How to understand that everything is done correctly

After setting up, you need to start the chainsaw. Check the stability of idling. In this case, the chain must not move. When you press the accelerator, the chainsaw should accelerate steadily and stop without delay.

At minimum and maximum rpm, the Husqvarna 350 should run stably, free from extraneous noise. At the time of operation, there should be no sharp loss of power or shutdown.

Chainsaw carburetor tuning. Or how not to pay repairmen!

Owning a chainsaw makes life much easier even for an amateur, and in some professions this tool is virtually indispensable. However, like any relatively complex device, a chainsaw requires periodic maintenance. Due to untimely or inadequate maintenance, as well as as a result of the impact of both planned and excessive loads, various kinds of malfunctions may appear. For professionals, interruptions or erratic saws reduce efficiency or can lead to a ruined working day. One of the fairly common malfunctions is the incorrect setting of the chainsaw carburetor, which gets lost due to unsuccessful attempts to adjust or displace the adjusting screws for other reasons.

How to remove the carburetor and whether to do it before tuning

In the event that the chainsaw does not develop speed or, on the contrary, works at excessively high, the carburetor can be adjusted without removing.

But if the chainsaw does not start, the rpm freezes at the same level or it is unstable. Chainsaw carburetor tuning will not change the situation. It must be removed to clean or replace parts. In this case, it is necessary to act in the following order:

- Having unscrewed the retaining fasteners, remove the upper saw casing.

- Remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts that hold it.

Disassembly of the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, be very careful when folding the parts onto the prepared fabric. Due to the small size, there is a risk of losing components during disassembly and flushing.

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Channels, tubes and nozzles are blown out with compressed air, if possible, after rinsing them in an ultrasonic bath.

Husqvarna Saw Carburetor Adjustment.

For the break-in mode, so that the parts receive sufficient lubrication, the carburetor setting of the Husqvarna chainsaw is made so that the maximum speed is 600-700 rpm. below working. If it is not possible to set the operating maximum frequency by the tachometer, you should not change the presets with the H screw. It is forbidden to exceed the value of the maximum number of revolutions by the manufacturer. If, after completing the adjustment, the saw chain moves when the engine is idling, turn the screw T counterclockwise to bring it to a complete stop.

For accurate adjustment, the saw must be warmed up for at least 10 minutes, set on a flat surface. The tire should point away from the person making the tune. At the initial stage, the highest idle frequency should be found. To do this, screw L is smoothly turned first from left to right, then vice versa. When the maximum revolutions are found empirically, screw L should be unscrewed counterclockwise by a value from 1/8 to a quarter of a full revolution.

Idling is adjusted by the nozzle marked with the letter T. It must be turned from left to right until the chain starts to move. Then gently feed in the opposite direction until the rotation of the chain stops. The screw H is considered to be installed correctly if the noise of the saw at full throttle without load remains low. If the exhaust is too smoky and the saw makes a lot of noise, the mixture is too rich. It is necessary to turn the H jet clockwise until the correct sound is set. How to properly tune the carburetor, you can watch the video below.

Adjusting the carburetor of a Husqvarna chainsaw

Modern chainsaws have a complex system and consist of several main units that periodically require maintenance and adjustment. In this article, we’ll talk about how to adjust the carburetor on a Husqvarna chainsaw.

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know how it works and how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers.

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for limiting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw. At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode.

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems with the operation of the saw can be caused by defects in this particular element. For example, a valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation, it will be necessary to repair or replace the unit.

Three adjusting screws installed in the carburetor body are responsible for setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode:

- screw (L). adjusts the amount of fuel in the low and medium speed mode;

- (H). is responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Improper adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or malfunction, leading to rapid wear or even seizure.

Tools required for work

Before proceeding with the tuning of the Husqvarna carburetor, you need to take care of having all the tools that may come in handy. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, as the adjusting screws on Husqvarna chainsaws may have different cross-sections. You will have to purchase a special, this is a feature of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

Design and scope

Your Husqvarna 240 chainsaw goes beyond standard firewood functions. With its help, you can easily clear a large area from shrubs and old trees, form the crowns of ornamental plants in the garden, use it in construction for cutting boards. Sufficient power and length of the bar allows you to cut wood both along and across.

Husqvarna 240 Chainsaw Carburetor Replacement

The classic design of the brand is combined in this model with high technical characteristics and ease of use. The Husqvarna 240 saw is in the household class, but its performance is not much different from professional tools. Manufacturers have provided in this saw such necessary functions as easy start, double air purification, vibration reduction. Ergonomic control levers and handle provide maximum comfort during work and reduce the strain on the operator. The main components of the mechanism are located in such a way as to speed up and simplify access to them in case of repair.

