Throttle flap

The throttle valve is installed in the carburetor body and is responsible for increasing the supply of the fuel mixture directly to the engine cylinder. At the moment of pressing the gas, the throttle valve opens slightly, thereby increasing the throughput of the channel and fuel from the carburetor cavity, rushes into the cylinder in a larger volume.

Combustion of a larger volume of fuel increases the amount of generated energy, which affects the power and speed of the processes. The damper is installed on the shaft passing through the entire carburetor body. At the exit of the shaft from the housing, a mount for the gas cable is installed, next to it is a cone-shaped adjusting screw responsible for adjusting the idle speed. By tightening the screw, you can slightly adjust the position of the shaft and the damper installed on it, thereby increasing or decreasing the idle speed, slightly opening or vice versa closing the damper.

Sticking injector valve. frequent breakdown and how to avoid it?

A common cause of carburetor failure on a STIHL chainsaw is a sticking valve in the injector. The reason for sticking is a violation of the storage of the chainsaw, or rather the instructions of the manufacturer STIHL 180 for proper preparation for storage.

As follows from the instructions, before long-term storage, it is necessary to drain the fuel from the tank, then start the saw and burn the gasoline from the carburetor. Failure to comply with this elementary rule entails the following consequences. The forsknui valve, being in direct contact with the fuel, sticks to the body, since the gasoline evaporates little by little and only sticky oil remains. It is impossible to replace the nozzle, since they are not in the repair kit, you can only try to knock it out and rinse it, which is not always possible to do without damaging the nozzle.

Fuel pump

A fuel pump is installed directly in the carburetor body, which operates under the action of an air pulse from the crankcase of the chainsaw, which is transmitted through special channels. A diaphragm is installed in the pump, it is she who is responsible for pumping fuel under the action of an impulse. A gasket is installed between the diaphragm and the body, which is responsible for the tightness of the fuel pump.

How to adjust with your own hands, the nuances of the setting

The carburetor of the STIHL 180 chainsaw, indiscriminately, can only be adjusted for the number of idle revolutions. It is impossible to increase or decrease the fuel supply in different modes using special screws. The manufacturer restricts access to adjustments and does not install these screws. How to adjust the carburetor to the correct idle speed is described in great detail in the manufacturer’s instructions.

In the event of certain malfunctions, and with experience, it is possible to increase or decrease the fuel supply by increasing the clearance when opening the needle valve.

To increase the flow, the rocker arm of the needle valve in the distribution chamber must be bent up, and to decrease, down. This regulates the stroke of the needle and, accordingly, the throughput of the valve.

You should not carry out the adjustment yourself, since this must be done very accurately and in case of an error it is almost impossible to return the initial position of the rocker arm.

Air damper

The carburetor choke is installed on the opposite side of the throttle and is responsible for starting a cold engine, it is controlled by the engine control lever. For a cold start, the air damper is completely closed, for normal operation, open.

In the photo, there is a hole in the center, and there is a washer in the middle. this is the air damper

Device and principle of operation

So, the carburetor is designed and manufactured by a STIHL subsidiary called Zama. Original carburetors, on their body have a company logo that guarantees product quality.

The appearance of the Zama carburetor

Chainsaw STIHL 180. device and carburetor adjustment

The STIHL MS 180 chainsaws are designed to make their use as easy as possible for inexperienced users. For this, some of the settings available on more powerful saws have been abolished in the saw carburetor. But the ability to customize is still there, and repair, as well as adjustment with your own hands, is possible.

Nozzle

The fuel injector is mounted in the carburetor body in such a way that it is a connecting link between the distribution chamber and the cavity in which the throttle valve is installed. Simultaneously with the fuel, air is supplied to the nozzle and an air mixture is formed. The nozzle has a check valve that blocks the flow of air in the reverse sequence, that is, from the throttle chamber to the distribution chamber.

STIHL 180 chainsaw carburetor: DIY adjustment, repair, device

The STIHL 180 chainsaw (aka STIHL MS 180) is the most popular and recognizable model of the German brand. This chainsaw is simple and reliable in operation. The only component that requires close attention is the carburetor. This article will discuss carburetor adjustment, repair and maintenance.

