How much oil is required for a tiller motor?

Before pouring new oil into the tiller yourself. The owner of agricultural machinery must find out how much fluid is already in the internal combustion engine. It is quite possible that at the moment a complete replacement of the existing lubricant is NOT required, and instead of it you can simply top up the missing amount of technical fluid.

To check the content level in the oil tank yourself, you must:

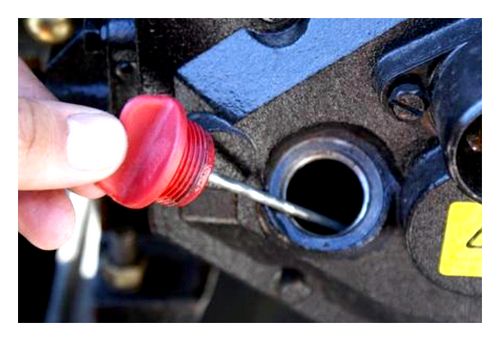

- Unscrew the plug of the standard filler hole provided in the crankcase of the utility tiller;

- Insert the oil dipstick into the factory engine crankcase through the hole provided by the manufacturer, pull it out and check the level of the oil contained;

- There are special marks on the built-in dipstick, as a rule, these are marked “MIN” and “MAX”. After removing the dipstick, you need to look at what mark the oil stain is. It should be located in the middle between these marks. If the fluid level is below the “MIN” mark, then you will need to add grease;

- If there are factory marks on the stylus being used, then the operator will have to navigate the length of the fixture. After measuring the volume of the liquid, its volume should reach the middle of the probe;

- In some cases, the operator may NOT have a probe. In this case, the amount of grease can be checked visually. To do this, you need to look through the filler neck. if the liquid level reaches almost the neck, then the owner does not need to add engine oil for the tiller.

After self-checking the level of the existing lubricant, you need to close the standard filler cap as tightly as possible and make sure that the liquid does NOT leak out.

Is it possible to pour automotive engine oil into the tiller?

The difference between internal combustion engines for used in the household tillers and modern cars is:

- The specifics of the factory design;

- Forcing level;

- The material from which the motor components are made.

The use of automotive factory engine oil for continuous lubrication of parts of the tiller’s internal combustion engine gradually leads to an accelerated daily wear of the standard chrome-plated cylinders of the latter, its piston group, as well as to mechanical damage to the carburetor, factory filter elements and rubber fuel pipes.

Changing the oil in the tiller engine

It is necessary to change the oil in the tiller strictly observing the frequency specified by its manufacturer. Some brands advise doing this every 30-40 hours of work with equipment, others. at least once every 100 hours of work. Following these recommendations, users will be able to protect the motor from the effects of increased loads and significantly extend its working life.

The procedure for changing the lubricant in a cold engine of a utility tiller looks the same as for imported Subaru internal combustion engines. And for branded power units of famous Russian brands Zubr. Centaur. Neva in the modification MB-1 and MB-2. As well as other popular manufacturers. To change the oil in the tiller engine with your own hands. It is necessary:

- Place a deep, wide container under the lower surface of the engine crankcase, immediately under the standard drain plug;

- Carefully pry off the plastic plug of the standard drain hole, remove it and wait for all the used engine oil to drain out;

- Pour about 2 liters of new factory engine lubricant into the empty crankcase and tighten the factory filler plug tightly.

To make it easier for the user to replace the old grease with a new one, it is better to use LEIKOME, which will NOT allow oil to be spilled on the housing of the agricultural unit.

Diesel Tiller Oil

Engines in which diesel is refueled. Differ from gasoline power units. Accordingly, to maintain their smooth operation, you need to choose a completely different type of lubricant.

The main factor in buying lubricant for a factory diesel engine is its viscosity, marked with the SAE designation followed by a set of letters and numbers.

The latter will tell the buyer exactly in what conditions it is best to use the selected lubricant:

- SAE 0W, SAE 5W or SAE 20W. designed for operation in regions with severe and prolonged winters;

- SAE 20, as well as SAE 40, SAE 60. marking without letters means that it is a high-viscosity fluid that has proven itself perfectly in hot summer weather;

- SAE 5W-30, SAE 10W-40. multigrade oils that work effectively both in winter and hot summer.