If you follow the operating instructions and regularly carry out preventive inspections of the chainsaw, repairs can in most cases be avoided. But even in the event of a breakdown, the tool will not cause you significant inconvenience. original spare parts can be easily purchased and replaced. The detailed structure of the Husqvarna 240 chainsaw is shown in the diagram below:

Nuances of adjustment

After making the adjustment, the chainsaw should easily pick up and drop speed, work stably at low and high speeds. If the saw chain rotates at idle speed after adjusting the carburetor control screws, this is a sign that the adjustment has been made incorrectly and it is necessary to correct the position of the screw (T).

Also, when adjusting the Husqvarna carburetor, it is worth considering the response time of the chainsaw to the rotation of the screws. The settings do not change immediately, but within five, ten seconds.

One of the indicators of an incorrect adjustment is a strong smoke during the operation of the saw, which indicates a large amount of fuel entering the combustion chamber. If such a situation arises, you need to correct the position of the screw (L).

The “Husqvarna 240” chainsaw described in this section, the technical characteristics of which are of interest to you, has a 40 cm tire and a capacity of 2 liters. of. The engine power is 38.2 cm 3 and the fuel tank. 0.3 liters. Oil can be poured into the tank in the amount of 0.2 liters. Before purchasing this equipment, please note that it belongs to the household class and weighs 4.7 kg. The number of connections in the equipment is 56, the width of the slot. 1.3mm, but the noise level is 100.7dB.

Chainsaw Specifications Husqvarna 240

At the heart of the Husqvarna 240 is a 2-stroke engine with carburetor. Powered by a gasoline-oil mixture. The service life has been increased due to improvements in the crank assembly and a special coating of the cylinder. Fuel economy is reduced by 20% thanks to the innovative X-Torq system, which also reduces the harmfulness of exhaust gases. Capacious fuel tank and low fuel consumption extend the operating time of the tool, without interruption for refueling.

The rest of the saw has the following technical characteristics:

- productivity. 2 liters. from.;

- chain pitch. 3/8 inch;

- fuel tank capacity. 300 ml;

- oil tank. 200 ml;

- tire length. 40 cm;

- weight. 4.7 kg.

What is important to remember the consumer

Chainsaw “Huskvarna 240”, specifications which should help you make the right choice, a fine-tuning file is required after purchase. In this case, we are talking about setting carburetor. It is also important to remember that this equipment does not have an oil flow control system for chain lubrication, but it often happens that the oil tank empties faster than the tank intended for the fuel mixture.

The structure and principle of operation of the Husqvarna carburetor

To successfully tune your Husqvarna chainsaw carburetor, you need to know how it works and how it works. In fact, everything is not as difficult as it seems at first glance.

The saw carburetor has a built-in fuel pump, which is responsible for transporting a mixture of gasoline and oil, as well as a diaphragm, a needle valve with a rocker arm. Their joint work allows metering the fuel supply to the main chamber and two dampers.

One of the valves is designed to adjust the fuel supply to the cylinder when the gas is pressed, it is called the throttle, the second is responsible for limiting the air supply from the air filter to facilitate starting a cold Husqvarna chainsaw. At the moment when the operator cuts off the air supply to the carburetor with the help of the air damper, the fuel mixture becomes leaner and its supply to the cylinder increases, due to which the chainsaw starts much easier than when a cold start is carried out in normal mode.

In the operation of the Husqvarna carburetor, a nozzle valve is involved, which atomizes the fuel and prevents air from entering the main chamber. Often, problems with the operation of the saw can be caused by defects in this particular element. For example, a valve, if the chainsaw is not stored properly, may stick, the fuel supply will stop, which will make the engine impossible to operate. Also, irregularities in the operation of the injector can cause air to leak into the main fuel chamber of the carburetor. In such cases, adjusting the position of the adjusting screws will not correct the situation, it will be necessary to repair or replace the unit.

Three adjusting screws installed in the carburetor body are responsible for setting the quality and quantity of the mixture, as well as the number of revolutions of the crankshaft in idle mode:

- screw (L). adjusts the amount of fuel in the low and medium speed mode;

- (H). is responsible for traction at high speeds and their number;

- (T). changes the position of the throttle valve, thereby regulating the amount of fuel mixture entering the cylinder and the operation of the engine of the tool in idle mode.

