Adjustment of the STIHL FS 55 lawn mower carburetor

The aforementioned equipment option costs 13,490 it is a premium device device. With it, you can take care of the territory in a large suburban site. Equipment yields young and old grass, reeds and weeds, also a young shrub.

The primer broke

Primer-a manual mini-pump for forced swinging fuel in a carburetor. For a successful start of the motor, it may be necessary to pump 20 ml of gasoline manually.

The adjustment membrane is spoiled

The membrane is often deformed (from time to time and breaks) due to continuous operation of motorcycles or a trimmer for grass for several hours. If you abuse such a “shock” mode of operation, damage to the membrane occurs more often. New breakdowns will be sprinkled like an abundance from a horns:

- the piston will break;

- The number of attempts by the unsuccessful start of the motor will increase sharply;

- The fuel mixture will contain very not a lot of gasoline;

- The necessary (thermal) power will fall sharply.

Clogging the adjusting space

Departments may accumulate in the adjustment compartment. The needle does not cover the hole one hundred percent, and a lot of gasoline enters the fuel chamber. the engine shifts it, maybe floods the spark plugs. Because of this, the gasoline mixture contains an inflated amount of vapor of gasoline. The efficiency falls noticeably.

Signs of unbalancing

Carburetor debugging is certainly done in the manufacture of the device. Texas 330 Lawn mowed Carburetor adjustment. Usually, the owners will find out about the need to adjust the supply of fuel with their own hands only after rather severe breakdowns, in the process of correcting which, the module was removed and, for example, was cleaned.

Signs of a malfunction in the settings are the following:

- It starts, but the engine stalls here. since the engine can only work when a certain amount of gasoline is submitted, with a very “poor” combustible, in other words, overlapping the supply channel, the motor will stop;

- A very large fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the consistency. In this case, there is a lot of fuel, on the contrary, and the mixture comes out extremely dense.

The main problems and malfunctions of the carburetor.

Mesh filter. There are only two difficulties with this element more often:

In order to find out the cause of the breakdown, the fuel filter lid is unscrewed to extract the mesh filter. If the mud just accumulated on it, then flushing in gasoline or purge will help.

With visible damage on the mesh filter, it is necessary to put a new. There may also be damage to the fuel supply pipe (during the repair they practice checking this element).

The starting device of the carburetor in most cases does not work due to blockages. Should be used for flushing acetone or the same gasoline.

Purging parts of a carburetor with click of compressed air. permissible and comfortable repair practice.

The hull of throttles, places of ligaments of the parts of the carburetor, intake or graduation pipeline. all of the listed parts are subject to depressurization. You can probably check the simple method. spread the problem area with soap foam.

Caliber company. Brand’s base and popularization

Enterprise OJSC Caliber was founded in 1932. From the very beginning of its appearance on the market, the company aimed at the production of high.quality and inexpensive economic and industrial equipment. During the war years, the company’s plant provided production services: sharpening the tool, as well as turning, milling and heat processing of parts for Soviet weapons.

Today, in the assortment of the company you can find electric and gasoline equipment for home and garden, as well as operating machines in production. Gasoline and electric trimmers for grass are very popular among brand products. They are distinguished by high reliability, modest consumption of fuel and electricity, as well as stability during operation in severe conditions

Another important advantage is low for brand technique. The correct pricing policy of the company makes it possible to purchase its products to almost everyone

Chips on the choice

In accordance with the current statistics, it is the gasoline models of mowers that are most in demand. This is largely due to their mobility and functionality. However, when choosing a specific model of technology, it is necessary to take into account a number of other parameters. In such situations, it will be useful to compare motorcycles with other types of trimmers.

Electric devices are connected to a household network with a voltage of 220 V. Such machines do not pollute the air due to the lack of exhaust gases. No less important points will be the minimum noise level and relatively small weight. At the same time, the processed area is significantly limited.

The battery models today are the least common trimmers for grass for grass. The electric engine of such mowers does not feed from the network, but from the battery, which provides maximum mobility. However, the operating time of the equipment is limited by the battery charge and is an average of 35-45 minutes. Another important point is the relatively high cost of battery models.

When choosing a specific model of a gasoline trimmer for grass, it is necessary to take into account its technical characteristics. So, low.power devices are equipped with coils with a fishing line. On more reserved and powerful models, knives and cutters can be used as cutting elements.

Another important factor is the operational conditions. Do not forget about the cost of mowers.