The classification provided by the American Petroleum Institute divides motor oils for domestic and professional hillers according to their operating groups. Accordingly, the following types of lubricants are found on the market:

- API CJ-4. used in proprietary high-end very powerful motors, which are specially designed for operation under high loads. Experienced gardeners recommend using factory oils of this type for the daily lubrication of engines manufactured by the brands Briggs Stratton and Honda;

- API CC. used for power units without built-in superchargers and with turbocharging. These oils provide continuous protection against corrosion, gum formation and increased wear on inline engine parts.

When choosing oils of THESE types, you need to pay special attention to their manufacturers. It is best for users to trust well-known companies, which include the brands Elf, Liqui Moly, Motul, Shell and others.

Do I need to add oil to gasoline for a tiller?

The answer to this common question can be given based on the type of factory engine of the existing tiller. Agricultural units are equipped with 2 or 4-stroke power units. Gasoline for a tiller with a factory 2-stroke engine must be diluted with engine oil, always adhering to the proportion indicated by the manufacturer.

It is important to remember that 2 and 4-stroke internal combustion engines operate on different principles. The combustion of fuel in engines of the first type occurs continuously in 2 strokes. At the same time, branded oil, with which the fuel mixture is prepared. Contains not only lubricating components, but also additives that improve the quality of fuel. In 4-stroke factory engines, oil and refueling fuel for the tiller are always poured separately, into the tanks specially designed by the manufacturer for this.

Oil in tiller

Stable operation of the tiller’s moving mechanisms is ensured by introducing a lubricant produced in the form of oils with different densities, properties and additives. Oils are consumables that must be replaced at intervals clearly established by the manufacturer. The protection of the tiller parts from heating, corrosion and increased wear directly depends on lubricants, therefore, the choice of technical fluids must be treated with special responsibility.

How to choose a tiller oil?

The tiller’s factory manual for regular use can provide accurate information on the proper brand lubricant for the built-in motor of the tiller. As a rule, the manufacturer indicates the type of liquid, its base and manufacturer’s brand. The proprietary manual also contains instructions from the manufacturer of the equipment, suggesting how much grease to pour into the factory engine and how to do it correctly.

However, not everyone has a proprietary manual of the used tiller. In this case, the operator needs to remember that, depending on the original purpose, there are 2-stroke and 4-stroke factory oil on sale. Most often, household tillers are equipped with factory 4-stroke motors, however, immediately before purchasing lubricant, it is still better for the user to first study the markings embossed on the engine wall.

Another important factor when choosing a technical fluid is its density. The oil should envelop the moving parts of the tiller’s internal combustion engine and for this it should be uniformly colored and sufficiently viscous. At the same time, you should not choose too thick liquid, otherwise it will not be able to seep into the smallest grooves of the factory engine.

Tiller gear oil. self-change

The standard gearbox of any tiller needs lubrication no less than its factory engine. The gearbox is initially a complex structure consisting of several gears responsible for transmitting power from the engine to the working bodies of agricultural machinery. During the operation of the gearbox, the gears are constantly in contact with each other, which leads to the gradual erasure of their teeth. To slow down this process, you need to use a quality lubricant.

You can check the level of lubricant contained in the gearbox at a certain point in time as follows:

- Clean a 70 cm piece of wire that will act as a probe;

- Bend the homemade probe into an arc;

- Push the wire through the filler hole in the gearbox to the end and pull it out.

If the oil stain is 30 cm from the bottom edge of the dipstick, then you do not need to add oil. Otherwise, the operator must add the missing amount of liquid.

It is necessary to change the lubricant in the cold tiller gearbox only if it was found that it was painted in a dark, almost black color. Another indicator of the need for an urgent replacement is that a large number of foreigners and solid fractions are impregnated in the lubrication.

How to choose a tiller transmission oil?

When choosing a lubricant, consider the following factors:

- Lubricity is the main parameter of any, including branded gear oil for the used tiller. It is necessary to protect the rubbing parts of the gearbox. gears and bearings from burrs, grooves and staining. As the viscosity of the oil increases, its ability to lubricate increases. Another way to improve this parameter is to add various additives to the fluid. The viscosity of the lubricant used directly affects its ability to cover the gearbox parts with a strong oily film. At the same time, the viscous liquid quickly thickens at low temperatures, losing its ability to protect the elements of the mechanism;

- Resistance to thermal oxidation. this property of the oil is responsible for its stable operation at very high temperatures. To do this, manufacturers add special antioxidant additives to the composition of the liquid;

- Corrosion Protection. Many branded tiller lubricants contain corrosive inhibitors. Their main function is to prevent the appearance of foci of rust on the moving parts of the gearbox;

- Resistance to the formation of foam. for this purpose, antifoam agents are added to the oils, which prevent the foaming of liquids during their operation.

