Warning, counterfeit!

There is also sad news: every technique, popular with consumers, after a certain period of time acquires a fake. Fakes come to us from China and although they carry the brand logos, they do not meet the declared (expected) quality at all. Fortunately, knowledgeable people have even learned to visually recognize the substitution.

They are ready to share this video information on the Internet, we will describe these signs in the article.

- The casting is rough, porous, and of low quality;

- body color is dull;

- The air filter screw is located on top of the chainsaw. instead of the proper end position of the original product;

- The shape of caps of fuel and oil tanks is also different: the original saw has screwdriver caps, while the fake one is simple and slightly convex;

- Serial numbers are completely missing;

- the chain brake is attached on one side, when the original “STIHL” MC 361 chainsaw has a double-sided attachment.

STIHL chainsaw 361 in operation

- The fake chainsaw has a simplified carburetor without an integrated compensator:

- Use of non-original spark plugs without proper STIHL brand logos.

In order to verify the authenticity of the STIHL MS 361 chainsaw, it is advisable to have a look at the Instruction Manual. it will also differ significantly from the original, which you can find on the Internet.

And the final test is this

STIHL and Partner saws

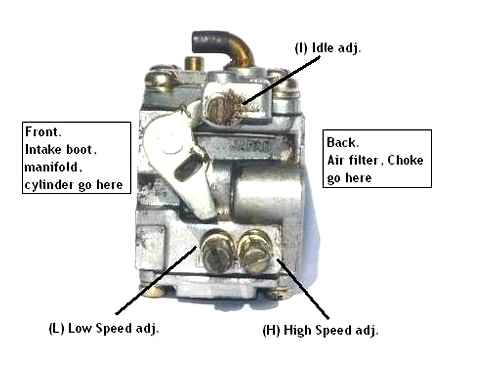

In STIHL 250 and 361 chain saws, as well as in the Partner 351 and 350, carburetor adjustment is done with the help of screws H and L by adjusting the proportions of gasoline and air. if you let them go, you can add a big quantity of fuel and therefore the rpm will be high, on the contrary, they will go down.

Read also: How to calculate energy consumption

The idle speed in Partner chainsaws is adjusted with a screw with the letter T, and in Stihl, as a rule, you should look for the marking LA. The standard setting of the chainsaw is done during the final tests. Generally after such adjustments the percentage of fuel in the working mixture is higher than the air, which does not correspond to the optimal parameters. But these must be retained during the first few hours of operation during the break-in period. After that you can adjust the saw yourself, but it will work well on the factory settings.

But if you decide to adjust it yourself, it is necessary to do it in this sequence:

- L screw adjustment;

- then adjust the H jets;

- after that go to the idle speed adjustment with the screw T (if STIHL chain saw. LA).

First turn the screw L in both directions to find the maximum engine speed. If that point is found, then the same screw should be turned by ¼, thereby slightly reducing the revolutions. If the chain continues to idle, turn the T (LA) screw immediately until the chain has come to a complete halt.

After adjusting the maximum rpm with the H screw, it is necessary to check the frequency with the tachometer. In the case when it does not correspond to the ones specified in the service book, it is necessary to repeat the tuning. If you hear a lot of smoke coming out of the exhaust pipe at maximum engine rpm, the mix is too rich in fuel, and if you hear noises and the engine gets warm, it is lean. Then adjust the idle speed. If properly adjusted, the engine should sound smooth at low RPM and the chain should not move.

No petrol in the chain saw carburettor. repair

The most common cause of this common breakdown is a clog in the fuel foam filter or pipes responsible for the steady flow of fuel into the factory metal engine cylinder. Every third Chinese gasoline-powered tool regularly suffers from these clogs. This is due to the low quality of the built-in filters and tubes that are included with inexpensive Chinese chain saws.

Repairing the malfunction is reduced to removing and washing the contaminated parts.

