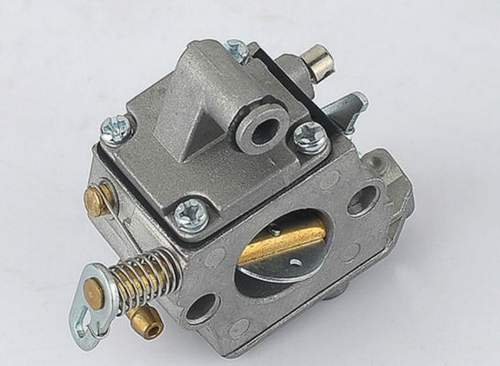

Do-it-yourself Stihl 180 chainsaw carburetor adjustment is easy to do. The main thing is to approach the work process carefully and responsibly. In order to make it easier for you to understand what is following, we have prepared detailed instructions.

Adjusting the carburetor of the Stihl 180 chainsaw.

1. The start of adjusting the carburetor of a Stihl 180 chainsaw is to check the maximum number of revolutions. There is always a malfunction in the ignition at the highest level. to fix the problem, make a small turn of the screw counterclockwise. As soon as the ignition operation is normalized, this adjustment step is completed.

2. The second stage. checking the acceleration of the Stihl chainsaw. To do this, gently press the gas button and observe how quickly the engine accelerates to maximum speed. If the process is too slow, turn screw L counterclockwise. Step. 1/8 turn. Repeat until the optimal position is found.

3. Adjustment and adjustment of the carburetor at idle. start the engine and test the uniformity of its work, provided that the chain remains stationary. Stable engine operation is a confirmation of the correct adjustment.

4. Test engine operation under different loads. If there are no comments on the operation of the Stihl 180 chainsaw, you were able to correctly adjust the carburetor of the Stihl 180 chainsaw yourself.

Adjusting the carburetor of a Stihl 180 chainsaw, a video tooltip to which you can see on our website, is quite within the power of each tool owner. But, if you are faced with more serious problems, you cannot deal with them yourself. Become a customer of the RemTechService service center. our masters will quickly repair damage of any complexity. Also, our company sells spare parts for Stihl chainsaws. both original and more affordable counterparts.

Who can repair carburetors

All of the following applies to any chainsaw model, including gas trimmers, scythes and other equipment. Adjusted, of course, for design features.

There is an opinion that it is better not to climb inside a chainsaw yourself. For those who are used to working with a hammer and sledgehammer, perhaps this is so. For the rest, any more or less accurate person who does not shake hands can correct any problem with his work. In general, this is work available to anyone.

Faults that can be fixed by carburetor repair

Let’s make a reservation right away. diagnosis is an insidious thing. Sometimes the same symptom occurs due to completely different reasons. But we will check everything and find it together. So:

The chainsaw does not keep idle. Either she stalls at idle, or they walk, or high.

The idle nozzle may be clogged. It needs to be cleaned. How to do it. more on that below. But so far about alternative reasons.

It is possible that the problem is in the fuel system. Check fuel hoses, fuel supply.

Sometimes problems with revolutions (or rather, their absence) are solved by cleaning the check valve of the fuel tank (gasoline tries to leave the tank, but the air does not return instead). It looks like the one shown below in the figure:

Do not forget to adjust the carburetor in the only possible way. to change the amount of air supplied, which is reflected at idle very much. Everything is described in the instructions for the saw. For those who are too lazy to go into the instructions, here is a screenshot:

The saw does not start

A special case of the previous problem. The solution is required the same.

Saw lost in power, increased fuel consumption

Two very subjective indicators. In order to reliably state this or that, instrumental measurements are necessary. From the practice of repair organizations, very subjective things are often given out under one or another. In some cases, effects resulting from a dull circuit can be taken for loss of power. Naturally, the performance in this case will be low. Sometimes it seems that the saw is quieter (clogging of the cooling system, exhaust system). Increased fuel consumption may be due to leaks.

Often the problem is the muffler, not the carburetor!

Chainsaw stalls hot. after work and warming up

- Problems with the carburetor (on how to eliminate and diagnose. below);

- Overheating. problems with cooling. Clean your saw;

- Lack of air supply;

The chainsaw begins to stall or change speed when tilted to its side. In the vertical. everything is fine, when turning. the speed drops (or grows) and it stalls

It is connected with the design features of its fuel system, filling the chambers. In addition, it is necessary to check the gas pump. sometimes the problem may be in it.

The procedure and sequence for disassembling and adjusting the carburetor of the Stihl 180 chainsaw

Preparatory work

First of all, it is necessary to understand that the carburetor of any engine is a unit into which the flows of air and gasoline converge. Therefore, for its normal operation, these flows must come in a working, not clogged form. In addition, the combustion products in the engine must freely leave the chamber through the muffler. Therefore, every time, before repairing and adjusting the carburetor, we must check:

- Intake air filter;

- Remove and clean the muffler;

- We check that there are no problems with the fuel system. supply hoses, fuel tank operation (operation of the breather for compensation of reduced pressure, see above);

In principle, it is not even so vital to turn idle speed. Serviceable elements will already give normal performance characteristics.

