Symptoms and causes of malfunction

When checking the performance of the ignition coil, it is possible to identify malfunctions according to the following signs:

- the car engine cannot be started;

- the dashboard shows the presence of an error;

- misfiring occurs;

- excessive heating of the coil.

Possible reasons for the failure of the coil are:

- mechanical damage;

- overheat;

- the use of low quality candles;

- adverse environmental influences.

Mechanical damage to the coil can occur due to strong vibration or oil leakage. As a result, the integrity of the coil insulation may be compromised, which can lead to a breakdown.

It is convenient to check the LEDs for serviceability with the same multimeter. How to do it correctly, read here.

The use of substandard spark plugs can cause breakdown of the insulator and the formation of back gases, which have a negative effect on the rubber tip of the coil. Tip damage can cause high voltage breakdown to ground.

When operating the vehicle, the reel may be affected by factors such as moisture, dust, dirt.

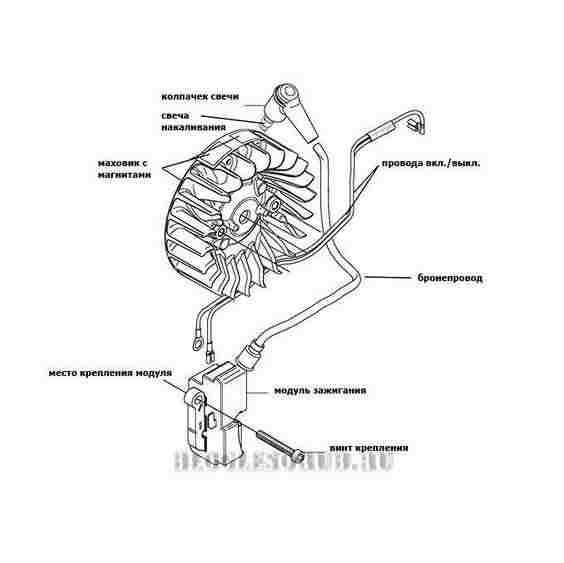

Purpose and device of the ignition coil

The ignition coil is necessary to create a high voltage in the car engine, which causes a spark in the spark plugs of the engine cylinders. This spark ignites the fuel.

Such a coil is a step-up pulse transformer consisting of two windings and a magnetic circuit. The primary winding of the coil is made up of a small amount of thick copper wire, and the secondary winding is made up of a large amount of thin wire.

The principle of operation of the ignition coil is that when the primary circuit, powered by a low-voltage battery, is opened, a current pulse arises in it, due to which an electromotive force is induced in the secondary winding. The magnitude of the voltage arising there, due to the large transformation ratio, is many times higher than the supply voltage of the primary winding.

It reaches a value of 25-35 kV. High voltage hits spark plugs.

Car diagnostics: how to check the ignition coil with a multimeter for operability

An important element of the car ignition system is the coil. In the event of a malfunction, the vehicle may be interrupted.

It is possible that the car, due to the engine stopping due to a malfunction of this coil, will not be able to move at all. Therefore, it is important for a car enthusiast to know how to check the performance of the ignition coil.

Ignition coil test circuit with a multimeter

The method for assessing the health of the ignition coil by checking the spark slip between the spark plug and the car body for modern cars is fraught with the failure of complex control electronics. Therefore, a device such as a multimeter is often used to test ignition coils. Before checking if the ignition coil is working properly, it must be dismantled. Then you need to make a visual inspection of the device for cracks, chips and other defects. Next, the coil must be cleaned of dust and dirt.

Checking the coil with a multimeter consists in measuring the resistance of the windings. Each type of such device has its own parameters. In the best case, it is necessary to familiarize yourself with the documentation for the coil and compare the measurement results with the nominal values. As a first approximation, the resistance of the primary winding should be in the range of 0.4. 2 Ohm, and the resistance of the secondary winding. from 6 to 8 kOhm. Although some coils may have secondary winding ratings up to 10-15 kOhm.

Based on the measurement results, conclusions are made about the health of the coil. For example, a large primary winding resistance indicates an open circuit. A significant difference in the resistance of the secondary winding from the nominal value may indicate an interturn short circuit. If it is close to zero, then this is a short circuit.

Findings:

- The health of the ignition coil has a great impact on the performance of the vehicle.

- The performance of such a device can be assessed using a multimeter.

- Based on the results of measuring the resistances of the windings, it can be determined that the ignition coil is faulty.