- Remove the cover of the plastic saw body;

- Clean the space underneath and proceed to remove the hoses and filters. Tubes are attached to the outlet fittings with clamps. To disconnect the hoses without damaging them, you must loosen and remove the clamps. After that the tubes should be blown with compressed air and washed with clean gasoline;

- To remove the filter you must first remove it from the factory housing. After that the element will need to be placed in a container with clean gasoline. After a day the filter can be removed and give it time to dry;

- After flushing all parts should be carefully installed and fastened in place in the carburetor.

This cleaning pattern allows you to thoroughly clean the most vulnerable parts of the fuel system without having to disassemble the entire carburetor.

Preparing the tools

Make sure you have the right tools for the job before you begin. To do the work yourself you may need

The first screwdriver is needed for adjusting the main screws. You can purchase one from your local dealership. When adjusting the carburettor on a STIHL chain saw, you can use the electronic tachometer. This diagram shows how to determine the frequency of rotation of the crankshaft. If you are an experienced chain saw user you can also carry out the adjustment by ear.

Adjusting the carburetor on the STIHL Ms 250 chain saw

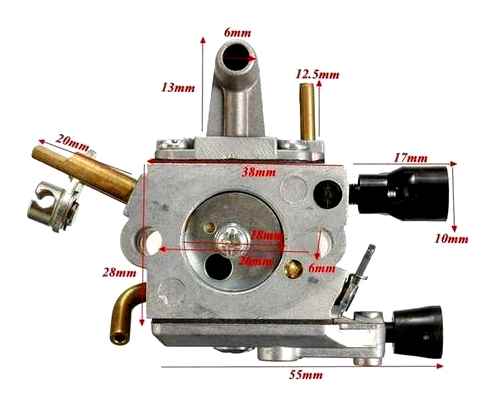

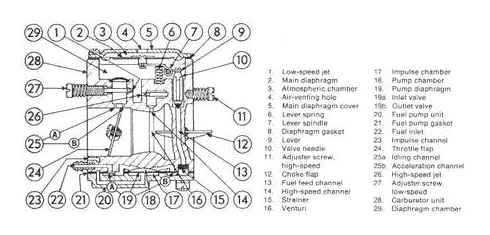

In Fig. Figure 1 shows a modern carburetor for a German-made STIHL 250 chain saw. It is a unit the size of half a human fist. The manufacturer of the mechanism is Walbro, Taiwan. Casing material: rustproof steel alloy. A slide valve is mounted at the bottom of the device, which provides an even flow of fuel-air mixture into the engine combustion chamber.

Here are also the holes for fastening the assembly to the power unit housing. Between the flanges of the mixture and the engine combustion chamber is installed sealing gasket. There is a booster pump under the throttle rod. It consists of a small piston with a rubber ring.

There are a number of user-friendly spring-loaded adjusting screws on the front of the housing:

Correct Way To Adjust Or Tune The Carburetor On A Chainsaw

STIHL chain saw carburetors can be adjusted with these screws.

The carburetor for STIHL 250 chain saws is innovative. To avoid freezing of the mechanism when working during the winter, it is equipped with a special system that performs preheating of the steel case during operation. To do this, the unit is switched to winter operation.

Casing blown with heated air blown from engine. This mode of operation prevents icing up, freezing of nozzles, provides normal fuel-air mixture supply. When switching to summer operation, the hot air damper is closed. Summer mode is characterized by natural cooling of the unit.