Husqvarna 240 Chainsaw Carburetor Cleaning

Screws (L) and (H) cannot be adjusted without specific knowledge and experience. Improper adjustment of the quality and quantity of the fuel mixture can cause the engine to stop working or malfunction, leading to rapid wear or even seizure.

Tools required for work

Before proceeding with the tuning of the Husqvarna carburetor, you need to take care of having all the tools that may come in handy. To carry out this type of work yourself, you will need:

A regular slotted screwdriver will not work for adjustment, as the adjusting screws on Husqvarna chainsaws may have different cross-sections. You will have to purchase a special, this is a feature of repairing Husqvarna chainsaws, they did everything so that the saw could be repaired only in a specialized Husqvarna service.

Design and scope

Your Husqvarna 240 chainsaw goes beyond standard firewood functions. With its help, you can easily clear a large area from shrubs and old trees, form the crowns of ornamental plants in the garden, use it in construction for cutting boards. Sufficient power and length of the bar allows you to cut wood both along and across.

The classic design of the brand is combined in this model with high technical characteristics and ease of use. The Husqvarna 240 saw is in the household class, but its performance is not much different from professional tools. Manufacturers have provided in this saw such necessary functions as easy start, double air purification, vibration reduction. Ergonomic control levers and handle provide maximum comfort during work and reduce the strain on the operator. The main components of the mechanism are located in such a way as to speed up and simplify access to them in case of repair.

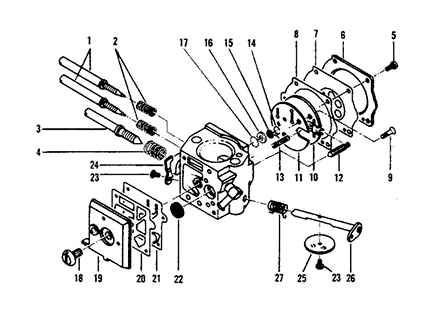

If you follow the operating instructions and regularly carry out preventive inspections of the chainsaw, repairs can in most cases be avoided. But even in the event of a breakdown, the tool will not cause you significant inconvenience. original spare parts can be easily purchased and replaced. The detailed structure of the Husqvarna 240 chainsaw is shown in the diagram below:

How to properly adjust

For this, the device has 3 adjusting nozzles. The idle speed screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter of a turn.

- Hold the gas button with one hand for 15 seconds. At this time, we turn the H jet to the right until it stops and reaching the maximum speed. Then we turn it back one and a half turns, or until the “squeal” of the engine disappears.

- After releasing the throttle, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture.

If this happens, it is necessary to tighten the jets of the minimum and maximum speed until they stop. Then turn them back one and a half turns and try to start the saw.

How to remove the carburetor and whether to do it before tuning

In the event that the chainsaw does not develop speed or, on the contrary, works at excessively high, the carburetor can be adjusted without removing.

But if the chainsaw does not start, the rpm freezes at the same level or it is unstable. Chainsaw carburetor tuning will not change the situation. It must be removed to clean or replace parts. In this case, it is necessary to act in the following order:

- Having unscrewed the retaining fasteners, remove the upper saw casing.

- Remove the gasket and part of the air filter by unscrewing the bolts or snapping off the fasteners.

- There is a fuel hose on the right side of the carburetor. We remove it together with the air damper control rod.

- Remove the carburetor from the mounts that hold it.

Disassembly of the carburetor is carried out in accordance with the instructions supplied with the kit. When disassembling, be very careful when folding the parts onto the prepared fabric. Due to the small size, there is a risk of losing components during disassembly and flushing.

All parts obtained in this way are washed in a special liquid, dried and wiped with a lint-free cloth.

Channels, tubes and nozzles are blown out with compressed air, if possible, after rinsing them in an ultrasonic bath.

DIY carburetor repair

If in the process of carrying out a full diagnosis of the Husqvarna chainsaw, carburetor defects were found, then some of them can be repaired without contacting a Husqvarna AB service center. For example, you can independently:

- change the gaskets under the covers of the main chamber and the fuel pump;

- clean or replace the strainer;

- replace the diaphragm or needle valve of the main chamber;

- troubleshoot the fuel pump diaphragm.

Gaskets, diaphragms and a rocker needle valve can be found in the repair kit provided for each Husqvarna chainsaw carburetor model.

Also, if you have some experience, you can try to restore a faulty injector valve, but you cannot guarantee a positive result when trying to restore an injector, if it is faulty, manufacturers recommend changing the carburetor completely.

