Chainsaw carburetor adjustment

This procedure is necessary specifically in cases where the household garden tool does not start or, after starting, immediately stalls. Chainsaw carburetor adjustment is also needed when its power has dropped or the amount of fuel consumed has increased significantly.

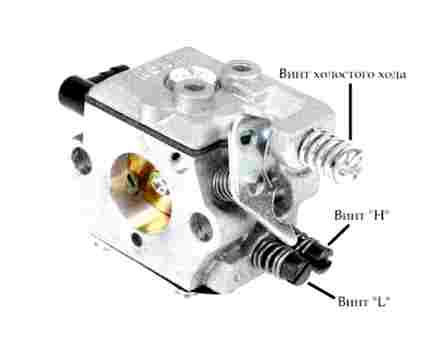

For self-adjustment, each manufacturer includes adjusting screws in the complete set of their garden equipment. The bolt, marked with the letter H, is used to adjust the position of the main jet and the operation of the internal combustion engine at high speeds. Bolt L is required for basic adjustment of the position of the built-in motor-driven idle speed. Accordingly, the T screw is required by the owner of the chainsaw to quickly adjust the idling of the factory engine. In some cases, this bolt is also marked with the letters S or LA..

However, the adjustment may be preceded by the repair of the carburetor itself, when it is not able to fulfill its function as a fuel mixer..

If fuel for some reason does not enter the engine, you need to check the condition of the fuel supply unit. Often the reason is the supply of low-quality gasoline, and therefore the fuel passages are clogged..

If the fuel mixture has stood for a long time, the additives have collapsed, the mixture can clog the passages and grate with sediment. Then a long flushing is required, which is done using solvents in a service workshop..

Features of setting up Chinese chainsaws

Chinese chainsaws, especially newer models, may have some nuances in carburetor settings. Here are the main features:

- to adjust the carburetor of a Chinese chainsaw, you first need to set the idle mode so that the chain does not move along the tire;

- in the medium speed mode, a smoky exhaust may appear, it is removed by turning the lean mixture screw;

- the maximum number of revolutions of the chainsaw engine must not be exceeded (use a tachometer);

- if you adjusted the carburetor on a Chinese chainsaw correctly, when the gas is reset to a minimum, the device will not stall, and will also quickly develop speed.

Video about adjusting the carburetor of a Chinese chainsaw

Video about adjusting and tuning the chainsaw carburetor

How the carburetor works

Regardless of the manufacturer, the principle of operation of the carburetor of internal combustion engines is not the same. For mixing non-combustible air, the carburetor is a device that includes:

- a constricted air tube;

- fuel supply system;

- regulating air damper.

Air at atmospheric pressure, passing through the air cleaner, is supplied to the narrowing zone, where its flow rate is regulated by a flat damper overlapping the cross-section. After constriction, a vacuum occurs in the pipe. In the course of the vacuum sucks fuel from the fuel supply tube, the exit from which is required to be regulated by a fuel needle connected to the float chamber by a nozzle. Chainsaw carburetor device by and large is not characterized by fuel mixers of internal combustion engines.

The principle of mixing is to regulate the air damper, the level of the float, starting from the degree of vacuum. Before adjusting what is responsible for supplying the fuel mixture to the chainsaw. We open the air – not just fuel comes in, the engine rises. The correct ratio of the combustible mixture depends on the precise adjustment chainsaw carburetor. Adjusting the carburetor on a chainsaw fuel delivery as adjust. If there is a lot of air in the fuel, the power drops, the mixture is called lean. With a lack of air, there is a large fuel consumption, incomplete combustion, carbon deposits on the cylinder are not exhaust of unburned fuel. This says the mixture is oversaturated..

Chainsaw Ural, according to the instructions, requires running-in with the use of an enriched fuel mixture. Therefore, the carburetor comes from the factory with the adjustment during the running-in. When switching to operating mode, the node is reconfigured.

Signs of good chainsaw carburetor performance:

- the engine runs smoothly, sounding like a four-stroke;

- fast set of revolutions;

- the chain does not spin when idling.

How to adjust the fuel flow on a chainsaw

What to do if gasoline does not flow into the chainsaw carburetor?

The first of the reasons for this breakdown is the clogging of the fuel filter with dust and dirt. This happens due to the presence of a large amount of harmful impurities in gasoline and used engine oil. Over time, they accumulate on the surface of the filter, due to which it loses its ability to pass fuel. To solve the problem, you will need to thoroughly clean the filter by rinsing it in a bath with a cleaning agent. If the filter has holes or other signs of wear, it must be replaced immediately..

