Cutting ceramic tiles at home How to cut ceramic tiles at home? Types of the right tool and advice on how to choose the right one. Application methods and characteristics.

How to choose the right one?

In order to start trimming ceramics at home, it is best to start by choosing the right tool.. In each case, a different set of fixtures will be required, since the tiles differ in size, texture and performance. For example, for glazed tiles that are porous and soft, it is better to use a glass or tile cutter. It will be easy to cut the material with it. To cope with a harder surface, like ceramics, he will no longer be able to.

For porcelain stoneware, a more thorough hike will be required in the form of specialized electrical devices. The greater the strength of the raw material, the more thorough the approach should be. Thus, it is possible to cut the tiles on the front side. Glass cutting tools, as well as other devices that work on a similar principle, will not help here. But the electric devices will be just right! The main thing is to pay special attention to the edges of the products, since working with the relief structure is considered difficult due to the formation of chips or pattern violations, even with a slight deviation.

Tool types

Currently, modern technology offers many devices designed for pruning. They are subdivided into specialized and amateur ones, however, this division is rather arbitrary. Each of the selected tools has a high functionality, suitable for better cutting porcelain stoneware at home. Some are small, while others are very cumbersome. Most often, the choice falls on:

- Glass cutter and pliers;

- Jigsaw;

- Angle Grinder;

- Tile cutter;

- Diamond wire;

- Sharp forceps.

These options are suitable for tiles with a soft surface. It is worth knowing that a large amount of work performed with such tools will still become too exhausting. Adjusting with them will be a great finishing touch though.

Cutting ceramic tiles at home

Today, tile occupies a solid first place among convenient and practical materials. It is used for finishing the floor, walls and facades of the building. It is used in the kitchen or bathroom, as well as in the hallway. You can do the installation of ceramics with your own hands, however, this process is not complete without cutting the material, for example, quite often it is required to cut the tiles when laying diagonally.

In addition, the question arises, how to cut ceramic tiles at home? For cladding work, the modern market offers a wide variety of options. The final decision, as a rule, depends on many direct and circumstances. After all, in order in order to correctly cut the tiles, special skills are not required, but it is necessary to have information about certain subtleties in working with cutting tools.

Aligning the edges after cutting the tiles

If you have sharp jagged edges, use wire cutters or pliers to level them. The uneven edge is bite off, and the chips are leveled with a round file. The edges of the tiles are processed with coarse-grained sandpaper.

Cutting ceramic tiles with a glass cutter

If the amount of work with tiles is small, it is quite possible to do without a special machine for cutting tiles, using a conventional roller glass cutter (diamond). Cutting ceramic tiles with a glass cutter is done in the same way. First, the tiles are soaked in water for 30-40 minutes. After marking with a marker or pencil on the front side, the tiles are laid on a flat board or plywood. The incision is made with strong pressure only once. Pressing evenly on the tool, roll it in the direction from the far edge of the tile towards you so that a groove appears on the surface of the enamel. To make a break along the formed mowing line, place a nail, match or thin wire under it, and press on the tiles from both sides at once.

It is quite difficult to perform a large amount of work with a glass cutter, since the process takes a lot of time and requires concentration. After all, you need to constantly monitor that the incision is in the right place. And of course, you can’t cut through thick floor tiles with a glass cutter.

The subtleties of working with an angle grinder

If cutting ceramic tiles is done with this tool, it is very important to observe safety precautions. Wear protective eyewear when working with an angle grinder. In addition, the instrument must have a protective sheath that absorbs most of the ceramic tile splinters. A protective cover is also needed in order to ensure your safety if the disc suddenly breaks at high speeds.

Tile cutting with an angle grinder is carried out using a diamond wheel. Before starting work, make sure that the circle is securely fastened, then turn on the tool and cut along the previously marked mowing line. Remember that this method of cutting tiles is the most dusty and noisy, so use the angle grinder only in emergencies, for example, when you need to cut porcelain tiles. An angle grinder is also needed to level the edges of tiles when an angle cut is needed (for joining tiles on ledges).

Tile cutting angle grinder with diamond wheel

How to cut a tile with a glass cutter or an angle grinder?

With a glass cutter, you can make a straight cut in the material quite quickly. To do this, perform the following operations:

- Outline with a pencil (felt-tip pen) the line along which they are going to cut the tile;

- Press a square of material to the table with one hand, and with the other, directing the glass cutter towards yourself and holding it at an angle of 90, hold the tool with pressure along the intended mowing line;

- The trimmed plate is placed on a wooden block (or on the edge of the table) and with a blow of the palm, break the tile along the cut’s mowing line.

Scheme for cutting tiles with a stele cutter.

In addition, difficulties arise in its application when performing a curly cut mowing line. Now let’s look at how to cut a tile angle grinder.