In any weather and operating conditions, ZIC 10W-40 and Gazpromneft Super T-3 85W-90 fluids have proven themselves well. These oils are distinguished by a wide range of operating temperatures, as well as high viscosity levels and m of useful additives.

What kind of oil to pour into the tiller engine

In order for the tiller to work flawlessly for a long time, it must be properly maintained and operated. Oil. It is a key factor in keeping the engine running. What kind of oil to pour into the tiller’s engine let’s try to figure it out on this page of the site.

The most correct recommendation for the selection of oil will be the engine manufacturer’s recommendation for the tiller. Therefore, we will familiarize ourselves with the operating instructions of the main engine manufacturers for the tillers and give excerpts from the instructions.

The choice of engine oil, like any other type of oil, depends on two main parameters. the operating category and the viscosity class.

CLASSIFICATION OF VARIETY OIL

API classification by service category (American Petroleum Institute). For more details see here

CLASSIFICATION of graded OIL by viscosity

SAE (Society of Automotive and Transportation Engineers) classification. See more here

Winter. with the letter W (Winter). Oils meeting these categories are low-viscosity and are used in winter. SAE 0W, 5W, 10W, 15W, 20W, 25W

Summer. no letter designation. Oils meeting these categories are highly viscous and are used in summer. SAE 20, 30, 40, 50, 60.

All-season. At the moment The most widespread are universal oils, which are used both in winter and summer.

Such oils are designated by a combination of winter and summer series: 5W-30, 10W-40

Use oil with a lower SAE number (less viscous) in winter and in summer. Oil with a higher value (more viscous).

Multi-viscosity grade oil is comprehensively stable under seasonal and temperature changes. For example, SAE 10W-30 oil is suitable for multigrade use. At low temperatures, it is equivalent in viscosity to SAE 10W oil, and during operation it has the same lubricating properties as SAE 30.

Manufacturer’s Recommended Tiller Engine Oil.

| Tiller engine make | Manufacturer’s Recommended Engine Oil | ||

| summer | winter | operational class | |

| Robin Subaru (Subaru) | SAE 10W-30. in temperate climates | SAE 5W-30. in cold regions | Automotive engine oil; class SE or higher (SG, SH or SJ recommended) |

| Honda (honda) | SAE 10W-30 is recommended for use at all temperatures. If you wish to use a seasonal oil, select an oil with a suitable viscosity index Based on the average temperature in your area |

SG, SF. | |

| Lifan (Lifan) | SAE-30 | SAE-10W-30. All-season | |

| Briggs Stratton (Briggs) | Briggs Stratton recommends the use of synthetic oil when operating at temperatures below 0 ° C. If you have synthetic oil, you can use Briggs Stratton 10W-30 non-synthetic oil part number 998208 Note: Synthetic oil that meets the ILSAC GF-2 certification mark, API and API service symbol labeled “SJ / CF ENERGY CONSERVING” and above can be used at all temperatures. Change of synthetic oil is carried out according to the Usually schedule. Air-cooled engines heat up faster than car engines. Using a non-synthetic thickened oil (5W-30, 10W-30, etc.) at temperatures above 4 ° C will result in high oil consumption. If using such oil, check the oil level more often. |

SF, SG, SH, SJ or above | |

| DM-1-01 (JSC Kaluga engine) |

M63/ 12G1 or M53/ 10G1 GOST 10541-78, oil that meets API requirements: SF; SG; SH and SAE: 10W30; 15W30 | ||

| DM-1K Instruction from OJSC “Red October” |

M10GY, M12GY TU 38.10148-85 M63/ 12G1 or M53/ 10G1 GOST 10541-78, |

||

| Cascade MB-6 | Motor oil M-5s / 10G1, M-6s / 12G1 GOST 10541-78 (It is allowed to use engine oils for carburetor engines according to SAE classification in accordance with the recommendations for use at various ambient temperatures. Mixing of mineral and synthetic oils is not allowed.) | ||

Engines of THESE brands are installed on almost all currently produced tillers such as Neva, MTZ, Salyut, Kaskad, OKA, Ugra, Celina, Tarpan, Agat, Favorit, MKM and many others.

