How to choose a circular saw

A circular saw, popularly referred to as a circular saw, is today a fairly popular hand tool that allows you to process wood and other materials derived from it. How to choose a circular saw for wood? This question is of interest to everyone who works with wood and needs a quality tool. Nevertheless, it should be noted that, in addition to fiberboard, chipboard, plywood, such a device also makes it possible to work with laminate, plastic, organic glass and slate. To do this, you just need to replace the equipment on the device. put a saw blade with suitable dimensions and select the optimal mode of operation.

The presented saw is included in the arsenal of working tools, both for professional craftsmen and home users. A wide range of models from modern manufacturers enables each customer to find the most suitable option for their case. How to choose the right circular saw to get a good tool without overpaying for it? We bring to your attention some useful tips on this matter.

Circular saw for wood: how to choose and not be mistaken?

The correct choice of a circular saw, as a rule, takes into account the following parameters:

- Cutting disc size. the larger it is, the more powerful the device on which it is installed will be. This indicator indicates the capabilities of the saw and largely affects its final cost. Besides. the higher these values, the more massive and heavier the unit itself will be.

- Sawing depth. this option makes it possible to conditionally divide tools into three types. The former provide cutting to a depth of 40 to 50 mm and are used mainly in the domestic sphere. in the country or at home. The second type is universal, the cutting depth in this case is at the level of 50-65 mm. The third category includes models capable of cutting from 65 to 140 mm. these are already professional class products.

- Disk rotation speed. is responsible for the quality of the work performed. By the way, the increased speed causes the formation of high temperatures during the processing of materials. Not all of them can withstand such heat loads, so experts recommend choosing a hand-held circular saw that has the ability to adjust the idle speed.

In addition to the main indicators mentioned above, in the process of searching for the necessary equipment, you should also pay attention to the presence of additional useful functions, namely:

- slow start. prevents jerking of the mechanism during the start, which significantly extends the service life of all internal components;

- stable speed option. protects against disk jamming;

- engine brake. protects the user from possible injury, and the tool itself from breakage.

We hope we have provided enough information, as a result of which the question of how to choose a hand-held circular saw will no longer pose big problems for you.

Do we need high speed?

The power of the motor and the speed of the blade determine the performance of the saw. The quality of the cut also depends on the speed. However, it must be borne in mind that for different materials the optimal cutting speed will also be different. So, polymers with a low melting point are best processed at a low rotation speed (so as not to melt the edges), and hard wood and MDF. at a high.

It is for the target setting for the desired material that the speed control is used. In other cases, this option remains unclaimed. Therefore, circular saws often have only one idle speed. about 5000 rpm. So advice for summer residents who do not strive for the heights of sawing creativity: get a single-speed saw.

Read the information on the disk: everything is written there

Information about the parameters of the cutting blade is presented on its flat side. Most often, you can find a designation consisting of three numbers, where:

- the first number corresponds to the outer diameter of the disc in millimeters,

- the second reports the number of teeth,

- the third is equal to the diameter of the shaft that rotates the disk itself.

In addition, the maximum permissible number of revolutions per minute is indicated, often the thickness of the cut and, most importantly for us, the material for which the disc is intended.

How to choose a circular saw

Power saws are the most popular type of tools for working in the country. The range of their capabilities is very wide: from felling tall trees to figured cutting of ice figures. The latter, of course, is exotic, but it also takes place.

How the saw keeps you safe?

A circular saw is a really traumatic thing that must be handled with care and respect. The designers have done a lot to prevent accidents with this high-speed and sharp machine.

Here are some examples of this concern:

- The cutting disc is closed from above with a fixed safety guard, and from the bottom. with a movable spring-loaded sector, which hides the disc until the saw comes into contact with the workpiece being cut. When the tool is fed forward, the sector guard should be slightly turned, and the workpiece to be sawn will already push back and expose the saw blade. After removing the “circular” from the material, the lower part of the casing, thanks to the compressed spring, automatically returns to its original position.

- The tool is equipped with a special safety device. a slip clutch. It is triggered when the disc may jam in the workpiece. This is often the case with gambling beginners. In this case, the disc stops rotating and the motor continues to run. And best of all, it does not burn out and does not lead to unplanned expenses.

- Protection against accidental activation is performed by installing a special button next to the start key. To turn on the saw, press them simultaneously. It is perhaps impossible to perform such a combination of different movements by accident.