What is it for

The main purpose of the ignition coil is to convert a low-voltage electrical pulse from an interrupter, ignition amplifier (switch) or engine control unit into a high-voltage pulse required to generate a spark in the spark plug.

The spark plug has a one-, two- or three-lobe breakdown gap with a distance of 0.4 to 1.1 mm, depending on the characteristics of the engine. It is believed that in air to form an electric spark between two conductors, an impulse of at least 6 kilovolts is required per 1 millimeter of the gap.

Thus, the electrical impulse generated by the ignition coil must be at least 10 kilovolts to ensure reliable ignition. Taking into account the voltage drop across the limiting resistance and high-voltage ignition wires, usually the voltage of the electromagnetic pulse is chosen about 12. 20 kilovolts.

A voltage pulse from the ignition coil can cause serious electric shock (!)

Such lesions are especially dangerous for people suffering from heart disease, they can lead to a failure of the heart rhythm. Ordinary rubber electric protective gloves do not protect against impulses of more than 15 kV, their standard breakdown voltage is only 6.3 kV.

It is necessary to be extremely careful when working, checking the performance of the ignition coils. Even by measuring the resistance of the primary winding, you pass a multimeter current through it, which transforms the high-voltage pulse into the secondary winding.

How to check the health of the ignition coil

Checking the ignition coil for systems with an ignition distributor begins with a “continuity” (resistance measurement) of the windings.

What resistance should there be on the ignition coil

To do this, the multimeter switch is first set to the 200 Ohm position and the resistance of the primary winding is measured by applying the multimeter probes to the terminals “” and “K”.

The resistance should be in the range from 0.2 Ohm to 3 Ohm (depending on the coil model and the accuracy of the soap meter). In any case, the contacts “” and “K” must ring.

Then the multimeter switches to the “20kOhm” position, that is, the measurement limit is set to 20 kiloOhm. Next, the resistance between the terminals “K” and the central terminal of the high-voltage wire is measured (for this, the probe must be resting against the contact copper zone inside the circular niche of the high-voltage wire installation). Resistance should be in the range from 2 to 4 kilohms.

It is more efficient to check the ignition coil directly in the operating mode. To do this, you can build a circuit similar to that shown in Figure 7:

But it is even easier to connect the “” contact with the positive terminal of the battery with a wire with a thickness of at least 2 sq. Mm. Connect the ignition wire with a known good spark plug to the high-voltage terminal of the coil. Connect the body of the candle to the ground of the car, the car engine or the negative terminal of the battery, if the battery is removed from the car, and the check takes place under stationary conditions.

Next, connect a wire with a cross section of at least 2 sq. Mm to the terminal “K” of the ignition coil. If the other end of the wire touches the negative terminal of the battery, sparks should jump in the candle. The touches must be short-term, so that the primary coil does not burn out and a good spark jumps over. In this case, it is better to carry out the stripped end of the wire along the battery terminal so that there is a flow of sparking.

However, sometimes the second test method is not suitable for electronic ignition coils. Sparks may not be observed if the coil is intact.

In general, the most reliable way to check is to “throw” a known good ignition coil.

It is more difficult to test dual ignition coils. Their primary winding is usually connected to the connector. You can call it with a multimeter only if you know the circuit of the ignition coil. The secondary winding is ringed between the two high-voltage terminals. The secondary resistance may be slightly higher than 4 kilohms.

It is difficult to determine the malfunction of individual ignition coils without knowledge in the field of radio engineering, since it is necessary to assemble an electronic circuit for verification.

However, there is a 100% way to find a faulty coil. If the engine is troit, you can sequentially disconnect the connectors from the ignition coils with the engine running.

If, after disconnecting the coil, the engine speed changes, the engine begins to double, therefore, there is an ignition spark in this cylinder. Then reconnect the connector and proceed to checking the next coil until they find a cylinder in which, when the connector is disconnected, the nature of the engine does not change.

Video. how to CORRECTLY check the ignition coils:

Of course, it is easier to do this with the help of computer diagnostics. It can immediately display the error code and decryption, for example, “misfire to cylinder 3”.

But the absence of a spark in a particular cylinder is not a reason to say that the coil is faulty. An additional resistor is built into the individual ignition coils (position 8 in the cutaway individual coil diagram below).

It is usually easy to reach by removing the rubber tip 9. Next, you should measure its resistance (from 500 ohms to several kilo ohms). If it does not ring, you should change.

