Low-quality gasoline

The fuel can get into the grease because of its own poor quality. Why Quality Matters?

A car owner often buys fuel that has a variety of additives added (benzene, toluene). It can quickly penetrate into the lubricant due to the additives. Auto oil, which has been affected by poor fuel, rapidly deteriorates its own characteristics. It leads to fuel distribution unit malfunctions.

Sometimes it is enough to simply change the gasoline to eliminate the problem. It is necessary to choose fuel carefully. Replace it right away if you notice that the oil smells like gasoline.

Adjustment

Every user has faced the problem of unstable carburetor, because over time, any technique can fail. This is one of the first reasons why you need to adjust the unit yourself.

Specialists advise to follow the sequence of actions, if the adjustment is made independently:

- These last few steps will need to be repeated several times until the motor begins to show stable operation;

- At the end of the control lever put on the gas.

Care of the carburetor, its replacement and repair

Sometimes, to bring a carburetor for a power tiller to a stable, working condition, adjustment is not enough, repair or replacement is necessary.

It happens that the air damper of the carburetor is not fully closed. To fix this problem, you should monitor the operation of the actuator. If you find jamming. fix it. over, given that the carburetor provides the fuel supply and therefore drives the single axle tractor itself, you should closely monitor the condition of this part and properly care for it.

To avoid serious damage to the carburettor, you must constantly monitor its operation. In addition to adjusting the idle speed, you should regularly clean the carburetor and replace worn parts. Since the carburetor interacts with the fuel mixture and the air, the cause of its contamination may be in either the first or the second source.

To make the degree of contamination significantly less, you can use filters, which should be cleaned and replaced as necessary. In addition, the quality of the fuel has a significant impact. Poor-quality fuel fluid can lead to damaged parts and premature replacement. If the need arises, a carburetor for a power tiller can be purchased at the car market or store. Have it replaced, adjusted and cleaned by an expert.

How to deal with the carburetor if the single axle tractor has not been used for a long time

In this case you should perform the following actions:

- Separating the unit from the engine.

- Clean the dust, using a soft brush and gasoline.

- Unscrew float and connector.

- Flush filter and all parts with clean fuel.

- Flush it out with compressed air.

- Check that all the parts are dry.

- Assemble the unit and install it on the engine.

The carburetor does not require daily overhaul or adjustment, but care must be taken to keep it in good working order.

When the engine of a power tiller malfunctions, the most common cause is contamination of the device. It is very often connected with the quality of gasoline.

The problem may be caused by a dirty carburetor or by a wire connecting the accelerator pedal to the carb. If disconnecting the wire while the engine is running, the revolutions are normalized, then you need to change the wire.

What problems have you faced with the carburetor of your power tiller and have you been able to solve them yourself??

How to adjust the carburetor on a power tiller?

The adjustment of the carburetor of your power tiller is performed differently by different manufacturers. Here’s a look at how to properly and accurately adjust the fuel assemblies in various brands of agricultural units.

Cascade brand power tillers

The majority of brand-name models produced by Cascade include KMB-5 carburetors.

To adjust this fuel assembly, you must:

- Drain the remaining fuel from the factory float chamber;

- Open the fitting and run air inside the fuel assembly;

- Adjust the position of the throttle flap exactly so that a neat 2-millimeter gap is gradually formed between it and the air duct, located under the flap;

- Clamp the bolts responsible for adjusting the fuel supply;

- Start loosening the screws one by one slowly until the revolutions of the power unit decrease;

- Slowly screw the screws back in alternately.

As a result, the user will achieve elimination of engine dips and reduce fuel consumption.

The Neva MB-1 and Neva MB-2 power units

Most often, the factory design models MB-1 and MB-2 brand Neva provides carburetors K-45 or their modifications. The order of their adjustment will be the same.

For factory fuel units of K-45P type the adjustment should be performed as follows:

- At first, it is necessary to screw in the factory screws to the end, designed for the own manual adjustment of the intensity of the maximum and minimum gas supply;

- Next, it is necessary to unscrew each of these steel screws in turn;

- Next, the operator will need to start and fully warm up the power unit of the used motoblock;

- After that, it will be necessary to adjust the operation of a fully serviceable engine at the lowest possible idle speed;

- If necessary, repeat the previous 2 steps. This should be done until the action of the power unit at the lowest possible speed of the standard idle speed is as stable as possible;

- If you can’t get a result after a few repetitions, then the adjustment and full throttle screw needs to be unscrewed and screwed back in. This procedure must be repeated until the engine resumes its operation.