Features of STIHL 250 chain saw

| Manufacturer | STIHL | STIHL | STIHL | STIHL | STIHL | |

| Model | 360 | 250 | 440 | 341 | 361 | |

| Cylinder volume, cm³ | 61,5 | 50,2 | 70,7 | 59 | 59 | |

| Power, kW | 3,4 | 2,6 | 4,0 | 3,1 | 3,4 | |

| Maximum rpm.without load, tire | 13500 | 14000 | 13500 | 13500 | 14000 | |

| Torque, Nm | 3,7 | 2,7 | 4,50 | 3,6 | 3,7 | |

| Vibrations at the tube handle, m/s 2 | 3,5 | 3,4 | 4,2 | 3,1 | 2,9 | |

| Vibration at the rear handle, m/sec 2 | 5,5 | 4,3 | 4,5 | 3,1 | 3,6 | |

| Fuel tank capacity, l | 0,63 | 0,47 | 0,78 | 0,69 | 0,69 | |

| Oil tank capacity, l | 0,32 | 0,32 | 0,40 | 0,33 | 0,33 | |

| Unit weight, kg/kW | 1,7 | 1,8 | 1,5 | 1,8 | 1,6 | |

| Weight without reg. tools, kg | 1,7 | 4,7 | 5,9 | 5,5 | 6,6 | |

Chainsaw carburetor adjustment

There are a lot of factors that influence the quality and performance of your chainsaw, but today we’re going to talk about carburetor problems. So many things depend on this machine, including your well-being. You took the chainsaw in your hands, and it does not start, or it starts and starts to sneeze and shoot, with a complete loss of power. Your day is ruined, and in your head thoughts. what is the reason, where to look for a wizard and how much will it cost to repair.

However, you should not despair in advance, most carburetor faults can be corrected with your own hands, or make adjustments in the neighbor’s garage.

STIHL 180 Sore Points

Every tool has its weaknesses and the 180 is no exception, but the worst place is 100% the air filter. The replacement filter element of the 180 is a real piece of crap.

Why the Germans did not change the design and did not put on this model multi-stage mesh filter instead of a piece of incomprehensible, through which all the garbage flies into the carburetor, God only knows. Maybe it’s done on purpose?

Well, the filter needs to be changed regularly. I don’t recommend flushing it.к. After that it loses its shape and at the joints with the body can leak.

The second thing is the crankshaft oil seals. I have faced the situation many times when with intact bearings the oil seals leak, air gets into the crankcase, the maximum RPM increases with all that follows, up to the scoring of the piston. What is it, a factory defect or operating conditions, but the fact is, oil seals are not infrequently the cause of serious engine problems.

Cost of repair and carburetor replacement

If you are not experienced in repairing STIHL chain saw parts, it is best to leave this to professionals. The price depends on the complexity of repair and the region. The average values are as follows:

- gasoline saw diagnostics. 300;

- replacement of the carburetor. 300;

- comprehensive service (the complex includes flushing, installation and adjustment). 1000;

- External cleaning without disassembly. 300;

- adjustment. 300;

- carburetor and engine rebuild. 2000

- Sealing the nozzle. 200.

Regular adjustment of the carburetor can improve the efficiency of the chainsaw and reduce fuel costs. It is recommended to follow the technology precisely or let a specialist do the work.

Algorithm of removal and installation

In cases where the STIHL 180 carburetor needs to be cleaned or disassembled, you will first need to remove the assembly from the chainsaw. This must be done in accordance with a certain algorithm of actions:

- To put a protective cover for a chainsaw on the bar.

- Removing the top cover of the chainsaw.

- Unscrew the two nuts fixing the air filter and carburetor.

- Remove the air filter housing.

- Disconnect the wire from the engine control lever.

- Carefully remove the lever from its seat in the housing, at the same time disconnecting the choke linkage from it.

- Pull the carburetor toward you and disconnect the fuel supply and throttle linkage.

To facilitate disassembly, you can additionally unscrew the rear handle and disconnect the throttle link first from it, and then only from the carburetor. This may be necessary because the chainsaw’s. к. without some experience it is rather difficult to disconnect the pull rod from the carburettor and it is easier to disassemble the knob first.

Install the part in its place, following the reverse order of the algorithm.

When removing and installing the chain saw’s engine control lever, you must be very careful because. к. the seat on the body of the saw is the weak link in the saw and is often broken by inexperienced users.