Safety engineering

- Work must be carried out with goggles and a respirator.

- The area around the workplace must be free to avoid the possibility of injury from the saw blade..

- It is advisable to work with a partner who, using a vacuum cleaner, will remove construction dust.

Using the “angle grinder”

A diamond disc mounted on an angle grinder allows you to quickly cut the tiles according to the markings made. With this universal tool, both straight and curved tiles can be cut. The advantage of an angle grinder over an electric tile cutter is its mobility. But it loses in terms of the quality of the cut obtained, after which the edges of the tile need additional processing (grinding).

Manual tile cutter

The manual tile cutter allows you to take tiles that are less than 6 mm thick. It is an affordable tool that allows you to quickly cut fragments of tiles according to measurements taken. Such a tile cutter is convenient for those amateur craftsmen who perform cladding work with their own hands. Professionals use an electric tile cutter, which we will talk about a little later..

Important! The denser the structure of the tile, the easier it is to cut a narrow strip from it..

Handle the manual tile cutter as follows:

- marking is made on the surface of the tile with a felt-tip pen;

- the tile is laid on the base of the tool in such a way that the wheel coincides with the marking;

- skip the wheel along the mowing line of the marking once, controlling the handle of the glass cutter;

- with the help of “wings” the tile is fixed on both sides of the cut for even division into two parts;

- with a light movement of the hand, hit the handle, while getting the desired fragment for laying out the cut row.

Important! If after several hits the tile remains intact, then you should not waste time on this “tough nut” by taking another tile.

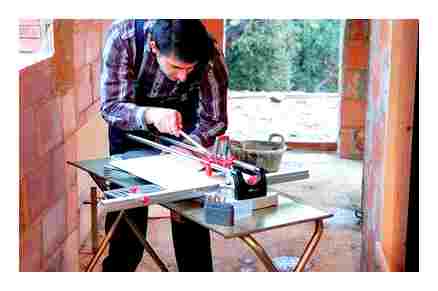

Electric tile cutter

This tool, equipped with a diamond blade, is the most ideal device for cutting any kind of tile. At the same time, using the circular saw of the tile cutter, ideally even cuts are obtained, the edges of which are slightly smoothed and rounded..

Electric tile cutting machine copes with any amount of work, no matter how large they are. The design of the perfect tool is capable of providing a high level of safety to the person working with it..

Important! Stone tiles covered with carbide chips must not be processed with an electric tile cutter. Since this causes the destruction of the diamond saw from interaction with this coating material.

The marked tiles are laid on the working platform of the tile cutter and slowly advanced under the diamond saw blade. At the same time, they try to hold the tile tightly, pressing it to the platform with both hands..

How to cut tiles with wire cutters

Nippers are indispensable when cutting holes for water pipes, platbands in tiles. hoods, fireboxes and other structural obstacles. Better fracture is done with a pair of wire cutters equipped with two carbide clamps. The upper clamp cuts through the glazed surface of the tile, while the curved lower clamp holds the tile from below. Before work, a contour is applied with a felt-tip pen, along which it is necessary to make a cut. Rather, in this case, the tool does not cut, but bites off fragments of the tile until a groove of the desired size is obtained..

Important! Do not try to “bite off” large pieces of tiles at once, otherwise the edge will turn out to be completely sloppy. In any case, the resulting cut needs processing, which is carried out with a file or special sandpaper.

How to cut tiles

Manufacturers offer to use a different tool for cutting tiles, which can be selected depending on the volume and characteristics of the material chosen for the manufacture of tiles. The tile is cut:

- roller glass cutter;

- electric tile cutter;

- manual tile cutter;

- tile nippers;

- angle grinder (“angle grinder”).

Let’s dwell in more detail on the features of the application of each of the above tools..

How to cut tiles with different tools

When carrying out facing work of any premises with the help of tiles, it is necessary to lay not only whole tiles, but also their parts. This raises the question of how to cut the tile so that the edges are smooth. It is even more important not to break the entire tile, the cost of which is quite high. Both tasks are achievable only if the craftsmen use special tools in their work, among which there are professional expensive equipment and cheap fixtures. When performing one-time work, you can use inexpensive tools.

