Chainsaw carburetor repair. adjustment, adjustment

A chainsaw is also needed in construction, gardening, and landscaping. its presence greatly simplifies a number of woodworking tasks. The main node of this tool is the engine, the operation of which depends largely on the condition and settings of the carburetor. This is where the fuel mixture is prepared. So if the saw won’t start, stops, or doesn’t deliver the expected power, it’s very likely that the carburetor isn’t working properly. Fortunately, in many cases you can cope with it yourself. Only for this you need to know and understand the device and principle of operation of this unit and, of course, the chainsaw itself.

The carburetor’s main function is to mix fuel with air in the right proportions. If the latter is disturbed, it has an almost immediate effect on engine operation.

STIHL MS 181 C BE chain saw carburetor

Chainsaw carburetors may differ in design. However, their basic elements and principle of operation remain approximately the same.

It is an aerodynamic tube, across which the air damper is located. with its help the intensity of the air supply is regulated.

This part is where the base tube is drained. here the airflow rate increases, i.e.е. Air is always supplied to the carburetor under some pressure.

This is where the fuel comes in contact with the air flow. The fuel flows into the atomizer from the float chamber through the nozzle (metering device).

Is a container that keeps the fuel mixture in a stable condition.

Construction diagram of a chainsaw carburetor

The basic principle of a chainsaw carburetor is as follows:

- When starting the engine, the main flap opens and a jet of air is blown into the air duct at a certain speed;

- the speed of airflow and the level of the float in the chamber are controlled by the position of the choke, namely by the difference in pressure between the float chamber and the air duct;

- fuel from the float chamber is sucked into the jets, and from there into the diffuser;

- passing through the diffuser, the air captures the fuel coming in;

- the resulting mixture is fed into the cylinder chambers through the intake funnels.

the pressure in the float chamber is approximately equal to atmospheric pressure, but in the air ducts of the carburettor when starting the chainsaw engine there is a vacuum. The opening of the choke leads to an increase in the intensity of the air supply. as a result, more fuel enters the carburetor and the engine rpm increases.

What you need to know?

To perform the procedure, you should ideally know the structure and principle of the gasoline saw carburetor, but this is the subject of a separate article. Our task is to learn how to properly and quickly adjust the carburetor “at the knees” without special skills, devices and tools. So let’s stop only at the obligatory minimum.

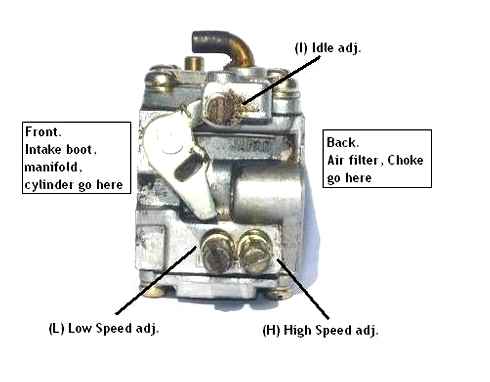

On any carburetor of a Chinese saw, regardless of the manufacturer, there are 3 adjustment screws:

Adjustment is done by changing the quality and quantity of combustible mixture (fuel-air mixture), t.е. fuel entering the engine cylinder of a chainsaw. mix ratio is adjusted with the screw T (throttle position adjustment). Adjust the blend quality with the L. For this reason, the following rules should be followed during adjustment:

Carb Adjustment on The Chinese Chainsaw

- The engine should idle stable and the chain should remain in place without rotation;

- There should be no heavy smokiness when the engine is running;

- the engine should have good injectivity, t.е. when you sharply press the throttle knob, should quickly gain speed, and when you release the knob, gently drop the speed and work steadily at idle.

CORRECT WAY To Adjust The Chain Tension On Your Chainsaw

Knowing these 3 simple rules, you can easily adjust the idle stroke on any chain saw made in China, for example: PIT, Friendship 2, STIHL, Echo CS 353ES, Patriot PT 3816, Husqvarna 5200 and others.

When the carburetor needs adjustment?

All carburetors have been set and adjusted at the factory since the tool was first sold. However, in the process of operation, the settings are gradually knocked down, and the mode of operation changes in accordance with the operating conditions. Signs of carburetor malfunction may include:

- the fuel consumption is too high and you can see thick smoke coming out of the exhaust pipe;

- engine power is clearly insufficient to perform normal tasks;

- the engine speed “floats”;

- after starting the engine, it stops immediately or after a few seconds;

- The engine cannot be started at all;

- the chainsaw “shoots”, there are sharp pops in the engine of the tool.

Notice! The cause of poor engine performance may be the wear of the piston group, then the adjustment of the chainsaw carburetor does not give a complete resolution of the problem. Also, no adjustment will give the expected effect, if at the same time there will not be made cleaning of the unit from small particles of garbage. The most problematic elements are jets and filters, both gasoline and air.

