How to mount a tiller on a power tiller correctly

It is impossible to give a concrete answer to this question. Everything is depending on the personal characteristics of the motoblock, the ground and the criteria for use. For example, for processing heavy soils with a solid tiller with reinforced cutters sharpening is not necessary. You won’t see any tangible effect from this procedure, but you’ll waste a lot of time and effort.

For processing a site with a lighter power tiller with small cutters sharpening is a good option to improve the quality of work. There is a disadvantage, too. First, sharpening only lasts for a few hours, then the function must be repeated, and this is a long and labor-intensive process. 2) Sharpened blades help to crush the roots of weeds, which, in turn, can only speed up their reproduction.

If you do dare to sharpen the tiller. remove it from the power tiller, clean it from the ground. Sharpen each cutting element as carefully as possible with an emery, so as not to destroy them.

READ Engine installation on the Mole single axle tractor

There are two types of equipment cutters:

It is worth mentioning that there are four- and three-blade cutters, but it has little effect on the result of work. This design feature is aimed at reducing the load of the engine.

Power tiller design

Before you start assembling the tiller, you need to understand what is a power tiller and what is included in it. The upper part of the frame is usually welded. The fuel tank and engine are mounted here. Fastening is carried out on brackets. The engine itself, or power pack, is equipped with a clutch and a gearbox. Its power can be different, it all depends on the type and purpose of the power tiller.

Cutters are a scheme of 2 blocks, each block contains 12 individual cutters. 3 separate assemblies with 4 blades mounted at 90° angle are used for each unit. units have a 30° offset. Steel sheet with a thickness of 5 mm is used for the manufacture of one knife. The stand is made of 6340 mm metal angle. The blades are attached to the stand, their other end is welded to the flange to combine 4 blades into one design. The whole cutter is connected by bolts, washers, flanges. The design is durable, so it can withstand considerable loads. If you plan to use this equipment permanently, you should prefer only the factory version.

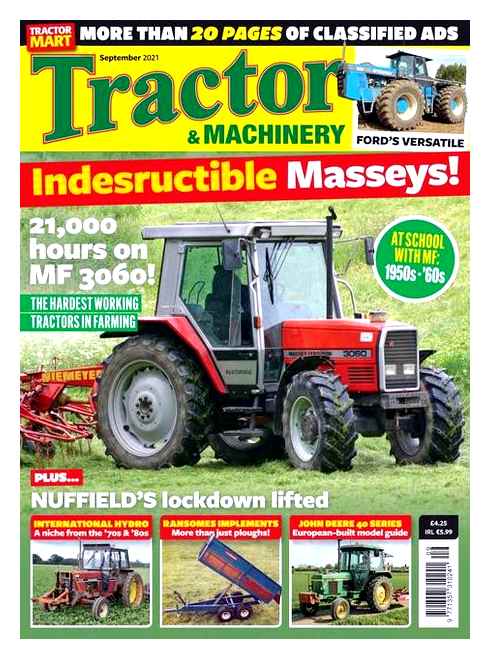

Factory cutters with sabre-shaped blades

Those who begin to use power tillers, ask the question: what kind of blades to take the best? Types of power tillers can be conventionally grouped into 2 big groups:

Sabre-shaped cutters are best suited for all types of work.

Sabre-shape cutters are the most popular, such schemes are called standard. They are effective, the effectiveness of using exactly this type has been proven for dozens of years. Cultivators often come with a sabre blade design. Best suited for all types of work. The advantages that sabre cutters have are obvious. Optimum blade shape. They are suitable for many different applications. Only carbon-quality steel is used for the blades. high-strength.

Sabre cutters have a collapsible design, which makes installation and maintenance easy and efficient. The steel from which the knives are made is completely immune to welding operations. In order to improve the mechanical properties of the product, a so called thermal hardening is applied during production. Steel is treated with high-frequency currents for strength.

goosefoots

These models appeared on the market relatively recently. With their help, any virgin soil can be cultivated, and they are also effective in cultivating hard and difficult soil.

- Continuous design, which provides high accuracy of work;

- equipment fights weeds well;

- easy to use, parts can be replaced at home.

Such models, unlike saber-shaped cutters, are made of carbon steel, which is a little less durable.

Homemade tillers for the power tiller

Manufacturers offer different versions of tillers for the tiller. It is possible to use one set of cutters or buy two different types of devices, changing them depending on the soil conditions.

Some craftsmen prefer to use homemade products, which, if properly assembled, will be no worse than the factory ones.

The main advantage of creating a tiller yourself is that it can be adjusted to the specific features of the plot.

Frequently Asked Questions Regarding Single Axle Tractor Cutters

One of the most frequent questions is considered: “Do you have to sharpen the cutters on a single axle tractor??” The answer to this depends on what blades you have installed, whether they are self-sharpenable. Also the answer to this question depends on the type of soil with which you are going to work. If you plan to mainly plow wet soil, it is recommended to additionally sharpen with an angle grinder. The sharpening of power tillers is important and requires special attention.

