Adjusting a chainsaw carburetor

Chainsaws are very popular gardening tools. They have become very popular with gardeners and those who take care of the territory in their yards. Construction or repair work is not without chainsaws. Chainsaws are even more important in the wood-cutting profession.

Any chainsaw requires proper care, maintenance and tuning before working. If you put too much strain on the tool, it can shorten its working life and cause tool breakage.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare fuel before it is fed into the engine cylinder. This is the function of the chainsaw’s carburetor. It is the one that will determine how well the chainsaw works and how much fuel it wastes when running. If you see that your chain saw is not running smoothly, you may need to adjust the carburetor.

When is it necessary to adjust the carburetor of a chainsaw??

Here is a list of the most common cases in which a chainsaw carburetor adjustment is needed:

- The engine fires, but the chain saw stalls or fails to fire. This may be caused by too much air in the fuel tank.

- Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to run well, the mixture must be of good quality.

- The bolts in the carburetor have lost their hold due to a damaged carburetor housing.

- Getting debris in the carburetor. This can happen if the filter is damaged or low-quality fuel is used. You will need to disassemble the carburetor completely, flush it and readjust it.

- The engine does not idle or does not develop full power.

Important! If the engine doesn’t run well because the piston is worn, adjusting the carburetor won’t work. In addition, it is desirable to clean carburettor from debris along with tuning. this will improve the efficiency of the procedure.

What kind of carburetors are used on Chinese chainsaws?

The most optimal designs of carburetors for chain saws are developed by the world’s leading manufacturers. German STIHL, Japanese Walbro and others. These better designs are hard to beat. That’s why most Chinese manufacturers copy the best models.

Today on sale a large supply of Chinese carburetors for chainsaws.

Some are nameless, from an unknown manufacturer and do not even have markings. They are offered simply for a specific chainsaw model. E.g. carburetor for STIHL MS 361 chain saw.

Others have brand names of well-known brands.

Others have their own catchy names. in Russian transcription King-Cong, Technopark, Reset and others.

Block: 2/6 | Number of characters: 728

Why do carburetors need to be adjusted?

Proper carburetor adjustment increases fuel efficiency. Adjusting the device to factory parameters increases the power of the saw while significantly reducing the cost of wood processing.

Chainsaw carburetor diagram and tool description

Warning! The saw is operated with fuel in the ratio 15:1 (1 liter of oil is added to 15 liters of petrol). It is forbidden to use the tool if the amount of oil is reduced.

Block: 2/6 | Number of characters: 490

Adjusting the carburetor of a Chinese chainsaw

Having mastered the theory and prepared a suitable tool, you can confidently move on to the process. The first manual focuses on domestic and hobby saws with standard carburetor types, which are more widely available than the more expensive brands. Here are the nuances of adjusting the classic model at 45-52 cc (with and without primer). To fully convey how to adjust the carburetor on a Chinese chainsaw, each movement and task is explained.

For understanding, let us briefly identify each screw and its function. L (Low). responsible for low and medium revolutions. H (Hight) adjusts RPM at maximum stroke when throttle is fully open. T (TAS. Throttle Adjustment Screw) adjusts throttle gap when throttle is closed, affecting idle rate when throttle is fully released. The rotation of the screws, is done through special holes located on the left side of the tool.

First of all, you need to warm up the machine for about 1 minute with short accelerated turns. If the engine refuses to start because of the unadjusted carburetor, it should be returned to the factory settings, screwing the screws all the way in (clockwise, without fanaticism) and unscrewing in the desired position. Standard number of revolutions from zero point for 45-52cc carburettor without primer is 2 full turns for the L screw, and 2.25 turns for screw H. With the primer, the low values are slightly different: L = 2.25, and H = 2.25 turns.

For clarity of position when turning, a mark can be made on the handle or rod of the screwdriver. It is possible to draw it with a marker, glue a thin strip of masking tape or mark it with a file.

The carburetor adjustment is made with the engine running and starts with the L screw. By turning the screwdriver counterclockwise (½ to 1 full rpm).), it is necessary to achieve the maximum rpm at idle. The main thing is to keep to a limit so as not to accidentally unscrew the screw completely.

Following the low rpm, the idle speed screw (T), which is responsible for the base position of the throttle, is adjusted. turn the screw until the chain starts to move, then unscrew it (about 1/2 of the way) until the chain stops. This achieves optimum distribution at idle speed.

The final stage of adjustment involves the last screw (H) which is responsible for high RPM when the throttle is fully depressed. To see any change in performance, the throttle must be fully open, so you must hold the throttle for the duration of the adjustment. Simply turn it clockwise or anti-clockwise a little to get an adequate engine sound. Without tachometer, this operation is done by ear, trying to achieve a moderate stroke (the saw should not roar).

