How to choose the right disc by tile

For cutting, metal discs are used with diamond dust on the edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots for watering, and will create chips when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

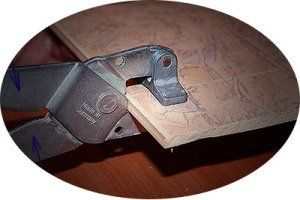

Tile cutter tong

Tile cutting tongs are the cheapest (200-400 rubles), and they are only suitable for small volumes of work with thin ceramic tiles at home.

After scoring, press down on the tile with a cracking pliers

- Make markings taking into account all gaps and seams (-5 mm).

- Attach a metal ruler to the mowing line and slide the cutter along it once. The pressure should be medium to form a visible streak. Lead him from the far end to you.

- Place the tongs with their feet along the mowing line of the crowbar near the edge. Sponges Should be on top of the glaze and the straight part on the bottom. The line of the break should run right halfway between the edges of the upper lip.

- Press gently on the handles to break off the tile. Do NOT lift it high, otherwise it will break after falling.

We make a drink at 45 degrees

Ceramic skirting board pencil best for protecting sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45-degree angle to the tile bevel, but not everyone has such a tool. It is easy to make such an angle yourself using the same angle grinder. “approximately”. The disc is guided along the line of the cut, with the disc tilted slightly inward.

Dust tiles at 45 degrees

How to cut porcelain stoneware

It is considered that porcelain stoneware is the hardest material from which floor tiles are made. You can trim it in the same way as a regular tile.

Sometimes I go to cut floor tiles more difficult than porcelain stoneware. There is a hardened tile, on which, after being carried out with a tile cutter, it is almost invisible to cut into the glaze. And even a diamond disc does NOT take it on an angle grinder. The cut is torn, like after a tractor. In such cases, you need to use an angle grinder, and dust the groove 2-3 mm from the back to mark the place of the break.

How to cut a tile with a letter D

Since the tile cutter can only cut the tiles straight, many have difficulty with L-shaped cutouts. The easiest option. Divide this tile into 2 rectangular elements, but then you get an extra ugly seam, which will be striking.

But this can be avoided by trimming the short side of the angle grinder and then cutting the long side. Tile cutter.

Step-by-step instructions on how to make L-shaped cuts on tiles

Second method: in any way available to you, a cut is made on the glaze, and the excess is gradually broken off with pliers. Irregularities are sanded with sandpaper. This option will even allow you to get a rounded incision for abutting the risers.

How to cut tiles without a tile cutter

If you only need to cut a few tiles, it doesn’t have to be spent on a tile cutter. You can use the tools at hand:

- Glass cutter.

- Drill. It should preferably be with a victorious tip, as it will scratch the tile better.

- Nail.

- Construction knife.

Attach a metal ruler to the notch area and cut once with a glass cutter or drill. A deep scratch should remain on the enamel. If you use a knife, but you will need to spend several times.

Place the tile at the corner with the cut and press down on the edges with a sharp motion. The cut will NOT be perfectly flat, unlike the tile cutter, but you will NOT have to spend extra money.

All about cutting tile with an angle grinder. What disc to cut tiles

Tool accessories are selected for a specific material. Several types of discs are suitable for cutting tiles.

How the chip-free angle grinder dusty tiles: a comprehensive beginner’s guide

Installing wall or floor tiles is almost never complete without undercutting. Parts need to be adjusted to size, cut to the shape of the base, t Traditionally, a tile cutter is used for this, but more and more DIYers choose an angle grinder. Let’s figure out how to cut tiles with an angle grinder without chips and is it possible in practice.

Stone circles

Cutting element of significant thickness. Due to this, the cut is wide, the amount of dust increases during work. The main disadvantage. Consumables wear quickly. over, if chips or other defects appear on it during operation, the circle is immediately changed. Otherwise, it can collapse, damaging the workpiece and closing the harm to the person working with it. Stone discs are the cheapest.

Why an angle grinder is better than a tile cutter

To begin with, the tile cutter is designed to cut tiles. For each of its varieties: thick or thin, more or less durable, you can find a suitable tool model. The main advantage of the tile cutter. It gives an even cut without chipping. There is not a lot of dust during operation, the risk of spoiling the plate is minimal. Not so with an angle grinder.