The second cause of breakdown is contamination or breakage of the tube through which fuel is supplied to the carburetor. If the hose is not cut off, it will be enough to thoroughly blow it out with compressed air from an aerosol for cleaning. If the tube is broken, it will need to be replaced. When installing the hose, the places of its joints with the fittings must be carefully treated with a sealant..

There is another malfunction that occurs much less frequently than the previous two. It consists in a breakdown of the valve that regulates the rate of fuel supply to the carburetor. If dust or small chips get inside its mechanism, then the flap is blocked and remains in the closed position. Repair of the assembly can only be performed with the replacement of the damper, since it, most often, cannot be restored.

The new chainsaw is adjusted to the recommended mix. All you need to do is fine-tuning with three screws; you don’t need to disassemble the carburetor. How to adjust the carburetor on a chainsaw, how to adjust the fuel flow. The purpose of the adjusting screws:

- “L” regulates the fuel supply at low rpm;

- “H” is needed to regulate the maximum fuel supply;

- “T” idle speed control.

How the carburetor works

In different models of chainsaws, the structural device of the carburetor may differ, however, the principle of operation of this part is always the same: the forced air flow moves in the direction of the air (pulse) channel, the air is regulated by the air damper. Entering the impulse channel, the air changes its speed. The speed change is influenced by a special valve that closes the air intake hole. Fuel is supplied to the air duct and mixed with the air flow. As a result, a combustible fuel-air mixture is formed, which then enters the engine and burns there..

Figure 1. Diagram of the principle of operation of the chainsaw carburetor

Figure 2. Husqvarna 137 chainsaw carburetor

Figure 3. The principle of operation of the fuel system on the example of the carburetor of a chainsaw with a two-stroke engine

The main task of the carburetor is the continuous and high-quality operation of the engine..

Repair: basic malfunctions and their elimination

Most often, problems with the fuel supply arise when the tiny openings of the nozzles are clogged and when the membrane-rocker pair fails. The brass cross of the rocker arm can bend or jump out of the landing site and cut off the fuel supply when it is not needed. The soft membrane can dry out over time, lose elasticity, warp and also incorrectly shut off the fuel supply.

This is what the new membrane looks like (right)

There are two ways to clean the jet hole:

- The carburetor is purged with compressed air from a compressor or pump. The gasoline supply hose is removed from the tank, an air hose is put on the fitting and the carburetor is pumped.

- If the problem is not resolved, it is removed, disassembled, access to the jets is obtained, and the entire carburetor of the chainsaw is cleaned and rinsed. The jet is cleaned in place or unscrewed (it is threaded).

The soft membrane on old carburetors most often fails after long interruptions in operation. It just dries up without gasoline. Therefore, before starting after a long downtime (a year or six months in summer in the heat), you need to open the gas tank tap, fill the Ural chainsaw carburetor with gasoline, and do a test run after half an hour.

If the carburetor is several decades old, the membrane material can change its properties simply from time to time..

An unusable membrane cannot be repaired, it is simply replaced.

Lack of tightness

Other malfunctions of the KMP-100U carburetor are loss of tightness. The gaskets between the carburetor and the engine body, and between the parts of the carburetor, must not suck in air during operation and leak fuel when the engine is turned off..

The gaskets can deteriorate for the same reasons as the membrane, that is, dry out, become fragile from time to time.

How to adjust the carburetor on a Ural chainsaw

Adjustment of the KMP-100U is simple and accessible to every user. The carburetor has two adjusting screws (analogs of the H and L screws on some modern imported chainsaws) for setting the average and maximum speed. They are accessible from the outside, no need to disassemble the case for adjustment.

Above you can see 2 screws with springs, these are the adjusting screws

The Ural chainsaw carburetor is adjusted on a warm engine. Initial tuning should be carried out on a warm, but muffled engine..

- Both screws can be screwed in all the way, but without excessive force. Screws have sharp, thin tips that can deform if overtightened.

- Then the first screw, which is closer to the cylinder, is unscrewed by 1 turn. The second screw is unscrewed by 0.5 turns.

- Start the chainsaw, give full speed. In case of a failure of revolutions, the screws can be unscrewed by another 1/3 or 1/4 turn, listening to the operation of the engine and finding the optimal mode.

It is impossible to know the exact number of revolutions. On each chainsaw, this is individual, depending on the characteristics of the carburetor, the state of the piston system, the quality of the fuel, the temperature outside, etc..

To adjust, it is enough to remove the cover, there is no need to remove the carburetor itself from the chainsaw

Ural chainsaw carburetor repair kit

For carburetors KMP-100U, repair kits are still sold – a set of gaskets, a membrane, in other configurations there may be a rocker arm with a spring to it.

The spring defining the position of the rocker arm must never be stretched. The rocker cross must lie exactly, strictly parallel to the plane of the carburetor, otherwise the fuel supply will be incorrect.

