Features of manual and mechanized sharpening

Dull cutting edges of the saw chain appear:

- a noticeable decrease in productivity;

- ejection of fine shavings;

- the appearance of a characteristic smell of burnt wood.

To restore the cutting properties of the chains, several types of sharpening devices are used.

In the simplest version, it is a holder mounted on a rail complete with a set of special files, in the other. a sharpener with a power drive. Both technologies have their own advantages and disadvantages.

Low-performance and time-consuming manual chain sharpening helps to preserve its resource. The mechanized method provides good performance, but the lack of an individual approach to each cutting link of the chain negatively affects its durability.

Tensioners

The classic budget-grade chainsaw chain tensioner is usually a threaded bolt with an adjusting component, standard or side-mounted. The chain tension is adjusted with the included wrench or screwdriver.

expensive models are equipped with easy-to-use devices that allow you to tension the chain with one movement of the lever or turn of the adjusting disc.

In the first case, the degree of tension is fixed with a lock nut, in the second, the tire and the chain tensioner are locked in a predetermined position by installing the cover. In both versions, reliable fixation of the chain in a given position is guaranteed, the possibility of compensating for its extension with minimal loss of working time.

Saw chain replacement and adjustment sequence

It is not technically difficult to change the chain of a household and professional chainsaw on your own. The key to the successful implementation of the adjustment work will be the exact observance of the recommendations of the attached instructions.

Due to the thermal expansion of the metal, the chain is installed on the chainsaw and the subsequent adjustment is made only on a cold tire.

- In the classic solution, the technology provides for the inclusion of a lock against accidental engine start, unscrewing the threaded fasteners, dismantling the tire and cleaning the guide groove from sawdust.

- Next, you should make sure that the dimensions of the shanks correspond to the width of the groove, determine which side to put the chain on the chainsaw, fix the tire and adjust the chain in the sequence indicated by the instructions.

- Before putting the chain on the chainsaw, you should make sure that the direction of the chain on the chainsaw meets the stated requirements, and the chain tensioning mechanism has sufficient free play.

After adjusting the new chain, it is recommended to run the saw at medium speed for 2-3 minutes, then check the chain tension again. This moment can be combined with visual control of the lubrication system.

Advantages of making a chain set

The chain and the bar are included in the list of interchangeable equipment, so the sawyer, depending on the peculiarities of the work, can use several sets of different lengths and productivity. Average service life of wear-resistant branded tires allows the service life of three saw chains.

The cutting edges of the saw chain links need to be sharpened periodically. The indisputable advantages of using a set of several chains are uniform wear of the drive sprocket and good compatibility with the chains included in the additional set.

How to tension the chain on a chainsaw: installation and proper operation

Regardless of the class and purpose of the chainsaw, the cutting device includes a guide bar and a saw chain with a tensioner. The instructions contain information on how to properly tension the chain on the chainsaw in order to exclude additional loads on the engine and accelerated wear of the headset.

This element of the sawing mechanism is used under conditions of high variable loads, therefore, during operation, it requires constant monitoring. A characteristic feature of the used saw chains is the increase in size due to the formation of gaps in the joints of the links.

Negative consequences of incorrect chain adjustment

Checking the condition and tension of the chain is included in the mandatory list of preparatory work.

How much it is possible to put the chain correctly depends on:

- the duration of its subsequent operation;

- safety of cutting operations of increased complexity;

- resource of the engine and chainsaw as a whole.

A dragged headset dramatically reduces work performance, initiates excessive loads on the power unit and transmission. There is also tire overheating and excessive fuel consumption.

A loose chain can fly off the bar or break. The formation of traumatic moments is partially or completely eliminated by emergency stop systems and catchers, which, with more or less success, unravel the chainsaw chain and determine its suitability for subsequent operation.

Installing a part with damaged or deformed links can lead to uneven wear of the guide groove of the tire and other undesirable consequences.

Reasons for premature failure of saw chains

Accelerated elongation of the part occurs during the running-in phase and in the last quarter of the service life. During these time slots, the headset needs special attention and careful maintenance.

