How to cut Plexiglas

wikiHow operates on the principle of a wiki, which means that many of our articles are written by more than one author. Volunteer authors worked on editing and improving this article.

Number of views of this article: 22 874.

Acrylic glass (polymethyl methacrylate) is a hard transparent plastic better known as plexiglass. Plexiglass, or organic glass, is mostly used instead of glass because of its strength, it is not as brittle as regular glass. You can buy Plexiglas in sheets and cut it with ordinary woodworking tools. Part 2 describes how to cut small and large sheets of organic glass.

Use this method to cut small pieces of Plexiglas. (A sheet you can easily handle without help.).

- Leave as much paper on the glass as possible until you finish your project. When you are ready to remove the packaging, simply pick up one corner of the protective packaging and remove it.

Lay the sheet (still covered by the protective wrapping) on a flat, level surface. If you don’t have a workspace, you can put up some wood sawing scaffolding. Use as many work surfaces as possible to support the weight of the plexiglass.

Take a yardstick to measure the piece you want to cut. Do not use fabric or metal measuring tape. A yardstick is best for this material.

- Place the yardstick on the line you have marked.

- Using the glass cutter or knife, traverse the line five to ten times. The deeper the cut, the easier the pieces of Plexiglas will come off. There are several ways to cut the Plexiglas:

- Use a glass cutter.

- Cut with the sharp end of a paper knife or the blunt side of a paper knife.

- Cut off the Plexiglas on both sides to make it easier to break off. Technically, you don’t “cut” the Plexiglas, you just make deep notches to make it easier to break it off.

Place the cut piece on the edge of your work area. If you only cut one piece, position it so that you can clearly see the trimmer line of the cut you marked.

Press down on the cut piece. Apply enough pressure to break off the cut piece. It is easier to do if you place wood blocks along a piece of Plexiglas and push it down. This pressure will be more than enough.

- Clamp a piece of organic glass to a table or machine.

- Use a power saw to smooth out the corners of the glass. This method will work if your Plexiglas sheet is at least 5 cm thick. Place the plexiglass so that you have enough protrusion to provide enough clearance for the saw blade.

- Take a drill with a buffer for thicker pieces of Plexiglas. Coat the sanding pad with the polishing compound before you start polishing the surface of the glass.

Use high speed metal blades. Buy blades designed for cutting Plexiglas. Use a carbide blade if you are cutting more than one sheet of Plexiglas at a time or a thicker piece.

- In a bottle, mix together a couple of drops of emulsion and water to make a spray.

- Spray the blade with this solution. There is no need to apply this solution liberally, and in most cases it is not useful at all.

Work with a saw at the right speed. The ideal speed when cutting Plexiglas is 3450 rpm. The speed of the material should be about 10 cm per second. Maintain a correct and constant speed so as not to break the Plexiglas or cause the blade to jam.

Polish the sharp corners. Use an electric saw or drill with a polisher to smooth out the corners.

Material Features

Not everyone knows what plexiglass is. How to cut it at home and what are its features? First of all, Plexiglas has the performance characteristics of a strong plastic, and also resembles regular glass in appearance. This material is transparent. However, unlike glass, it does not break.

These properties have made plexiglass popular. What to cut it with in the home? Not so easy in this case. The material itself is sufficiently strong. Plexiglass is widely used. Because in some cases it is dangerous and problematic to use ordinary glass. The material can be processed using almost all available methods. However, there are some nuances to consider when working with plexiglass.

Cutter

It is possible to cut insignificant thicknesses of polymethylmethacrylate with a utility knife or a home-made cutter.

To make the line for the trimmer cut even, it is necessary to make a marking. Along the planned line of cut it is necessary to place a metal ruler and press it firmly by hand. With careful, but firm movements guide the cutter several times along the ruler. When the material is cut by more than 50%, carefully break it down along the line of the resulting fold. Roughness and irregularities should be treated with an emery cloth or a grinder.

As to the disadvantages, this way of cutting plexiglas requires a certain skill and dexterity. Lack of experience and sloppy movements can cause damage to the building material.

Cutter

Small thicknesses of polymethyl methacrylate can be cut with a utility knife or a home-made cutter.