When measuring with a tachometer (on a 45 engine), achieve the following values: 10,000 rpm for maximum stroke and about 3,000 for idle. For motors with other displacements, the plus and minus values are similar.

For a more complete and clear representation of the process, check out the following video, demonstrating how to adjust the carburetor on a Chinese chainsaw. The video contains valuable Комментарии и мнения владельцев from an experienced repair technician, and shows how to perfectly adjust the tachometer. Even if you adjust by ear, you can be guided by the sound of the engine from the video.

Adjusting the carburetor of a Husqvarna chainsaw

For the most part, the procedure is almost completely similar to the above instructions, except for a couple of important nuances. First of all, if you want to adjust the carburetor of a Husqvarna chain saw with your own hands, you should get a special screwdriver with a special tip in advance. The adjusting screws on this brand of chainsaw carburetors, have specific head shapes and require a tool with the original slots.

- First of all, you have to adjust the position of the L screw, which should be turned to reach the maximum idling speed.

- Next the throttle gap is adjusted with the screw T. turns until the chain begins to turn, then unscrews until it stops.

- The high RPMs are adjusted with the H screw, which can be set by the sound. If you don’t have experience, it’s better to use a tachometer.

These points are a brief paraphrase of the above instruction, where each action is explained in maximum detail. If you have any questions, just scroll above, or check out the following video, which shows how to adjust the carburetor on a Husqvarna 137 chainsaw. If you don’t have time, start watching from minute 37, where the adjustment begins. In the rest of the chronometer, the old master shares his experience, tells about the peculiarities of the construction of this model and makes the repair.

How to adjust the carburetor of a chainsaw without a tachometer

The equipment of such devices requires adjustment according to the tachometer. If you improperly adjust the carburetor on equipment without a tachometer, the chainsaw can quickly malfunction. But it is also possible to adjust the saw without a measuring device. Consider the step-by-step instructions for tuning a chainsaw.

Tightening and loosening screws

In the construction of the chainsaw carburetor there are adjusting elements of different classifications. These can be adjusted with a normal screwdriver. There are three such elements in total:

- H screw. Required to adjust the maximum rpm of the equipment;

- screw T. This is responsible for the idle speed setting;

- L screw. Adjusts the low rpm of the chainsaw.

Turning each screw changes the setting. First turn the H and L screws until they are fully seated, but not too tight, and then gently unscrew two revolutions, no more. screw T is tightened all the way in without loosening.

Start the chain saw

After making the initial settings, the equipment should be started. Then loosen the idle speed screw together with the slow speed adjuster for a few seconds to get the machine more stable. In case of low idle, turn back the T-screw.

Checking acceleration

As you increase the speed of the equipment, the stroke should not fail. If there is a problem with this point you need to adjust the RPM to a lower value by turning the L screw.

RPM drop moment

The last step is to catch the moment of torque drop. Do this by adjusting the H screw. But it is very important to watch its twist. you need not overdo it

To do this, you need to squeeze the gas to the maximum power and twist this element. Then you need to catch the moment of over-fueling and rpm drop to start turning the propeller more. This allows you to properly adjust the saw without a tachometer for rpm. Once they have been adjusted, the chainsaw can be operated.

The efficiency of the method

This method of adjustment is effective for those apparatuses in which tachometers are not provided. But it will work effectively only under the following conditions:

- the fuel filter is free of mechanical damage and dirt;

- The exhaust system is not clogged with carbon deposits and allows you to gain high revolutions;

- the ignition system is fully serviceable: the spark plug and ignition module provide stable operation;

- all fasteners are in place and screwed all the way in before starting the adjustment procedure so that you can start to adjust them in the same positions.

If it was possible to carry out the adjustment of the equipment without a device that measures the revolutions of the carburetor, you do not need to do anything else. Only screws should be periodically adjusted if they become loose.

To adjust the carburetor of a chainsaw you do not need to have a tachometer handy. With the help of the adjusting elements can be adjusted the work of this device for a long time without recourse to the service. The main thing is to know how many turns to turn the screws and in what sequence to do it. Then the chainsaw will not need adjustment for a long time.

Chinese models

Adjusting the carburetor of a Chinese chainsaw, for example, Carver, is done in much the same way as the factory models. There are the same three basic adjustment screws L, H, T. Sometimes these models have the ability to adjust the idle speed. But as a rule, workers of specialized services and owners of such saws affirm that it is not always possible to tune a Chinese chainsaw qualitatively at once.

For classic Chinese models, the screw L should be 1.5 turns from the maximum value. The H screw has to be released one turn from its maximum value. The idle speed is adjusted in the same way.