Cutting tiles with a glass cutter

A direct cut of a tile with a glass cutter is quite simple to make, but you will have to tinker with curly cutting.

The operation is performed as follows:

- first, outline the fishing line with a felt-tip pen or pencil, along which the cut will be made;

- with one hand they hold the tile, and with the other they confidently hold the glass cutter along the intended mowing line, while the tool is directed “towards you”; the glass cutter must be kept strictly at right angles;

- the cut tiles are placed on a wooden glazing bead and hit with the palm. the tile breaks exactly along the cut line of the cut.

Important! Working with a glass cutter requires skill, which is acquired with experience. Therefore, in this way, you can cut a couple of tiles. To handle more tiles, more advanced fixtures should be used..

How to cut ceramic tiles

How to cut ceramic tiles, the complete DIY guide

How to use the tile cutter

The main difference between the tile cutter is the larger wheel, which can be used to cut a greater depth, and the presence of a mechanism that, after the cut, allows you to break the tile. Electric tile cutters, also available on the market, cut the tiles very carefully, the edges are smooth and slightly rounded..

Before cutting the tile, it should be soaked in water for 30-40 minutes, and then mark the part intended for cutting by applying the cutting line with a marker or pencil.

Working with a manual tile cutter

With a tile cutter, you can make an incision at a given desired angle. In this case, the markings are applied using a square with divisions. the cutting line on the tile is at least one cm from the edge of the tile. When using the tile cutter, align the mark with the pointer on the cutter. The tile is fixed at the same level, and the cutting element is moved away from itself. Move the cutter very slowly to the edge of the tile. So you can avoid overheating of the tile, the appearance of cracks and chips on it..

It is very important to break the notched element correctly. Using a tile cutter, apply pressure evenly to avoid breaking or deviating from the markings you applied. If you are using a manual tile cutter, you will not be able to cut strips less than 5 mm wide..

Aligning the edges after cutting tiles

If you get sharp, jagged edges, use nippers or pliers to level them. The uneven edge is bite off, and the chips are leveled with a round file. The edges of the tiles are treated with coarse sandpaper.

The easiest way to cut tiles: expert advice

Ceramic tiles are a durable and convenient material in many respects. But the installation process requires some preparation, accuracy and patience. In order to beautifully and efficiently tiling a working wall or a floor in a kitchen, it is necessary not only to be able to lay, but to know how to cut tiles. When decorating a kitchen backsplash with tiles, whole tiles are not always stacked. To veneer ledges, window frames, electrical outlets and edge switches, tile cutting or drilling is often necessary..

How to cut ceramic tiles

Wall tiles or glass tiles can be cut with a conventional roller glass cutter. Mark with a marker or pencil before cutting. Floor tiles are thicker and stronger, so a glass cutter will not be enough.

In such cases, a tile cutter (tile cutter) is used. It differs from a roller glass cutter with a wheel, which is much larger in the tile cutter, so the cutter can puncture the tile to a greater depth. The tile cutter resembles tongs in appearance, with its help you can not only cut, but also break the tile after the cut. The tile breaking mechanism consists of a metal tooth corner on the bottom of the forceps and a special corner on the top.

Electric tile cutting machine

If floor tiles are to be cut, the corner on the top of the tongs should only be made of metal. Therefore, if you decide to purchase a tile cutter, choose a tool not with a plastic, but with a metal corner. The plastic corner tile cutter is only suitable for wall tiles. Most cutters are equipped with a metal ruler with a stop, which is designed for serial cutting – if you need to cut tiles to the same size (for example, for a curb).

Ceramic tiles can be cut and an angle grinder with a diamond wheel is best suited for working with tiles. But this method is the noisiest and most dusty, so you can use an angle grinder only when it is impossible to saw with a tile cutter or other tool..

Cutting ceramic tiles with a glass cutter

If the volume of work with tiles is small, it is quite possible to do without a special machine for cutting tiles, using a conventional roller glass cutter (diamond). Cutting ceramic tiles with a glass cutter is done in the same way. First, the tiles are soaked in water for 30-40 minutes. After applying the markings with a marker or pencil on the front side, the tiles are laid on a flat board or plywood. The incision is made with strong pressure – just once. Pressing evenly on the tool, roll it in the direction from the far edge of the tile towards you, so that a groove appears on the surface of the enamel. To make a break along the formed mowing line, place a nail, match or thin wire under it, and press on the tile from both sides at once.