User manual

Particular attention should be paid to how to properly carry out the first start and run.in gasoline mowing. Competent actions will allow the maximum operation of the trimmer for the grass and reduce the costs of its maintenance and repair. Before you first start the device, you will need to carry out several preparatory actions. Their list includes a visual assessment of the state of the gearbox and the preparation of a high.quality fuel mixture, taking into account what kind of oil should be poured in accordance with the instructions and recommendations of the manufacturer.

Unfortunately, even competent and careful operation of high.quality gasoline lawn mowers does not completely exclude the risk of breakdowns. Consider the most common problems.

- The engine does not start. Perhaps the candle failed or the fuel does not enter the carburetor.

- Unstable work ICE at idle. One of the most common reasons in such situations is the wrong setting of the carburetor.

- The trimmer for the grass does not develop speed and does not provide sufficient power. Such phenomena are associated with the need to clean or replace the air filter, candles, as well as adjusting the carburetor and removal of soil in a muffler.

- Overheating of the engine, which can be caused by the use of low.quality fuel mixture.

Quite often, the owners of gasoline mowers have to face situations when they stall when pressed on gas. The most common reason in this case is the incorrect operation of the carburetor requiring adjustment. Most often this happens after a long.term storage of the device or as a result of its operation in difficult conditions.

When the gas is added, the fuel valve can be closed to the engine stop, which will need to be slightly weakened to resume the normal supply of gasoline. Often you have to face clogging of the saapun, that is, a check valve located in the fuel tank. Among other things, the reasons for the fact that the ICE of the trimmer for grass stalls, the cable sagging in the carburetor and stretching of the fuel hose can be sagging.

Elimination methods

The list of upcoming work with the engine can be as follows:

- replacement of the fuel pump;

- disassembly and flushing of the mesh filter;

- replacement of the adjusting lever;

- It is also necessary to clean the adjustment space;

- replacement of the membrane (or the entire block where this membrane is located);

- setting in intake, graduation and needle valves;

- replacement of the damper;

- cleaning the fuel channels and diffuser;

- replacement of springs of screws;

- Change of primer.

Not all these works can be completed. It often turns out that many of them have no need if a specific malfunction is immediately discovered.

Ground of a mesh filter

The reasons for the clogging of the mesh filter are poor.quality fuel cleaning, damage to the hose and/or the injection head.

Adjustment of the Carburetor of the Stihl MS 361 chainsaw with your own hands

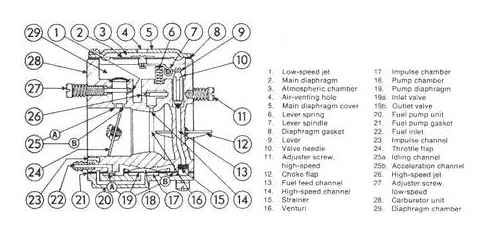

Three adjusting screws are designed mainly for factory adjustment. After assembling the carburetor and saw, each of them is tuned alternately, on special stands, taking into account the features of each chainsaw of the Stihl MS 361 chainsaw. The screws are securely fixed and do not spin spectacularly spontaneously. Adjustment is rarely required. Namely:

- With a critical wear of the piston system, when the degree of compression (compression) has changed a lot.

- When replacing the piston system, when the chainsaw does not work like during the factory setting.

- When working in the mountains, where, due to low atmospheric pressure, the engine lacks oxygen, and it is necessary to increase the air supply (impoverish the mixture).

In other cases, idle speed is most often required if the engine stalls in this mode.

Necessary tools

A feature of the Stihl MS 361 chainsaw is easy access to the carburetor. It is enough to remove the lid and the air cleaner. Therefore, no tool is needed for adjustment, except for a screwdriver. For professional adjustment, a tachometer will be required. He will show the number of idle and maximum revolutions. Proper adjustment should provide 2500 rpm in idle and 10,000 rpm at maximum speeds.

In the absence of a tachometer, maximum turns are determined by ear. Idle. in two borders: the chainsaw should not stall when the idle speeds are small, the chain should not move when the turns are too large.

The tachometer allows you to more accurately adjust the maximum and minimum speed of the chainsaw

A step.by.step adjustment algorithm

Before adjustment, you need to make sure that the air filter is clean. If it is scored, there may not be enough air to complete combustion of the fuel mixture. Therefore, the engine works incorrectly. Perhaps adjustment is not required, but you need to clean or change the filter.