Carburetor removal

The removal process is best shown in the attached video below. The basic minimum steps are also shown in order to bring the unit into working condition. Schematically, this process looks like this: remove the cover, traction, unscrew the unit.

Replacing and checking membranes

And specifically in this case, the rocker with a needle are also included in the kit, which are also subject to wear and in some cases require replacement. In a word, for the price of a new unit, you can repair an old almost unlimited number of times. If you consider that five. this is actually a lifelong set.

Option to repair and clean the carburetor without the use of repair kits

Video: How To Adjust A Carburetor Saw Stihl 180

In some cases, the following method gives excellent results. we take out the carburetor, remove all the membranes (top and bottom), and then leave what is left, soak in acetone for several hours. Often foreign objects and substances simply fall into the jets and channels (sometimes, for example, traces of sealants are found there!). Therefore, a simple cleaning gives an excellent effect. No costs and membrane replacements. Although the decision to replace them must be taken locally, guided by their condition.

Are Chinese carburetors reliable with Aliexpress?

It may seem surprising, but quite. This unit has almost the only requirement. the accuracy of its manufacture. In terms of geometry, as a rule, everything is fine with him. It does not carry any excessive mechanical or chemical loads. Therefore, a simple replacement may well be an appropriate option for a long time to extend the life of a chainsaw, which costs quite decent money.

Video

The trimmer for giving

Stihl Chainsaw Carburetor Adjustment 180 ms

Carburetor Repair Stihl 180 Chainsaw do it yourself

Chainsaw Carb Adjustment

We recommend adjusting the carburetor of the chainsaw at the service center. since this process requires certain knowledge and experience. In addition, special tools are needed: an adjusting key and a tachometer. We strongly advise against regulation carburetor yourself, but we understand that there are situations when a service center is very far from you, and there is no way to get to it, but the work is worth it!

If the chainsaw does not start, then read our article The chainsaw will not start. What to do? and calmly and consistently go through all the steps in order. If chainsaw start, but does not gain momentum or is unstable, or stalls at idle, then in this case you can try to fix it yourself.

First: preparing for carb adjustment

Before adjusting the carburetor of the chainsaw, you need to make sure that the air and fuel filters are clean. If you take on the carburetor adjustment, then, of course, you know where these filters are and how to check their condition. Next, inspect the carburetor adjusting screws. It happens that the adjusting screw is the same, as on the Stihl MS 180 chainsaw. Or they are not there at all, as on Husqvarna chainsaws with the AutoTune system. But, as a rule, there are three screws.

Second. idle adjustment with screw T

The T screw is responsible for idling, it is regulated by a conventional screwdriver and, most importantly, it can be adjusted without any risk of spoiling it. But before you regulate it, start and warm up the engine. After the engine warms up, we try to carefully adjust the screw T at idle. If it is twisted clockwise, then the idle speed should increase. When twisting. will decrease. Be sure to unlock the hand brake and adjust the screw to achieve stable engine operation, but if the chain starts to scroll, unscrew the screw a little so that the chain remains idle at idle.

Third. why do we need screws L and H

We pass to the following screws, they are also regulated on a warm engine. They are denoted by L and H, they need to be regulated very carefully, and that’s why. These screws are responsible for the quality and quantity of the mixture during engine operation. And since the lubricant dissolved in the mixture enters the engine together with gasoline, there is a risk of disrupting the lubrication process or exceeding the maximum allowable engine speed. If you don’t have a tachometer, then you won’t be able to check it. In addition, you do not have a special key and you will have to pick up a hollow tube instead. And it can scroll and mislead you about the position of the screws when you want to return everything back.

Before adjusting these screws, make marks or remember their location. It is best to look for the correct position of the screws in the reference tables. The tables indicate the number of revolutions by which you need to unscrew the screw relative to the state that is tightened to the stop. This information is necessary if someone is up to you or you yourself arbitrarily rotated the screws. If no one has violated their position before, then this data can be dispensed with.

Fourth. rpm failure

If the chainsaw starts up, but when you press the gas trigger you feel a failure in the set of revolutions, then try to adjust the screw L. Turn it a quarter of a turn in different directions and at the same time try the reaction of the engine to pressing the gas. Try to find the position of the screw at which the engine acceleration will be uniform and fast. There is no point in turning it at a larger angle, the screw itself cannot be unscrewed by as much as it can, so a quarter of a turn should be enough.

Fifth: maximum speed adjustment

Screw H is generally not desirable to adjust independently. He is responsible for the quality of the mixture, which affect the maximum engine speed. On his own, he also cannot go astray. Therefore, it will be enough if you twist it 1/8 turn in both directions and achieve optimal engine operation in your opinion at maximum gas. But, I repeat, it’s better not to do this on your own. For precise adjustment of the maximum speed, a tachometer must be used.