Husqvarna 240 Chain Saw. Carb Rebuild and Dissassembly

The first thing to do before removing the carburetor from Husqvarna is to clean the saw with a compressor, since dirt can interfere with a quality repair. Next, you need to open the top cover of the chainsaw, remove the air filter, disconnect the rods from the air and throttle control levers. After that, unscrew the screws securing the carburetor.

It is quite easy to disassemble the carburetor body for repair. The main chamber cover is held in place by four screws, which can be removed with a regular screw, the fuel pump cover is secured with one wide screw.

Below is a video that will make it clear how exactly you can repair the carburetor without contacting a Husqvarna service center.

Chainsaw Specifications Husqvarna 240

At the heart of the Husqvarna 240 is a 2-stroke engine with carburetor. Powered by a gasoline-oil mixture. The service life has been increased due to improvements in the crank assembly and a special coating of the cylinder. Fuel economy is reduced by 20% thanks to the innovative X-Torq system, which also reduces the harmfulness of exhaust gases. Capacious fuel tank and low fuel consumption extend the operating time of the tool, without interruption for refueling.

The rest of the saw has the following technical characteristics:

- productivity. 2 liters. from.;

- chain pitch. 3/8 inch;

- fuel tank capacity. 300 ml;

- oil tank. 200 ml;

- tire length. 40 cm;

- weight. 4.7 kg.

How to properly adjust

For this, the device has 3 adjusting nozzles. The idle speed screw (T) is located at the top of the carburetor. Below there is a pair of jets for adjusting the fuel supply at minimum (L) and maximum (H) rpm, left and right, respectively.

The procedure for adjusting the carburetor on a Husqvarna chainsaw is as follows:

- Warm up for 5 minutes.

- Turning screw L, we bring the engine to the highest speed in an unloaded state and return it back a quarter of a turn.

- Hold the gas button with one hand for 15 seconds. At this time, we turn the H jet to the right until it stops and reaching the maximum speed. Then we turn it back one and a half turns, or until the “squeal” of the engine disappears.

- After releasing the throttle, turn the idle screw (T) clockwise until the chain starts to move. After that, we rotate it in the opposite direction until the chain stops moving.

During the adjustment process, a situation may arise in which the chainsaw stalls. This may be due to excessively twisted jets, too rich or poor mixture.

If this happens, it is necessary to tighten the jets of the minimum and maximum speed until they stop. Then turn them back one and a half turns and try to start the saw.

Factory settings

The factory default setting for the Husqvarna carburetor is the position of the screws (H) and (L), in which a working chain saw is guaranteed to start. For Husqvarna tools, this is one and a half turns from fully tightened screws (H) and (L). In the process of adjustment, you must first set the screws to the standard position, then start the chainsaw and make precise adjustments to the power, the number of maximum revolutions and idle speed.

How to adjust the carburetor on a Husqvarna 240 chainsaw?

Any technique is subject to breakdowns from time to time. The main malfunctions of the Husqvarna 240 chainsaw are associated with the repair of the carburetor, other components of the fuel system, and malfunctions of the oil pump. If the oil pump breaks down, the chain for the Husqvarna 240 chainsaw stops rotating due to lack of lubrication. Also, damage to the gas tank or fuel hoses can be the reason why gas is leaking out of the saw. If the saw has completely stopped starting, first of all, you should make sure of the quality of the fuel mixture, check the spark of the spark plug. If necessary, clean the spark plug or replace it with a new one, adjust the carburetor.

Adjustment of the carburetor is also required in cases where the chainsaw began to start poorly, stall under load, and also if the type of fuel or operating conditions have changed. It is worth adjusting the carburetor after pre-cleaning the air filters and warming up the engine.

Then proceed according to this algorithm:

- Screw L turns to the maximum. Then immediately return the screw a quarter of a turn back.

- While holding the throttle grip, turn screw H a quarter of a turn.

- Release the throttle and turn the screw T clockwise until the chain starts to move. Then immediately turn the screw back until the chain stops.

The location of the corresponding screws is shown below:

How to properly adjust the carburetor of a Husqvarna chainsaw with your own hands

The chainsaw is an indispensable tool for people living in private households. It is a mechanism consisting of carefully fitted parts and assemblies.

Like any mechanism, it requires periodic maintenance and adjustment. Especially because of poor quality fuel. Consider the principles and procedure for adjusting the carburetor of a Husqvarna chainsaw.