Motors of such well-known companies are tested and tested on the specified oils, therefore, the result of operation in accordance with the recommendations of the manufacturers will be the best. The use of engine oil of the specified grade and viscosity will significantly extend the life of the engine and improve its performance. Using too little or too much oil can cause serious problems including engine seizure.

Manufacturers recommend NOT to use oil with additives for 2-stroke engines as well, as it does not contain enough lubricant, which will reduce engine life.

Use only SE, SF, SG engine oils for general gasoline engines.

Categories of motor oils for gasoline engines

| SA | For low stress applications where no additives are required |

| SB | For use in the medium stress range. It features low oxidation properties, stable lubricating properties, protects motors from wear and prevents corrosion of bearings. |

| SC | For use in gasoline engines manufactured in the period 1964-1967. And NOT equipped with a PCV system. Minimizes deposit formation over a wide temperature range as well as engine wear and corrosion. |

| SD | For use in gasoline engines manufactured between 1968-1971 equipped with a PCV system. Better than SC category Reduces deposit formation over a wide temperature range, engine wear and corrosion. |

| SE | For use in gasoline engines manufactured after 1972 Compared to SD category, better resists deposit formation over a wide temperature range, Reduces engine wear and corrosion. |

| SF | For use in gasoline engines manufactured after 1980. Compared to SE category, it better resists the formation of deposits over a wide temperature range, Reduces engine wear and corrosion. |

| SG | It appeared in 1988. Its characteristics are comparable to the oil of the SF category and differs in additional quality improvements. |

| SH | Highest category of motor oils, Introduced since 1992. |

Categories of engine oils for diesel engines

| CA | For low to medium stress applications in engines powered by low sulfur diesel fuels. Reduces bearing corrosion and deposit formation at high temperatures, but not suitable for high stress conditions. |

| CB | For low to medium mechanical stress applications in engines fueled with high sulfur diesel fuel. Compared to CA category additionally Reduces corrosion of bearings and other engine parts. |

| CC | For applications with medium to high mechanical stress in uncharged and turbocharged engines. It is sometimes used in gasoline engines operating under extremely high loads. Reduces the formation of deposits at high temperatures (and in gasoline engines. And at low temperatures) and corrosion of bearings and other engine parts. |

| CD | For use in high-speed, supercharged and turbocharged engines. Reduces high temperature deposits and corrosion of bearings and other engine parts. |

We provide information on the oils used from the website of the manufacturer of tillers and cultivators of the Patriot (Patriot) brand

Patriot engine oil for 4-stroke engines (information from the official website)

Special high quality engine oil for use in modern four-stroke gasoline and diesel engines with air and water cooling installed on lawn mowers, cultivators, generators, tillers, mini tractors and other equipment.

Enhanced additives reliably protect the engine under extremely severe operating conditions, providing excellent antiwear, anti-corrosion properties and extending the oil life before oil change.

Specially formulated to provide oil film stability.

1.Prevention of the formation of carbon deposits, varnish deposits and sludge;

Cooling of pistons, crankshaft bearings and other engine parts;

The most effective protection of the engine against wear during cold start;

Reduction of noise during engine operation;

Extension of engine life;

Flawless engine cleanliness.

WE RECOMMEND TO CHANGE THE ENGINE OIL AFTER THE FIRST 5 HOURS OF OPERATION. Change the engine oil ONCE PER SEASON OR AFTER 25 OR 50 operating hours are reached, DEPENDING ON THE TILERRY’S WORKING CONDITIONS.

| Oil 4-stroke semi-synthetic Expert. Special all-season semi-synthetic engine oil for use in modern four-stroke gasoline and diesel engines. The use of the latest additives packages allows you to reliably protect the engine under extremely severe operating conditions. The oil has excellent antiwear, anti-corrosion and energy-saving properties. |

