What you need a sabre saw for: selection, rating and video reviews

Sabre saw is designed not only for professional craftsmen, but also for those who are far from this sphere. Thanks to this tool, it is possible to quickly, and most importantly, qualitatively perform almost any work associated with cutting material. In this topic, we will touch on the features of sabre saws and talk in detail about the specifics of selecting this device.

Sabre saw is a multifunctional equipment, which in appearance resembles a drill. It has an elongated body with a handle and operating button that is at forefinger level. To provide protection when using the tool, it has fuses that protect against accidental pushing of the button. The machine is also equipped with a special cutting blade that moves in a straight line, capable of pendulum-like actions (on some models). According to the principle of operation and tasks, which will be described below, sabre saw can be compared to the usual hacksaw for the average user.

The mass of a sabre saw varies in the range of 2. 5 kg. In a sense, the weight determines the power and scope of the equipment. Many sabre saws are available in lengths from 8 to 35 cm. This range allows working with different material thicknesses.

Why do you need a saber saw?

The distinctive feature of the equipment is that for its work it is not required to fasten the material. The tool can work without support and in any position. It is worth noting that few professional tools have such functionality. It is true that it is much harder to cut the material without support, because of the strong vibrations.

The equipment in question helps not only accurately, but also in a short time to cut a large amount of materials. If you compare the tool with a hand saw, the latter loses in many ways. This refers to the fact that the sabre saw can saw in straight and curved paths, which greatly expands its scope of use, answering the question. what do you need a sabre saw for. Naturally, it requires experience to make curved cuts, but this can be learned quickly.

Design and principle of operation

The concrete sabre saw is the counterpart of a hand-held wood saw powered by an internal combustion gasoline engine or a powerful electric motor operating from 220-230 volts AC. Working tool. the bar and the cutting chain with diamond elements provide a rather deep cut (30-40 cm) and the possibility of end entry into concrete with a turn of 90 degrees. This is very important and relevant to the arrangement of niches, windows and doorways.

Of particular interest is the cutting tool. the diamond endless chain, stretched on a so-called tire (saber). The chain is fitted with special diamond segments and is water-cooled through a special channel.

The cutting tool is driven by either an internal combustion engine or a 1 to 3 kW electric motor. Clutches and gears are used as transmissions.

Modern sabre saws are equipped with a centrifugal clutch. The centrifugal clutch allows you to stop the cutting tool when idling, when jamming, when “meeting” a hard obstacle “out of reach” and in other emergency situations.

It should be noted that gasoline-powered saber saws have some objective advantages. Firstly, it has higher cutting power, and secondly it is one hundred percent energy-independent, autonomous and can work in the field.

How to work correctly with a saber saw

The saber saw itself is light enough, especially if compared to the chainsaw, its weight is about two kilograms, which allows holding it with one hand. If you compare a saber saw to a circular saw, the result is like comparing a chain saw. The advantage of the saber saw over these two saws is that the chain saw only needs wood and thicker wood, and the circular saw only works in flat mode, not allowing you to make protrusions and notches. Thus, it is clear that each saw has its own application area, exactly where it has no equal. Sabre saws are most often used when cutting pipes, window frames, for rescue work. In the choice of power supply, buy depending on the place where it will be used.

In ease of use, the main point is the anti-vibration system, the second most important is the function of tool-free replacement of the saw blade, thus reducing the time for maintenance.

In terms of safety, the sabre saw is by far the safest, as it has only one cutting side, while there is protection against unwanted activation. Also, the saber saw is considered a non-dusty tool and multifunctional, and can be a good helper to plumbers, rescuers, roofers. The use of this tool considerably reduces the time compared to manual work.

Types of saber saws

Concerning the sabre saw, it is similar to the usual drill, only instead of a drill it is fixed with a hacksaw blade, and the principle of the sabre saw is completely different from that of the drill. Power supply for both types of tools is the same. from the mains or from a battery.

The power consumption of a sabre saw ranges from 400 W to 1500 W, which is exactly the same as the power consumption of a drill.

Another similarity is the speed control, as well as the replacement of different attachments for different types of work. So, the variety of attachments keeps increasing, the most popular attachment is the hacksaw blade.

Also saw the light and variable serrated nozzles, which have become universal. This made it possible to use the part of the saw that was needed, most often when cutting wood, and it was possible to adjust either the quality of the cut or the speed of the work. But at this time there are also saws for plastic, ceramic, metal, glass. There are attachments for saws as well as other tools, for example, sanding, file, brush, file and many others.

The purpose of a sabre saw

The multifunctional tool is not superfluous in the home workshop. with its help any materials can be cut quite easily and simply. Electric hacksaws are amenable to:

- wood;

- plastic;

- tiles;

- metal;

- Brick and aerated concrete;

- plasterboard;

- Particleboard and fiberboard;

- plywood;

- composite materials, etc.д.

Sabre saw comes in handy for repairs and work in the homestead. It will help to perform straight and curved cuts. Its capabilities are more advanced than a hand saw, and the work is much faster and of higher quality.

The power tool allows for variation, inspiring the craftsman to experiment. With its help, simple workpieces and parts of complex shape are made.

Cutting is made with a sturdy hacksaw blade, included with the saber saw or purchased separately.

To avoid any inaccuracies and make a cut exactly along the line, you need to have a steady hand and have a good eye.

A beginner may encounter certain difficulties, so it is recommended to get acquainted with the tool in advance, having performed, for a start, little important work. You need to get a feel for the maneuverability of an electric hacksaw, and get a little experience in sawing. After that, you will surely become confident in your own strength.