In the days of the USSR, when not only chainsaws were in short supply, but also spare parts for them, the gaskets were made themselves, from sheet paronite.

In the absence of paronite, the gaskets were made of thick single-layer paper (not cardboard) coated with oil paint.

Device and principle of operation

The carburetor of the Ural KMP-100U chainsaw is a membrane type. It does not have a float chamber and a floating float with a needle that cuts off the fuel flow as the chamber fills like older carburetors. This gives the advantage that the engine of the Ural 2t Electron chainsaw can work in any position, even upside down. The float carburetor cannot work in an inverted position..

Setting Fuel Mixture to Factory Settings, Chainsaw

The KMP-100U device is fundamentally the same as that of all two-stroke engine carburetors. Its function is to prepare a gasoline-air mixture and supply it to the combustion chamber..

The system of the KMP-100U carburetor can be considered complex, because it must ensure the operation of the engine in three modes:

- Launch.

- Idling.

- Maximum RPM.

For each mode, special channels for the supply of fuel, air and the position of the dampers are involved.

The appearance of the new KMP-100U carburetor used on the Ural 2T Electron chainsaw

When starting a cold engine, the conditions for the formation of a working air-fuel mixture in the combustion chamber are very unfavorable for the following reasons:

- low crankshaft speed with a manual jerk of the starter, weak compression of the fuel mixture in the combustion chamber;

- some of the fuel is lost on the cylinder walls;

- low temperature makes ignition difficult.

Therefore, to facilitate starting, the supply of a rich mixture is required – more gasoline, less air. The air supply flap from the air filter in the cold start mode is closed, and the gas supply is increased by pumping (suction) with a primer.

After starting the engine, a vacuum is created in the combustion chamber during the piston stroke, so the fuel mixture from the carburetor begins to be sucked in there. More air is required for oxygen supply and complete fuel burnout. Air damper opens.

When the throttle is pressed, the throttle valve opens fully, gasoline and air flow in full flow, the engine runs at full speed.

The flow of gasoline at this moment is regulated only by the calibrated orifice of the jet in the carburetor.

In addition to the position of the air and throttle valves, calibrated orifices of the nozzle, the fuel supply is also regulated by a membrane. When the carburetor is filled with gasoline, the membrane presses on the rocker arm with a needle and cuts off the supply of excess fuel from the gas tank to the carburetor.

Walbro carburetor for Ural chainsaw

On the Ural 2t Electron chainsaw, the German carburetor from the Stihl MS 660 chainsaw, which is close in power, has proven itself well. Its fuel mixture supply almost completely corresponds to the Ural 2t Electron engine. Perfect fit is achieved by adjusting the screws. Also, the fitting dimensions are almost identical (between the holes on the carburetor and the studs on the engine). The difference of 1 mm is eliminated by sharpening both holes with a file, each by 0.5 mm.

This is how the Walbro carburetor looks like, which is put on the Ural chainsaw

Modification of the Ural chainsaw carburetor: we eliminate factory defects

Since the KMP-100 carburetor was the only one produced in the USSR, several million of them were produced. With such a mass and long-term production, the product could not be raw and unfinished. All the shortcomings were taken into account, finalized already at the beginning of production, and the factory, constructive and technological, KMP-100 and KMP-100U had no shortcomings.

All their problems arise from improper operation (low-quality fuel) or simply from physical wear and tear over time.

The KMP-100U carburetor requires improvement when the engine from the Ural 2t Electron chainsaw is used for another purpose. For example, like a boat motor.

In this case, it is not the carburetor itself that is subject to alteration, but the idle speed control system located on the throttle handle..

How to adjust the carburetor on a chainsaw?

All saws from the factory come with an adjusted carburetor..

And, since it is protected by a plastic case, it does not need additional adjustments for a long time. And you should intervene in its work only when the saw, with a guaranteed serviceable cylinder-piston group, begins to stall, which is most often caused by a lack of fuel and, as a consequence, an excess of air.

The second symptom of poor carburetor performance is excessive fuel consumption and increased smoky exhaust, indicating an excess of gasoline in the mixture. In this case, clean (or replace) the air filter and make sure that the cause has not been eliminated before climbing to the carburetor..

Sometimes a violation of the carburetor adjustment occurs gradually, due to increased vibration of the tool, as a result of which the adjusting screws can turn from their original positions.

First of all, even before removing and disassembling the carburetor, you should try to adjust it. For this:

How To Tune A Chainsaw | Adjusting The Carburetor

Carburetor adjustment should be started with screw L, which adjusts the fuel supply at low speeds. By rotating it, you should achieve the highest rpm. Turns increase when tightening this screw.