Makita GA5030 Angle Grinder

You can cut the ceramics with it, the result can be very good. But for this you have to try. It is desirable to have the skill of working with a grinder, otherwise there is a great risk of spoiling the material. The tool will cut any veneer if the correct blade is selected. We must be prepared for the fact that during the cutting process it will be very noisy, a lot of dust will rise into the air. Cut line may be chipped.

Stone discs

Sharpening bits are most often made of stone. They constitute a solid base with a minimum thickness of 6 mm. Thanks to their massive base, stone discs are ideal for sharpening tools that conventional fine bits cannot handle.

As a rule, stone discs are not suitable for tile cutting due to their great thickness. But they can make the tools at hand sharper without much effort. A stone wheel with sandpaper petals glued on is suitable for grinding materials. It is recommended to clean the tiles with a soft abrasive marked No. 120, 150, 180.

Which disc to cut ceramic tiles angle grinder?

There are at least 6 types of discs suitable for use with an angle grinder. Here the choice of the nozzle will depend on the quality of work and the achievement of various results at the request of the master.

Hole cutting

The angle grinder only cuts large diameter holes. Small ones are performed with a drill or perforator.

- Through the center of the circle hole, two straight mowing lines are marked, located perpendicular to each other.

- While guiding the grinder at an angle, make a small indentation along the circumference, trying to adhere to its inner diameter.

- Move gradually in a circle, evenly filing the thickness of the tile.

- Once the hole is sufficient, cut straight perpendicular to the mowing line through the center of the circle.

- Carefully remove the first segment to avoid chipping, then remove or knock out the remaining three.

Straight cutting

The simplest processing option that even beginners can handle. Angle grinder cutting tile in a straight line. To begin with, the tool is fixed on a flat surface. Position it so that the cutting edge hangs off the platform. The direction of the cut must remain within the tiler’s line of sight, with the tiles laid face up.

Curly cutting

It is more difficult than the first option, it requires a certain skill. The tile is processed with short cuts along the tangent of the mowing line to the outer contour of the drawn figure (oval, circle). This will allow you to cut off small extra fragments, and then achieve the desired configuration.

Also, plan small allowances for trimming, and at the end they refine the contour by grinding, achieving smooth lines and removing chips.

Steel wheels

Steel. A complex alloy of iron with carbon and impurities in the form of silicon, sulfur, manganese and phosphorus. The carbon component, which does NOT exceed 2.14%, gives the steel high strength and hardness values. This allows the metal to be used as a base material for the production of cutting discs for an angle grinder.

Another option for coating steel nozzles. Electrocorundum. It is an abrasive made of crystalline alumina or synthetic corundum, which increases the sawing properties of the disc. Such nozzles are marked in blue and are used to cut a variety of metal elements. Profiles, sheets, angles, fittings and pipes.

Cutting porcelain stoneware with an angle grinder: how to saw off without chips

Everyone who has had to cut faience, ceramics, porcelain stoneware with a cutting disc knows perfectly well that the problem is not to spray. Such an operation is not particularly difficult. The problem is learning how to cut a porcelain stoneware angle grinder without chips. At the same time, control the process at any stage, otherwise expensive material will go to scrap.

It is best to cut porcelain stoneware with the introduction of a guide bar as a support for the case of an angle grinder

Direct cutting of porcelain stoneware

It is considered correct to dust the porcelain stoneware slab on a table or workbench. The material is laid on the table top, fixed with clamps with rubber tips. The cut line should be outside the table surface. In this case, it is possible to cut porcelain stoneware with a very small angle of inclination, only 15-20 in. The master simply pulls the angle grinder towards himself, only lightly resting his hand on the stand.

Cutting Option Pull Angle Grinder

Why this method is good:

- The minimum load on the hands, if you need to spray a long enough seam, it will NOT be difficult to do this;

- The cutting line turns out to be even, it seems that the cutting was carried out NOT by an angle grinder, but by a tile cutter.

The only drawback of this method is that most of the dust escaping from under the disk falls on the floor, and the largest parts fall into the face and hands of the worker. Therefore, porcelain stoneware dusting is necessary in goggles and with the introduction of devices for collecting dust.

