. grease with high fat content;

- GL-3. oily liquid with anti-scuffing additives;

- GL-4. composition with a complex of additives against wear and scuffing;

- GL-5. grease with a wider range of additives than GL-4;

API classification helps to understand the performance of a lubricant product.

The brand of oil is not fundamental when choosing it; it is its API performance that is more important here. Usually, both small and giant brands make lubricants with the same quality level. The main thing is to avoid fakes.

Division of oils for manual transmissions by viscosity

Lubricating fluids for manual transmissions are classified not only by the method of manufacture, but also by the SAE viscosity standard. Thanks to this parameter, you can decide on the oil for the transmission at a certain time of the year. Unlike API marking, SAE viscosity grades divide all lubricants into winter and summer.

For winter operation of a car with a manual transmission, formulations of the following types are used: 5W, 10W, 20W and others. It is the English letter W that determines the season, in which it is recommended to use a lubricant.

The oil in the manual transmission must be changed when the season changes. Summer greases include the following SAE fluids without the distinctive letter “W”, for example, the following: 10, 15, 25, 30, 45 and others.

There are also all-season lubricant products for mechanics, they look like this: 5W-40, 0W-30, 10W-50. Such formulations need to be replaced only when the oil level in the manual transmission drops, and not when the season changes.

Recommended oil in the box: manual transmission

Gearbox grease is divided into classifications, which allow you to determine whether it is suitable for a manual or automatic transmission. Usually the lubricant is recommended by the car manufacturer, indicating in the instructions for it which product is most effective for this particular gearbox. But you can choose an oil liquid yourself if you understand the SAE and API classifications.

Since in a manual gearbox, parts are subjected to increased loads, for units of this type, lubricants with a complex of antiwear additives are required. According to API classification, these are GL-4 and GL-5 greases. They are considered the best for manual transmissions. But often the manufacturer recommends pouring oil into the gearbox with a thicker oil than the usual synthetic, namely GL-3. In any case, when choosing which car oil is best for your car, you need to focus primarily on the manual for the vehicle.

The service life of the transmission and the reliability of its operation directly depend on the frequency of oil changes and its quality. Many rely on service stations and purchase the lubricant that a car mechanic pours into the mechanics, but it should be understood that many auto mechanics save money at the expense of their customers. Therefore, it is recommended to independently choose a lubricant product and provide it to the LOCKSMITTER for replacement in the car. Do not forget that you need to change the oil every 30 thousand kilometers and change it in a timely manner to avoid problems with the gearbox. To understand why it is necessary to fill in a gearbox with a mechanical gearshift system this or a certain oil, you must first understand what are the differences between oils for automatic transmission and manual transmission.

What oil to fill in manual transmission

Each owner of a passenger car with a manual transmission is interested in what kind of oil is poured into a manual transmission. Transmission oil provides lubrication to all parts of the transmission and lowers the temperature inside this unit. Also, it is the oily gearbox fluid that helps remove abrasive particles and various debris from the transmission, reducing the likelihood of breakage and the risk of corrosion. But for a certain type of gearbox, a certain oil is needed, since the wrong choice of lubricant can lead to damage to the transmission.

Some general rules for changing gear oils

Before you purchase a lubricant product for your car’s gearbox, you need to carefully study the instructions for the car. Usually it indicates which oil in the manual transmission according to API and SAE is recommended for use in a particular unit. It is also precisely in the operating instructions for a passenger car that the frequency of replacing the lubricating product in the box is indicated.

If you do not know when to change the oil in the gearbox, in Examine the lubricant by carefully inspecting it visually. If particles of wear debris are visible in it, it has become dark or smells like fumes. this clearly the gearbox needs fresh lubrication. Experts recommend doing a visual inspection of the lubricant every 10-20 thousand kilometers. For cars with high mileage, this figure is slightly lower: 5-10 thousand kilometers.

High temperatures inside the gearbox lead to the fact that the surface of the system parts becomes more susceptible to damage, therefore it is recommended to choose a lubricant according to the manual for the vehicle. The manufacturer independently measured what loads the box is subjected to and determined the appropriate product according to API marking.

Functional purpose of grease for mechanics

The role of the transmission lubricant is very important, it ensures long life and prevents premature wear of parts inside the unit. In each manual transmission, there is a large number of different gears and gear parts inside, which actively interact with each other. Also in the mechanical unit, shafts and various bearings are in constant operation. All these parts without high-quality lubricant will quickly become unusable due to wear and stop functioning correctly.