Cutting tiles with a glass cutter

It is quite difficult to perform a large amount of work with a glass cutter, since the process takes a lot of time and requires concentration. After all, you need to constantly monitor that the incision is in the right place. And of course, you can’t cut thick floor tiles with a glass cutter..

The subtleties of working with an angle grinder

If cutting ceramic tiles is done with this tool, it is very important to follow safety precautions. Wear eye protection when working with an angle grinder. In addition, the instrument must have a protective cover that can absorb most of the splinters from the ceramic tiles. A protective cover is also needed in order to ensure your safety if a disc suddenly breaks at high speeds..

Tile cutting with an angle grinder is carried out using a diamond wheel. Before starting work, make sure that the circle is securely fastened, then turn on the tool and cut along the previously marked mowing line. Remember that this tile cutting method is the most dusty and noisy, so use the angle grinder only in emergencies, such as cutting porcelain tiles. an angle grinder is also needed to level the edges of tiles when an angle cut is required (for joining tiles on ledges).

Tile cutting angle grinder with diamond wheel

Tile cutting methods

The cutting method depends on the material and the complexity of the cut, we will consider the most common methods.

Open with a jigsaw

The jigsaw is used for small volumes of work and when it is necessary to create curved cutouts. An abrasive file is required to cut the tiles. Here are some recommendations for cutting tiles with a jigsaw.

- The tool should be able to adjust the speed, you should not set the maximum parameter. A neat result can be achieved by operating at low or medium speeds..

- The sole can leave scratches on the face of the tile; when sawing, the tile must be turned upside down. It is also recommended to glue the sole of the tool with masking tape to reduce damage to the tile..

- In a closed room, it is advisable to use a tool with a pipe. The branch pipe allows you to connect a construction vacuum cleaner, which eliminates a large amount of dust.

- When sawing tiles, do not put pressure on the tool or otherwise force the process. The jigsaw must be moved smoothly and effortlessly along the mowing line..

The jigsaw handles medium thick wall tiles. Sawing floor tiles or porcelain stoneware with this device is quite difficult. If it is necessary to cut thick tiles, then it is better to give preference to another tool.

Glass cutter for tiles

Any glass cutter is suitable for cutting ceramic tiles. The principle of operation does not differ from glass. Marking is applied to the tile, then in one motion you need to draw a straight line. The incision must be made with one press throughout the entire area and the first time, because then it will be very difficult to get into the first furrow.

When the line is drawn, the tiles are broken against the edge of the table or against a cylindrical object (nail, screwdriver tip). For the first variant of breaking, the tiles are hung from the edge of the table and pressed on the hanging part. If you break it against the cylinder, then the object fits under the cutting line, then you need to press on the two edges of the tile.

If a small cut of 2 – 3 cm is made, then you can break off part of the tile with pliers.

This cutting method is only suitable for straight cuts; it is almost impossible to make a round hole with a glass cutter. Also, the tool is poorly suited for textured surfaces, as it will get stuck all the time..

Before using a glass cutter, you need to take the spoiled tile and practice putting the mowing line on it first..

Tile material

The thickness and strength of the material often depends on the material from which the tiles are made. Some materials have a high density, so not every tool is able to cut them. Some materials require a delicate approach and should only be cut with specialized tools..

- Ceramic tiles are the most common variety; they are covered with a decorative glazed coating on top. Tile is divided into wall and floor tiles, the latter is usually thicker, which makes it more difficult to cut..

- Porcelain stoneware has a high density, which leads to its low water absorption. Because of this, these tiles are often used for floors, wet areas and streets. It will be difficult to cut porcelain stoneware with improvised means. cutting is best done with an electric or manual tile cutter.

- Clinker tiles are a type of high-density cladding, it is used for outdoor work (cladding, paving sites, etc.). Thick clinker requires an angle grinder or water saw (electric tile cutter).