To use it in facing work, you need to purchase a diamond disc, which allows you to use this universal tool for cutting tiles both along straight and curly lines. Compared to an electric tile cutter, an angle grinder is more mobile, but loses to it in terms of cut quality. After cutting the tile with this tool, you need to clean the sections with a file or sandpaper. Use an angle grinder like this:

- A cut line is drawn on the plate;

- The tile is fixed in wooden clamps, or it is pressed with the foot and an angle grinder is cut;

- The edges of the cut are cleaned with a file.

Electric ceramic cutter

At the heart of the electric tile cutter is a diamond disc that allows you to make even and beautiful cuts.

This device has a diamond disc as a working tool and will cope with tiles of any thickness.

When working, you get smooth cuts with rounded smoothed edges.

Such a machine can be used for any amount of work, it is used when cutting various ceramic and stone slabs, with the exception of those coated with carbide chips, which can damage the diamond disc.

They work on this device like this:

- The cut line is applied to the tile with a pencil;

- The marked tile is placed on the working platform of the machine, and tightly holding the plate with both hands and pressing it to the base of the device, slowly move the material under the blade of the diamond disc;

- When working, special glasses are used to protect the eyes and the level of cooling water in the machine pan is constantly monitored;

- The liquid is periodically changed during operation; it becomes clogged with ceramic chips;

- Do not try to increase the speed at which the tiles are fed under the disc; they may crack.

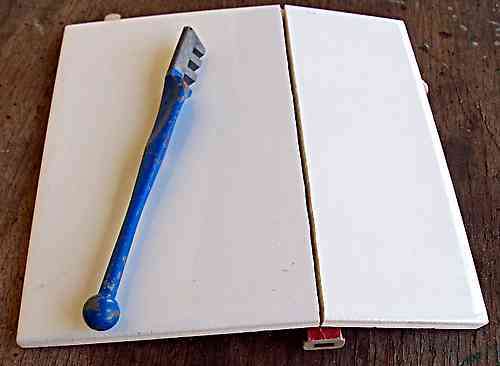

The use of a manual machine at work

Tile cutting scheme with a manual machine.

Such a plate cutter is used to cut plates with a thickness of no more than 5-6 mm. The tool has a quite reasonable price and makes it possible to relatively easily and quickly cut the required number of tiles; it is well suited for doing cladding work with your own hands.

It is applied in the following order:

- Mark the part to be cut with a pencil or felt-tip pen on the tile;

- The material is installed on the base of the device so that the cutting line is under the impeller of the machine;

- Using the tool handle, carefully cut the cut with the impeller along the marked mowing line;

- The tile is fixed on both sides of the intended cut using the so-called wings;

- Lightly hitting the handle of the machine, separate an unnecessary piece from the tile.

If after several such blows the tile remains intact, then try to cut the next plate.

Other ceramic tile trimmers

What is the best way to cut ceramic tiles if you need non-standard edge shapes? There are various devices for this.

- Nippers. Used to bite off small pieces, corners and semicircles. They leave behind an uneven edge, which must be trimmed with an emery wheel.

- Diamond string. It is fixed in an ordinary hacksaw for metal, used for curly cutting. It cuts only wall tiles and requires some skill, since during jerks, chips are formed on the surface.

- Crowns are used to make round holes in ceramic tiles for sockets and switches.

- Ballerina. With the help of such a drill, holes of various diameters are made. The size is adjusted manually by changing the distance to the cutter. Up to 20 cuts can be made with one nozzle.

How to cut ceramic tiles

In any case, special tools will be needed for the work. The simplest of them is a glass cutter, a manual tile cutter has a higher performance, for professionals it is recommended to opt for electric tile cutters. When you acquire a certain skill, the tile can be cut with an angle grinder, and a diamond string is used to make art products.

We cut ceramic tiles with an electric tile cutter

This tool belongs to the professional category and is quite expensive. With its help, a significant amount of work is easily performed, it cuts any tile quickly, accurately and beautifully. Allows you to cut less than 5 mm wide, make cuts at an angle of 45 degrees, recesses and holes. It is used for curly cutting. The cut has smooth and slightly rounded edges. In some models, the edge of the blade is immersed in water, in others, only the surface at the cutting site is wetted. During operation, all dust settles in the cooling water tank.

The design is very similar to a circular saw. It consists of a platform, a cutting disc fixed on it and an electric motor.

How to properly cut ceramic tiles with an electric tile cutter.

- Water is poured into the container so as to overlap the edge of the cutting wheel by 2-3 cm.

- Includes tile cutter.

- Press the ceramic tile against the machine and slowly move it under the disc, focusing on the marked line.

- The blade is moved under the cutting element with a force depending on the strength of the tile. It is not recommended to apply excessive pressure on the knife, this may cause the cutter to stop.

- To cut a corner, the tile is gently lifted, unrolled, and repeated.

It is necessary to monitor the condition of the cutting edge of the disc, replace it in time. Diamond wheels are commonly used. Also, regularly, as it gets dirty, they change the water in the bath.