The quality of the lubricant is important Not only because of the safety of dynamic parts inside the gearbox. It is high-quality products that allow you to control the temperature inside the box, effectively remove dirt and various impurities, cleaning the metal surfaces of parts from them. A lubricant has many different functions, so it is important to choose a quality product. But which one is best for the drivetrain? Is it better to buy a synthetic or mineral lubricant? These worthy issues need to be understood by every car owner.

What is the difference between manual transmission oils and automatic transmission fluids

The principle of operation of an automatic transmission differs from a mechanical one. In mechanics, a torque transmission system is used using gearing, which significantly increases the wear of parts in the unit. It is precisely with this that manufacturers recommend pouring compounds with additives against wear and corrosion in manual transmissions: GL-3, GL-4, GL-5. In automation, the main role is played by a hydroconvector, so hydraulic oil is used for it.

If you do not know what kind of oil to pour into your manual transmission, then it is better to turn to the manufacturer’s manual for help. The instructions for the vehicle contain all the necessary information about which lubricant should be used in the box of your car. It also indicates how much oil is placed in the gearbox and where the hole for its replacement is located.

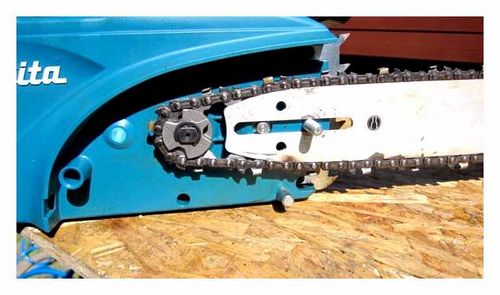

How the chain lubrication system works

As already mentioned, the pump is the main link in the lubrication system. It works as follows. When the engine speed rises, the gear, which is located on the main shaft, starts the pump operation by means of transmission. At this moment, the pressure in the oil supply system rises, and it begins to move in the direction of the tire. This movement ends where the saw casing touches the tire, in the very place where the longitudinal groove is located, to which the oil channel itself is directed when installing the tire. This groove is required to supply lubricant to the tire at any tension level of the chain mechanism, i.E. Regardless of the position of the bar when the saw is running, the groove will provide lubrication to it. The next link in the feed is the chain itself. Its links have their own separate groove or hole through which material is distributed along the chain length.

Automatic chain lubrication system

Many modern saw models, for example Makita, have built-in pumps with additional skip adjustment, with which you can adjust the amount of lubricant supplied. In older versions, dust This feature is usually absent. There, the oil supply is carried out in a constant and unchanged mode, or, as in the very first models, the user has to manually lubricate the chain. Those who own outdated copies need to know how to properly lubricate the chain mechanism by hand. It’s not hard at all:

- Take any old container and fill it with oil;

- The chain mechanism is gently immersed in this container.

These actions should be carried out periodically as the lubricant on the chain is consumed.

Consequences of a lack or excess of chain lubrication

For each machine, the operating mode of which is associated with lubrication based on machine oil, certain parameters must be observed. This primarily concerns the amount of oil required for its normal operation. Such problems can arise if there is not enough oil:

- Overheating of the circuit;

- Premature bluntness of cutting teeth;

- Seized or broken chain;

- Additional time spent on cutting;

- Increased sprocket wear;

- Tire failure.

For an electric chain saw, it is recommended to fill the oil tank in the following proportion: one full oil fill to a full gas tank, i.E. 1: 1. In some models, for example, Bosh, the lubrication system works in a fully automatic mode and if there is too much or too little oil on the chain, the saw itself begins to regulate its supply. However, if a malfunction occurs, and the oil starts literally pouring from the chain mechanism, then its excess can lead to the following undesirable consequences:

- Increased oil consumption;

- Excessive contamination of the tool body;

- Wide spray of oil from the chain.

As you can see, an overabundance of lubricant does not lead to critical consequences, but its excessive consumption will certainly hit your. Taking into account the fact that the cost of high-quality lubricating oil is quite high, it is better to use it carefully.

What oil should be poured into the saw

For most electric dust owners, it is not a big secret that the oil used to lubricate the saw chain is one of the main consumables. However, not everyone pays due attention to the quality of the lubricant. And it is completely in vain, since the term of its further operation will depend on how well this product will lubricate the working surface of the chain. Therefore, before pouring oil into the saw, you must pay attention to its technical characteristics.