Supply system design

One of the components of an internal combustion engine. the fuel system. It is essential for uninterrupted supply of fuel to the engine. This system consists of a fuel tank, fuel line, filters and a carburettor. The latter doses gasoline to maintain a specified crankshaft speed depending on the operating conditions of the power tiller. Gas tank is necessary for storage of reserve fuel. The fuel lines connect all components to each other, and the filters remove impurities from the fuel.

The most complex and responsible part in an internal combustion engine is the metering unit. The design of the carburetor, installed on the power tiller, allows the user to adjust the quality of the fuel mixture that enters the engine. In general, a DN consists of the following:

- Float chamber. It contains parts that are responsible for preparing the fuel mixture. In the receiving cup the petrol accumulates and acts on the float. the last one closes the fuel supply when the desired fuel level is reached by pushing on the shut-off needle.

- Mixing chamber. in the mixing chamber the inlet air is saturated with a fine dust of petrol. The latter is created by the discharged atmosphere in the mixing chamber. The reduced pressure draws fuel from the float chamber, which flows through the metering nozzle and atomizes in the air stream.

- Throttle valve. This assembly controls the speed of the crankshaft. The choke blocks the passage passage that carries air into the cylinder. The larger the cross-section, the faster the engine output shaft rotates. Adjust the choke by means of a steel cable fastened to the tiller‘s handle.

- Idle speed regulator. Typically, it is a metal or plastic screw on which the throttle actuator rests. Screwing the regulator in increases engine idle speed.

Needle valve

This mechanism, or simply a needle, is designed to maintain a certain fluid level in the chamber. The valve is installed in the carburettor body and screwed into it. It locks and opens the hole through which gasoline is injected into the chamber.

In some cases where low-quality fuel is used or there is excessive contamination of fuel in the tank, it may cause deposits in the needle valve. Sticky mass prevents the needle from closing properly, causing the valve to remain permanently open. In such cases, it is recommended to immediately replace the needle valve.

Causes of malfunction

It is possible to determine that the carburetor overflows by several signs:

- Plug condition. Dirty spark plug indicates a rich combustion mixture, which means high gasoline. Even a functioning or new spark plug can not cope with the flow of fuel entering the cylinder and over time will be covered with sludge, will be constantly wet and the engine will cease to start.

- Petrol leaks through the air filter. Signs of fuel can be found in the air filter housing.

- Gasoline leaks through the float chamber gasket.

It is worth noting that these signs may appear on their own, or after repair. Why is it possible for a carb to overfill??

Fuel cock failure

The tanks are equipped with vacuum fuel cocks, which have three outlets. One is the fuel intake from the tank, the other is the fuel supply to the carburetor. The third outlet, on the other hand, is for the vacuum hose. When the vacuum is created in the engine, the diaphragm of the valve starts pumping fuel.

Tip! If the engine will not start after a long downtime (no fuel pumped), so as not to wait until the engine itself will pump it can remove the vacuum hose from the other side of the faucet and your mouth create a vacuum until the carburetor is filled.

Clogged air filter

The scooter may also bleed fuel if the air supply is insufficient. To diagnose the filter for air permeability, do the following. Simply detach the air filter. If the engine now runs correctly, it is time to change the air filter. When all the same fills the carburetor on a scooter without a filter. “dig deeper”!

Blockage needle

Briefly about how the float chamber works. Fuel is flowing into it, thereby raising the float. When the float rises, it lifts the shut-off needle with it. When there is enough fuel in the chamber, the shutoff play closes the fuel supply port.

If the stop needle is worn (the tip or metal body is worn), it can not block completely the supply hole and gasoline continues to flow. The same effect is obtained in the case of getting a speck (a grain of sand) under the locking needle.

Key features

When checking the compression of the engine, remember that a difference of one or two units is acceptable. If the compression in the cylinders is very different from each other, it indicates that the valves are burned out or the rings are loose, and it is time to change them.

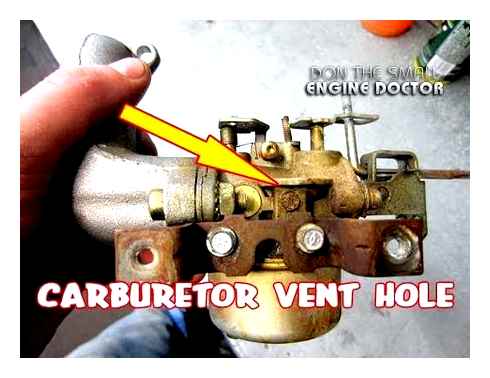

Gas leaking from small engine carburetor

It is worth paying attention to what color the car’s exhaust gases are. If the piston group is badly worn, the smoke will have a bluish tint.