What disc to cut porcelain stoneware angle grinder

Sawing of porcelain stoneware tiles can be performed in two ways, it all depends on the thickness of the material and on how complex the seam is to be cut. Since porcelain stoneware. It’s still not granite, but just an artificial imitation of it; two types of discs can be used for cutting:

- Vulcanite discs based on synthetic superhard ceramics. With such a circle, you can cut thin grooves, corners, trim the edges. In order to cut expanded clay, an angle grinder over a length of more than 10 cm, they are not suitable, but they are quite suitable for small jobs;

- Diamond cutting wheels. With this tool, you can cut seams of unlimited lengths. The only drawback of diamond is the rapid grinding of the cutting edge, which will need to be restored and cleaned periodically.

The optimum wheel diameter for an angle grinder is 115 mm, in which case the tool is easier to control by holding the body with both hands. A larger diameter blade will require a more powerful tool such as a circular saw.

Diamond cutting discs on their own. Quite an expensive and capricious tool, therefore they try to do most of the work with vulcanite discs, only the most delicate operations, such as trimming and adjusting the plane, are performed with diamond powder.

In addition, the discs for cutting porcelain stoneware angle grinder must have a solid edge without a notch or tortoiseshell profile. Such a tool cuts well natural granite, rubble stone, but with the slightest attempt to cut porcelain stoneware tiles along the cut mowing line, a huge number of enamel chips appear on the front surface.

If there is no specific preference for a well-known brand of cutting disc manufacturer, then it is best to buy discs from leading hand tool manufacturers. Simply put. Bought an angle grinder made by Makita, buy cutting discs with attachments made by the same company.

How to get rid of dust when cutting porcelain stoneware angle grinder

If the tiles are cut on a table, then, before starting work, a small piece of loose fabric must be pulled under the cutting line or a polypropylene bag must be hung. In this case, most of the dust flies down from the disk, so the amount of work on cleaning the room is reduced several times.

If you cut porcelain stoneware on a substrate directly on the floor, then the best solution would be to use a regular vacuum cleaner. The tip of the hose is attached along the mowing line of the angle grinder movement at a distance of 10-15 cm. It turns out NOT too convenient, since the nozzle has to be rearranged, but the dust is removed quite effectively. Immediately after completing the work, you need to blow out the angle grinder and collect part of the dust remaining on the surface of the porcelain stoneware.

How to Cut Highly Raised Angle Grinder Correctly

Most beginners and DIYers prefer to dust porcelain stoneware with a tool with a very large angle of inclination to the plane of the tile. The angle can be 45-60 in.

The tool can only be lifted high if there is a supporting surface on the cover

In this case, the angle grinder must be held with both hands and at the same time perform small oscillatory movements with the cutting disc. It is as if the porcelain stoneware had to be cut with a hand saw. This is not very convenient, but the method really improves the quality of the cut and prevents the formation of chips.

On the one hand, with such a movement, the angle grinder is easier to control the cutting line, on the other hand, the tool is in an unstable position when marking, which negatively affects the quality of the straightness of the seam.

Useful Tips

All kinds of angle grinder attachments are on sale, some of them provide connection of the vacuum cleaner nozzle to the tool’s protective casing. At first glance, the thing is quite convenient, but it is better not to use such devices, since the hose greatly interferes with work and often only worsens the quality of the seam.

In addition, it is necessary to cut porcelain stoneware, be sure to hold the body of the angle grinder with both hands, while the left hand should rest on the stand or guide rail, and the right hand should directly move the tool. This method provides not only partial relief of hands, but also allows you to more accurately align the position of the cutting disc in the vertical plane.

Regardless of which disc and how to cut the porcelain stoneware, after the completion of the work, the edge must be rubbed with hand or tape emery. In this case, you just need to slightly align the lower edge of the porcelain stoneware and in no case touch the upper front edge with an abrasive, otherwise chips will appear, and the quality of the seam will noticeably deteriorate.

Cutting ceramic tiles with a glass cutter

If the amount of work with tiles is small, it is quite possible to do without a special machine for cutting tiles, using a conventional roller glass cutter (diamond). Cutting ceramic tiles with a glass cutter is done in the same way. First, the tiles are soaked in water for 30-40 minutes. After applying the marking with a marker or pencil on the front side, the tiles are laid on a flat board or plywood. The incision is made with strong pressure. Just one time. Pressing evenly on the tool, roll it in the direction from the far edge of the tile towards you, so that a groove appears on the enamel surface. To make a break along the formed mowing line, put a nail, match or thin wire under it, and press on the tile from both sides at once.