Then the ignition coil of the spark-free cylinder is swapped with a known good coil from the adjacent cylinder. If a misfire is now observed in the adjacent cylinder, and the non-working cylinder starts working, then the problem is definitely in the ignition coil.

Video. how to calculate a faulty ignition coil:

Usually, the built-in switch fails first of all, the high-voltage coil itself is in good order, but you have to change everything entirely. There are masters who re-solder the output transistor in the built-in switch, but experience shows that restored individual coils do not work for long.

How it works

In general, an ignition coil is a transformer or autotransformer (transformer with one common contact). The primary winding is made of a thick copper conductor with varnish insulation, and contains, as a rule, from 100 to 200 turns. The secondary winding is made with a thinner wire, since less currents flow through it. The number of turns in it is from 20,000 to 30,000 thousand.

Simplified, the coil for the contact ignition circuit can be represented as:

Here: 2. ignition coil, 1. storage battery. When the engine rotates, the cam mechanism 5, installed in the distributor, moves, which opens the contacts 4. During a short opening, a large current flows through the primary winding of the ignition coil 2, which induces high induction in the secondary winding. A high voltage pulse is applied to the spark plug gap 3.

Such ignition circuits were used in automobiles until the early 90s. The main disadvantage of such circuits is the burning of electrical contacts 4, since a large current flows through them. Many motorists supplemented the circuit with an electronic amplifier like the circuit:

In such a circuit, the main current load is taken by the amplifying transistor T1, a small current flows through the breaker Pr, it does not collapse.

Since the 1980s, most manufacturers have started using switches in electronic ignition systems. Instead of breakers, more reliable Hall sensors, electromagnetic sensors, optoelectronic sensors were used. Such sensors are much more durable than switched ones; during their operation, the ignition angle does not change during operation, as in contact.

The ignition diagram of the VAZ 2110 is shown in the figure:

Ignition Coil Test (The Short Version)

In the diagram: 1. contact group of the ignition lock, 2. ignition coil, 3. switch, 4 ignition distributor.

Currently, the operation of the ignition coils is controlled by the engine control unit. The switch (ignition amplifier) in some models is built into the engine control unit.

Since the probability of breakdown of the control transistors is high enough to simplify the repair of the car, in many cases the electronic switch is structurally built into the ignition coils. However, this complicates the control of their performance. Sometimes, with a working coil, it has to be changed, since it is structurally inseparable from the switch.

Three types of ignition coils are currently used:

How to check the ignition coil with a multimeter or brute force method

The ignition coil is one of the main units in the control system of gasoline internal combustion engines. Its malfunction will inevitably lead to a refusal to start the engine.

Computer diagnostics can not always determine the malfunction of the coil. The maximum that the diagnostics can show is a “misfire” in one of the cylinders. The rest of the diagnostics of the ignition coil has to be done by “old-fashioned” methods, which are the most productive.

The main causes of the malfunction

The main causes of coil failure include:

- installation of abnormal ignition wires in the process of servicing the car (there were wires with distributed resistance, but the usual ones were installed without resistance, therefore, the ignition current is not limited);

- natural wear and tear;

- turn-to-turn high-voltage breakdown (the coil will ring out like a working one, but the quality factor decreases, and the pulse amplitude on the secondary winding is significantly reduced);

- overheating of the ignition coil;

- accidental battery polarity reversal;

- mechanical damage to the coil;

- installation of non-standard spark plugs (with a smaller or larger gap;

- sudden temperature changes (the car got into a puddle while driving, water got on the coil);

- short circuit of electrical wiring;

- drizzle on high-voltage wires.

The main symptoms of malfunctions

The main signs indicating a possible malfunction of the ignition coil are:

Diagnostics “classical” KZ

This does not mean that we are talking about how to check the ignition coil of a VAZ 2101-2107. “Classical”, in the sense of having the most common design, in other words, the one that was installed on carburetor engines. The check is carried out for an open circuit in the primary and secondary windings and a short circuit to the case.

The coil has three leads. Two of them are marked with signs “” and “-“, the third. central, the main high-voltage wire is inserted into it. The coil is checked in the following order:

- Set the multimeter switch to 200 Ohm. The indicator should show the number 1.

- Connect the test leads of the device to each other. On the screen. multimeter error, it is important to take it into account when measuring small resistances.

- Disconnect wires from terminals and center contact.

- Install probes on leads “” and “-“, polarity doesn’t matter.