To make the line for the trimmer cut even, you need to make a marking. Along the planned line of the cut, place the metal ruler and press it firmly by hand. Using careful but firm movements, run the cutter several times along the ruler. When the fabric is cut by more than 50%, gently break the material along the line of the resulting fold. Roughness and irregularities should be treated with an emery cloth or a grinder.

As to the disadvantages, this way of sawing Plexiglas requires certain skills and experience. Lack of experience and sloppy movements can cause damage to the building material.

Drilling

Quite often it is necessary to make a hole of a certain diameter in a product or workpiece made of Plexiglas. In order to do this you will need a drill. Depending on the parameters of the thickness of the workpiece, it will be necessary to select the diameter and grade of drill.

To make a hole in a thin sheet, it will be better to choose a drill with sharpening angle not more than 60 degrees, and here for drilling holes in thicker sheets of Plexiglas, it is necessary to choose drills with sharpening angle in the range from 70 to 90 degrees.

During the work it is necessary to ensure that the material does not overheat, it is extremely important, otherwise the place of processing will begin to melt, it will be impossible to fix it. To avoid overheating, make hole in several steps.

To perform the cut of acrylic sheet evenly, during the performance of the work it is important to monitor the feed rate of the cutting blade. It is better to begin cutting process with minimal rotational speed of power tool. It is possible to choose the optimal mode only experimentally. If during the work acrylic material began to melt and stick to the cutting blade, then stop the work, clean the blade from contamination, and sawed workpiece give time to cool.

When cutting acrylic it is better to work in a well-ventilated room, because organic glass when heated strongly smokes and releases into the environment chemical components that are harmful to health.

In order to cut a small piece of organic glass you can use a screwdriver with a slotted tip. The screwdriver is heated over a gas torch and runs its slotted end over the ruler that is attached to the workpiece.

Under the influence of the heated section of the screwdriver in the material will appear a shallow groove. This groove can be further deepened and then break off the edge of the glass or take a sawing tool and in the direction of the groove perform further sawing of the material. After making the cut, the edge of the workpiece will be uneven. It can be smoothed out by long sanding.

Such a method is quite time-consuming, but it does not allow you to spoil the glass by the sudden appearance of cracks or chips.

What to cut?

Colored and transparent organic glass has certain properties, which influence the electric tool at the moment when the material is cut. The fact that acrylic tends to melt at 160°C. If you want to bend a flat sheet, you can do it after heating it to 100°C. When the cutting blade of an electric tool is applied, the place of the cut is heated and the material in the melted form adheres to its surface, so cutting plexiglass is quite a problematic activity.

Despite the difficulties of processing, acrylic glass has a wide range of applications. To cut the material, thereby giving it the desired size, in the conditions of production using modern equipment:

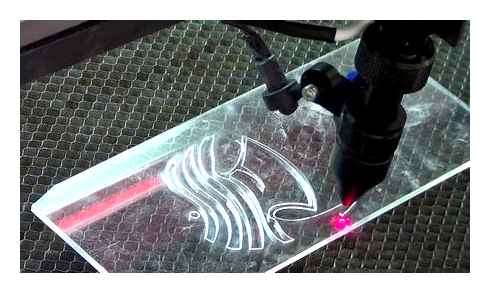

- Laser machine with CNC, where the laser, like a knife, cuts the acrylic surface;

- electric milling machine, which can be used to make holes or shaped cutouts;

- Machines equipped with a band saw;

- disk type electric cutter.

Laser and milling cutting have a high degree of productivity and are used in mass production. This equipment is capable of cutting acrylic material with a high degree of accuracy and precision. The most widespread nowadays is laser machining, the accuracy of work is achieved due to the fact that a beam with a thickness of 0.1 mm is formed.

The cut edges of the material are perfectly smooth after laser cutting. But the most important thing is that this method of cutting produces no waste.

Cutting acrylic glass using a mechanical cutter causes the material to heat up, which makes it melt, and generates considerable smoke. To prevent the melting process, the cutting operation must be accompanied by cooling the acrylic, which is done with water or a stream of cold air.

Craftsmen at home often perform the processing of organic glass themselves, using the available tools.

- Metal hacksaw. The cutting blade is characterized by small teeth with a minimum distance between them. Hacksaw blades are made of tough tempered steel alloy so the cutting edge dulls slowly. Using it enables a smooth cut by a tangential movement. In the process of work is not recommended to saw quickly, so that the acrylic is not heated and is not subjected to plastic deformation. The finished cut turns out with roughness, which will need to sand down with sandpaper.