What carburetor is used on the STIHL 180 chainsaw

The STIHL 180 chainsaw is equipped with a Japanese membrane-type Zama carburetor. Some users are confused by the China inscription on the carburetor. Yes, indeed they are going to China. But the plant is owned by STIHL (STIHL) and the quality remains high. However, there are also Chinese copies of the chainsaw with the corresponding carburetors. But these saws are usually cheaper than the original.

STIHL 180 chainsaw carburetor repair

The main malfunctions of the carburetor of the STIHL 180 chainsaw include the following.

- Gasoline is not supplied to the carburetor. A commonplace reason is the failure of the fuel pump. The diaphragm has lost its elasticity or is leaky. This happens due to material fatigue with prolonged use. As a result, when the engine is under vacuum, the diaphragm does not rise and does not open the fuel channel with the valve. It can be replaced with a spare one from the repair kit by disassembling the carburetor.

- Gasoline may also not flow due to a clogged filter element (mesh) in the channel between the fuel pump and the needle valve. It is also treated by replacing from the repair kit.

- The carburetor is overflowing. It’s not hard to guess that the problem lies in the main camera. Dirt particles get into the cavity between the needle and the channel, i.e. the valve does not completely close the channel when needed and the chamber is flooded. Very often the membrane stops performing its function due to stretching (natural wear). As a result, when lowering, the diaphragm does not fully raise the needle, and fuel continues to flow. The main membrane is also included in the repair kit. Replacing it is not difficult.

- Owners of STIHL 180 chainsaws often find it difficult to start after a winter standstill. In this case, there is a sticking of the valve in the nozzle. The manufacturer recommends burning the remaining gasoline in the carburetor before storing the chainsaw. Gasoline tends to evaporate and during long storage, engine oil remains in the carburetor, upon contact with which the injector valve begins to stick to the body. As a result, no fuel flows into the diffuser. Since the nozzle is not part of the repair kit, you have to knock it out and rinse it thoroughly. This must be done very carefully.

- If the idle jet or nozzle is clogged, it is enough to blow them with compressed air. Or rinse in gasoline, in 90% of cases it helps. But you cannot use needles or wires, because there is a risk of changing the flow area, thereby changing the throughput of the nozzles.

A common problem due to which the STIHL 180 is unstable is the loss of a retaining ring on the throttle shaft, as a result, it begins to wobble and play, which in turn leads to interruptions in operation.

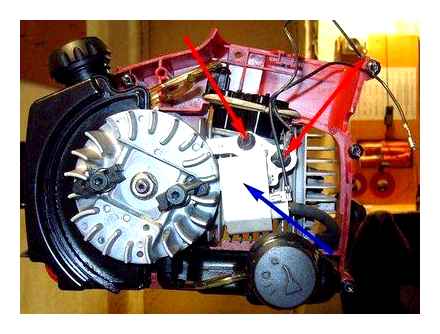

So, you’ve decided to remove the carburetor and diagnose it. The withdrawal procedure is as follows:

- Push the throttle trigger and lower the choke lever down. We turn the latch and remove the cover of the chainsaw.

- We unscrew both fastening nuts with an 8 socket wrench and remove the air filter with the housing.

- We remove the gas thrust (throttle valve) of the carburetor.

- Disconnect the cable from the control lever

- We take out the engine control lever from its place. In parallel, we disconnect the air damper rod.

- Pulling the carburetor towards you, remove it from the studs. Do not forget to disconnect the fuel supply hose.

A more detailed and visual algorithm for dismantling the carburetor from the chainsaw is presented in the video.

As for disassembling the carburetor of the STIHL 180 chainsaw, everything is simple. 1 bolt is unscrewed on the fuel pump cover and 4 bolts on the main chamber cover. This is enough to change all the necessary components from the repair kit.

How To Clean The Carburetor On A Stihl Chainsaw (MS180C) with Taryl

After disassembly, the carburetor must be rinsed in gasoline, and the channels and nozzles must be blown out with compressed air. Under no circumstances should the carburetor be blown out under high pressure and in the assembled state. Otherwise, you can stretch the membrane or diaphragm. Carburetor stops working properly.

In order to assess the condition of the filter mesh and membrane, you need to perform the following sequence of actions:

- Unscrew the screw.

- We assess the condition of the membranes, remove dust and dirt, and, if necessary, replace the membrane with a new one. Everything must be clean under the membrane The membrane must also be free of dirt

As for the STIHL 180 carburetor repair kit, it includes a set of gaskets for covers, a diaphragm and a membrane, a needle valve, a rocker arm with an axle and a spring.