Main components of the lubrication system

Typically, oil enters the saw chain lubrication system from a special reservoir, where it is periodically added. From there, it is pushed out by a powerful oil pump, doing this at regular intervals, sufficient to consume the previous injection. The main task of the oil mechanism is to prevent the occurrence of such situations when the lubrication on the chain becomes insufficient, and as a result of this, severe overheating of the cutting part may occur due to the sharply increased frictional forces. As a result, the chain can become dull and fail. Therefore, the oil must be constantly monitored. Typically a saw lubrication system consists of the following components:

- Oil tank for chain lubrication;

- Special oil filter;

- Oil line, which is a small rubber hose, which serves to supply oil from the tank;

- An oil pump that pumps the lubricant from the tank to the cutting mechanism;

- A special gear, with the help of which the force is transferred to the pump from the electric saw motor.

Why do you need chain lubrication on a saw

Saw oil is used as a chain lubricant to reduce frictional forces and reduce heat build-up. As a result, a fast and trouble-free operation of the cutting blade is achieved. Sometimes it happens that at certain stages of cutting, additional efforts are required to obtain the required cut, and this directly indicates an insufficient amount of lubricant or its not very good quality. In this case, it is recommended to immediately check the oil level in the tank or simply lubricate the chain to complete the current work.

General Guidelines for Choosing Saw Lubricant

When choosing an oil for lubricating a saw, each of the users asks the question, which of the options is more profitable and acceptable. a special oil for chain mechanisms or an ordinary machine oil? If you listen to the experts, then, of course, the first option is preferable, since the oil for lubricating chains was specially developed taking into account the technical characteristics of the saw.

Although conventional engine oil is cheaper than special oil, it must be taken into account that it serves a completely different purpose and will NOT guarantee moderate wear on working parts. So you can win a little in price now, but then you will have to overpay for the repair of prematurely worn mechanisms.

Many experts recommend using a brand of special oil with letter N for lubricating the saw. It is slightly more expensive, but guarantees a long and trouble-free chain operation. Its main advantages include:

- Excellent biodegradability;

- Increased adhesive ability;

- Presence in the composition of special additives that protect against premature wear.

By following these guidelines, you can significantly increase the life of your electric saw chain. However, the final choice of lubricant is always up to the user.

Overview of brands from various manufacturers

There are many tempting offers on the market today from a wide variety of manufacturers of Specialty Oils that can operate at high temperatures while still providing excellent gear lubrication performance. The most popular ones are presented in the following list.

- Forest Plus has high adhesion characteristics and can be used at ambient temperatures down to.15 ° C. Under certain conditions, the oil can be stored for 3 years. Sold in 1 liter and 5 liter packs. 5 l. 1140 rubles.

- Bio Plus products are plant-based. It decomposes quickly when released into soil. The oil can be used at temperatures down to. 15 ° C. Packaging. 1 and 5 liter containers.

- Synth Plus is made on a synthetic base. Withstands increased loads and can be used at particularly low temperatures down to. 25 ° C. Packaging. 1 and 4 liter containers.. 4l. 2970 rubles.

- CHAMPION adhesive oil is formulated to work over a wide temperature range. It is sold in 3 and 10 liter containers, which is very convenient for use in forestry.. 10 l. 2200 rubles.

- The HUSQVARNA Vegoil product is one of the most economical solutions for saw lubrication. According to the manufacturer, the consumption of this material is 40% less in comparison with others.

Using a special oil to lubricate the saw chain will ensure smooth operation for a long time. This will make it possible to carry out work quickly, efficiently and with a high level of safety, which ultimately will lead to significant savings in repairs and maintenance of the entire tool.

TOP 5 saw chain oils

Today the market is full of lubricants, which, according to their manufacturers, are capable of ensuring the smooth operation of the cutting set and its drive mechanism. But not every composition shows a truly high efficiency and effectiveness. We are talking about inexpensive fluids with a minimum of m required additives, as well as non-original oils, which are marketed under the name of well-known brands, that is, a fake.