- The reason for the rapid stretching of the saw chain can be the poor quality of the material of the budget model, the mismatch of the configuration of the crown and excessive wear of the drive sprocket, a malfunction or ineffective operation of the lubrication system.

- The full operation of the chainsaw chain also largely depends on the condition of the tire and the drive sprocket, the quality of the chain oil and the performance of the lubrication system, the timely and competent sharpening of the edges of the cutting links.

According to professional sawers, the operator’s style of work and the level of operational stress affect the durability of the headset. The chains of the budget group are more susceptible to stretching, the more expensive branded assortment has no Комментарии и мнения владельцев on technical and operational properties.

Methods for checking the degree of tension

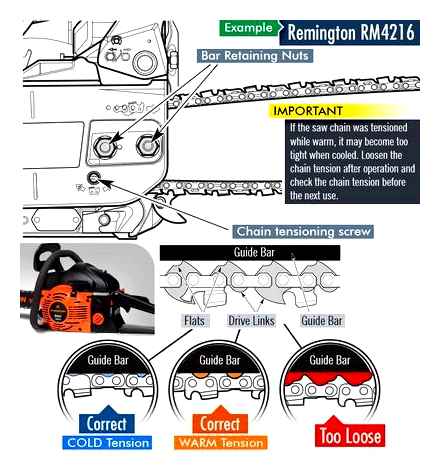

To check the degree of tension, it is enough to pull the chain in the middle of the tire, the exit of the link shanks is allowed no more than 2/3.

Chapter 5: Adjusting Your Chainsaw’s Chain Tension

- A properly adjusted chain should not stick when manually moving along the bar.

- Also, squeak and other extraneous noises in the area of the leading sprocket are excluded.

- After running the chain, it is necessary to check the tightness of the threaded fasteners of the bar and the protective cover.

After long-term operation, the chain is not tensioned due to the lack of adjustment travel of the tensioning mechanism. The construction of the chain allows its length to be reduced by removing several links. On the other hand, such savings translate into a loss of smoothness of the chain and forced wear of the groove of the tire and the crown of the drive sprocket.

What to turn on the chainsaw to tighten the chain?

In general, for all chainsaws, the procedure will look like this: loosen the fastening of the side cover and rotate the chain tensioner. But the cover mount and tensioner themselves may be different on different chainsaws.

Correct Way To Adjust The Chain Tension On Your Chainsaw

The easiest option is a side cover attached with one or two nuts and a tensioner in the form of a screwdriver bolt (either slotted or Phillips). In this case, simply loosen the nuts and turn the bolt clockwise. The bolt can be located either on the side in the cover, or in the front. again in the side cover, or in the body of the chainsaw itself.

But there is also a keyless chain tension. this is when neither keys nor a screwdriver are required to loosen the fastening of the side cover and rotate the tensioner. These systems look different from different manufacturers. Below you can see in the pictures what they are, and what to twist.

How to properly tension the chain on a chainsaw?

After you have worked with the chainsaw for a while, there will come a moment when the chain tension will loosen. This is due to its stretching and heating. Many do not know how to tighten the chain on a chainsaw, so they start looking for the answer in the instructions or on the Internet. Well, in this article you will learn how to do it correctly. The tension is approximately the same for any chainsaws: at least STIHL, at least Husqvarna, at least Champion, at least some other.

How should the chain be tensioned on a chainsaw?

The rule for how the chain should be tensioned is as follows: the chain should move freely along the tire, but not sag. A little more, a little less. it doesn’t matter. The main thing is to walk freely and not sag. In this case, if you pull the chains from the tire, grabbing it in the middle of the tire, it should reach the height of the links entering the tire.

During operation, make sure that the chain does not sag. If you notice any slack, tighten immediately. And after work, it is better to loosen the chain. This must be done due to the fact that the chain heats up during operation and stretches (including because of this it has to be tightened), and then, cooling down, shrinks. As a result, it can tear itself, and spoil the tire, and take away the shaft bearing on which the drive sprocket is held.

Here are all the rules for tightening the chain on a chainsaw. Thanks for attention!

