When adjusting the carburetor of the household trimmer is required?

Adjust the built-in trimmer carburetor when:

- Running in a new engine, during which 4 to 5 liters of fuel mixture were used;

- Sudden changes in weather;

- Changes in air pressure. for example, when the lawn mower is often used in mountainous areas;

- Long-term simple trimmer;

- The loads on the power unit of lawn mowers are growing rapidly;

- Arbitrary unscrewing of the built-in adjusting screws of the carburetor. this becomes a prerequisite for increased vibration of the internal combustion engine;

- Changes in the quality of the components of the fuel mixture;

- Pouring fuel with a carburetor, resulting in an increase in fuel consumption;

- The regular appearance of a thick layer of resinous deposits and carbon deposits on the surface of the electrodes of a standard trimmer spark plug;

- Starting the engine and turning it off arbitrarily or slowly accelerating;

- Lack of fuel flow into the cylinder of the power unit;

- Increase in the volume of emitted waste gases.

The lack of timely adjustment of the carburetor threatens serious damage to the trimmer, up to the complete failure of its factory engine.

Carburetor for trimmer: device, do it yourself setting

Stable and efficient operation of a household trimmer largely depends on the quality of the fuel used by the operator. The filled fuel mixture must be enriched with air. therefore, the built-in carburetor is responsible for this in the basic device of the lawn mower. This knot is one of the main elements of the streamer, so the operator must constantly monitor its serviceability and settings. Otherwise, the trimmer will lose its performance and may completely fail.

Lawn mowers carburetor device

The standard design of any gasoline trimmer necessarily includes a fuel system, the basis of which is the action of a standard carburetor. Its structure and initial principle of operation are almost the same for all lawn mowers, regardless of their design features and purpose.

The lawn mowers carburetor consists of an all-metal aluminum case, which protects the internal components of the unit from moisture, small debris and dust. In the lower part of the body there is a built-in diffuser, the second name of which is “Venturi nozzle”. The main function of this standard part is to supply air in the amount required by the fuel unit to enrich the fuel. A diffuser works according to a simple principle: the smaller its diameter becomes, the more intensively the air is sucked in. This is due to the fact that in the area of the smallest diameter, the level of air vacuum becomes maximum.

The upper part of the built-in factory diffuser is pre-equipped with fuel pipes through which, under the influence of air, the fuel mixture is drawn in. The rest of the carburetor parts: standard adjusting screws and a fuel pump, can be located both inside and outside the carburetor.

The lawn mowers carburetor device includes a throttle valve, the main task of which is to regulate the volume of intake air. The larger the amount of air, the higher the rated power of the trimmer power unit. Another function of the damper is to facilitate cold starting of the engine. If this is the first time the mower is started after a long period of inactivity, the shutter must be closed. Immediately after starting the engine, the part must be opened, otherwise the internal combustion engine will stall.

The carburetor for the trimmer is equipped with an impulse channel, which connects the internal cavity of the engine crankcase with the impulse chamber of the pump. The piston located in the engine cylinder creates reciprocating movements, which leads to gradual changes in pressure inside the crankcase. At the same time, the membrane is set in motion. Thus, the action of the pump is fully synchronized with the operation of the power unit.

The diaphragm of the standard carburetor takes an active part in the suction of fuel. It enters the fuel unit through the fitting. The fuel then flows through the built-in intake and exhaust valves, then through the strainer and fuel pipe. The fuel then flows next to the needle and gradually fills the chamber equipped with the control diaphragm.

The standard carburetor trim valve is connected to the diaphragm using a lever. Below the built-in membrane is a cavity into which air is sucked in through a special opening.

The lawn mower carburetor works on this principle in stages. This ensures continuous operation of the fuel unit and uninterrupted fuel supply to the cylinder of the standard power unit.

DIY lawn mowers carburetor adjustment

Periodic adjustment of the trimmer carburetor should be performed on a fully serviced power unit. Before starting the procedure, the operator must thoroughly rinse the internal combustion engine parts and inspect its CPG for burrs or other defects. In addition, you will need to clean or change the spark plug, as well as rinse the filter elements in the lawn mower design.

The lawn mower engine must be running under a certain load when adjusting the carburetor. It is best to install a cord of the appropriate diameter or cutting knives on the trimmer.

After installing the cutting elements, the operator should start the internal combustion engine of the trimmer and leave it to work for about 10 minutes. If, during the operation of the power unit at idle, it was noticed that the cord or knife rotated, then it is necessary to lower the speed created by the motor. To do this, it is necessary to return the lower adjuster, often denoted with the letter “T”, to the left side, at a complete stop of the installed cutter.