Thus, independent adjustment of the carburetor of a chainsaw is not a very difficult process and can in most cases be carried out by a self-taught person.

What to flush the carburetor of a chainsaw?

To clean the unit from heavy dirt, it is best to use a product that comes on sale in pressurized cylinders. The cleaner comes with a dispenser and a long thin tube, which makes it possible to spray the product in all hard-to-reach places.

It must be remembered that cleaning the carburetor on a chainsaw is performed with the use of flammable chemicals. Work with them it is necessary to wear a special protective mask and only in well-ventilated rooms.

To clean the carburetor on the chainsaw, the unit will need to be partially disassembled. The throttle, adjustment screws, carburetor body and other carburetor parts will need to be washed with a spray can and left to dry completely. Once all the elements are dry, the assembly can be assembled and installed back on the chainsaw.

What tools will be needed to adjust the carburetor

To adjust and adjust the carburetor, the following tools are used:

- Tachometer (a special device for adjusting the carburetor, with its help, the owner of the chainsaw can determine what the maximum number of engine revolutions of this model is, and then carry out the correction according to the manufacturer’s recommendations);

- an adjusting wrench (a special tool, which is often only available in service centers, is not supplied with chainsaws, as it can be used by inexperienced users, which will lead not to adjustment, but to a breakdown of the chainsaw).

Pay attention: adjustment and adjustment of the carburetor of any model chainsaw, as well as its repair should be carried out only by specialists of the service center, while the tool is under warranty.

Independent attempts to clean the carburetor, perform flushing and eliminate the existing malfunctions may not yield the necessary result.

Gasoline is not coming into the carburetor of a chainsaw

If fuel is not flowing into the regular chamber, this can indicate several failures at once. First you will need to check the air and fuel filter. With prolonged use of the saw, these elements absorb large amounts of dust, which further prevents the flow of clean air and fuel. A lightly soiled filter can be cleaned with gasoline, but if the part is clogged with a lot of dust, it will need to be replaced.

Another cause of malfunction is the needle. It is typical for this part to get stuck, especially in chainsaws made in China. To fix the problem, in most cases you just need to move the needle.

If the fuel does not come into the chamber, the owner of the saw should inspect the tool’s glands. These parts lose their tightness after several months of tool use. Over time they begin to leak gasoline, as a result of which the tool ceases to start. Repair is made by replacing glands.

The breather plug is an important starting aid for the chainsaw. It is near the gas tank lid and has two purposes. to keep the air pressure at an optimum level and to keep the fuel at an optimum level. If you want to check the breather plug, you have to unplug the fuel pipe and see how much gas is leaking. If it does not come out at all, then the standard breather is clogged with debris and dirt. In this case you need to clean the element and put it back.

If the fuel does not come into the chamber, it is necessary to check the fuel line. often a Chinese hose is used to complete a budget class tool which loses its tightness with time. In this case, it will be necessary to replace the line, paying special attention to the tightness of the joints of the channel.

Carburetor parts, preparation for adjustment and safety precautions

Before you adjust the carburetor, you definitely need to make sure that the air and fuel filter are clean. Also, make sure that there is no air suction into the engine from the side, otherwise you will not be able to properly adjust the carburetor.

Almost any carburetor in a chainsaw is adjusted with three screws:

- The main jug bolt, which is usually displayed with the letter “H”, it is used to set the maximum engine speed;

- The idle speed nozzle bolt, which is labeled “L” and is used to set the low rpm or idle speed;

- Idle speed adjustment bolt, which is designated differently: “S”, “LA”, “T”

Of course, you can find carburetors with fewer screws. Such carburetors, as a rule, are specially designed to protect their products from improper adjustment.

Before proceeding to the adjustment of the carburetor, you should study the manual to the chainsaw, and especially the part that describes the correct setting of the carburetor.

To set it up safely, follow these simple rules:

- Place the chainsaw on a level and stable surface ( shelf, workbench );

- Point the chain away from yourself and others;

- There must be a safe distance between the working chain and any surrounding objects.

Design and operation of individual units

The chainsaw is designed to be operated by mixing fuel with oil. This solution is then poured into the gasoline tank, from where it is delivered to the engine and ignited by a spark. Further, the motor and the chain path function independently, and in order to set the cutting side in motion, the throttle button must be pressed.

Before each process, it is important to inspect the available components of the chainsaw for proper operation: the chain must be well tensioned, the moving mechanisms must be lubricated, and the air filter must be in proper condition. It is recommended that the tool be cleaned of dirt and shavings when the cut is complete.

Ignition system

Modern gasoline-powered saws are equipped with a non-contact electric starter. Thanks to this structure, the user no longer has to worry about adjusting the gap and cleaning the contacts. This includes the following parts:

The rotation of the shaft generates electrical signals that are transmitted to the spark plug via a circuit. As a result, the fluid ignites.