Expert advice

New chains stretch more than old ones during the first hours of operation. Therefore, the tension should be checked after the first 12-20 minutes. work.

Hauling is fraught with unnecessary load on the engine with a loss of power and accelerated wear of the cutting attachment and chainsaw parts, primarily the drive and clutch sprocket.

After 3-4 chains are worn out, replace the tire with a new one.

After 6-8 chains and 2 tires are worn out, the condition of the drive sprocket should be assessed. On different models, they wear out after different service lives. The worn sprocket teeth are non-standard size. Even if the chain does not slip on them, its service life is reduced.

After each tension adjustment, it is recommended to lubricate the driven sprocket at the end of the tire. For this, there are special holes near it. The oil from the pump gets there according to the residual principle, and sometimes it does not get there at all. Therefore, along with a key and a screwdriver for tightening, you need to have an oiler on hand. 3-4 drops are enough for lubrication.

Insufficient lubrication accelerates the wear of the cutting attachment and the stretching of the chain. The planned oil consumption is different for different chainsaws. In some models, 1 tank of oil is consumed almost simultaneously with 1 tank of gasoline. Others have 1 tank of oil enough for 2 gasoline fillings. A sign of good lubrication is the oil shine of the chain and its smooth running along the groove.

Poor quality chains should not be used. They stretch quickly, disable the nodes in contact with them and require more frequent tightening.

When to tighten the chain

It is absolutely unacceptable to work with a strongly sagging chain.

The chain “jumping” during sawing can break the groove of the bar, disable the teeth of the driven sprocket.

A loose chain can damage parts of the mechanism. But the most dangerous thing is operator injury. Despite the brake and catcher, a loose chain can whip in an unpredictable trajectory, which is extremely dangerous.

The tension must be checked before starting work. During operation, the critical attenuation can be determined by two signs:

- the chainsaw starts jumping and twitching in the hands;

- the sound of work changes, a metallic ringing appears, a knock.

In this case, turn off the engine and check the tension.

Keyless tensioning system

It began to be used relatively recently, it is considered new, if not advanced. Differs from the classic nut, as follows:

- another tensioner mechanism;

- lack of an external tightening nut;

- adjustment without additional tools.

Instead of a turnkey nut for 13 on the lid, there is a wing (swivel cap) with a handle for tightening by hand. It also has a nut, but it is hidden inside. Instead of an adjusting screw for a screwdriver in this system, the tension is carried out using a tension wheel (adjusting knob).

Instead of a gear shaft, there is a sprocket and a tension washer.

- the mechanism itself is more complicated than a traditional wrench;

- the installation of the cutting attachment causes additional problems, because complicates the process of pairing all the parts in the right order;

- less adjustment stroke, a slightly stretched chain will still serve with a traditional tensioning system, here it will sag and become unusable.

Why is the chain loosening on a chainsaw

The chain tension on all chainsaws is constantly weakening. There are several physical and mechanical reasons for this.

- The chain is connected from a plurality of links, which are held together by bushings through the holes. Even with the most accurate factory fit, there is play between the bushings and the holes, otherwise the chain will not fold into an ellipse. During operation, all the backlashes are pulled in one direction, which leads to an increase in length. Even a micron backlash of 52 or more links in total leads to tangible values.

- Under loads, especially strong, the plate elements of the entire chain can stretch.

- Gradual chain slack occurs when parts are worn out. The teeth of the driving and driven sprockets, the outer edge of the tire groove are erased. Sprockets decrease in diameter, the tire becomes shorter.

- When heated, metal not only expands, but also lengthens. During operation, the heated chain becomes slightly longer and sags.

Chainsaw chain tension

The correct chain tension on chainsaws is of great importance. It affects the service life of the cutting attachment and the entire chain saw. over, with a critically incorrect tension, it is simply impossible to work with a gasoline chain saw.

Chainsaw chain tensioning algorithm

An illustrative example of how the chain tension occurs on a chainsaw is presented in the following

Tensioner device and principle of operation

The chain tension is adjusted by simply moving the bar:

- from the leading sprocket (from the chainsaw) to strengthen the tension;

- to the drive sprocket (to the chainsaw) to loosen the tension.