Next, use the H screw to adjust the quality of the mixture. If the saw smokes, this is a sign of a rich mixture, and if it squeals, it is a poor one. In the first case, screw H should be tightened, and in the second, vice versa. Be very careful with this screw; incorrect adjustment can even damage the saw. In no case should it be tightly twisted..

The adjustment is completed by setting the idle speed, which is set with screw T. At high speeds, the clutch cams are in the open position and the saw chain moves. The T screw adjusts the throttle adjuster stop from the outside and does not fit inside the carburetor. You should not keep the engine speed too low, while the load on the crank mechanism increases, but the chain must also stop at idle. This screw in some saws may have a different letter meaning.

Some carburetors initially have only one setting – idle, in which the quality of the mixture is set by the parameters of the jets and factory settings initially. The idle speed adjustment video on such carburetors is also suitable for all other types of similar devices:

A violation of the saw operation modes without screws for adjusting the speed and quality of the mixture may indicate that it needs to be repaired or at least cleaned.

It remains to add that the final adjustment should be made only on a heated saw that has worked for at least 10 minutes..

Chainsaw carburetor adjustment, disassembly, search for typical faults

Most modern chainsaws have very similar carburettors with a few exceptions..

Often the difference lies in the quality of the parts and the presence or absence of a primer connection tube – a manual pre-priming pump.

Therefore, we will consider them almost impersonal, without going into the nuances..

The device and principle of operation of the chainsaw carburetor

The task of the carburetor is to prepare a mixture of gasoline and oxygen and feed it into the cylinder in doses. Mixing takes place in the diffuser (16) – the converging part of the carburetor, where the air flow is accelerated. Gasoline of various fractions (coarser and finer) and purified air after the air filter enter the diffuser through 2 nozzles (15) and (12). Its amount is regulated by the air damper (7) at the diffuser inlet. The amount of the ready-mixed mixture supplied to the cylinder is regulated by another valve (8) behind it..

Two screws (17) and (10) (L and H) regulate the amount of gasoline passing through the jets. The amount of gasoline in the float chamber (14) is regulated by a needle valve (11), the operation of which is monitored by a membrane (13). The second diaphragm (4) doses the amount of fuel supplied to the chamber depending on the engine speed. On the way, it is filtered through a filter (6).

If both filters, air and gasoline, are clean, the channels and nozzles are not clogged, the membranes are intact, and the needle valve reliably regulates the amount of gasoline in the float chamber, then the carburetor is working properly, and for normal preparation of the mixture it is necessary to correctly adjust the amount of gasoline supplied through the nozzles. We will not talk about mechanical wear of metal parts of the body and valve rods of the carburetor, because it will be cheaper to simply replace it than to repair it..

Self disassembly and repair of the carburetor

Let’s make a reservation right away: if you are not an expert in this type of activity, then it is better to contact the service center. Sometimes the cost of a carburetor can be as high as a third of the cost of the entire saw.

But, if you decide to disassemble the carburetor yourself, we recommend finding a couple of free hands, putting a video recorder in them and taking a close-up video of the carburetor disassembly in detail. This will help unambiguously when assembling it, because it is almost impossible to mark small parts for the correct order of its carrying out..

Almost 80% of carburetor failures can be blamed on the nozzle supplying fuel to the diffuser. But, before cleaning it, we recommend stocking up on a repair kit, which necessarily includes membranes, gaskets, and sometimes this jet with a needle valve.

Even if disassembly reveals their integrity, it will be better to install new ones, because even a micronized change in the parameters of the membranes can affect the operation of the device..

If the jet has to be cleaned, then it is better to do this by first unscrewing it with a thin calibrated wire. It is better to blow the second jet with your mouth using a tube-guide or a bicycle pump, but in no case with a compressor – there is a high probability of damage.

We have compiled a video about the repair of a Stihl 180 saw carburetor, which has only an idle screw. But its internal structure is the same as that of almost all chainsaw carburetors:

And the point here is not only that the missing adjusting screws clutter up the picture, distracting from the essence of the process, but that this disassembled carburetor can also be slightly adjusted by adjusting the quality of the mixture. If your Stihl suffered from increased fuel consumption and smoked before the carburetor was repaired, then you can reduce the fuel supply by increasing the clearance of the needle valve by slightly bending its rocker arm. The reverse procedure can increase the fuel supply.

Always clean the filter when disassembling. To remove deposits, you can use the WD-40 preparation, but if you remember that this is actually white spirit with the addition of oil, then you can do with them. And the use of kerosene or acetone is also allowed..

The simplest, or preliminary, adjustment of the chainsaw carburetor can be done as shown in the video, and the final adjustment can be made after the saw has warmed up:

Dear readers, if you have any questions, ask them using the form below. We will be glad to communicate with you;)