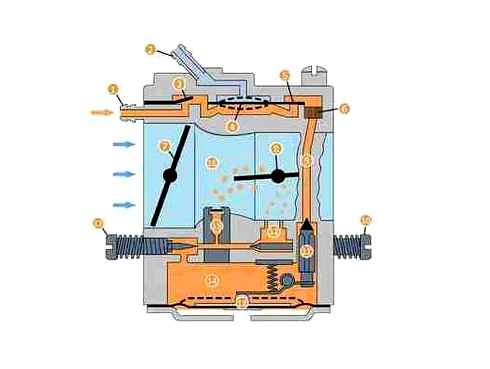

The carburetor assembly

The function of this auxiliary device is to mix the fuel-oxygen mixture. The carburetor has a wind tunnel with a choke. There is also a float inside the unit that regulates the position of the flap. When the chainsaw engine is turned on, the valve opens, oxygen enters the diffuser, mixes with the fuel and moves into the cylinder cavities.

The throttle knob adjusts the width of the open flap, which leads to increased air flow and increases the speed of the piston.

Clutch mechanism

Modern saws have a centrifugal clutch that engages automatically when the throttle key is pressed. The springs are responsible for pulling on the shaft, relaxing in accordance with the increase in frequency of rotation. Next, the drum rotates, and the saw chain begins to come into action. There is a locking band on the outside that blocks accidental activation of the saw. It is important to monitor the condition of the interlock very carefully, because improper use can lead to both tool breakage and human injury.

Fuel equipment

The device is assembled of three components:

Fuel flows from the tank through a hose to the fuel mixing unit, bypassing the gasoline filter (it is located at the end of the tube, which is immersed in gasoline). To facilitate the starting procedure, the fuel system of each chainsaw is equipped with a manual pump. It delivers gasoline directly to the carburetor, which will help make starting much faster.

expensive varieties of saws have a mechanical pump that acts together with the cranking of the starter. A tube is attached to return the surplus to the tank.

Gas Cleaning

Excess fumes must be removed in order to get a quality mixture into the gasoline part. The pre-filter and fine filter parts are responsible for this function. Also in cold weather, an additional element is installed to block the ingress of snow. However, this structure is made up of dense material, which negatively affects power. At other times, standard filters made of kapron, foam rubber or similar materials are installed. The exhaust is removed by turning the flywheel, which ejects the fumes through a special nozzle. Regular checking of this structure is a must. Otherwise it will cause a decrease in performance.

Starter construction

It consists of a cable drum, a return spring and a housing. Such a set is attached to the crankshaft so that when you suddenly pull the handle. Then a spring returns everything to its original position. You are unlikely to get the engine running at the first start and in order to do this you need to apply a certain amount of physical force.

It is however possible to speed up the procedure by enriching the system with a mixture from the tank. Also this cranking allows you to get a spark, thanks to which the ignition. You just have to press the off button to stop the operation.

Stopping the cutting chain

This chainsaw is a hazardous device. That’s why it needs a chain saw cutting chain brake. It is needed to stop in case of a strong impact, which is likely to throw the device into a person. It also stops rotating if the chain breaks during impact. All this is called the inert type of brakes. But there is another (manual) kind of brake. It helps to stop the cranking by acting on the appropriate handle. It is important to note that before sawing it is important to make sure that the brake band is working properly. It is dangerous to your health to use a chain saw with a damaged safety stop.

chain saw starter repair

If the chainsaw is started often, some of the chain saw’s components are often subjected to dynamic loads. As a result, the cable may break, a few teeth in the ratchet may crack, and the shaft will rotate at a much slower rate. Therefore, revision and even repair of the starter. operations carried out sometimes several times per season.

Replacing the cord

When it is pulled, there is constant friction of the cable against the body of the starter. To replace it, the body of the assembly is disassembled, and the ratchet drum is carefully lifted so as not to allow the return spring to come off its sockets. It is better to make such work by two persons: an assistant fixes the spring while you replace wire. After fixing the cable in the handle and in the grooves of the drum, the cable is wound onto the roller and the housing is assembled.

Repair of spring

If the starter spring material is not of good quality, the spring breaks (usually at its connection to the drum, where it forms a loop). It is not necessary to replace the spring in this case. It is enough to carefully clean its surface from dirt and traces of grease, carefully grind the place of destruction, then release the spring at 600 650 ° C (steel spring should become crimson). Cool the spring slowly, and at 100-150ºC you can gently coil its end to the shape of the limiting projection on the drum inner surface (steel will get the needed plasticity) and put it back. Elastic properties of the spring will not change.