A common question among farmers and landowners is, “How to build a tiller for a power tiller?”. In order to assemble the mower in the best possible way, it is necessary to get acquainted with the existing schemes. All blueprints required are given below.

Assembling a tiller for a power tiller is quite a difficult task. over, there are some complicated variants.

In order to assemble the cutters on a single axle tractor with your own hands, you need to have some experience. than one person is needed for the sabre milling machine. After all, the principle is to install all the elements more securely and correctly. For the “goosefoot” you need to have knowledge of metalworking. After all, first of all, knives must be forged.

It takes a long time to make an active tiller for a power tiller with your own hands. So it is much better to order it from a master. In order to still make it with your own hands, first of all, you need to understand the drawings and literature. over, in this video you will clearly and step by step see the whole process, which will greatly facilitate your work.

The process of assembling a cultivator tiller

There are two different forms of knives:

- Sharpened. “Petals” easily enter the soil without grip. This reduces the strain on the engine and the fuel consumption. But sharp blades can not completely remove weeds, they soon sprout again. These canopies have to be handled carefully so as not to damage the plants and for your own safety;

- With a semi-circular edge. They are distinguished by their safe operation. But when ripping, there is more resistance, tillers get stuck more often. Cultivator blades help to cope with weeds more effectively.

There are two ways of attaching the “petals”:

- Riveted. The element is indestructible. In this case, it is not very convenient to store and transport the device;

- bolted. The part can be disassembled.

To assemble the power tiller to your cultivator it is important to observe the correct direction. the sharpened part of the tine should point in the direction of travel.

The number of sections equals the number of attachment plates: if they are all the same, only three are possible. If they will move, four or six sections should be fastened. The blades must be marked beforehand.

How the tiller is assembled?

- When installing a three-blade cutter, the first blade is secured to the plate. at first it is not necessary to fully tighten the bolt. The two remaining blades are attached to the opposite side of the plate;

- Left and right blades are mounted on a four-blade and a six-blade burr, one after the other. It is worth dividing the “blades” into right and left blades in advance;

- If necessary, an additional section is mounted with a pin;

- The structure is bolted down as rigidly as possible;

- At the end of the shaft is mounted on a protective disk to protect plants from damage.

Cutter types

The attachment consists of four curved blades. “petals”. that are fixed to the shaft. Most of the blades are of the directional type: please note the direction of rotation when mounting. blades are usually bent on both sides, except for those on the edges of the shaft. There are models where all the “blades” are bent towards the gearbox: this prevents damage to the plants while ripping. But in this case, the working width is reduced.

Elements are made of pressed steel for the lightest machines, and of steel strip, often forged. The latter variant is the most robust. As a rule, the tiller is a separate part, but there are models in which two tillers are fixed on one shaft.

- Sharpened. the “petal” more easily enters the ground and does not allow adherence to the soil. Consequently, the load on the engine is reduced and fuel consumption is reduced. on the other hand, the sharp blade cuts the roots of the weeds, some of which remain in the ground and sprout again. Sharpened burrs must be used with great care.

- With a semi-circular edge, they are safer, but experience more resistance when ripping, and are more likely to get stuck. This element removes weeds more effectively, because it does not cut, but winds up the root and pulls it out of the soil.

Cultivator tool diameter determines the maximum ploughing depth. Relative is set by the coulter.

- riveted. the element cannot be disassembled. It is not so much a problem during storage as during transportation;

- Bolt-on. collapsible part. The photo shows a sample.

No welding is used for the connection. this reduces the strength of the product.

Types of cutters

The tool consists of four curved blades. “petals”. that are fixed to the shaft. Most of them are of the directional type: when assembling it is necessary to consider the direction of movement. The blades are usually bent on both sides, except for those on the edges of the shaft. There are models with all “petals” bent only in the direction of the gearbox: this prevents damage to the plants when ripping. But in this case, the working width is reduced.

The elements are made of pressed steel. for the lightest machines, and of steel strip, often forged. The last option is the most durable. The tiller is usually a separate piece, but there are also models with two tillers mounted on the same shaft.

- Sharpened. the “petal” enters the ground more easily and does not allow adhesion to the soil. Correspondingly, the engine load and fuel consumption are reduced. On the other hand, sharp blades cut the roots of weeds, some of them remain in the ground and sprout again. Sharpened burrs must be used with great care.

- With a semi-circular edge. safer, but in ripping experience more resistance, more often get stuck. This element removes weeds more effectively, as it does not cut, but winds up the root and pulls it out of the soil.

Cultivator tiller diameter determines the maximum ploughing depth. Relative is set by the coulter.

- on the rivet. the element cannot be disassembled. The difficulty is not so much in storage as in transportation;

- on bolts. collapsible part. Here is a sample on the photo.

We do not use welding for joining. it reduces the strength of the product.

Sharpening a self-made tiller

Homemade power tillers need to be sharpened. You will need an angle grinder with a diamond wheel, diameter 125 millimeters. A grinder is difficult to use because of the size and bending direction of the blades. Small blades can be sharpened with fine sandpaper.