- Another remarkable invention is the shaft braking unit after the engine is turned off. It limits the “stick out” of the disk and stops it immediately after the user removes his finger from the trigger.

What are the saws

The breadth of the tasks facing the saws has given rise to a variety of their schemes. However, for us, summer residents, two classes of structures, fundamentally differing in the type of working bodies, are of interest. And here you should immediately draw a line between these types of machines, so as not to confuse them in the future:

Circular saws. a technically correct name for tools that use a saw blade as a working body.

And chain saws are a generalized name for tools, the working body of which is a chain with cutting teeth. Depending on the type of drive (electric motor or internal combustion engine), the latter are divided into electric saws and gasoline-powered saws (popularly they are often called chainsaws, which, strictly speaking, is incorrect). But we’ll talk about them another time.

How to Use a Circular Saw to Cut Wood. Power Tools Tutorials. Thrift Diving

Sawing on batteries

The circular saw consumes a lot of energy during operation. Nevertheless, modern battery technology has made it possible to equip it with “batteries”. The cordless circular saw is good where electricity isn’t easy to pull up. For example, when performing roofing work, you no longer have to drag a multi-meter extension cord to the roof, always getting confused under your feet.

There is work for battery models and in extremely damp rooms, such as basements, where often “knee-deep water”. In this case, the main argument for their use will be safety precautions. Indeed, in a humid environment, 18 V battery voltages, even in the most extreme case, will not harm the operator. What can not be said about 220 V mains power supply.

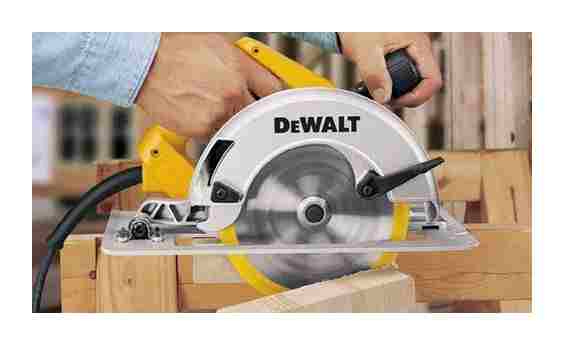

Hand circular saw

This is one of the first tools that a summer resident acquires. We can say that such a machine is “tough” for any business. During repair and construction work, hand-held circular saws (in common parlance “circular”) are used for longitudinal and transverse cutting of boards and beams, as well as MDF, chipboard, laminate and even aluminum.

The main advantage of a circular saw is the relative ease of making long and even cuts with it. It is indispensable when sawing a large number of boards (for example, when making edged boards). This machine also has a noticeable drawback. the circular saw cannot cut along the curve of the mowing line.

At first glance, the design of the “circular” is quite simple:

- electric motor located under the housing,

- reducer,

- saw blade, covered with guards,

- flat wide base with guide stop

- and the riving knife behind the disc.

However, among specialists, a circular saw is considered a very complex tool in technical terms. The bottom line is that here it is necessary to constructively provide justified safety requirements (saws remain quite traumatic machines), as well as maintain high accuracy of the saw blade settings.

Types of gearboxes, their advantages and disadvantages

The connecting link between the electric motor and the saw blade is a gearbox that transmits and converts the motor torque. On miter saws, two types of gearboxes are used. with a gear or a belt drive.

The cogwheels, which provide a rigid connection of the shafts, seem to be more reliable. They do not slip or fly off like a belt, and there is nothing to break there. It would seem that manufacturers of miter saws should give preference to such a reliable system. However, in practice, the belt drive on these tools can be seen more often than the gear.

What is the reason? There is also a downside to the reliability of the gear train. In the event of an emergency situation, the gear reducer may fail, and then it will need to be completely replaced or seriously repaired in a specialized service center.

The “unreliability” of the belt drive can also be looked at with different eyes. Yes, sometimes the belt flies or even breaks, but in order to install it in place or replace it with a new one, special knowledge and skills are not required. an ordinary user can also cope with this task. In addition, the belt provides some damping of radial and axial vibrations, which helps reduce wear on bearings and other engine components.

In the event of an emergency overload of the tool (for example, when the saw blade is jammed), even a well-tensioned belt will slip, which will save the metal parts of the motor from destruction. And the saw with a belt drive produces incomparably less noise, which is also a rather significant factor.