- The readings of the device, taking into account the error, should be within 0.5-2 Ohm.

- Now you need to measure the secondary winding.

- The device is placed in the 20 kOhm position.

- Install the multimeter probes to the terminal “-” and central contact.

- Normal value. 6-8 kΩ. Sometimes it can reach 12 kOhm. In any case, there should not be a cliff.

- Set the switch to 2000 kOhm position.

- Put the probes on “mass” vehicle and center contact.

- The instrument should show 1. This means that there is no leakage.

Reasons for failure

Failure to comply with the rules of operation. the main reason for buying a new coil. This happens in the following cases:

- Use of substandard spark plugs or spark plugs not designed for this type of engine.

- An unprofessional cleaning of the engine can cause the secondary winding to close to its case.

- Overheat. The potential laid down by the designers allows the coils to operate at high temperatures. However, cases of short circuit damage due to overheating are not so rare.

The last point requires a short explanation. Overheating of the coil can occur not only due to the high temperature in the engine compartment. Sometimes it is caused by oil leakage and a short circuit in the secondary winding. Therefore, if you suspect overheating, you need to check the ignition coil for both tightness and the absence of conductivity between the turns.

Checking the ignition module

This device is installed on cars with an injection engine, mainly on a domestic VAZ. Its peculiarity lies in the simultaneous supply of a spark: immediately to two cylinders 1 and 4, 2 and 3. Troubleshooting in this case is greatly simplified. If the corresponding pair of cylinders does not work. a module malfunction is diagnosed. In the vast majority of cases, this is true, but sometimes, however, very rarely, the entire module fails. In this case, you will have to check the ignition coil of the VAZ injector using a multimeter. This requires:

- Disconnect the connector from the module and remove the high-voltage wires.

- Set the switch to 200 ohm position.

- Alternately measure the resistance between the middle and outer pins of the connector.

- The meter reading should be within 0.5 ohms. In this case, it is necessary to take into account its error.

- Now you need to measure the resistance of the secondary windings. It is necessary to sequentially install the probes between the high-voltage terminals of the first and fourth, and then 2 and 3 cylinders.

- Set the mode switch to 20 kOhm.

- The instrument should show a resistance of about 5.4 kOhm.

Varieties of KZ

The ignition system of the car was improved simultaneously with the modernization of the engine. At the moment, there are three main types of short circuits:

- Classic, also called “bobbin”. Installed on carburetor cars until their production was discontinued.

- Ignition module. It is still installed on some models of modern cars, most often domestic.

- Individual coil. Most often responsible for sparking in 16 valve engines.

All SCs have one thing in common. appointment. Even in the most modern engine, the designers could not do without high voltage. Their device is different, and the method of checking one can be absolutely useless when diagnosing another. over, sometimes it can cause short circuit breakdown. Therefore, before checking the ignition coil, you need to make sure that this diagnostic method is applicable to it.

KZ design

Any ignition coil. it is primarily a high-voltage transformer consisting of two windings. One of them, the primary one, receives low voltage pulses. It is wound with a wire of large cross-section and contains a minimum number of turns (about 150). Therefore, its resistance is not enough.

The other winding is called the secondary winding, and a high voltage is induced on it, causing sparks in the cylinders. The cross-section of the wires of this winding is tenths of a millimeter, and the number of turns. several thousand. Accordingly, her resistance is quite large. several kilo-ohms. Specific figures have no meaning yet. The main thing is to remember that the primary winding. this is a few ohms, but secondary. units kOhm. This will come in handy in the future, since you can check the health of the ignition coil only by measuring its resistance.

Individual short circuit check

Coils of this type are installed on each candle, hence the name. Thus, not only was it possible to get rid of unreliable high-voltage wires, but also most importantly. significantly increase the effectiveness of each of them. Therefore, they are most often installed on 16-valve engines. A distinctive feature of individual coils is the high resistance of the secondary winding. This must be taken into account before checking the ignition coil of a 16-valve engine with a multimeter. It may be necessary to use a larger measuring range. The check sequence is as follows:

- Remove the contact block from the coil.

- We put the switch of the device in position 200 Ohm.

- We measure the resistance between the extreme contacts of the coil, it should be within 1 Ohm.

- Now you need to transfer the device to the 2000 kΩ range and install the probes on the middle contact of the terminal and the contact inside the rubber cap.

- Resistance should be 300-400 kOhm.