Electric tile cutter

With the word “tile cutter” in the name, there is not much similarity to the previous tool. In fact, an electric tile cutter is called a water saw. It has more in common with a circular saw than with a manual tile cutter. The device is equipped with a diamond disc that is capable of cutting almost any tile: thick floor porcelain stoneware, textured tiles, facing materials for facades, etc..

The main advantage of this tool is that it can provide fast cutting of any number of tiles with any cutting complexity. Also, when working with such a tool, the amount of dust does not appear as when working with other electrical appliances..

One of the main problems when cutting stone and ceramic products is the heating of the cutting disc. For example, when working with an angle grinder, the disc may overheat and fly apart, which could injure the operator. The water cooling system on the disc on electric tile cutters reduces heat.

Electric tile cutters are divided into several types depending on the location of the engine.

- Top-engine units are professional and consist of the tile cutter itself and the table top. The device has a sump, from which the liquid rises with a pump, then it returns to the container, so the circulation of the coolant is ensured. Two types of these devices are widespread: with a movable table or with a movable saw. With a movable table, the tile is fixed to the table top and moves under the cutting element. If the tabletop is motionless, then the disc is lowered onto the tile..

- Bottom-engine appliances are a small tabletop with a guide along which the tiles are moved. The disc drive is located under the table, and the cutting element itself is in a special slot. The coolant is under the disc, when it rotates, it plunges into it, cooling.

In this design, the tabletop and the engine itself remain stationary. At the same time, the size of the entire device is small, which makes it possible to use it in small rooms..

Also from the devices for cutting tiles, specialized units stand out..

- Stone cutter is a special device for cutting thick paving stones. The device is equipped with a massive disc, its power is significantly higher than that of the two above-mentioned plitorers. In most cases, stone cutters are connected to a 380 V network.

- The electric manual tile cutter does not have a table, it consists of a disc and a motor. In principle, it is similar to a hand-held circular saw.

How and how to cut tiles

Tiled coverings. irreplaceable element in the interior. Even if the tile does not prevail, it will still be present in humid areas: in the bathroom, on the kitchen backsplash or in the toilet. Cutting is one of the most critical steps in tile laying. Consider possible ways to cut tiles.

Manual tile cutter (mechanical)

In most sources, this device for cutting tiles is called manual, although in fact it would be more correct to call this device mechanical. The manual tile cutter works like a glass cutter and is specially designed for easy and error-free cutting of tiles. The cutting element is a diamond roller, which is fixed on a movable element, a carriage. The carriage moves along two guide rails. Compared to using a glass cutter, making a straight cut is much easier.

The manual tile cutter has a special stop for breaking off the cut part of the tile. Lever design relieves pressure on the press. Depending on the model, tile cutters differ in the presence of various design features..

- Dry running, grease sliding or roller bearing.

- The presence of a device for figured cutting.

- Resizing for different types of tiles.

When working with a manual tile cutter, it is important to follow a certain sequence of actions.

- At the first stage, you need to make a markup, on the front side you need to apply a cutting line.

- The tiles are laid on a tile cutter so that the line matches the protrusions on the bed.

- The cutting element is installed at the beginning of the marking line, then, with a slight pressure on the lever, we stretch the carriage.

- After that, pressing in the middle of the cutting line of the cut, we break the tile.

Junction points

The complexity of the cut depends on the location of the tile relative to other elements. It is desirable that in these places there are no important and expensive tiles (borders, decor) – this point is decided by the preliminary layout of the elements. For example, curbs should not rest on communications or sockets. In places where the tile meets sockets, with batteries or with plumbing equipment, complex cuts are made on the tiles (circular, semicircular cut).

The number of junctions in which tiles need to be cut are best kept to a minimum at the planning stage..

Round holes: how to make tiles

Drill and feather drills help! And it is better to take for work on concrete – those with victorious tips.

- The former have sharp tips that are harder than the glaze, so they do not slide off the surface.

- The latter can deepen holes with a diameter of 3-12 mm.

First you need to make a mark on the tile. Attach a dowel to it and chop it off with a hammer – it will be easier to fix the drill in the mark. Then, at low speeds, make a hole or screw in self-tapping screws with self-drilling tips.