4-stroke semi-synthetic oil Specific. A special all-season semi-synthetic engine oil for use in modern four-stroke gasoline and diesel engines. The use of the latest additives packages allows you to reliably protect the engine under extremely severe operating conditions. The oil has excellent antiwear, anti-corrosion and energy-saving properties. |

Supreme 4-stroke mineral oil. Special high quality performance engine oil for use in modern four-stroke gasoline and diesel engines with air and water cooling. Enhanced additives reliably protect the engine under extremely severe operating conditions, providing excellent antiwear, anti-corrosion properties and extending the oil resource before changing it. |

Tiller engine oil change intervals

| Briggs Stratton (Briggs) | First 5 hours – change oil. Every 8 hours or daily – Check oil level. Every 50 hours or every season – change oil. |

| Honda (honda) Lifan (Lifan) |

Checking the oil level. With every use. Oil change. The first month or after 20 hours of work, thereafter. Every 6 months or after 100 hours of operation |

| Robin Subaru (Subaru) | Checking the level and adding engine oil. Every time the engine is used (add oil to the maximum mark). Engine oil change: First change after 20 hours of operation; then. Every 100 hours of operation |

A few more recommendations from shhodo manufacturers, the use of oil in tiller and cultivator engines:

- Check the oil level, set the engine on a horizontal surface, wait for it to drain into the crankcase.

- When changing the oil Drain it on a hot engine by unscrewing the drain and filling caps

- DO NOT use additives or additives in the oil

- Dispose of used oil in a way that does NOT harm the environment, do not Drain it on the ground, do not throw it in the trash can, the best option is to take the oil in a closed container to your local recycling center.

Please note that there are engines that have a built-in additional gearbox, which also requires periodic oil changes. Here is an excerpt from a Honda engine user manual:

What are the tiller gearboxes. varieties and purpose

The tiller design is quite diverse. Modern units are equipped with the following types of gearboxes:

- Angular gearbox for tiller. It is the connecting piece between the engine and transmission. Such a mechanism is distinguished by good characteristics and availability, therefore it is actively used by farmers of small and large lands. The corner model can be modified, making it much more productive;

- Reduction gear for tiller. With the help of this type, the engine load increases and its speed decreases. These gearboxes are among the most reliable and multi-tasking ones, since they consist of durable steel parts and a high-quality cooling system. This technique is highly efficient regardless of workload;

- Reverse gear. This type of reverse rotation is the presence of reverse. The mechanism is installed between the bevel gears, namely on the main shaft. But the gearbox cannot boast of high performance, it has a low speed;

- Gear reducer. This mechanism is installed on heavy tiller models. With its help, torque is transmitted to the wheels of equipment. The gearbox is highly reliable and has a simple design. But maintaining such a mechanism is extremely difficult;

- Worm. This is a gearbox with a special screw, there is also a gear worm wheel. All used spare parts are high-strength, the technique is efficient and durable. A gearbox of this type is very relevant due to the presence of the angular speed by reducing the type and the torque of the highest type. Even a homemade gearbox will allow the machinery to work with little noise and a smooth ride. Before implementation, it is worth paying attention to gear ratios.

Each type of gearbox with its own Distinctive characteristics. You should pay attention to them during the selection and installation of the mechanism.

What kind of oil to fill in the tiller gearbox?

How well and durable the tiller gearbox will serve depends directly on the quality and characteristics of the oil.

When purchasing a lubricant, it is worth considering the advice of the tiller manufacturers. It is also worth paying attention to the price of oil. Cheap tools DO NOT guarantee good gearbox performance.

It is worth noting the following types of oils according to Labeling on the market:

- SAE. An excellent composition for work with frequent temperature changes. A number is indicated before the letter W. this is an indicator of the minimum temperature at which the lubricant is poured;

- ASEA. The most popular universal products. These figures depend on the conditions in which the equipment can work;

- API. Are in the Highest Demand. They serve as a good lubricant, regardless of the type of gearbox and the conditions of use of equipment.