The filter is removed and tried how the engine works without it. If good, then the problem is in the filter.

The presence of a carrier in the sparkler and a silencer grate is also checked. If the output of exhaust gases is difficult, the engine also works incorrectly and the problem is not in setting up the carburetor.

Standard adjustment

The manufacturer of the chainsaw of the Stihl MS 361 in the operating manual (.37) recommends the next algorithm for adjusting the carburetor:

- High speed adjusting bolt H rotate clockwise until it stops, but not more than 3/4 turnover.

- The cloth of the idle stroke l is twisted clockwise until it stops. Then turn counterclockwise for 1/4 turnover.

- Start and warm up the engine for 7-10 minutes.

- Further, the idle stroke is adjusted to the adjustment of the stubborn screw LA when the engine is running. It is screwed clockwise, increasing idle speed until the chain starts to move. Then the lace of the la is unscrewed by 1/2 turnover.

- If, when adjusting the La screw, it is not possible to adjust the idle speeds correctly (the engine stalls or the circuit spins), they are adjusted with a screw L. It is unscrewed by 1/4 turnover. Then they continue to adjust the La screw, unscrewing it counterclockwise until the chain stops. Then in the same direction is about 1/2 turnover. But so that the engine is not stalled at idle.

In addition to the recommendations of the manufacturer, there are practical points for adjusting the carburetor.

Adjusting screws of the carburetor of the chainsaw STIHL MS 361

Nuances that you need to know

When turning any screw, the factory setting changes

Therefore, it is extremely important to remember or write down the number of revolutions for which the position of the screws has changed when adjusting. For example, if the screw is twisted to the stop, it must be twisted, be sure to count the speed

Only this will make it possible to return to the parameters of the factory adjustment if it turns out to be unsuccessful.

High speed adjustment is easiest to carry out with a running engine. The screw n is rotated with small steps on 1/4. 1/2 turnover in one direction or another. By pressing the gas handle, they try how the engine reacts to the change in the settings. Changes in revolutions are determined by ear or using a tachometer.

After adjusting high speeds, it is most often required to correct the adjustment of the idle.

Pros and cons of the model:

Naturally, the list of positive points should be classified by the brand itself.

- The need to constantly check the fuel level;

- Small motorcycle resource;

- Low power;

- High cost;

- Scanty set.

The presence of not particularly catastrophic shortcomings of the model does not have a negative effect on the popularity of the unit, because ideal technology simply does not exist.

Adjustment and repair of the carburetor of the lawn mower

The trimmer for grass does not apply to complex household appliances, because most of its breakdowns are mechanical and are quite successfully eliminated with their own hands. Even if the motor refuses for severe reasons. damage to the piston ring, for example, the repair is reduced to the substitution of the part.

And with a relative design, such a device of the device as a carburetor needs to be adjusted.

Adjustment and repair of the carburetor of the lawn mower

The trimmer for grass does not apply to complex household appliances, because most of its breakdowns are mechanical and are quite successfully eliminated with their own hands. Even if the motor refuses for severe reasons. damage to the piston ring, for example, the repair is reduced to the substitution of the part.

And with a relative design, such a device of the device as a carburetor needs to be adjusted.

Removing the handle

Direct disassembly of the STIHL 180, begins with the removal of the handle, which is attached to the chainsaw housing using three rubber shock absorbers. To remove, it is necessary to remove the plastic plugs from the inner cavity of shock absorbers, after which with the help of a powerful screwdriver, squeeze the upper shock absorber first, then the one which is closer to the posterior handle.

A gas trigger is installed in the back of the handle, which is connected to the carburetor through the wire traction in order to disconnect the thrust from the gas trigger, it is necessary to unwind two screws and disassemble the handle.

When the handle remains on one shock absorber, it is necessary to turn the chainsaw housing from the inside of the handle and breaking to the side, remove the case from the last elastic band.