Further configuration of the fuel assembly is as follows:

- The “L” regulator, located in the case, is responsible for enriching the fuel mixture with air when the engine is running at low revs. The position of this screw must be adjusted first. To do this, the operator will need to achieve maximum engine speed when idling. to do this, turn the screw “L” alternately to the right or left side. As soon as the maximum speed is reached, the screw will need to be returned 1/2 turn to the left;

- The screw “T” or “LA” is necessary to adjust the idle speed. When turning it to the left, the engine speed will decrease, and when turning to the right, it will increase accordingly;

- The “H” regulator, provided on the left, is responsible for enriching the fuel mixture with air when the internal combustion engine trimmer is operating at high rpm. This screw is also needed to adjust the engine power and the amount of fuel consumed. Adjustment of its position is carried out by turning the screw to the right or left side to achieve the maximum permissible engine speed. After that, the screw “H” will need to be returned 1/2 turn to the left.

The alternate execution of THESE actions will allow you to correctly configure the fuel trimmer unit, without the risk of exceeding the permissible load on its main working mechanisms.

The trimmer is NOT gaining momentum. what to do

Any person who owns a summer cottage or land plot is well aware of the problems of dealing with excess vegetation. Now a trimmer has come to the rescue, which has successfully replaced the usual braid in this field. This unit is very convenient in operation, but it, like any mechanism, tends to fail due to difficult working conditions or Incorrect operation. Situations where the trimmer does NOT pick up speed are quite common. To understand this problem, it is necessary to understand some aspects related to the operation of the apparatus.

Technical issues

Technical problems with lawn mowers mainly occur in the fuel supply and ignition systems. You can deal with them yourself.

- When the hand mower won’t start or stalls, the problem could be with the spark plug. Dark carbon deposits indicate poor carburetor adjustment and poor gasoline quality.

- A clogged fuel hose may be the cause of improper trimmer operation. Filters are also often clogged.

- Another internal problem. the muffler is covered with carbon deposits. From this, the trimmer speed drops sharply. Exit. you need to clean the muffler.

Motor

The engine is the most important part of any machine. There are several reasons for ICE breakdowns:

- Incorrect proportions of oil with fuel (for two-stroke)

- Old fuel mixture;

- Wear and destruction of the piston ring;

- Traces of scratches on the cylinder and piston;

- Operation of the device for wear.

All this leads to the fact that the engine either does not start, or stalls.

Fuel system

For trouble-free operation of the trimmer, the functioning of the fuel system is of great importance. Gasoline passes through all its assemblies and parts, so they must be cleaned regularly. In addition, only high quality fuel must be used. To prepare a combustible mixture in a two-stroke engine, motor vehicle oil cannot be used, since it has insufficient properties.

Filters

A clogged air filter is another reason for the unreliable operation of the device. To check the involvement of this element in the malfunction, you need to start the lawn mower without it. A dirty filter can be washed in gasoline, dried or replaced with a new one.

A clogged fuel filter DOES NOT let fuel into the cylinder, and the engine stalls at full throttle due to an elementary shortage of gasoline. This element is located inside the tank on the intake hoses. To eliminate the problem, instead of the old filter, put a new one on the hose or thoroughly rinse the one that was removed.

Candle

In case of problems with the candle, sometimes it is enough to dry it or clean it with sandpaper and put it back in place, setting the gap correctly. it should be 1 mm. If the spark plug is heavily soaked, it is better to replace it with a new one. With optimal trimmer operation, the candles do not fail so often.

Carburetor

This mechanism is an important trimmer unit. In order for the carburetor to work properly, several conditions must be met:

- Disassemble and clean it at times;

- Adjust the idle speed according to the instructions;

- Contact the wizard when adjusting.

In the event of a breakdown of this unit, you can do its repair yourself, but only if you have certain knowledge.

One of the reasons for poor carburetor performance is a loose cable. To eliminate the problem, you first need to disassemble the entire assembly, and then thoroughly rinse all the parts, lubricate and tighten the cable, but not very much, so as not to stretch.

Features of the trimmer

All trimmers are classified by type of power: gasoline or electricity (mains or battery). It should be noted that gasoline mowers are superior in many respects to their electric and battery counterparts. While they all perform similar functions, the differences in performance, agility and efficiency are very noticeable. However, the general principle of operation of all types of hand-held mowers Almost does not differ. the devices are equipped with motors (two- or four-stroke internal combustion engines or an electric motor) that set the cutting unit in motion (a reel with a line or a metal disc). All elements are attached to a straight or curved bar, including a trimmer handle, on which the main buttons are located.