The tire is moved using a simple gear mechanism that transfers the force from the adjusting screw to the tire.

There is a spike on the adjusting shaft, which must necessarily fall into the hole on the tire when it is installed. It is this engagement that causes the tire to move when adjusting.

The screw is located under the hole in the cover that covers the drive sprocket, on the side or front, depending on the model of the chainsaw.

The screw in most models has a slot for a flathead screwdriver. Rotating it clockwise or counterclockwise moves the tire slowly, millimeters per revolution. This makes it possible to simply and accurately achieve the desired tension.

The tensioner mechanism is simple, therefore reliable enough. It fails for the only reason. if the teeth of the drive gears are made of soft or brittle metal. Some unscrupulous manufacturers use parts made with powder metallurgy. The teeth on such gears quickly “lick”.

In such cases, you have to change the entire node. You can tension the chain by hand or with a vise. The tire is neatly, without pressure on the grooves, is fixed in a vice, the chainsaw is pulled from the vice until the desired chain tension is reached. This is a temporary measure. The chain has to be tightened often, and without an adjusting mechanism it is inconvenient to do this.

The adjustment is carried out with the bar and chain fully installed in place, with the fastening nuts being loosened, of which, depending on the model, there may be one or two.

Why clamps the chain on a chainsaw

- the chain is too tight;

- the groove of the tire, the space around the sprocket under the cover of the tire mounting, the clutch mechanism are clogged with a mixture of sawdust and oil;

- the tire is completely incorrectly installed (the pin of the tensioning mechanism does not fall into the hole, it is skewed);

- one or more of the chain links are seized 4

- the chain is deformed, the guide segments are bent;

- damaged tire groove.

Adjusting the chain tension takes only a few minutes without experience, and with experience it takes less than a minute. It is not burdensome to follow the correct tension, and not to follow. is more expensive for yourself.

How to determine the degree of tension

A quick check of the chain tension is very simple: you need to grasp the prong and pull it up. If the chain is tensioned correctly, then the tail will be immersed in the groove of the bar by 1/3 of its height. An excess of this indicator indicates excessive tension, and a decrease in the indicator indicates weak.

Normally, the saw should move freely along the tire, without much effort. If the movement of the element is difficult, this is a sign of excessive tension.

With a strong tension on the cutting element of the chainsaw, the tire begins to heat up and grind, the load on the engine increases, and it wears out quickly. Do not start up the machine with a loose chain, as it can be pinched and cut off when sawing, which poses a danger to the user of the machine. The chain can fly off the tire and injure limbs, and it often breaks itself and damages the tire. Also, working with a weakened chain element leads to one-sided tire wear, after which the device stops making even cuts, and the saw is taken to the side.

Is it possible to shorten the chain yourself

In the case when the chainsaw chain has stretched so much that it is no longer tensioned, it becomes necessary to reduce its length.

This also has to be done if the available bar is shorter than the chain, and it is not possible to choose a suitable sawing element.

The main problems with the chainsaw chain

Chainsaw users are often faced with the problem of saw chain tension. It either weakens spontaneously, or stretches and flies. As a rule, these troubles are caused by unit breakdowns. Therefore, before proceeding with the chain link tensioning procedure, you should check and eliminate possible causes that may lead to misalignment.

The reasons for the stretching of the chain on the chainsaw may be heavy loads or insufficient lubricant supply to the tire. This causes the saw to overheat, expand the metal, enlarge the saw element, and throw it off the bar. Oil flow can be disrupted if the pump breaks down, channels clogged, oil hose breaks.

If you changed the chain on the chainsaw to a new one, then be prepared for the fact that during the running-in period it will stretch a little. It is only necessary to check the tension in time so that the element does not fly off the tire.

A chain made of low-quality steel also stretches quickly.

When the driven or drive sprocket is worn, the grip on the chain links decreases, causing the saw element to fly off. In this case, you will have to unscrew the chain drive and change the sprocket. Also, the saw blade of the unit can fly off due to its stretching or deformation of the tire.