Cutting tiles with a glass cutter

It is quite difficult to perform a large amount of work with a glass cutter, since the process takes a lot of time and requires concentration. After all, you need to constantly monitor that the incision is in the right place. And of course a glass cutter is not possible to cut through thick floor tiles.

How to cut ceramic tiles

Wall tiles or glass tiles can be cut with a conventional roller glass cutter. Mark with a marker or pencil before cutting. Floor tiles are thicker and stronger, so a glass cutter won’t be enough.

In such cases, a tile cutter (tile cutter) is used. It differs from a roller glass cutter with a wheel, which in the tile cutter is much larger in size, so the cutter can puncture the tile to a greater depth. The tile cutter in appearance resembles tongs, with its help you cannot not only cut, but also break the tile after cutting. The tile breaking mechanism consists of a metal tooth corner on the bottom of the forceps and a special corner on the top.

Electric tile cutting machine

If floor tiles are to be cut, the corner on the top of the pliers should only be made of metal. Therefore, if you decide to purchase a tile cutter, choose a tool not with a plastic, but with a metal corner. The plastic corner tile cutter is only suitable for wall tiles. Most torches are equipped with a metal ruler with stops, which is designed for serial cutting. If you need to cut tiles to the same size (for example, for a curb).

Ceramic tiles can be cut with an angle grinder with a diamond wheel. It works best with tiles. But this method is the noisiest and most dusty, so you can use an angle grinder only when it is impossible to spray with a tile cutter or a second tool.

What and how is the easiest way to cut tiles: expert advice

Ceramic tile. Material, durable and comfortable in many ways. But the installation process requires some preparation, accuracy and patience. In order to beautifully and efficiently tiling a working wall or a floor in a kitchen, it is necessary not only to be able to lay, but to know how to cut a tile. When decorating a kitchen apron with tiles, whole tiles are not always stacked. To veneer ledges, window frames, electrical outlets and edge switches, tile cutting or drilling is often necessary.

The subtleties of working with an angle grinder

If cutting ceramic tiles is done with this tool, it is very important to follow safety precautions. Wear protective eyewear when working with an angle grinder. In addition, the instrument must have a protective cover that can absorb most of the splinters from ceramic tiles. A protective cover is also needed in order to ensure your safety if a disc suddenly breaks at high speeds.

Tile cutting with an angle grinder is carried out using a diamond wheel. Before starting work Make sure the circle is securely fastened, then turn on the tool and spray on the pre-marked mowing line. Remember, this is the way to cut tiles. The dustiest and noisiest, therefore the angle grinder Use only in case of emergency, for example, when you need to cut porcelain tiles. An angle grinder is also required for leveling the edges of tiles when an angle cut is needed (for joining tiles to a ledge).

Tile cutting angle grinder with diamond wheel

Aligning the edges after cutting tiles

If you get sharp, jagged edges, nippers or pliers are used to align them. The uneven edge is bitten off, and the chips are leveled with a round file. The edges of the tiles are treated with coarse sandpaper.

How to use the tile cutter

The main difference between the tile cutter. Larger wheels, which can make a cut of greater depth, and the presence of a mechanism, such as after the cut allows breaking the tiles. Electric tile cutting machines, which are also available on the market, cut the tiles very carefully, the edges are smooth and slightly rounded.

Before cutting the tile, it should be soaked in water for 30-40 minutes, and then mark the part intended for cutting by applying the cutting line with a marker or pencil.

Working with a manual tile cutter

With a tile cutter, you can make an incision at a given desired angle. In this case, the markings are applied using a square with divisions. The cutting line on the tile is NOT closer than one cm from the edge of the tile. When using the tile cutter, align the mark with the pointer on the cutter. The tile is fixed at the same level, and the cutting element is moved in the direction push. Move the cutter very slowly to the edge of the tile. So you can avoid overheating of the tile, the appearance of cracks and chips on it.

It is very important to properly fracture the notched element. Using a tile cutting machine, evenly distribute the pressure to avoid breaking or deviating from the markings you have applied. If you are using a manual tile cutter, you will NOT be able to cut strips less than 5 mm wide.