Since the problem of low revs is more common with petrol trim options, they will receive more attention. So, the lawn mower is very comfortable to work and unpretentious in maintenance. At the same time, most of its malfunctions are caused by the user’s ignorance of elementary things, which are written in the instructions. Therefore, before starting to operate the unit, you must carefully study the manufacturer’s manual. In particular, in order to start the engine, the following steps must be taken:

- Turn on the ignition button;

- Press the silicone button several times to pump gasoline;

- Close the air damper;

- Set the throttle lever to the high speed position;

- First make a slight jerk with the starter handle to feel the resistance of the engine, then sharply sod.

If the lawn mower starts up but stalls, set the choke to the middle position and try again. When the engine starts, you need to reduce the gas and open the air damper, since the trimmer functions only on suction.

External factors

Several factors, not related to its breakdown, affect the decrease in the speed of lawn mowers:

- Contamination of the filter due to the ingress of particles of dirt and dust;

- Use of low-quality fuel;

- Improperly prepared mixture (relevant for trimmers with two-stroke gasoline engines)

- Contamination of the muffler mesh with vegetation particles, soil elements and other objects.

over, in the second and third cases, carbon deposits form in the combustion chamber, and the carburetor elements become clogged.

Step 21

Put on the pump cover.

Problem 3: membrane failure

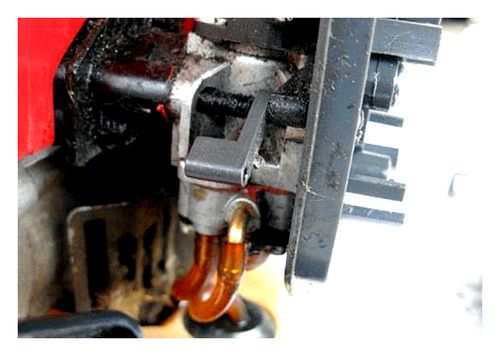

Problem 1: Clogged holes, channels and nozzles with dirt

The first thing that happens is that the holes and nozzles in the fuel supply system are clogged with dirt. Filters installed in the tank and directly in the carburetor do NOT help. They still allow small particles to pass through, which become a prerequisite for lawn mowers failure.

The principle of operation of the carburetor lawn mowers

The throttle valve determines the amount of air to be supplied, and the engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it goes through the fitting into the carburetor. The fluid then flows through the pump inlet and outlet valves. Filtered by the grid. The needle valve moves into the diaphragm chamber.

Phased operation of the device:

- Air supply to a tube with an air baffle (damper). The baffle regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a constriction. A float chamber adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with a constriction it is already low. Due to the pressure drop, the fuel penetrates through the jet.

- The acceleration of the air flow facilitates the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air / fuel mixture enters the engine cylinder through the fuel pipe.

Here the area of the open air damper depends on the level of air density in the system. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor for lawn mowers is the creation of an optimal fuel mixture due to the correct supply of air.

DIY lawn mowers carburetor adjustment

Regardless of the garden tool model, adjusting the carburetor trimmer requires careful preparation. The lawn mower owner will need to check the spark plug, air filter, and carburetor itself. In case of contamination, all elements must be cleaned, or, if necessary, replaced.

The trimmer comes standard with 3 adjusting bolts. The first of them is marked with the letter L, and is used to tune the engine when it is running at low speeds. The second bolt is marked with the letter H, and is necessary to adjust the internal combustion engine when it is operating at the highest possible speed. The third bolt can be labeled T or LA to allow the operator to set the engine to idle.

The process for setting up a lawn mower carburetor is as follows:

- First, you need to carry out a series of actions with the adjusting bolt L. To do this, it should be returned clockwise until it stops. The bolt L will then need to be returned half a turn in the opposite direction. This will make it possible to adjust the optimal enrichment of the fuel mixture with oxygen when the engine is running at low speeds;

- Then you will need to adjust the operation of the internal combustion engine in idle mode. To do this, turn the bolt T alternately in different directions until the mowing head or knife stops turning;

- At the end, you will need to adjust the level of fuel enrichment with oxygen when the engine is running at maximum speed. To do this, bolt H will need to be returned clockwise until it stops, and then return it 1/2 turn in the opposite direction.