It is necessary to consider that on time of break-in of the new engine the carburetor is adjusted on the lowered delivery of fuel, with the purpose of restriction of capacity of the engine. After the running-in period is over, the fuel flow increases to nominal value. These adjustments are made with the help of the adjustment screws on the carburettor body (there are usually two or three of them).

Tools for adjustment

To adjust the carburetor you will need a Phillips or slotted screwdriver of different length or thickness.Size depends on the design of the unit and the peculiarities of the engine assembly. It should be noted that some manufacturers make carburetors, designed for the use of special tools.

In particular, special type screwdrivers may be required for tuning Husqvarna carburetors and other imported tools. It is advisable to clarify this issue when buying a chainsaw, so you can buy the necessary additional equipment in advance.

In addition, you will need purified gasoline or acetone to flush and clean the device. These are used to clean the outside surfaces of the carburetor. All internal channels are flushed with kerosene, diesel fuel or white spirit. Before flushing, the carburetor is disassembled, and all rubber or plastic parts that could be damaged by contact with aggressive chemical compounds are removed.

Open-end wrenches or open-end wrenches are used for carburetor disassembly. Flushing the internal passages is performed in a specially designed tray, sometimes plastic syringes are used for this purpose.

Gasoline is not coming to the chainsaw carburetor

If the fuel does not come into the regular chamber, it may indicate several breakdowns at once. First you need to check the air and fuel filter. These elements absorb large amounts of dust when the saw is in use for a long time, which then prevents clean air and fuel from seeping in. A lightly soiled filter can be cleaned with gasoline, but if the part is clogged with a lot of dust, it will need to be replaced.

Another cause of malfunction is the needle. The needle can stick, especially in a chainsaw made in China. To fix it, in most cases you just need to move the needle.

If the fuel does not flow into the chamber, then the saw owner should inspect the tool glands. After a few months of tool use, these parts lose their tightness. Over time they start leaking gasoline, and the tool will stop starting. Repair by replacing oil seals.

The breather plug is important for starting up the saw. It is located near the gas tank lid of the saw, and it performs two tasks at once. it maintains optimum air pressure, and prevents the fuel from leaking. To check the breather plug you need to disconnect the fuel pipe and see how much gasoline is leaking. If it does not come out at all, it means that the regular breather valve is clogged with debris and dirt. In this case, it will be necessary to clean the element and install it in place.

If the fuel does not come into the chamber, you need to check the fuel line. often a Chinese hose is used to complete a budget class tool which loses its tightness with time. In this case you will need to replace the line, paying special attention to the tightness of the joints of the channel.

Features of the Chinese chainsaw carburetor

Their design and parameters differ, depending on what power and model chainsaw they are designed for. All of them are almost identical to the original carburetors by design, but not always by quality. Today you can not consider all Chinese products 100% junk. In turn, in terms of quality, they can be divided into three groups conditionally:

- Low-quality. Unsuitable alloys are used, which oxidize, crumble and break. Lack of fit accuracy, calibrated holes are not as required, resulting in over or under fueling the combustion chamber. Critical parts fail quickly. Plastic parts quickly become coarse or soften by gasoline and stop working. Axles and wire rods bend, and fastener threads break. These products cost the cheapest. They are made in semi-institutional factories, on adapted equipment. As a rule, they do not have names and markings.

- Average quality carburetors. These are factory assembled products. Here they do not skimp on alloys; there is in-line production with quality control. These are quite serviceable carburetors that can have a service life even longer than that of the entire chainsaw.

- Quality carburetors. First of all, these are products of world manufacturers, whose facilities are located in China. Geographically they can be considered Chinese, but they are made according to the technologies of the company. the brand owner, which values its reputation. For example, Japanese Walbro carburetors are produced in the PRC.

In addition, among the Chinese manufacturers there are those who rely on high quality. They invest a lot of money in powerful production, register their own brand and work on its reputation.

How to adjust your Partner chainsaw

To work you need a screwdriver.

Adjusting the carburetor by yourself if you have a tachometer and know how to work with it. Otherwise, self-tuning makes no sense, the setting of a chainsaw should be trusted to a professional mechanic.

Tuning of the chainsaw carburetor is carried out by only one screw, the other two are hidden from the consumer by the manufacturer. The designation of them on the body is such:

The manufacturer adjusts the operation of the carburetor for optimum performance, leaving the possibility of corrective adjustment of the unit in extreme situations. When using the unit in the recommended temperature and air composition ranges, it is not necessary to engage in adjustment.

To adjust the operation using fuel of a different quality than the standard, use the L and H screws. To reduce the octane number of gasoline, turn the screws from left to right. To increase the RPM. To increase the octane rating, turn from right to left. Set slow speed.

Adjusting the carburetor of a Partner chainsaw or other makes is done with the following rules in mind:

- Carry out accurate work only on a hot engine. Minimum working time. 10 minutes.

- The air filter must be unclogged and clean.