- Thus, you need to check each coil. There should be no significant differences in the readings of the device.

Typical malfunctions

The coil is a fairly reliable element; it rarely fails. On the same Togliatti classics, KZ often “worried” the engine itself. However, for various reasons, the coil sometimes breaks. You can find out by the following symptoms:

- the engine is troit, that is, there are misfires in the cylinders, and they periodically do not work;

- check engine lights up on injection vehicles;

- there is a loss of engine power;

- the engine does not start, this symptom is typical only for carburetor cars;

- the engine becomes “gluttonous”, average fuel consumption can increase by more than 10%;

- difficult to start the engine in severe frosts;

- on cars with an ignition module, failure of two cylinders at once.

With a high degree of probability, it is possible to assume a coil malfunction only in the latter case. All other symptoms are characteristic of many other nodes. Therefore, when they occur, it is necessary to check both the ignition coil and the rest of the system elements.

How to check the ignition coil for serviceability?

The operation of a gasoline internal combustion engine is impossible without an ignition coil (KZ). It is she who generates high voltage to form a full-fledged igniting spark. This has remained unchanged since the inception of the car, despite the fact that the coil itself has undergone a significant transformation during this time. But still, if the spark disappears, it first of all falls under suspicion. Therefore, even the owner of a modern car needs to know how to check the ignition coil and what symptoms will be if it is damaged.

How to check the ignition coil

One of the most important elements of the ignition system of any gasoline engine is the coil. It is she who is considered the main unit of contact, contactless, as well as electronic ignition systems, playing the role of a kind of energy storage device intended for further distribution of the charge over the cylinders.

Causes of coil malfunction

Partial damage to the ignition coil leads to unstable engine operation, and its complete breakdown makes it completely impossible to start the engine. That is why, when the engine is tripled, its power is lost, or other signs of fuzzy operation, one of the first steps should be to check the ignition coil. This element fails quite rarely, and the malfunction, as a rule, consists in the following:

- Insulation damage due to strong heat, vibration or high voltage, which in turn leads to a short circuit in the coil windings;

- Overloading caused by faulty high voltage wires or spark plugs can cause the coil winding to break.

Methods for checking the ignition coil

Checking the ignition coil using the “old-fashioned” method can damage the electrician of a modern car

For proper self-checking of this car part, it is recommended to perform certain steps in stages. First of all, after removing the coil, you need to visually inspect it and make sure that there are no external signs of a short circuit: black dots indicating burnout, cracks, or other signs of breakdown.

In our country, for a long time, there were two equally popular ways of how to check the ignition coil for operability: by checking the spark between the car body and the spark plug or by measuring the resistance of the windings with a multimeter (tester). The use of the first method can be fatal not only for the coil, but also for the electronics of most modern cars, therefore, its use is strongly discouraged by manufacturers. It is safer to check this unit of the car with a measuring device.

Using a multimeter when checking a coil

In order to independently get a complete picture of the health of an element of the ignition system, you need to figure out how to check the ignition coil with a multimeter. This procedure should not cause any particular difficulties.

First, the primary winding is checked, to the positive and negative contacts of which the device is connected in the resistance measurement mode. Factory default values may vary slightly from manufacturer to manufacturer, but average resistance values should be between 0.4 and 2.0 ohms. If the device shows zero resistance, then a short circuit has occurred in the coil, if infinity, you need to look for an open circuit.

Checking the ignition coil with a tester

To check the secondary winding, a multimeter is connected to the positive terminal of the coil and the terminal from the high voltage wire. The resistance value of this winding for coils with a lamellar core is 6-8 kOhm, for other types. the parameter may exceed 15 kOhm.

It is possible to draw a conclusion about whether the obtained indicators are within the limits established for a particular model only with an idea of its other technical characteristics: the duration and energy of the spark discharge, the spark discharge current and the value of the inductance of the primary winding.

Any malfunction of the ignition coil badly affects the efficiency of the car engine, and this can lead to a decrease in its durability. That is why its timely diagnosis and repair (or replacement) is necessary, if necessary.

Checking the secondary winding for breakage

To carry out such a diagnostic procedure, you must set the multimeter to measure electrical resistance (ohms). Next, we connect one of the wires of the diagnostic device to the positive or negative terminal of the ignition coil, and the second to the central terminal.