Belt Drive Miter Saw.

By the way, some manufacturers (including such reputable ones as Bosch and DeWalt) have completely excluded the gear unit from a number of their models by installing the saw blade directly on the motor shaft. This solution also has its pros and cons. On the one hand, the load on the bearings increases, on the other, the noise emitted by the tool decreases, the reliability of the structure increases, and maintenance and repair are simplified.

Power and speed

The power of the miter saws can vary depending on the model from 800 to 2500 watts. 1600-1800 W is considered the golden mean. tools of this power are most in demand today, because they do their job equally well both in home workshops and in small production.

What does knowledge of the value of such a parameter as power consumption give us? Firstly, the correct correlation of the power of the miter saw and the structure of the material being processed will avoid overloading the tool, which prolongs the time of its active operation.

Secondly, the more power the saw, the larger the diameter of the blade that can be installed on it. As an example to support this claim, let’s compare two miter saws from Bosch. For the PCM 7 model, whose power is 1100 W, you should select a disc with a diameter of 190 mm or less. But for the GCM 10 J Professional with a power of 2000 W, a disc with a diameter of 254 mm is suitable. It should be borne in mind that with an increase in the saw power and the outer diameter of its disc, the dimensions and weight of the tool increase. So, the first of the models given as an example weighs 9 kg, and the second already 14.5 kg.

Another technical characteristic that you should pay attention to when choosing a miter saw is the number of revolutions of the saw blade. The value of this parameter ranges from 3200 to 6000 rpm. A clean and high-quality cut (no chips of the coating, chipping of wood fibers, etc.) is possible only when working at high speeds.

So, for example, with a saw blade diameter of 260 mm, its angular speed should be at least 2800 rpm. In expensive professional models, the angular speed, as a rule, is not lower than 4000-5000 rpm. even with large disc diameters. Several manufacturers offer miter saws that can be adjusted according to the type of work being done.

Additional accessories

Almost all modern models of miter saws have some kind of additional devices and functions aimed at facilitating work and increasing safety. At the stage of selection, the future user of the tool will have to figure out which of them are really necessary to solve the typical tasks facing him, and which will be an unjustified waste of money.

The dust extraction system consists of a branch pipe and a dust bag or hose of an industrial vacuum cleaner connected to it. The second option is preferable because it allows you to more effectively capture the fine dust of the material being processed, which is formed when performing an accurate cut when the saw operates at high speeds and / or with discs with an increased number of teeth.

The dust extraction system should not be considered as an additional, optional function, even if you are faced with the task of choosing a miter saw for your home, i.e. low-intensity episodic work on it is assumed. Working without a dust extraction system, you risk not only the safety of the equipment available in the workshop (and first of all the saw itself), but also your own health.

The blade guard completely covers the saw blade until it is immersed in the material being cut, significantly reducing the risk of accidents when using the miter saw.

Cutting depth limitation is used to perform work on grooving or trimming profiles.

The laser “draws” the guide line on the workpiece where the saw will cut. The presence of this option increases the accuracy of the cut (especially when sawing at angles other than 90 degrees), facilitates the work, reduces the time for preparatory work.

Illumination of the working area is useful when working in workshops or workshops with insufficient general lighting.

Smooth start provides a gradual set of revolutions by the engine when turned on, which prevents the tool “jerking” at the start, reduces the risk of saw failure due to a sharp current surge and the likelihood of equipment jamming at the beginning of work.

Automatic shut-off when the saw blade is jammed is another useful feature to increase safety when working with a miter saw.

Adjusting the number of revolutions allows you to vary the cutting speed. Most miter saw models do not have this function. However, it allows you to better tailor the sawing process to the characteristics of the material being processed. Recommended for those who intend to work not only with wood, but with various materials based on it, plastic, plexiglass, etc.

Maintaining constant rpm during load increase. With this function, the engine speed does not drop with strong pressure, since the electronics make their own adjustments to the speed. As a result, the cut is neat and clean.

Collector motor

Brush motors look much more attractive from the point of view of the ratio of dimensions and power. With a comparable mass, the torque of a collector motor is several times greater than that of an induction motor. It is capable of delivering up to 5-10 thousand rpm, and the organization of the control system and speed stabilization is much simpler.