Rules for sharpening knives on homemade equipment:

- Only sharpen knives with a 45° angle. The side of the hollow space must be determined beforehand;

- It is not necessary to remove a lot of metal, 1-2 sharpenings per season is enough. The sharpening frequency may change depending on the intensity of use and the type of soil to be worked.

If the cultivator is frequently used on wet ground, the condition of the tines must be checked. Corrosion is prevented by the use of special rust preventative. Avoid contact of cutters with stones and other hard objects. This prolongs the life of the equipment, reduces the need for frequent blade sharpening. After work, the tillers should be cleaned of soil, plants and other contaminants. Use a rag or brush, different cleaners are not suitable. If the tillers are to be stored for a long time, the blades should be lubricated with solidol, and graphite grease should be used for the shaft ends.

Self-made milling cutters can be installed on mole cultivators, Centaur and many others.

Cutter on a single-axle Kentavr tractor: meaning, application

The tiller for the Kentavr power tiller breaks large clods of soil during work, allows you to work the soil comprehensively, which is the main task of the device.

Cutter consists of blades (made of strong steel), which are bolted to the frame. The frame itself is presented in the form of the so-called “herringbone”.

It should also be noted that the active cutter for the power tiller allows first-class processing of the ground, and with minimal labor.

How to assemble a cutter on a single axle Kentavr tractor?

Before you begin assembling, it’s worth paying attention to the types of parts:

The first is considered standard, as it has an acceptable shape, and the blades are made of durable steel. The gooseneck cutter is a sturdy, unassembled and solid part.

If briefly, the instructions for assembling a tiller for the Kentavr power tiller are as follows:

- To begin with, it is necessary to consider the important fact that the sharpened part of the cutter must cut into the ground during work. This requires the correct direction of rotation.

- At the very beginning of assembly, it is necessary to prepare the single axle tractor.

- The mechanism itself should be leaned on the frame (the so-called coulter).

- Then tilt at an angle of forty-five degrees.

- Next, put under the handlebar of the tiller of the motoblock wooden trestle.

- The final step is the removal of the wheel.

For the assembled part to serve firmly and for a long time in the work, it is worth constructively calculating its functions. For proper assembly of a tiller with your own hands for a power tiller, it is recommended to familiarize yourself with similar parts. Watching instructional and informational videos on how to assemble the cutters will also be effective.

After that you can begin to create a drawing. Then, following it, assemble the necessary elements for assembly. It is important to proceed step by step during assembly. In the end it is worthwhile to be sure to check the mechanism in action.

In general, everyone will be able to assemble milling cutters for a power tiller by himself, which will further help with productive cultivation of the land.

Is it necessary to grind milling cutters on a single axle tractor?

There is no definite answer to this question. It all depends on the individual characteristics of the power tiller, the soil and the conditions of use. For example, sharpening is not necessary for processing heavy soils with a powerful power tiller with reinforced cutters. You will not see any tangible effect from this procedure, you just waste time and effort.

For processing a site with a lighter power tiller with small cutters sharpening is not a bad option to improve the quality of work. But there is a disadvantage too. First, sharpening is enough only for a few hours, then the procedure must be repeated, and this process is long and laborious. Secondly, sharpened knives contribute to the crushing of the roots of weeds, and this in turn can only accelerate their reproduction.

If you do decide to sharpen the tiller, remove it from the power tiller, clean it from the ground. Very carefully sharpen each cutting element with emery paper, so as not to damage them.

Types of cutters

The most common and popular type of cutters for power tillers is considered to be the “goosefoot” knife model. They can be made by your own hands with a basic set of tools. It is recommended to use in the farm only those types that were made by following the technology of forging and have the properties of self-sharpening.

Blades differ in shape and working principle. For example, these “goosefoots” differ in the presence, location, design of the cutting edges. The material used to make the cutter bar plays an important role. Depending on the quality of the material, the level of depth as well as the quality of the treatment of the layers of ground.

Let’s look at specific examples of cutter varieties:

Saber-shaped bodies

Sabre-shaped cutters are standard on all power tillers. They are equipped with them in the factory. Most farmers use active saber-shaped cutters. Among the advantages of this type are:

If the blades are factory-made, they use a sheet of alloyed or high-carbon steel as the material. It undergoes thermal hardening, is treated with electric current of high frequency. Bush blades are not recommended for use.

If it is necessary to use a self-made cutter, it is recommended to take hardened, heat-treated steel. For example, structural spring steel 50 XGFA.

Goosefoot blades

“The goosefoot blades appeared in 2000. Since then, the blades have become popular because of their many qualities. They appear due to the special shape of the blades. If you look at them, they resemble a goosefoot, which is why they got their name. The construction itself is one-piece and indestructible.

Factory products are distinguished by their static parameters. Among them, the standard dimensions for knives look like this:

The cultivator has a speed of up to 5 kilometers per hour with working blades. It is customary to make them from mild steel for working the soil. This enables the blades to be self-sharpening. So, with proper handling, they can be not sharpened at all.

With the help of “goose feet” people work virgin land or other, difficult types of soil. Do not use these blades for ground work that contains a lot of roots. Because of them, the system will always get clogged and delay work in the field.