If your measurement results in a value of about 6-8 kΩ, this is considered normal for most coils. Some can produce values up to 15 kOhm, which is also considered acceptable, but it is better to clarify this parameter in the technical documentation of the car. In the case when the deviations of the measured results are serious, in relation to the numbers indicated in the technical documentation, we can talk about an open circuit in the secondary winding.

Visual inspection of the ignition coil

The appearance of the ignition coil may vary depending on the model. At the same time, it has characteristic details. a body, a cover, two contacts and a central terminal. During a visual inspection, it is enough to carefully look at the case and look for chips, cracks or burned areas on it. The body is made of ebonite, and it does not pass current, in most cases the coil malfunction is associated with internal damage.

Preparatory stage

Before proceeding directly to the diagnosis of the ignition coil, you need to get a multimeter (capable of determining voltage and electrical resistance, Ohm) and find the technical documentation for the car. Various ignition coils are installed in the cars, and the parameters of a particular model are written in the “passport” of the car. If the car was bought “hand-held”, technical information about its units can be easily found on the Internet.

The parameters of the ignition coil required for its diagnosis are the resistance of the primary winding and the resistance of the secondary winding. If it was not possible to find them, you can rely on the general numbers when testing the element, which will be discussed below.

Methods for checking the ignition coil with a multimeter for basic faults

The ignition coil is an integral part of the vehicle’s starting system. Without it, it will not be possible to achieve the start of the motor, while it is realistic to start the engine without a battery, which also plays an important role in the formation of the first spark. The ignition coil is quite simple, but even it can become unusable in case of various vehicle malfunctions or due to a factory defect. At the same time, when starting the engine, the operation of the ignition coil is not limited, and if it fails when the engine is already started, this will lead to its complete stop. Checking the ignition coil with a multimeter is a sure and easy way to determine the health of the unit and the need to replace it.

How to check the ignition coil

Checking the ignition coil is a three-step process that starts with preparation, then goes through a visual inspection and ends with testing with instruments. The unit can be checked on specialized diagnostic stands in dealerships or professional services. Self-check of the ignition coil is carried out using a multimeter. a universal diagnostic device for a wide range of applications.

Diagnostics of the electronic engine control system and the electrical circuit of the distributor

The ignition coil is located in the distributor, and to check the voltage, it is necessary to bend the latched latch and remove the wires that fit to it from the distributor. Next, you need to take a multimeter and set the parameters for measuring the voltage on it. After that, one of the multimeter wires is applied to the terminal of the ignition coil, and the second to the car body (that is, to ground).

The result of such a measurement with a working ignition coil should be 12 volts, displayed on a multimeter. If there are problems with the electronic engine control system or the electrical circuit of the distributor, the multimeter will show 0 Volts.

Checking the ignition coil with a multimeter

Checking the primary winding for an open

The diagnostic procedure for the primary winding of the ignition coil is practically the same as for checking the secondary winding. Take the multimeter again, which has the electrical resistance measurement mode set, and connect its wires to the positive and negative terminals of the ignition coil, that is, to the external contacts (in most cases).

If, as a result of the measurement, the multimeter shows values of about 0.5-2 Ohm, then there are no problems with the primary winding, and it is operating normally. When the resistance differs from these values, the fact of a break in the primary winding is stated.

Spark testing

It is very easy to test the functionality with a spark. This can be done even on the go, but it does not guarantee that the problem is in this particular device.

Tools and materials

To carry out the spark test, you do not need special equipment, it is enough to prepare the following tools and materials:

- candle key;

- pliers;

- a working candle.

This tool is indispensable. In addition, it is advisable to have an assistant on hand.

Testing by measuring resistance

You can check the ignition coil in another way. For it, you can use resistance as a test characteristic. During the test, the resistance is measured on both windings.

Procedure

During the check, you need to get a spark. To do this, follow these steps:

- Before the test, you need to turn the ignition key to the “0” position so that you do not get an electric shock. Then you need to check all connections, including on the coil and candles, that is, ring the entire electrical circuit.

- Next, you need to remove the tip from the candle on the 1st cylinder and connect it with a working candle.

- Then you need to take the tip with pliers and massage the candle. Spark plug massaging

How To Check A Simple Lawn Mower Ignition Coil

In this case, the skirt of the candle should be pressed against a metal surface that has no coating in the form of paint or other material. Can be used for massaging engine.

If there is no known spark plug in good condition, you can unscrew the spark plug from the engine. This can be done with a spark plug wrench and follow the steps above. But in this case, the used plug may be faulty, therefore it will be necessary to carry out a test with several plugs, also changing the tip. This will increase the likelihood that the cause of the fault is in the coil.