It is not surprising that despite the disadvantages of collector motors (high noise level, the need for regular maintenance, which consists in replacing collector brushes), most miter saws are equipped with them.

How to choose a miter saw. tips and advice

Outer and rim diameter of the disc

The main parameters when choosing saw blades, which you should pay attention to first of all, are the dimensions of the outer and bore diameters. Most of the miter saws produced today are designed to work with discs, whose bore diameter is 30 mm.

There are exceptions with deviations in both directions, but there are relatively few of them. The outer diameter of the saw blades varies much wider. The most popular are 10 “and 12” discs. It should be borne in mind that 12 inches can mean both 300 mm and 305 mm, and 10 inches can mean 250, 255 and even 260 mm, and discrepancies occur even from the same manufacturer. Discs of smaller (185-216 mm) and larger (up to 360 mm) diameters are less common, since less equipment corresponding to them is produced.

Increasing the diameter of the saw blade allows you to process workpieces with a larger section, while increasing the productivity of the tool and the quality of the cut at the same speed. However, larger discs also require higher torque and therefore additional headroom. However, it will not be possible to use saw blades whose outer diameter exceeds that specified in the tool’s passport: the trim design simply does not allow installing such equipment, which will save especially careless users from dangerous experiments.

It is possible to install a disc with a smaller diameter, but this is not recommended. This will lead not only to a loss of the effective radius and productivity of the tool, but also to a decrease in the calculated dynamic resistance, as a result of which the engine, in the absence of rpm stabilization, can “run out of gear”.

How to Choose a Circular Saw | Ask This Old House

The purpose of the miter saw

The very name “trimming” serves as an indication of the purpose of this saw. the design of the ends of the workpiece, cutting wood across the fibers. In this it differs from its closest relative. a circular saw, which is usually used for longitudinal cutting of wood.

Modern powerful motors and particularly robust saw blades allow crosscutting to cut not only wood, but also plastic, thin metal profiles and pipes, wood-based composite materials. For these materials, the concepts of “longitudinal” and “transverse” are very conditional: if such terms are used, then we are talking not about the structure of the material, but about the shape of a specific workpiece. Of course, the shape of the workpiece can be very diverse, sometimes without a clearly defined longitudinal axis.

The applicability of a miter saw in one case or another is determined solely by the convenience of feeding a particular workpiece. Thus, the name “miter saw” cannot be considered fully reflecting the potential of this tool, just such a name has historically been assigned to stationary circular saws with a movable cutting unit.

A miter saw can cut material not only at a right angle, but also at an arbitrarily chosen angle, for which it is sometimes called an electric miter box. over, in many modern devices, it is allowed to change the angle not only in the horizontal, but also in the vertical plane, that is, it is also capable of sawing at an angle. With a miter saw, you can even select the grooves if necessary.

As you can see, the capabilities of this tool are much wider than you might have thought at first. It is not surprising that trimming can be found more and more often in small carpentry industries, on construction sites, in home workshops. They are resorted to in the manufacture of window frames and door frames, when laying floors (cutting parquet boards, laminate, skirting boards) and other finishing works (sawing lining, various aluminum and plastic profiles), in the manufacture of wooden furniture.

The device and functionality of the miter saw

The trimming device is easy to understand from the figure, which shows the main components of the tool. Everything else is just add-ons that do not change the principle of operation, but only improve functionality and usability.

Handle with power button.

2. Saw blade.

3. Protective cover.

4. Clamp for fixing the workpiece.

Workpiece stops.

6. Mechanism for fixing the table at a given angle.

7. Horizontal angle adjustment scale.

8. Table.

Vertical angle adjustment mechanism.

10. Dust collector.

11. Engine.

12. Carrying handle.

The main elements of the miter saw are an electric motor and a saw blade made of high quality, ultra-strong steel. The motor, the saw blade and the gearbox connecting them make up a functional block, here is also a handle with a toggle switch.

The entire block is attached to the base. the bed, on which the workpiece to be sawn is placed. On the base are fixed the turntable, which moves when the cutting angle is set, and the stop. The beds of relatively expensive devices are made of durable and lightweight aluminum or magnesium alloys, which ensures not only the reliability of the base, but also the mobility of the entire tool due to weight reduction.

The functional unit is connected to the bed via a pivot arm using a spring-loaded hinge. The swing arm is called a pendulum, and the miter saws of this type are called pendulum.