If the chain on your chainsaw weakens, then a malfunctioning tensioning mechanism can cause this malfunction.

Rules for replacing and tightening chains on a chainsaw

The chain tension on the chainsaw affects not only the normal operation of the machine, but also the safety of the operator working with it. A chainsaw is a highly traumatic tool, and a loose saw chain can have dire consequences. In turn, an over-tensioned chain increases the load on the tool. Therefore, before each start-up of the machine, you must make sure that this important element has the correct tension.

Tension Algorithm

Before tensioning the chain on the chainsaw, you must turn off the engine of the unit, or disconnect it from the mains if it is an electric saw. Do not adjust or replace the saw blade while it is hot. If this is done, the metal will shrink after cooling and the tension will be too great, which can lead to increased stress on the engine and deformation of the tire.

The chain tensioner is located on the right side of the machine, under the cover, in the place where the clutch brake is installed and the bar mount is located. On Husqwarna, STIHL, Poulan and Partner chainsaws, the external tensioner looks like an ordinary bolt.

So, in order to adjust the chain element of the apparatus, you need to perform the following steps.

- Loosen the nuts on the right side cover slightly so that the tire is not skewed.

- Insert a screwdriver into the tensioner adjusting bolt and turn it to the right (clockwise). From these actions, the tire will begin to move, and the chain will be tensioned. If you rotate the bolt to the left (counterclockwise), then the chain links will relax.

- Next, you should tighten the chain to a state so that it does not sag and dangle.

- Check the tension of the element: grasp the cutter link approximately in the center of the bar and pull it down with a slight force. The chain should be taut, have elasticity, and the shank of the cutting link should fit into the groove of the bar by about 1/3 of its height.

On a Makita electric saw, the tension adjuster is designed in such a way that it can be turned without the use of any tools. Turning it clockwise will tighten the chain, if you turn the adjuster in the opposite direction, the tension of the chain element will loosen.

How to remove a rivet

To change the elements of the chain or shorten it, you will need to separate the links as follows. Fix the chain element in a vise and grind off the rivets, namely their protruding parts. To do this, you can use a file or file. Take care not to grind the side of the link.

It is not recommended to use an angle grinder, since there is a risk of overheating the links, which will lead to a change in the physical properties of the metal.

Using a beard (as it looks like, shown in the photo below), knock out a rivet.

There is another option for separating the links. To do this, you do not need to grind the heads of the rivets. Place the link, namely its rivet, over a hole in the metal or over the slightly parted jaws of the vise. Next, you should put a locksmith’s barb on the rivet head and hit it several times with a hammer.

Continue knocking out both rivets alternately as they are firmly secured by the opposite side of the link. Gradually, the rivets will begin to come out of the top of the link, and it will come loose.

The advantage of this method is that the rivets can be reused as they do not grind.

Chainsaw saw element replacement

If you need to replace the chain on the chainsaw, then follow these steps.

- Remove the cover covering the sprocket. To do this, most often it is necessary to unscrew the fastening nuts.

- Having unscrewed the fasteners, remove the cover that covers the clutch with an asterisk.

- Grasp the bar with your hand and push it towards the sprocket to loosen the chain.

- Remove the chain element from the drive sprocket.

- Now you need to install the chain on the chainsaw. Take a new saw blade and slide it onto the drive sprocket first.

- Then you need to put the chain on the bus, placing the element in its groove around the entire perimeter. It is important that the links fit properly onto the driven sprocket on top of the tire. When installing, pay attention to the direction of the cutting links. They should be directed away from the unit, on the top of the tire.

- Run the bar in the opposite direction to the engine to tighten the chain a little.

- After laying the saw element, before putting the cover back in place, it is necessary to align the screw, through which the tension is adjusted, with the adjuster located behind the bar. Only then can you put on the cover and screw the nuts slightly. Next, insert a screwdriver into the adjusting screw and apply the final tension. How the correct chain tension is made was described above.

- Raise the bar slightly and tighten the nuts, thus securing it. It is important not to overdo it and not to rip the thread.