- Acrylic cutter. This device is sold in retail chains and is designed for cutting Plexiglas with a small thickness up to 3 mm. To obtain an even cut, a ruler is fixed on the surface of organic glass, then a cutter is used to cut through the material (about half of its thickness). After this kerf the sheet is broken off along the planned line. The finished cut turns out uneven, so later the workpiece will have to go through a long grinding.

- Circular saw. Plexiglas saw blade should have small, frequent teeth. If you use a disc with a large spacing between them, chipping and cracking can occur on the material to be machined. After getting the cut the workpiece requires a finish sanding.

- A cutter with a bearing. This power tool performs a quality cut on plexiglass, but the cutting blades quickly dull and become unusable. The acrylic heats up quickly when you work with the cutter and this process is accompanied by strong smoke. To avoid material heating, water is used to cool the working surface.

- Electric jigsaw. This tool is convenient because it has the ability to regulate the feed rate of the cutting blade. To work with organic glass use special cutting blades that are fixed in the jigsaw holder. Such saws can be replaced by a wood blade, the main thing is that the teeth of the blade should be frequently arranged and have a small size. Use slow speed, otherwise the material will stick to the blade. After you perform the cut, you can sand the workpiece or treat it with a lighter flame. The jigsaw can be used to make straight or curved cuts.

- angle grinder. For sawing thick sheets of plexiglass it is possible to use a disk with three large teeth, which is designed for woodworking. Such a tool copes well with making straight cuts. Acrylic glass does not melt or stick to the blade during cutting. It can be used to work acrylic 5-10 mm thick.

Some do-it-yourselfers use an ordinary glass cutter to cut organic glass. The results of exploitation of the listed tools completely depend on the experience of the master, and in this case no one is insured from the possibility of spoiling the material.

Cutting rules

In order to qualitatively cut plexiglass with their own hands at home, experienced craftsmen advise adhering to some rules (they apply not only to acrylic, but also to plexiglass, and cellular polycarbonate).

- Cut to size a shaped workpiece or cut a flat piece of acrylic glass will be much easier if you begin by heating the material over a heat source: a gas burner or a construction hair dryer. It must be done from a considerable distance so as not to melt the material.

- Cutting a piece of plexiglass of a small thickness from 2 mm to 5 mm can be done with an electric jigsaw. It can be used not only to make a straight cut, but also to make a circle cut. To work, take a narrow and thin blade with fine teeth.

- It is easier to cut glass with a blade that is marked MP. S. Steel for the blade is hardened and highly durable.

- Use a low feed rate for glass. The speed of each tool can be adjusted in a practical way as you work. When sawing, it is important to make sure that the acrylic glass does not start to melt.

- Wear safety glasses or a face mask when cutting cut organic glass. When sawing the material many small splinter chips are produced that fly off in different directions at high speed.

The greatest difficulties in home cutting organic glass occur when creating complex curved cuts. The easiest way to solve this problem is to use laser industrial equipment, where automated control allows you to perform all the necessary functions with the highest accuracy and without human intervention. Acrylic must be hand-cut on a previously made template. The easiest way to make such a cut is with a mill. The contours of the resulting workpiece will be jagged and rough, which can be removed by grinding.

At home, you can speed up the process of cutting organic glass by using a heated nichrome wire connected to a 24 V source. A heated nichrome wire pierces the acrylic through the cut in the desired location. It makes the cut edges smooth.

You can assemble such a device yourself at home, the main thing is to choose a quality nichrome wire with the right diameter to withstand heating to a temperature of 100°C.

Laser

The most convenient method of cutting acrylic is called a laser. However, this method can not be used at home, it is used exclusively in industrial production.

A thin laser allows to make precise cuts and cut out even the smallest details of the future construction or product. If necessary, you can go to a specialized workshop or enterprise engaged in the production of organic glass and glassware. It is advisable to make drawings and markings on the polymethylmethacrylate sheet in advance.

The laser allows you to accurately cut and plexiglass, even small parts, is used only in industrial production

What else can be used to cut Plexiglas

In addition to mechanical methods, thermal methods are used to cut Plexiglas. This makes it possible to quickly cut sheets of material of any thickness, as well as to obtain workpieces with curved surfaces.