Fifty.five gas mower FS

Adjustment of the carburetor of the Nymeitsky Wobber Benzosos

Nonvavadennik of gasoline mowers in robots with landscaping in terms of wear, and sometimes breakdowns of their nozzles. It is impossible to attribute the tool to the side on the side nozzles, all breakdowns are exclusively mechanical in nature, as you can fix it with your own hands. Among the vipads to complete the implementation of regulatory work in order to turn the tool into a very solid cutter. Adjustment of the carburetor (idle) repair of the carburetor of the gasoline mowls STIHL FS55 STIHL FS carburetor adjustment Fifty.five Motokos Repair of the STIHL FS 56 carburetor repair. Carburetor adjustment. One of these operations. adjusting the carburetor of a gasoline mowing manual. Carburetor installation before supply to the engine is bred by fire. Adjustment of the STIHL FS carburetor fifty.five stihl fs55 (motorcycle lawn mowing) Test Original Repair Motokos STIHL FS55 Repair of the STIHL FS 56 carburetor. Carburetor adjustment. Trimer Stihl FS diagnostics fifty.five motorcycle brush. If the proportions do not come true, in a robotic trimmer you will see animals:

The entire process of regulating the carburetor of the transmission brand is only in improving the position of three gint: l, which regulates the supply of gasoline to the braid at low speeds, h, which regulates more turns and glasses, t, which improves the idle passage. Speed. Thus, if it is necessary to install a carburetor of a gasoline mowing line of the brand of fifty.five or other types of this series with the following rank:

- Engine heated (10 needles at idle).

- Adjust Guint N, turn left / right until the maximum idle move.

- From a known point, enter in the direction opposite to the direction ¼ turn, how to establish the desired robotic position.

- Adjustment idle move The carburetor of a gasoline mower is carried out in a similar way, turning to the reverse (change of scraps) and a year later (increased speed). Reach the position of maximum rigidity of the robot engine in different positions.

- Guint L is regulated by itself, small protrusions to the maximum.

FUEL TANK VENTS AND WHAT YOU NEED TO KNOW (funny blooper)

The whole process is carried out by ear, so for a more successful robot you can get a tanometer. STIHL FS Fifty.Five Carburetor adjustment The most accurate tool for the tool can be obtained in the Kosa Motors department, as well as buy oil for compressor and all the necessary spare parts and accessories for timely maintenance.

Read insert the piston into the Stihl 180 cylinder

Removing the handle

Direct disassembly of the STIHL 180, begins with the removal of the handle, which is attached to the chainsaw housing using three rubber shock absorbers. To remove, it is necessary to remove the plastic plugs from the inner cavity of shock absorbers, after which with the help of a powerful screwdriver, squeeze the upper shock absorber first, then the one which is closer to the posterior handle.

A gas trigger is installed in the back of the handle, which is connected to the carburetor through the wire traction in order to disconnect the thrust from the gas trigger, it is necessary to unwind two screws and disassemble the handle.

When the handle remains on one shock absorber, it is necessary to turn the chainsaw housing from the inside of the handle and breaking to the side, remove the case from the last elastic band.

Advantages and disadvantages

One of the most significant advantages of the trimmer for the STIHL FS 38 grass is that it can take a service position in which it is more convenient to change the cutting headset and wash the casing. This model is the lightest motorcycle in the entire line of trimmers. Due to this, the user can easily cope with large volumes of work with minimal costs. Also an important advantage of this model can be considered its lightness and compactness. This allows you to transport it to almost any type of technique. Manual fuel pump allows you to run the unit even after prolonged downtime and in cold weather conditions. The height of the D-shaped handle provides pleasant and comfortable work even for a long time.

Tested more than 50 models of motorcycle

Of the shortcomings of this model, one can distinguish the absence of a belt complete with a trimmer. Since the entire load lies directly on the hands of the operator, and if there is a belt, it removes the back and shoulders

Features of operation

Each STIHL lawn mower is designed strictly for the work provided for in the engine power. The manufacturer categorically does not recommend that it independently receive or somehow improve the device of braids for grass. Therefore, before buying a Stihl law mower, it is necessary to clearly determine the upcoming front of work.

It is completely inappropriate to purchase a powerful trimmer for grass for periodic mowing of grass on the lawn, for this quite light gasoline or electric models of mowers.

- Observe the mode: work/rest at intervals for 20 minutes.

- Use high-quality gasoline at least AI-92.

- To prepare the fuel mixture, the original Stihl engine oil (50: 1) should be used.

- When driving an engine up to 2-3 full refueling of the fuel tank, prevent operation at the maximum load.

- When preserving braids for grass for the winter period or the estimated break in operation, in order to avoid engine breakdowns, it is necessary to drain the remaining gasoline from the fuel tank.

- To ensure stable functioning, systematically check the condition of the fuel filter. clean or replace it with new.

- To prevent serious malfunctions, it is necessary to avoid clogging of the air filter.

- Comply with safety requirements during the operation of the Stihl lawn mower.