In order not to be mistaken when choosing an oil, it is best to give preference to the following chain compounds:

- 1. Forest Plus from Stihl. The main advantages of this formulation include good adhesion as well as high workability up to 15⁰C. Observing the recommendations indicated by the German manufacturer, the service life of the composition will reach 3 years;

- 2. Bio Plus from Stihl. THESE lubricants are made from a natural vegetable base. Thanks to this, the oil decomposes in the soil and does not harm the soil. German manufacturer’s grease can be used at temperatures up to 15⁰C;

- 3. Synth Plus from Stihl. This oil successfully withstands increased loads and work at temperatures down to.25⁰C. A balanced synthetic base is used for the production of the composition;

- 4. Husqvarna Vegoil. The use of this material from a well-known Swedish manufacturer allows you to save up to 40% oil without compromising the protection of the drive and the cutting parts of the saw. The oil prevents the formation of resinous deposits and rust on the surface of the tool parts;

- 5. Champion BAR CHAIN OIL. Inexpensive chain oil designed for intensive use in summer and winter. The liquid is released with high adhesion and decent anti-corrosion properties.

Regular use of any of THESE oils will ensure trouble-free operation of the saw chain and bar, regardless of the stress on the cutting attachment.

Saw chain lubrication system. design and operation

In most cases, factory-installed power saw fittings include:

- Reservoir for periodic introduction of liquid;

- Mesh filter, which cleans the liquid from foreign solid fractions;

- A short hose made of technical rubber, through a composition it flows from the tank to the moving parts of the tool;

- Oil pump. under its action, the liquid is pumped from the reservoir to the rubbing elements of the tool drive;

- Gear. through it, the force from the electric motor is transmitted to the saw oil pump.

The pump plays a key role in this unit. As soon as the engine speed rises, the built-in gear receives enough force to drive the oil pump. When operating, the pump increases the pressure inside the lubrication system. As a result, the air pushes the liquid out of the tank towards the tire. Getting into the place of contact between the saw housing and the guide, the liquid flows into the groove, which is needed to lubricate the bar. The end link of the lubrication system is the chain, in the links of which grooves or holes are also provided. Through them, the chain saw oil spreads along the entire length of the cutter.

Functions of lubrication for electrical dust circuit

The mechanisms for transmitting power from the engine to the sawing organs of the power tool consist of several elements. During operation, they succumb to increased and continuous friction. To reduce the stress on these parts, the owner of the chain tool must ensure that a suitable hydraulic fluid is available.

Saw chain oil speeds up the operation of the installed cutting attachment. In addition, the lubricant protects the metal parts of the tool from dust and moisture on their surface, which lead to corrosion and destruction of the drive mechanism.

Another important function of the fluid is to protect the chain, bar and saw drive from gum and carbon deposits. A high-quality composition maintains the integrity of the metal guide, preventing it from glowing, as well as further destruction. As a result, the cutting headset of the power tool will cut efficiently and evenly for several seasons in a row.

What kind of oil to pour into the chain saw?

Choosing oil for chainsaws, gardening equipment owners have 2 options: a special proprietary product or ordinary machine lubricant used to maintain the operation of moving parts of equipment. It should be noted that a special lubricant is better and more efficient, since in its production, brands take into account the peculiarities of the operation of electric dust drive mechanisms, as well as the load on them during operation.

To improve its performance, brand-name electric chain saw oil always contains important additives. It is they who make high-quality brand lubricants better and more expensive than machine lubricants.

Most gardening machine operators and saw manufacturers advise the use of compounds marked “N” on the packaging for chain lubrication.

Their main benefits include:

- High degree of biodegradability;

- Special additives responsible for protecting rubbing parts from wear and heat;

- Increased adhesion.

All these qualities prolong the life of the drive and the cutting set of the tool, which significantly reduces the frequency of bar and chain replacement.

Electric Chainsaw Oils

As is the case with gasoline saws, electric powered garden chain tools need to be lubricated. Oil in this type of equipment is necessary only to ensure the operation of the cutting attachment. Without the right amount of high-quality lubricant, the tire and chain will start to wedge and fail quite quickly. To prevent this, the owner of the tool must constantly monitor the liquid level, as well as rinse the parts responsible for the headset drive in time.

Oil does NOT flow to the saw chain. reasons and DIY repair

Most often, the saw pump is the culprit for the lack of lubricant supply. During operation, he, like all other elements of the system, lends itself to increased loads. In addition, the pump gradually becomes clogged with debris, which passes through the strainer along with the oil. The accumulation of fine debris interferes with the normal operation of the pump and, over time, leads to serious damage to the tool.

At the same time, it is far from always a problem in which the chain is not lubricated on the saw. Connected with the pump itself. The gear wheel, which is responsible for transferring power from the engine to the oil pump, can also fail. It can shift when hitting the saw or simply become unusable due to wear. This is easy to spot when looking at the star. If during self-diagnosis it was proved that the star is out of order, then it must be replaced.