The main tool here is a nichrome filament that is connected to a transformer with 24 V. At the ends of the thread are handles of insulating material. When an electric current is passed through the nichrome filament, it is heated to 160 0C. This temperature is sufficient to melt acrylic glass. Therefore, when the red-hot filament comes in contact with the plexiglass, it melts, resulting in a neat, even cut, the edges of which require no additional processing. A slotted screwdriver can also be used instead of nichrome thread.

What else you can cut plexiglass with

Besides mechanical methods for cutting plexiglass thermal methods are also used. This allows you to quickly cut sheets of any thickness, and to obtain blanks with curved surfaces.

The basic tool here is a nichrome filament, which is connected to a transformer with 24 V. There are handles of electrical insulating material on the ends of the filament. When an electric current is passed through a nichrome filament, it is heated to 160 0C. This temperature is sufficient to melt acrylic glass. Therefore, when the red-hot filament comes in contact with plexiglass, it melts, resulting in a neat even cut, the edges of which require no additional processing. A slotted screwdriver can also be used instead of nichrome thread.

How to cut wood, plywood, chipboard

Despite many questions and attempts to cut wood products with an angle grinder, many experts do not recommend using this tool for such work, and take other tools for this purpose. jigsaws, circular saws, etc.д. This is due to the high degree of danger in performing such work. Among the causes of increased danger, the most important are:

- The possibility of the blade teeth catching a large amount of wood and causing the tool to slip out of your hands suddenly;

- Heating of the disk in the process of cutting, which leads to its brittleness. In this case, even a slight misalignment will cause the blade to break, causing small pieces of it to fly off to the sides;

- High probability of breakage of the filament, which can cause injury to the craftsman.

Now there is a large variety of special tools for working with wood. So why risk your own life?

What to cut plexiglass with

Let’s understand how to cut with tools so that you choose the best way, comfortable and most effective.

For cutting with an electric saw (s/jigsaw) you need to use special blades designed specifically to work with plexiglass. In the absence of using blades made for cutting copper or aluminum. In this case, check the sharpening of the teeth. They must be well sharpened, have the same height and be in the same plane. That is, do not have a gap in the teeth in different directions. For the best quality of the cut the electric saw has to be set at the top speed. After such cutting the edges are usually rough. They must be sharpened with fine sandpaper. Naturally, before sawing it is necessary to mark the place of a cut with a sharp knife or a nail, having attached a metal ruler.

Hand hacksaw for metal. This method is almost no different from working with an electric saw. One nuance that must be remembered, the blade of the hacksaw should be as tight as possible, otherwise you can bend the line for the trimmer cut, which later will be quite difficult to fix. Before you start, fix the plexiglass securely to avoid bending.

Circular or circular saw

Give preference to high-speed blades, which have a tooth frequency of at least two per centimeter. If you use carbide-coated blades, they will leave a minimum of roughness and give the maximum smoothness of the cutting edge. The height of the blade should be at least three millimeters greater than the thickness of the plexiglass. This will help to minimize the shredding of the cut edges. It is better to lubricate the blade with wax or soap. If the thickness of plexiglass will be more than six millimeters, the blade should be cooled with water so that the edges of the cut will not melt.

- What to cut plexiglass with. a special knife-cutter can be used when cutting plexiglass with thickness not more than five millimeters. This is probably the easiest way if you have no special tools handy. We are equipped with a metal ruler, bring it to the place of the cut, press it firmly and move it with the cutter knife several times with a strong pressure.

If the cutter is sharp enough and a strong pressure, then 2-3 times you get a groove which is half the thickness of the Plexiglas. This is enough to simply break the plexiglass along the marked line. Slide the line for the cut plexiglass trimmer to the edge of the table and press the dangling edge firmly and sharply. Plexiglass breaks off. The sharp edge should be trimmed with fine sandpaper.

Because of plexiglas’ low melting point, it can be cut with a jigsaw with a nichrome wire inserted instead of a saw. To the ends of the wire bring through a transformer voltage of 3-4 V. The wire gets hot and goes into the plexiglass like butter. This method is very convenient for making shaped cuts. Another good thing about this method is that it gives the smoothest cutting edge. One important thing to remember is the insulation of the handle. It should be made of wood or plastic and not conduct electricity.