Before using the oil, it is definitely worth Reading the instructions of the tiller manufacturers.

| Mark Tiller | Tiller gear oil type |

| Neva MB-2 | Transmission oil TEP-15 (-5 ° C to 35 ° C) GOST 23652-79, TM-5 (-5 ° C to 25 ° C) GOST 17479.2-85 according to the international viscosity classification system of engine oils SAE90 API GI- 2 and SAE90 API GI-5, respectively. Filling volume 2.2 liters |

| Neva MB-1 | Transmission oil in accordance with GOST 23652-79 (TAD-17I, TAP-15V, etc.). |

| MKM-3 Mobile-K (lander) | TAD. 1711 GOST 23652-79. Can be filled with SAE 90, SAE 75W / 90 according to API GL-4, GL-5 classification. Refueling 1 liter |

| Salyut-5 fireworks 100 |

TM 5-18 (TAD17Y) |

| Belarus 08N-09N | In summer (above 5 ° C) Motor oils M-10V2 or M-10G2 GOST 8581 (duplicate. Motor oil M-bz / 10V GOST 10541) In winter (below 5 ° C) Motor oil M-8G2, GOST 8581 (can be replaced with M-4 s / 6v1 GOST 10541) |

| MTZ.05 | M-8B1, M-8V1, M-8G1, according to GOST 10541-78 |

| cascade MB6 cascade MB6-62 |

Transmission oil according to GOST 23652-79 Transmission oil GOST 23652-79 or aircraft type MS-20 GOST 23652-79 |

| Ugra NMB-1 | ТСn-10 GOST 23652-79 or other type, which corresponds to SAE 80. 85W API: GL3. GL4 |

| Eyes MB-1D1 (2) M | Transmission oil TAD-17I, TAP-15V and others in accordance with GOST 23652-79 |

| Celina MB | From the factory in tillery gear oil “RAVENOL” EXP SAE 80W-90 API GL-5 Can be filled with SAE 90 GL-5 gear oils |

| Tarpan | Transmission oil TAD-17I or analogues of the SAE 90 SAE 75W / 90 type API GL-4, GL-5. |

| Favorite MB. 3, MB. 4, MB. 5 | TAD-17i or MS-20 |

| agate | TAD-17I; MS-20 |

| motor Sich | Lubricating oil TAD17Y, Tap-15V, TEP-15, TSP-15K, TSL-14 in accordance with GOST 23652 |

| Vario | oil 80W90 |

| Patriot garden | oil 85W90 |

| Zubr | TAP 15 oil |

How to choose a tiller oil

The type of fluid used depends on the viscosity grade and service category. These are winter, summer and all-season oils. The degree of density depends on temperature conditions, equipment operation mode, and its design features. The most common are synthetic and semi-synthetic petroleum products, which are excellent for efficient operation of internal combustion engines in tillers.

The service category determines the quality of the lubricant. To simplify the choice of engine oil in an internal combustion engine, classification systems have been created on any fuel, the most common are API, ACEA, ILSAC.

In a single system for all, two rows of viscosity grades are indicated: winter with a letter (W) and summer without a letter assignment, as well as their combinations to designate an all-season oil. If the lubricating fluid is low-viscosity, this is an option for cold seasons, high-viscosity is created for the warm season.

Universal all-season compositions are more widespread, since they are used in any weather, these are 5W-30, 10W-40. To understand which oil to pour into the tiller, you need to focus on the classification table for oil product grades.

Changing the engine oil

Before using a new lubricant, you need to find out which oil was previously filled into the tiller.

The oil composition, ideally, should be of the same grade and from the same manufacturer that has already been poured into the internal combustion engine. As studies by the Central Research Institute have shown, even mixing the same type of lubricant does not work without partial loss of its properties. The first time you need to replace the lubricant after a complete break-in of new equipment.

Here is a brief instruction on how to pour oil into the tiller:

- First, it is required to warm up the motor;

- The old composition is drained, for this a suitable container is used;

- Upon completion, wipe the elements of the cultivator with a dry and clean cloth;

- Pour lubricant to the required level, usually this is almost a full container;

- Check with a dipstick or wire how much oil is poured;

- Clean the filler hole with a cloth and close it.

If there is no bottom drain, the lubricant must be removed through the filler hole. Replacement of liquid material will be needed after downtime, repair with replacement of spare parts and with increased engine load.

Changing the oil in the gearbox

Tillers “NEVA”, as well as motor-cultivators MK100 and MK200 Equipped with mechanical gear-chain reducers housed in aluminum housings. The MK70 motor-cultivator has a mechanical chain reducer in a steel case. In order for the gearbox to serve for a long time, it is necessary to regularly maintain motor vehicles. For diagnostics and troubleshooting, contact Authorized Service Centers.