The pendulum provides movement of the working module. To perform a cut, the lever must be lowered down, “drowning” the saw blade in a stationary workpiece (for unobstructed sawing, there is a slot in the swing circle of the bed). This is the simplest version of a miter saw. As a rule, all modern models are equipped with a mechanism that ensures the rotation of the desktop, along with all mechanisms, in a horizontal plane.

Thus, the guides and table elements remain stationary, and the tool itself changes its position in the horizontal plane. The use of such a tool gives more opportunities for facing.

The saws of the combined type have another hinge, which allows the lever to rotate about the vertical axis (that is, with such saws, the cutting angle can be changed in two planes). Often rotation around a horizontal axis is allowed only in one direction. opposite to the electric drive.

But there are models that allow you to tilt in both directions.

Such technical solutions greatly expand the list of functionality of the tool. Cutting inclined in relation to the vertical allows you to face workpieces whose height is greater than the active radius of the disc.

The cutting width of a miter saw is relatively small, especially when working at an angle or tilt. For example, an average pendulum saw with a 10-inch disc at a right angle will cut a 95 x 95 mm bar or a 69 x 135 mm board (setting any other angles reduces the allowable workpiece size). In other words, the miter saw is not suitable not only for ripping, but also for cross-cutting wide workpieces.

To increase the cutting width, the saw is equipped with a traction function. The working block at the trimmer with this function moves not only around the hinge axis, but also along the mowing line of the cut along the guide rods, due to which the maximum kerf width at an angle of 90 ° increases from 80-180 mm to 280-340 mm. Such tools are called broaching miter saws or horizontal motion saws.

At the same time, the mechanisms that implement the movement of the saw along the workpiece differ depending on the manufacturer and model of the device.

Body material

Most of the models are made of high-strength plastic. The body of a professional tool can be made of metal, which increases the working life of the tool.

Ability to work with metal

Saws capable of cutting metal are multifunctional tools. It is also successfully used to perform work on wood, plastic.

In comparison with the usual angle grinder, which is used for metal cutting, most of the cutting characteristics performed with a circular saw have better parameters.

Benefits:

- Higher productivity;

- Reducing noise and vibration;

- The ability to cut metal at an angle;

- No sparks;

- The metal hardly heats up;

- Safety (the disk is not prone to tearing);

- Longer service life of a carbide disc (100 times higher than a disc for an angle grinder);

- Low cutting price (only the guillotine is cheaper);

- High cut quality (no burrs).

Disadvantages:

- Relatively high price per disc.

Plunge-cut circular saw

The plunge-cut saw was developed to solve a problem that arises when cutting a workpiece with a circular saw: insufficient sawing accuracy. Positioning the saw blade with absolute precision is not possible, since there is no way to control the position of the blade relative to the workpiece.

The plunge-cut saw is devoid of these drawbacks, it has a slightly different principle of operation. In non-working position, the disc is completely hidden under the protective cover and located above the base plate. The cutting blade is lowered only when the tool is switched on.

The plunge saw can be used to make local repairs to floorboards or to cut the desired opening in the worktop. Cutting precision is adjustable to the millimeter. Sawing capacity at 90 °, depending on the model, ranges from 10 to 75 mm.

When working with laminated material, the top layer is cut to an incomplete depth of the workpiece, excluding the appearance of chips.

Benefits:

- High precision of workpiece processing;

- Multifunctionality;

- The ability to perform cross and longitudinal cuts.

Disadvantages:

- High price compared to conventional models;

- Difficulties in cutting parts of small width. their minimum size is limited by the dimensions of the support part of the tool.

Circular saw design and how it works

Most circular saws have a similar design, the difference is in additional elements that expand the functions of the tool or increase the safety of working with it.

The main elements of the saw design:

- Body with one or two handles;

- Saw blade guard;

- Platform to hold the disc in position;

- Riving knife to free a disc stuck in wood;

- An electric motor on the shaft of which the disc is attached with bolts.

The peculiarity of the saw. with its help, you can cut the material only in a straight line (transversely or longitudinally), without the possibility of arc cutting.

The principle of operation is to transfer the torque from the motor shaft to the saw blade, which rotating at high speed around the axis, cuts off wood or other material.