Clear adherence to the requirements of the operating instructions is the key to the durable and reliable work of the Stihl motorcycles.

Where to start diagnostics motorcycles

If the lawn mower does not start or immediately stalls after starting, it is necessary to sequentially check all the main nodes and assemblies. The test algorithm is as follows:

- Fuel tank (fuel quality);

- Candle and candle channel;

- Air filter;

- Fuel filter;

- Breather;

- Graduation channel.

These nodes are most often source of basic problems, which can be eliminated after a thorough inspection.

Stihl string trimmer primer bulb doesn’t fill. reason

Check the fuel mixture

Before starting the engine of a gasoline braid for grass, check the presence, and the quality of the fuel mixture. Do not save, do not greedy and “do not smarter” in this matter. Repair or replacement of the piston group will cost you too much (sometimes up to 70% of the cost of a new tool). Prepare the oil fuel mixture strictly according to the instructions. Calculate its number from real needs. Excess gasoline left after work loses its qualities over time.

We diagnose a candle and candle canal

If the quality of the fuel mixture is not in doubt, and the lawn mower stalls when starting, then a flooded candle may be the reason. Here, a regular candle key is suitable for repair (every motorist has probably has a spare candle.

- We twist the candle and wipe;

- We thoroughly dry it (you should not bake it);

- Excess fuel in the chamber we drain through the candle hole and dry it;

- We clean the old candle from the carbon on a sugar or a ladies’ file;

- We set a gap with a distance of 1 mm (you can check with any coin);

- We return everything to place and try to start a trimmer for the grass.

If the working candle is working, the nest, where it is located completely dry, and the lawn mower does not want to start, lubricate the threaded connection with gasoline. It should be slightly moisturized. No matter what wonderful spark gives out a candle, there is simply nothing to light up in a dry chamber.

If the trimmer engine for grass still does not start, such a cause as the lack of spark due to weak contact between candles and a high-voltage wire should be excluded. If the connection is of high quality, and there are no sparks, most likely, you have “flew” the ignition unit. Here you can’t do without a master, t. to. The part is not repaired, but sold by a whole knot.

Diagnosis of the filters of the lawn mower

Another reason why the gasoline braid for grass stalls is an air filter. To exclude it, try to remove the filter and start a trimmer for grass without it. If it turns out, then you will have to change the air filter to a new one, or at least blow and carefully clean the old.

You can’t start a gasoline trimmer for grass due to contamination of the fuel filter. This is the next stage of our algorithm. Here we check the state of the filter element and, if necessary, change it with the new. When replacing, try not to leave a suction pipe without a filter, this is prohibited by any operating instructions. Rush can turn into the repair of the piston group of the engine.

Sapun and graduation channel

Often, “delicate” branded models of benzos are not launched and stall due. The main function of this element is to align the pressure in the gas tank. When clogging this node, a vacuum is created in the tank that prevents the supply of fuel. Eliminate the malfunction can be cleaned by cleaning the sounds. You can use a regular needle for cleaning.

Normal work of cos with internal combustion engines can be disturbed due to dirt from the exhaust channel or clogging of the muffler grid. There is such a problem on the models of the older generation. You can solve the issue with traditional cleaning and removal.

Conclusions and results

As a result of our review, we found out that for a buyer with a small area (5-7 acres) and a small budget, the FS 38 lawn mower is best suited. And for connoisseurs of econsmicity and environmental friendliness, as well as more modern technologies. the FS 40 lawn mower. Dachants and gardeners with areas of over 7 acres, in 80% of cases, will be selected by FS 55 or FS 55C, since it is equipped with a gearbox, a bicycle pen and a background belt, which will help to cope with higher grass and hard shoots on large volumes.

Professionals or utilities will prefer gasoline braids for FS 120 and FS 250 grass, as they are equipped with a powerful engine and are relatively inexpensive. They are also equipped with a hard shaft for installing a all kinds of cutting and sawing sets, and are suitable for large volumes of work. These trimmers for grass will cope even with small trees, shrubs, reeds.

For the most selective and demanding buyer, STIHL can offer gasoline braids for grass with 2MIX and 4MIX technologies, with a multifunctional handle and a comfortable launch system that meet the highest European standards. Such as FS 70 (for small volumes of work) and FS 131 (for large volumes of work).

We wish you successful purchases and long years of service with STIHL gas troops! Do not forget about annual free service benzos STIHL!