There are reasons not related to the carburetor for which the chainsaw will not start up or work unstable. The most common ones are piston wear and air leaks through gaskets or seals. In these cases, adjusting the carburetor and even replacing it will not help. These reasons can be determined by measuring the compression or pressure testing of the engine. And for this, special equipment is already needed. It is in our service center. we can make a diagnosis and establish the cause of the malfunction.

Do-it-yourself Stihl 180 saw repair carburetor

chapel.ucoz.com

?Do-it-yourself Stihl MC-180 chainsaw repair. Useful p.

Chainsaw Stihl Repair Do-it-yourself ms-180. Useful articles about chainsaws. Band Sawmill

Do-it-yourself Stihl MC-180 chainsaw repair. Useful articles about chainsaws.

STIHL MS 180 HOW TO ADJUST THE CARBURETTOR How to adjust carburetor STIHL chainsaw MS 180

How to adjust carburetor stihl ms 180 what are the revolutions of min and max? And also a similar video about the adjustment on mine.

Adjustment carburetor STIHL Stihl MS 180

Find out more on our website: Let’s be friends in the social. networks :.

mount MS-180 with its hands. Useful articles about chainsaws.

Read the same

Do-it-yourself Stihl MC-180 chainsaw repair. Useful articles about chainsaws.

Recently, cases of handling after independent repairs have become more frequent. trimmer stihl (Stihl ms 180), husqvarna (Husqvarna 142, 137), partner (Partner 350, 351, 352, 372), homelite (homelite 3314, 4016), jonsered, echo, poulan, efco, etc. The Internet has posted a lot of material on self-repair of gasoline powered tools. Please do not try to repair chainsaws, trimmers, etc. do it yourself

Task: I bought a husgwarna saw. Maybe someone will help with advice on how to break it in correctly.

Solution: On Husqvarna saws, the carburetor is initially set to a slightly more enriched mixture, while more lubricant is supplied with the fuel, this is done so that the saw runs at lower (relative to the norm!) speed! At idle, all this will not burn. The cylinder and piston do not need to be rubbed, they are covered with thin layers of chromium and are ready to work.

Running in is work without overloads! But not in the twentieth. No: When a car’s engine is run in, they don’t drive it at idle!

After such a break-in, Husqvarna recommends adjusting the speed in service. There, the mixture is slightly impoverished to normal, thereby increasing max. saw revolutions and increasing productivity. This procedure is optional, but desirable. After it, the saw will become more economical and more productive.

There is an opinion that this procedure is the company’s marketing move that draws customers into its service centers, but objectively, such factory settings can reduce the risk of saw overheating in

the break-in period, and if you do not adjust in the future, then increase the resource, though to the detriment of fuel economy and performance.

Checking the functioning of all elements to ensure the safety of the chainsaw:

Check the chain brake at maximum acceleration (once a day)

Check the function of the installation and start lever

The chain must be tensioned, but at the same time move freely with your hand.

Do not spill fuel and oil during refueling. Prevent dirt from entering tanks when refueling.

Sharpen the chain after replacement and whenever necessary.

Having decided on the type of chainsaw, pay attention to its characteristics, which must be taken into account in order to make the right choice.

The life of a chainsaw is defined by masters and amateurs differently. Non-professionals consider the end of the work resource as a complete exit

tool failure, specialists. the first major engine (or reduction in compression by 40%).

To maximize the life of the chainsaw will help caring for the tool. Always choose the optimal chainsaw mode for operation and do not allow significant overloads.

The cutting head condition directly affects the cutting speed. If the chain is dull, the efficiency will significantly decrease, and the risk of a tool failure, on the contrary, will increase. This is due to an increase in engine load. For this reason, it is recommended to regularly correct the chain. You also need to pay attention to checking compliance with the norm of the shape of the cutting tooth and

What could be the reason that the Stihl MC 180 saw does not start?

Because If you still have gas in the tank, then 80 percent you need to clean the carburetor. this is the first. The second. the saw starts up if fuel is supplied to the cylinder, there is a spark and compression. The lack of fuel supply can be seen by a dry candle (we disassemble and clean the carburetor, change the fuel filter, clean the pulse channel). If there is no spark, change the spark plug, if the replacement did not help, then you need to change the magneto. If there is no compression, then the piston, cylinder and oil seals must be changed. For starters, I advise you to remove the muffler and look at the condition of the piston (there are scuffs on the piston or not).

the moderator chose this answer as the best

add to favorites link thank

more than a year ago

If the Stihl МС 180 saw does not start, it is necessary to check the air filter, gas supply, spark plug performance. Although it is enough to open and then close the gas tank cover. Vent the combustion chamber. Remove and dry the candle.