Depending on the cutting depth, the tool is divided into saws:

- Small. 40-46 mm;

- Medium. 50-55 mm;

- Large. 65-70 mm;

- Professional. 65-140 mm.

The best circular saw manufacturers. which company to choose

European and Asian companies have been competing for a long time, fighting for a leadership position in the construction tool market, while improving product quality and expanding its functionality.

Top circular saw manufacturers:

How to choose a circular saw for home and garden

A circular saw is a hand-held tool for sawing workpieces from a wide range of materials: wood, plastic and even metal. The tool is indispensable on the personal plot, where the construction of a country house is underway. In the apartment, a saw will be needed during the renovation: it can be used to cut plywood, laminate, door fittings, plastic panels.

Which circular saw to choose

Recommendations for choosing a circular saw for home and garden:

To carry out a small amount of work from time to time, you can purchase a tool with a power of 1-1.2 kW.

For construction work at a summer cottage, where it is required to cut timber, boards, plywood and other sawn timber, you can purchase a circular saw with a power of more than 1.2 kW and a cutting depth of at least 60 mm.

For professional use, you can purchase models with a capacity of more than 1.2-1.5 kW, with a high number of revolutions (more than 5 thousand) and a maximum cutting depth at right angles (more than 60 mm).

If it is necessary to manufacture grooves and cutouts in blanks, you can purchase a plunge saw.

When performing work related to the construction of metal structures, where metal cutting is required, you can consider the option of using a circular saw for metal. The advantages of using it are described above.

Rpm

This parameter determines productivity, cutting quality and the ability to work with different materials. The higher the indicator, the denser materials the saw can handle. It should be borne in mind that the higher the indicator, the less likely the disc will jam.

Military DS1250

An inexpensive circular saw for cutting boards, timber and soft metals has a power of 1.25 kW and comes with a 185 mm blade. It receives power from the mains, weighs only 3.4 kg, it is easy to carry from place to place. During operation, it almost does not vibrate, but the model also has a minus. there is no blocking from accidental activation on the case.

The Military hand saw is inexpensive, only 2400 rubles

Smooth start

If the circular saw is started immediately at full throttle, it will lead to an unpleasant jerk of the device in the hands. In addition, the engine is then subject to wear more quickly. Soft start is responsible for the tool starting up and accelerating gradually. The function increases the convenience of use and prolongs the life of the saw.

Bosch PKS 40

The 0.85 kW manual device handles both longitudinal and cross cuts. Equipped with the CutControl system, which monitors the evenness of the cut, and is completed with a branch pipe for connecting a vacuum cleaner. Also included in the kit is a 40-tooth nozzle, which is suitable for most cuts. Comes with a solid molded sole, easy to hold with one hand. On the downside, users refer only to the lack of speed control.

You can buy a Bosch PKS hand saw for 5100 rubles

The rating of hand-held circular saws helps you choose a compact but functional device for your home and summer cottage. The tool is suitable for fast and accurate processing of wood of any thickness, but it is important to know what criteria to look at when buying.

Bort BHK-185U

The circular saw with 185 mm blade handles wood and other materials up to 64 mm thick. Convenient to operate, has an ergonomic body with a rubberized handle. Maintains a maximum speed of 4500 and quickly makes a cut. The disadvantages include the weak fastening of the screw, which is responsible for adjusting the cutting depth.

Average

How to choose a hand-held circular saw for wood for your home

A hand saw seems to be a simpler tool than a stationary circular saw. However, it must be chosen very carefully, otherwise the tool can be disappointing.

Which blade is best for a hand-held circular saw

When choosing a handheld circular saw for your home, it is important to pay attention to the attachment:

- For a medium-power household appliance, 185 mm discs are suitable.

- Semi-professional devices are distinguished by increased sizes of cutting wheels. up to 210 mm.

- Professional tools have the widest discs up to 235 mm.

The smoothest cut is ensured by discs with frequent and fine teeth

The more teeth the blade has, the smoother the edge will be. In particular, it is recommended to choose:

- 50-60 teeth for a neat, almost planed cut;

- 40 teeth for standard cuts;

- 18-25 teeth for sawing wood along the grain.

Rating of the best hand-held circular saws for wood for the home in 2021

When choosing a home circular saw, you can familiarize yourself with the best models that have earned high ratings from users. Such devices support cutting of any wood, regardless of its hardness, and the price remains affordable for everyone.