If the engine has individual modules, it is sufficient to swap them for verification. For example, the module from the second cylinder is placed on the first, and from the first. on the second. Only the modules need to be swapped, leaving the wiring in the cylinder.

Types and design features of ignition coils

The ignition coil, called a module, is present in all modern ignition systems: contact, contactless and electronic. Its purpose is to convert the low-voltage on-board current from the vehicle battery into a high-voltage one. High voltage causes spark on the spark plug electrodes, which ignites the fuel-air mixture (FA).

In general, the coil is a transformer with two windings.

Depending on the design features, three types are distinguished:

- individual;

- classic with a common design;

- twinned.

All three types have a similar design, there are only some differences. So once you’ve figured out how to test your ignition coil, you can apply that knowledge to all kinds. You can make a device for checking with your own hands (the author of the video of the HF Auto Electrician).

The design of the classic module includes a primary winding, inside which there is a secondary. Each of the windings has two leads. The primary is supplied with power from the mains. On the secondary, one terminal is high-voltage and is considered an output, and the second is connected to the primary winding. The whole structure is housed in a sealed case, on the cover of which all leads are brought out.

The dual module has two cores. One is internal, located in the winding, the second is external, located above the windings. If a classic coil has only one pin for high voltage, then a two-pin coil has two. They generate simultaneously a spark for two cylinders.

Dual case circuit

The individual coil fits onto a separate candle. The main part of the module consists of turns of copper wire that receives the primary voltage and a secondary circuit that converts the incoming current. The winding, which is the primary, is located inside the secondary converter and has a core that is located inside it. The high voltage that is generated in the secondary winding is directly transmitted to the spark plug by means of a tip, a pressure spring and an insulator. A high-voltage diode is designed to cut off the current.

All types of modules are characterized by resistance, which differs for different models of the mechanism. If the resistance value differs from the nominal value, this indicates a malfunction of the device.

Getting resistance readings

Engine problems can arise from a power failure. If there is a break in the windings or a short circuit, this removes the power unit from the operating state. All types of modules cannot be disassembled, so it is impossible to repair them. In order to make sure that the device needs to be replaced, you need to know how to check the ignition coil.

The most accurate check of the device’s performance can be done using special equipment, which are equipped with service stations, for example, an oscilloscope. There are two ways to check the health of the ignition coil with your own hands at home.

Procedure

Checking the ignition coil with a tester makes it possible to accurately determine that the interruptions in engine operation are associated with its malfunction. To carry out the test, the device must be removed from the car.

Before carrying out the test, you need to find out what the nominal resistance should be. The values of the nominal resistances for the primary and secondary winding of the modules that are installed on the machines may differ. Therefore, you should determine how much they should be for a particular device. Before testing, check the resistance of the measuring device by shorting its probes.

Testing with a tester consists of the following steps:

- First you need to check the primary winding. In this case, the probes of the device must be connected to its terminals, which are most often located on the center terminal on the sides. Having measured the resistance with the device, the resistance of the tester must be subtracted from this value. The result is compared with the nominal value. If there is any deviation, then it means that the module is faulty.

- The next step is to check the secondary winding. In this case, one probe of the instrument is connected to the side terminal and the other to the center terminal. The resulting value must again be compared with the nominal value.

There are special features when checking resistance with a tester for an individual and dual module. You can measure the resistance of the secondary winding in a double coil at any terminal. Its design is such that one impulse is applied to the outputs. It should be borne in mind that for engines with four cylinders, a block can be installed, which consists of two such modules. Therefore, it is advisable to check the resistance at all central terminals.

When an individual module is checked using a tester, the probes during the test are connected to the terminals located on the sides, in the place where the chip with wires is connected.

Particular care must be taken when testing the secondary winding so as not to reverse the polarity. In multimeters, the probes are colored differently. One is red and the other is black. When checking the secondary winding, the red probe is attached to the tip rod on the candle, and the black one to the center terminal on the chip.

Testing the module with a multimeter

precisely, the diagnosis of the ignition coil is carried out using special equipment, for example, an oscilloscope. But at home, it is enough to check in the two ways described above. If it turns out that the coil is faulty, it is replaced with a new one.

Tools and materials

The check can be performed with a special device: an ohmmeter or a multimeter. The device must be able to adjust the range of indications.

Testing tools