Another reason why oil is not supplied to the saw chain is the depressurization of the system. Pressure must be built up to circulate fluid inside the assembly. If it is not there, then this indicates the formation of holes or cracks, which may appear in the walls of the oil hose, as well as in the place where it is connected to the pump or to the saw guide. In any of THESE cases, you need to carefully check the oil supply system and restore its previous tightness.

Tips for choosing oil

The fact that you need to pour oil into the saw is understandable. But another point, which one, can also be stagnant by surprise. The whole variety of existing types of grease can be divided into several types:

Special, adapted specifically for the saw. in its composition it contains adhesive additives, which serve for better adhesion of the liquid with the blade itself and do not allow it to drain instantly.

New environmentally friendly formulations made only from safe plant materials.

Motor and transmission oils. can also be used as a lubricant for SEPARATE models, which is regulated by the instructions for them. However, mineral oil should be avoided. In addition to the lubricating effect, engine oil can also be used to remove residues of “biological” lubricant, which not only clogs the oil system, but can also provoke serious breakdowns.

Incredibly, many craftsmen have learned to use waste engine oil and even regular table sunflower oil for chain lubrication. This way out of the situation, although it is economical, since it allows you to reuse the resource, but carries with it many threats to the cutting working mechanisms. So, used car oil can clog the oil filter and pump, which is generally threatened by the prospect of going to a landfill. This increases the load on the motor, often leading to overheating and its breakdown.

Vegetable oil is generally a risky option, which categorically cannot be used for pouring into an oil tank. As a last resort, when applicable, use to lubricate the outside of the chain.

Of the options offered, the special oil is the best. Experienced experts advise purchasing grease from the same company as the saw itself, but the price of such a product can be overstated by several orders of magnitude in comparison with universal chain grease, which is a serious competitor to expensive and not always available branded counterparts.

Features of the lubrication process

Saw chain oil is necessary to ensure that the cutting blade performs the tasks assigned to it as quickly and efficiently as possible. And the fact that at a certain stage of operation it is necessary to Apply great efforts to make the cut is one of the main indicators of the need to either check the oil level (if possible), or manually lubricate the chain. Modern electric saws most often have a built-in system for auto-pumping oil into the chain and bar area, therefore the second option with manual chain lubrication is used only for outdated primitive designs.

Most often, the oil for the electric chain saw comes from a special tank, where it needs to be filled periodically. Already directly from it with the help of an oil pump. a separate component of the oil supply, by converting the rotational gait of the gear to the translational rods, the chain receives oil in the volume necessary for normal functioning.

It is also very easy to monitor its level thanks to the transparent window of the container filled with oil for a convenient indication of its remaining.

Unlike the new modifications of the saw, the older ones do not have such a constructive possibility. But it is possible to eliminate this shortcoming. To do this, take a container (you can use an ordinary household bucket) and fill it with oil, into which the chain mechanism is simply immersed before operation. Such actions need to be done often, since part of the oil will go not only to lubricate the canvas, but also simply go to waste with sawdust.

Saw oil. a guarantee of its correct operation

It is hard not to agree with the fact that chain saw oil is hardly the most important consumable component for this category of power tools. After all, a high-quality lubricating product not only simplifies the operation process, facilitating the contact of the cutting blade with materials of different hardness and density, but also significantly increases its production resource for at least several years. Therefore, the question of which oil to pour into the saw to lubricate the chain is one of the central ones, which each user must decide for himself, deciding to acquire a household assistant in the form of an electric shovel. We will talk about all the features of this seemingly difficult process further.

Oil supply system. nuances of care and maintenance

The oil injection part of the saw structure, like the one-piece unit, needs to comply with all the requirements prescribed by each manufacturer individually for a specific series and its modification.

Often, during the use of the Electric Chop, you may encounter a problem when oil does NOT flow to the saw chain, which can significantly affect the condition of the working elements rubbing against each other. This may be due to several reasons, such as:

- Failure of the oil pump and its gear;

- Clogged passages in the oil filter, through which the lubricant flows;

- A hole in the tire is clogged;

- Depressurization of the oil tank itself.

As you can see, there can be a lot of versions due to which oil is NOT supplied to the saw chain, which you can figure out on your own, but it is much better to resort to the help of experienced specialists.