Advantages and disadvantages

Zama carburettors are very reliable and easy to operate. Specifically, a carburetor is installed on the STIHL 180 chainsaw, on which there are no screws for adjusting the quality and amount of the mixture, as we are used to. One screw greatly simplifies adjustment.

The diaphragm carburetor has no significant drawbacks. With such a carburetor, the chainsaw works in any position. For side sawing, vertical, etc.

Despite the aforementioned advantages, the carburetor is sensitive to fuel quality. In addition to clean air from the air filter, the carburetor needs to be supplied with clean fuel from the gas tank. But this is not always possible, therefore, at least once every six months, it must be cleaned and blown through.

How to adjust carburetor of chainsaw STIHL MS 180

Adjusting the carburetor of the STIHL 180 chainsaw

Usually, special screws are responsible for the quantity and quality of the fuel entering the diffuser, by adjusting which we change the cross-section of the fuel channel. But on the used carburetor of the STIHL 180 chainsaw, to facilitate the operation of the saw, these two screws are missing.

The channels are designed in such a way that the optimal amount of fuel enters the diffuser at all engine speeds. And here the LD screw is responsible for the adjustment, the rotation of which regulates the air supply to the idle jet. How does the engine speed change?

So, to adjust the carburetor of the STIHL 180 chainsaw, you need a regular flathead screwdriver and an electronic tachometer (optional). The adjustment algorithm is as follows:

HOW TO ADJUST IDLE SPEED on STIHL MS 170 180C Chainsaw

- Check the air filter. If necessary, replace the filter element.

- Tighten the LD screw counterclockwise to the end, and then unscrew it 2 turns. Attention, the thread is left! To access the screw, a screwdriver hole is provided on the saw body. Start the engine and warm up for 5-7 minutes.

- Turning the LD screw slowly clockwise, freely adjust the idle speed. 2 situations are possible:

- The engine idle speed is very low. The engine does not keep idling. Turn the LD screw until the saw starts to rotate, and then turn the screw 1/2 back (the chain should stop).

- The saw is spinning at idle speed. In this case, slowly turn the screw counterclockwise until the chain stops, then turn the screw another 1/2 turn in the same direction.

If, after all manipulations with the carburetor settings, the chain continues to spin at idle speed, the saw must be returned to the dealer for a service center.

The video below shows a detailed adjustment of the carburetor of the STIHL 180 chainsaw using an electronic tachometer.

How the STIHL 180 carburetor works: device, principle of operation

The main components of the STIHL 180 chainsaw carburetor are the following:

- fuel pump (with internal diaphragm);

- main (membrane) chamber;

- diffuser;

- throttle and air dampers;

- needle valve;

- fuel jets;

- nozzle with valve;

- idle speed adjusting screw.

The principle of operation is as follows. The chainsaw crankcase is connected to the fuel pump in the carburetor by a special channel. Due to the alternating piston stroke, a vacuum is created in the engine crankcase. Due to this, the diaphragm in the fuel pump rises and the valve opens to supply fuel to the carburetor.

Further, the fuel passes the filter element (mesh) and through a special channel enters the main chamber. A control diaphragm is installed in this chamber, which regulates the fuel supply by pressing the rocker arm, which in turn lowers the needle valve.

The vacuum generated in the carburetor diffuser by turning the air throttle valves is responsible for raising the control diaphragm. As soon as the engine starts, the mixture must be leaner. We lower the air damper, the vacuum in the diffuser is minimal, the membrane falls into place.

From the main chamber, fuel enters the diffuser using a nozzle with a check valve, or through the idle nozzles (when the gas throttle is closed). There it is mixed with the intake air and the already prepared mixture enters the engine cylinder. A check valve prevents air from the diffuser from entering the main chamber.

How much does a new carburetor cost

STIHL 180 chainsaws are in great demand in Russia, primarily due to their reliability. The carburetor is no exception and is also quite reliable and unpretentious. Adjustment or repair of the carburetor is required only after long-term operation, not less than 5-7 years (at average workload). The tuning process itself is simplified as much as possible by STIHL engineers, this is the first chainsaw in which only one screw is provided for adjustment.