Sabre saws are one of the universal tools.

How to Use a Jigsaw

- circular saw;

- electric jigsaw;

- lopper;

- file;

- a metal brush to remove rust and old paint residue.

In some cases, the tool is used as an electric chainsaw or angle grinder. The variant of application depends on the nature of the work, as well as the type of attachment installed.

Interestingly, when cutting metal with a saber saw, sparks do not fly in different directions, because they simply do not.

Branches from the trees are removed even in the most remote places is absolutely safe, because it is not required to bend in uncomfortable positions.

Speaking about the advantages of the considered power tool, it is necessary to mention its disadvantages as well. The main one is still the universality of the saber saw. The fact is that a specialized tool always copes with the work better than a “universal” one.

But there are a couple of justifying moments here. First, no one would call buying a bunch of power tools for home use just to get them out of the attic occasionally a smart decision.

And secondly, an electric hacksaw can quite replace a large-sized specialized counterpart on hard-to-reach areas.

Working principle

The sabre saw blade not only reciprocates in a straight line, but also in a reciprocating motion. It moves back and forth, lifting to its starting position as it moves.

This means that the cutting element, having made a cut, does not pass over the same place a second time. The blade is retracted in automatic mode. This reduces the friction of the hacksaw on the surface to be cut, which in turn makes it easier and faster to work.

As a result, unnecessary physical effort and frequent replacement of the removable part of the saber saw is not required.

How To Use A Reciprocating Saw. Ace Hardware

The working elements of the power tool are enclosed in an ergonomic housing with the exception of the hacksaw blade. There is a conveniently located lever button on the outside that adjusts to your index finger. The sabre saw has a number of options, the main ones being:

Guides help to keep lines and angles correct when sawing, avoiding irreparable errors. These are not part of the tool, so they must be purchased separately. In fact, the saw guides are designed to keep the electric sabre saw accurate and increase its effectiveness.

There are three groups of sabre saws on the market. household, professional and semi-professional.

Models differ in several ways:

- power;

- performance;

- frequency of strokes of the hacksaw blade for a certain period of time;

- manufacturing materials;

- safety factor;

- service life;

- dimensions;

- wear resistance;

- cost.

Professional equipment is intended for professionals. For home craftsmen it is quite suitable household power tools. Semi-professional electric sabre saws are needed for craftsmen who occasionally engage in carpentry.

The cutting attachment for reciprocating saws must be selected based on the material to be worked with. Pay attention to the size and pitch of the teeth, as well as their shape and degree of sharpening.

It should be understood that a coarse tooth speeds up the work, and a fine tooth increases the quality of the material to be sawn.

From this it can be concluded that blades with big teeth should be used for rough but fast working when quality is of secondary importance and speed is a priority.

In specialized stores there are short and long blades (within the range of 100-400mm), with and without dusting. Removable elements are unified in shape and size, so they fit almost any model of electric sabre saws produced by different manufacturers. Optimal saw blade length is 120-170 mm. Such blades produce the most accurate cuts.

Design and principle of operation

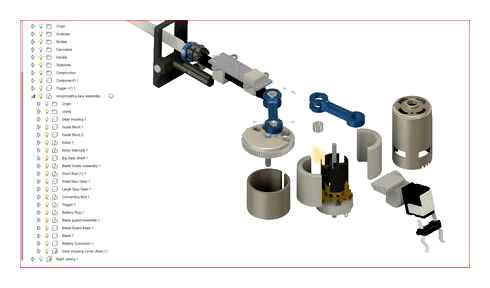

Sabre saws have the following structure:

- Sturdy plastic body with a built-in motor. Handle for easy grip. Shapes depend on the type of model.

- There are buttons on the body, which help to regulate the speed of the cutting blade, to switch on/off the tool, to start the saw backwards.

- At the base of the chuck there is a lever that fixes the saw blade in a stationary condition.

- You need to make a socket for the cutting blade where the element is fixed.

- A support bar is placed in front of the socket to provide a stop in extreme cutting conditions.

- Beam cutter blade.

Such electric saw partially resembles a reinforced jigsaw. The device works as follows:

- The motor performs reciprocating motion of the rod. All of this is done through a crank mechanism.

- The rod ends in a chuck that holds the hacksaw material.

- To extend the life of the saber electric saw, the tool is equipped with a pendulum mechanism.

Thanks to the clever device and the ability to adjust some parameters, saber saws are easy to use.

Do not throw away dull blades

Leave a couple of blunted blades, they may still be useful for cutting plastic pipes, for example.

When using new blades, there is a high probability that their sharp teeth will strongly cling to the plastic and rip the workpiece out of your hands. That’s why it’s better to use blunted blades that, by the way, cut plastic no worse than special blades made for this purpose.

Sawing material

When buying sawing material for a certain type of work, consult a specialist or the seller of the product. Nowadays there is a wide range of sawing materials on the market.

The density of the material determines how the tool will work with it.

Denser material needs a sharpening stone with a coarse tooth.

The bigger the tooth, the faster the material will be sawn, but some kind of defects can’t be avoided. So be choosy about which blade to use.

And during the work don’t forget to set an appropriate mode for the material you’re cutting.

When installing wiring in an apartment during the renovation or construction of a house, there are many force majeure situations in which the sabre saw can help a lot.

It is not a superfluous tool for the household, either. Read. what tools should an electrician have.