Features of the tiller reducer device

In each tiller unit, the design includes certain details. They differ slightly in different types of gearboxes.

In detail, the mechanism consists of the following parts:

- Covers and pulleys;

- Forks and shift wasps;

- Bearings;

- Control and shift lever;

- Bushings on the input shaft;

- Shaft block;

- Intermediate shaft gears;

- Washers and oil seals;

- Double-row chain;

- Left and right semi-axles;

- Double asterisks;

- Asterisk block;

- Clutches;

- Input shaft;

- Bracket and springs;

- Clutch forks.

You can take a closer look at the structure of this node in the diagram. The tiller gearbox is quite complicated, but following the diagram, you can easily cope with its dismantling and reassembly.

The following steps are taken:

- The reducer is completely removable;

- The screws are loosened, the protection covers are removed;

- The input shaft sleeve is removed very carefully, the fork and lever are dismantled;

- The input shaft is removed together with the gear;

- The shaft sleeve and chain are removed;

- The shaft block is dismantled together with the sprocket;

- The intermediate shaft is removed together with the gears;

- Clutch with left and right axle shafts are removed.

After all THESE actions, you can get the reducer for analysis. At the end of the repair, it is reassembled.

How to check the oil level in the tiller

To independently check how much oil is in the tiller, namely in the internal combustion engine, you must perform the following steps:

- Install the equipment on a flat horizontal surface;

- Unscrew the plug in the engine crankcase;

- Insert a special probe from the marking into the hole;

- Pull out the dipstick and see at what mark the oil stain is;

- If the mark is below the minimum, you need to add oil.

In the case when there are no marks on the probe, you can focus on the length of the device itself. The oil stain must reach the middle of the test element. If there is no dipstick, then the working fluid must be poured to that level until it is no longer visible from the neck. In order to check how much transmission oil is in the tiller’s gearbox, you need to do the following:

- Place the unit on a flat surface;

- Use a metal rod about 1 meter long;

- Insert the resulting dipstick into the filler hole to the end;

- See the level of fat marks on the wire.

If the dipstick is stained more than 30 cm, it means that the working fluid cannot be refilled.

The transmission of the motor cultivator models includes a gearbox, which is also a gearbox. To replace the oil composition, regardless of the number of speeds, special transmission oil products are used. As in the case of the gearbox, the lubricant level is controlled by a special dipstick with marks or a wire.

Changing the oil in the tiller engine

The working life of the engine of an agricultural unit depends not only on the quality of its components and assembly, but also on how correctly and how often you will change the engine oil. Adhering to the manufacturer’s recommendations, you will be able to extend the life of the unit and save it from typical breakdowns.

To change the grease in the tiller, it is necessary to preheat the motor of the unit. To change the oil in the tiller engine, you need to proceed in the following order:

- First place the unit in a horizontal position. The oil fill and drain holes are always located on the left side of the chiller engine. The oil remaining inside the motor must be drained through the drain hole, which is closed with a conical threaded plug. If the plug is twisted too tightly, then you can unscrew it with a long screwdriver;

- Place a wide container under the drain hole, at least 2 liters in volume, and slowly unscrew the plug. After completely removing it, wait 10 minutes until the lubricant is completely drained from the tiller engine;

- After that, tighten the drain plug and start filling with new engine oil. It is best if you choose 10W40 synthetic or mineral oil as a new formulation. Its volume should be equal to the amount before draining the oil.

The lubricant in the tiller engine should be changed at least once every 25-30 hours of operation. If you DO NOT use the unit too often, and all work takes about the same amount of time, then you can change the oil once a year. At the same time, remember that if you DO NOT have time to work 30 hours per season, then the oil still needs to be changed, since during the downtime of the tiller, the properties of the composition noticeably deteriorate.

If you have just purchased a tiller, then you need to change the lubricant in its motor after the first 5 hours of operation of the unit. The fact is that after assembling new tillers, Small debris remaining inside the engine gets into the oil, which leads to engine jamming and minor breakdowns. In order for the motor of the new unit to be completely cleaned, the oil in it will need to be replaced three more times. 2 times after 5 hours of operation, and the third. after 10 hours.