Finally, the operator should stop the trimmer motor and start it again. If the unit has been configured correctly, the lawn mower engine will confidently pick up speed when the gas trigger is pulled, and quickly reset when the trigger is released.

Step 8

Now we need to get the needle.

To do this, unscrew the bolt on the mechanism, holding it with your finger. The fact is, there is a spring and a careless action will lead to the fact that it is lost.

We take out the needle, see photo and spring.

Step 15

Install a spring and a needle valve in the carburetor cover. Holding the spring with your finger will tighten the mounting bolt.

Step 6

There is another gasket under the membrane. We also carefully remove it, in no case damaging it.

The principle of operation of the carburetor petrol trimmer

Fuel supply adjustment at minimum speed

Before starting carburetor trimming Trimmer, it is required to warm up the engine to operating temperature.

Fuel adjusting screws

To do this, we start the internal combustion engine and let it run for 10-15 minutes at idle. At the first stage, when the trimmer is working, slowly tighten the screw “L” until the beginning of intermittent operation or until it stalls. Next, we unscrew the screw орота of a turn and check the speed of a set of maximum revolutions. If the lawn mower reaches high revs easily and quickly, this will be the most economical mode. In most of the models on the market, the fuel screw “L” is turned clockwise, but there are trim tabs where the decrease and increase in the supply of the mixture occurs in the opposite order.

Adjusting the idle trimmer

Location of carburetor adjustment screws

The screw “T” (“AT”) serves as a limiter for the reciprocating movement of the fuel flap and when it is tightened, the engine speed increases, and loosening leads to a decrease in the crankshaft speed. Professionals advise adjusting the idle screw of lawn mowers so that the internal combustion engine works a little accelerated at minimum speed, but the head with a fishing line or knife remains motionless. If after the performed manipulations it is difficult to start the trimmer “cold”, then just tighten the “T” screw a quarter of a turn and try to start the engine again.

Carburetor Trimmer Adjustment

The initial step in restoring the correct operation of the fuel system is to clean the air filter.

Trimmer carburetor with screws

Experts recommend rinsing it in a solution of water with detergents after every 10-15 hours. Direct adjustment of the carburetor trimmer is done with three adjusting screws:

- Fuel adjusting screw (“L”)

- High speed adjustment screw (“H”);

- Propeller responsible for engine idling (“T” or “AT”).

Carburetor Adjustment Lawn Mowers Highlights

Despite the high productivity, mobility and simplicity in work, modern lawn mowers can hardly be attributed to complex devices. Over time, any mechanism is subject to wear and tear, and then parts and assemblies require special attention from the owner. One of these trimmer elements is the carburetor, designed to form the fuel mixture and feed it into the combustion chamber. Increased consumption with proper observance of the proportions of gasoline and oil or a drop in engine power indicate the need to adjust the carburetor of the gasoline trimmer.

Adjusting the maximum speed screw for lawn mowers

After restoring the fuel supply at minimum speed and adjusting the idle speed, it is necessary to check the stability of the mechanism at an increased speed.

Tuning at maximum speed

The engine is adjusted at high rpm to protect against overheating and to reduce hand fatigue when pressing the throttle button. If the internal combustion engine is unstable at maximum speed, then the screw “H” must be tightened slowly to ensure smooth and precise operation.

During operation of the lawn mowers it may be necessary to adjust the fuel screw (“L”) for the optimal set of revolutions.

Carburetor Trimmer Repair Tips

- Regardless of the manufacturer, there is a factory defect in the carburetor parts of the lawn mowers.

Adjusting screw spring

For example, the tuning method described above may not give positive results with an excessively large number of turns in the springs of the screw for supplying the mixture and, as a result, the impossibility of optimally reducing the level of supplied gasoline. To eliminate this, you can shorten the spring yourself a little or, in accordance with the operating manual, purchase a new one.

Many lawn mower owners follow the fuel mixture recommendations listed there when buying oil.

Petrol trimmer oil

So, often the information on mixing gasoline with oil indicated on the bank differs from that indicated in the trimmer passport. As a result, black carbon deposits can quickly form on the spark plug, which leads to a drop in power and an increase in fuel consumption. Then, when preparing the working mixture, you should follow the recommendations specified in the operation manual. In most cases, the proportion for a run-in ICE is 1:25. It should be noted that many tool owners prefer to prepare fuel “by eye”, which will certainly lead to rapid wear of the piston streamer in the event of a decrease in the portion of oil and the formation of carbon deposits on the spark plug with an increased amount of lubricant.