If, having checked the compression in the cylinders, no serious deviations from the norm can be found, then there is no reason to worry, and the oil most likely comes through the crankcase because of the clogged debris hose. Hoses can be easily cleaned or replaced.

Typical malfunctions of the gasoline engine of the power tiller

Any mechanism requires periodic maintenance and timely repair and a single-axle tractor is no exception. Carrying out major repairs and replacing parts of the power tiller is better to entrust to professional craftsmen who have the necessary equipment and experience to perform the necessary work. There are also situations where you can service or carry out minor repairs on your power tiller by yourself. Faults in a power tiller can be roughly divided into two categories:

According to frequency of occurrence, defects in the engine occur much more often than in the transmission.

Characteristic gasoline engine malfunctions

Engine does not start

The frequent reason the engine does not start is a low oil level in the crankcase, or oil level sensor failure (check and add oil if necessary, disconnect the sensor, try to start without it).

- absence of external leaks;

- Fuel in the tank;

- The position of the fuel tap (should be in the open position);

- position of the air damper (it should be closed before starting when the engine is cold, and immediately open after starting);

- Check that the spark plug has a spark (to do this, unscrew the plug, place it on the surface of the power tiller, without removing the cable and without touching it with your hands, and then start the engine).

If there is no spark, replace the spark plug with a known good one or check the electrodes. See Ignition System Troubleshooting.

If the spark is good, inspect the underside of the spark plug and the electrodes. Dry surfaces mean that the problem is in the fuel supply to the cylinder. If, on checking the spark plug, you find that it is wet, then there is no problem with the fuel supply. The cause of the failure is most likely caused by If fuel is not coming through the carburetor.

No fuel is flowing through the fuel line to the carburetor. To correct the fuel supply problem, it is advisable to start by checking the fuel supply through the fuel line to the carburetor. If no fuel is coming through the carburetor. then maybe or (and):

Eliminate the possible causes of malfunction by cleaning the plugged element or replacing it.

Fuel is getting to the carburetor, but is not getting to the cylinder. If the fuel reaches the carburetor, but does not enter the cylinder, it means that the problem is in the carburetor. In most cases, it is enough to remove it, disassemble and rinse well with clean gasoline, blow out all the holes with compressed air and put it back in place. If you have the necessary skills and knowledge for this, then you can do it yourself, if not, it is better to turn to experts on repair. If parts of the carburetor are worn or damaged, you can replace the whole carburetor. The store MOTOZAVR offers a wide range of quality parts for the fuel system (carburettor, fuel filter, etc).e) at the best prices.

Faults of ignition system

there is soot on the electrodes of the spark plug (in this case you should thoroughly clean the plug with sandpaper, then wash it with gasoline and dry it);

the gap between the electrodes does not correspond to the value specified by the manufacturer in the engine manual (then it is necessary to adjust the gap by bending the side electrode until the necessary value of the gap is obtained);

damage to the spark plug insulators or high-voltage wiring (they cannot be repaired, the spark plug or wiring must be replaced);

the “STOP” button was shorted to the common ground (short circuit should be eliminated);

Ignition coil may be defective (replace the ignition coil).

Leakage (air leakage)

if a single-axle tractor does not start or runs rough after starting, it is possible that there is air leaking through the carburetor seals, spark plugs, cylinder head and connections of the carburetor and engine cylinder (crack in the inlet manifold gasket).

If you find leaking connections, inspect the mounting bolts, tighten the spark plug, and check the integrity of the gaskets;

startup is affected by the malfunction of the choke. Incomplete closure of the carburetor choke makes it difficult or impossible to start the engine (if there is a sticking. also it is necessary to eliminate it).

the engine does not start or starts with great difficulty, runs intermittently, does not develop optimal performance (change the piston group)

If during engine operation there is thick black smoke coming out of the muffler and the electrodes of the plugs are covered with soot, or there is too much oil on them, the following may be the probable cause:

the carburetor receives too rich (enriched) fuel mixture (adjust the carburetor);

Worn piston ring (replace piston rings. a job for professionals);

the air filter is clogged, if it has an oil bath, the oil level in it is probably higher than normal and the oil is being drawn into the cylinder (service or replace the air filter).

If the smoke that comes out of the muffler while the engine is running, light in color, and on the electrodes of the plugs a white deposit is noticeable this is a signal of a depleted fuel mixture getting into the carburetor (not enough gasoline in the mixture). Such problems are solved with the help of carburetor settings.

Any spare parts necessary for repair of a power tiller, as well as free consultation on their selection and installation you can get in the Internet-shop MOTOZAVR.