- Stop the rotating chain with the adjusting screw until it has come to a complete standstill. The screw is turned from right to left.

- Note safety rules. Point the chain in the opposite direction from yourself. Put the saw on a flat surface. Do not touch objects with the cutting part.

Fine tuning with the screws takes place in this sequence: L. H. T. Screw L is the maximum number of revolutions by turning it from left to right or in the opposite direction, until the maximum is reached. In this process you will need a tachometer or a good ear of a craftsman to determine by the sound of the rev limit. If the H regulator is not set correctly, the engine will break down. The cost of repair would cost more than half the total cost of the chainsaw.

The idle speed is adjusted. Screw T rotates counterclockwise until the chain stops. If you can’t adjust the idle speed yourself, you’ll need to call a master. Working on an out-of-tune chainsaw leads to personal injury.

How to Adjust the Carburetor on a Chainsaw?

All saws come with an adjusted carburetor from the factory.

And because it is protected by a plastic housing, it does not need additional adjustments for a long time. And intervene in its operation only when the saw with a guaranteed good cylinder-piston group starts to stall, which is most often caused by a lack of fuel and as a consequence. an overabundance of air.

The second symptom of a bad carburetor is excessive fuel consumption and increased smoky exhaust, indicating an overabundance of gasoline in the mixture. In this case, before getting to the carburetor, you should clean (or replace) the air filter and make sure that the cause is not eliminated.

Sometimes the adjustment of the carburetor is made gradually, due to the increased vibration of the tool, which can turn the adjusting screws from their original positions.

The first thing to do before removing and disassembling the carburettor is to try and adjust it. To do so:

Carburetor adjustment should begin with the L screw, which adjusts fuel supply at low rpm. It should be rotated to the highest rpm. The rpm will increase as you tighten the screw.

Next adjust the quality of mixture with the screw H. If the saw emits smoke, it is a sign of a rich mixture, and if it squeals, it is a sign of a lean mixture. The H screw should be tightened in the first case and vice versa in the second. You have to be very careful with this screw, because wrong adjustment might even kill the saw. It should never be tightened too much.

The adjustment is completed by the idle speed setting, which is set with the T screw. At high RPM the clutch cams are engaged and the saw chain is moving. The T screw adjusts the slide adjuster stop on the outside of the carburetor and does not go inside the carburetor. Do not turn the engine rpm too low that puts extra load on the crank mechanism and makes sure the chain stops when idling. This screw may have a different letter value in some saws.

Some carburetors initially have only one setting. idle speed, in them the quality of mixture is set by the parameters of jets and factory settings initially. The video of idle speed adjustment on such carburetors is also suitable for all other types of similar devices:

And saw’s malfunction without RPM and mixture quality adjustment screws may indicate that it needs to be repaired or at least cleaned.

It remains to add that the final adjustment should only be made when the saw is warm and has been in operation for at least 10 minutes.

How to adjust the carburetor of chain saw?

Most models of gasoline saw carburetors have three adjustment screws:

Setting of required parameters is done by turning these screws.

Use the electronic tachometer for fine tuning the carburetor. It will allow you to easily ascertain the values of the chainsaw engine.

Basic carburetor adjustment

The H and L screws must be rotated by the hour bar to the stop and then rotated by 2 turns to the opposite side. This standard procedure when adjusting popular chain saw models. Other variants are also possible.

Idle speed regulation

First of all, it is necessary to adjust the position where the highest idle wraps will be, by rotating the L screw. When you find this position with the tachometer, you need to turn the low revolution screw (L) by a quarter (1/4) against the clockwise direction. The chainsaw lance may twist at this. If this happens, turn the idle screw (T) counterclockwise until the lance does not rotate at full speed.

How to adjust the maximum values of the chainsaw?

To change the maximum wraps, it is necessary to interact with the H screw. If you tighten the screw, the wraps will be higher, and if you unscrew them, they will be lower. As a rule, the most admissible engine revolutions are within the 11500-15000 rpm range. If you try to work with a higher wrenth, you will have a problem with ignition. In this case, the screw should be tightened slightly.

Checking the acceleration

If you press the gas button on the chainsaw, the engine will increase the number of wraps. This should happen soon enough. If the tool is fully wound, the L screw should be tightened a little, not more than 1/8 turn.

When the tuning is completed, you need to check the work of the chainsaw at idle again. the engine must work properly, and the lance must not be damaged. If the engine does not run properly or the valve stops moving, you need to repeat the regulation leaving out the basic tuning step.

Sensitivities which should be kept in mind while adjusting

Do not tighten the low revolution screw (L) too much in relation to the high revolution screw (H). This will become the reason of the reduced mixture to the engine (too much air relative to petrol). As a result, the piston will be dry during operation and become very hot.

It is better to remember the initial position of the carburetor screws in order to be able to put the factory settings back in place if the saw doesn’t start or works incorrectly afterwards.