If you need a hole for a socket on an already tiled wall, it is better to use castellated ones with a centering drill, and you will not find it. It’s easier to work with such. Nakernil contours, set the drill and – to the point. Deepened – drilled with a crown.

It is worse if it is not centered. Then you have to circle and drill at a low start. You will have to grind the grooves along the contour, then bring the work to the end. Just do not be zealous: the crown heats up quickly, it must be periodically cooled in water so as not to burn out.

5 Ways To Cut Tile – Everything You Need To Know For Your First Tile Project

And if you are impatient to cut when laying, there are many options. See in the table:

Professional tool

They say about this: “Iron and jelly cuts.” If the volume of work is hoo, it is pointless to suffer with a glass cutter. It will become dull after a dozen tiles. Better to make it easier for yourself with tools specifically designed for cutting. They will be discussed below..

Jigsaw

The jigsaw will not take floor tiles, it is too thick. But wall tiles are a nice thing. Especially if you pre-hold the tiles in water for a couple of hours. Then no dust, no chips, and a minute of business:

- you need to fix the tiles in the grooves,

- mark line notch,

- turn on medium speed on the jigsaw and make through cuts along the contour.

How to cut ceramic tiles: 4 hacks for cutting without chips – at an angle, and in a semicircle

I walked over the tile with a glass cutter and break it. The split will go exactly along the barely visible strip.

Tile cutters “take” porcelain stoneware and cement floor tiles with a thickness of 6 mm. What’s remarkable: the harder the material, the easier it is to work with. On the cutting tool, you can cut a narrow strip in a straight line or at an angle without chipping. No chipping to you – love to watch.

How to properly cut ceramic tiles and other material – in the article. Here are the cases when all means are good..

Manual tile cutter

It is convenient to work with a mechanical tile cutter even for amateur tilers, not to mention professionals. True, at first you will have to decide for yourself with the force of pressing (the palm will hurt). But this is a trifling matter. The main thing is that the design of the manual model is unpretentious, the cost is acceptable, and choosing a device of good build quality (for example, Topex 16B260 600 mm) is a matter of time.

We give a tip of a good tool:

- the frame is made of aluminum – this makes the structure lighter. It is good if it is equipped with a metric ruler and a protractor – for accurate measurement of the cutting area;

- the cutting element must be firmly attached to the structure;

- double tubular guides favor an even cut, do not leave chipping on the tile;

- thanks to the ball bearing, the knife cuts smoothly. No effort is needed.

Machine cost: up to 100

At home, a glass cutter will help out

When you need it quickly, a glass cutter is indispensable. It is nowhere easier to work with him at home: he marked it → jerked at a right angle towards himself → slowly broke the tile, placing a glazing bead or a nail under it. Well, or over the knee, if it’s long.

Angle Grinder

Networked or rechargeable, small or large – it doesn’t matter. The angle grinder is more likely to do rough work because jagged edges remain on the mowing line. But you can get used to working clean, if the cut is successfully masked when laying.

This is a tool for all occasions: suitable for shaped and straight cutting, you can make a hole in the tiles of the desired diameter. The main thing is to choose a suitable cutting wheel diameter. Diamond coated – tougher and cuts slightly deeper than carbide. It is better to nail the product with a clamp to the tabletop or fix it in a vice, placing plywood under the bottom so as not to spoil the table.

3 steps to properly cut ceramic tiles that often chip.

- Mark the tiles along the entire length on the front and back sides.

- Make a surface cut up to 3 mm in one pass from the outside, then from the underside.

- Repeat until you reach your goal.

There will be a lot of dust, noise and flying debris. Therefore, do not neglect glasses, headphones and a respirator, otherwise it is more expensive for yourself.

Ceramic tiles: features

We are happy! Expensive ceramics are not affordable for everyone. Now to do the styling without unnecessary scrap – and the trick is in the bag. And with this, just no problems arise, because burnt clay is thin and medium in hardness.

It is enough to soak the ceramics for an hour or two, it is cut evenly. Adheres to surfaces like a native. Not a job, but a song. Especially when the arms are growing out of the right place and there is something to hedge.