STIHL oil pump 180, 170-250.Cleaning the oil circuit.

Like all machines, gasoline-powered tools eventually have to be disassembled and reassembled even when they are working properly and in perfect working order. The STIHL chain saw disassembly, in turn, is presented as a strict step-by-step, but uncomplicated procedure. We will present the corresponding steps, supplemented by informative photos and even a video, whether you need a complete or partial disassembly of the STIHL 180.

Due to the fact that this chainsaw is very popular among customers, we will present a peculiar scheme, which is the same for most other Stihl products to disassemble as well. STIHL and experienced users recommend that you have a look at some of the components of your chain saw if you don’t like the way it sounds, if there is a slight change in the operating rate, output or other seemingly insignificant nuances.

It is also advisable to review your chainsaw before preserving it for the winter, to lubricate the parts that need it, to get the important parts. As for the latter, you can always buy chain saw parts on the pages of the KosiKosa store, and we will be happy to help you with this.

How to disassemble a STIHL chain saw correctly

Before you can dismantle your STIHL chain saw you first have to do the following preparatory steps. Prepare a comfortable table, dry rags, brushes to gently wipe down parts, clean water, gloves and a dry place away from the fire. It is also important to understand that the machine should be free of fuel. It’s better to work it out than to drain it and let the saw cool for some hours before disassembling. The procedure is simple and straightforward:

- Remove chain, guide bar and side cover;

- Use a compressor if you have one, brushes, a dry sponge to clean the STIHL of oil, dirt, dust, sludge and sawdust. Pay special attention to the drive sprocket. it may contain a lot of fouling and dirt;

- if it is difficult to remove large amounts of dirt mechanically, you can use clean gasoline;

- find three rubber buffers and take off the handle. This can be done by removing the plugs. Using a strong screwdriver, squeeze out first the upper shock absorber, and after that the one by the rear handle;

- Disassemble the back of the handle by removing two screws. This is how we disconnect the rod from the gas trigger (it connects the carburetor and the gas trigger, which is in the handle);

- at the moment of the handle fixation only on the shock-absorber. we as if unscrew all “insides” of the saw and breaking aside. remove from the last fixation on the type of rubber band;

- the starter is removed by removing the upper housing cover, and unscrewing the 4 screws on which it is mounted. Next, remove the tank covers. fuel and oil. Under the starter is often an accumulation of dirt, sawdust, which should also be cleaned;

- A 13-mm socket will help you unscrew the flywheel. We block the crankshaft from twisting by unscrewing the plug, namely through its hole we fix the piston lock;

- On the fact that the piston is blocked. you can unscrew the flywheel nut;

- Remove the clutch beforehand. disconnect the drive sprocket. Lock washer is removed from the grooves, also the needle bearing;

- Disassembling the STIHL 180 chain saw involves removing the clutch with a size 19 head. Next, remove the deflector plate and the oil pump drive;

- disconnect the ignition wires and air damper rod from the part referred to as the engine lever, and remove the lever itself. Further we unscrew nuts of carb and air filter with suitable head for 8 with extention (if it is present);

- by unscrewing two nuts and pulling a little. you will remove the next part, the muffler;

- there are 4 screws in the bottom of the saw that hold the motor. When removing it gently, don’t forget about the carburetor’s rubber pipe, which can be nicked.

Disassembling the engine of the unit is a separate scheme, but in general, how to disassemble the STIHL chain saw. we reviewed. Regarding other popular models like the 250. the procedure should be carried out in the same way. Like other parts, you can always order a file for sharpening chains from KosiKosa.

When to adjust the STIHL 180 carburetor

To begin with, it is worth determining why you may need to adjust and repair the carburetor STIHL ms 180 at all. So, to do this is necessary in the following cases:

- If the chainsaw won’t hold idle speed;

- Repair may be necessary if the saw will not start;

- there is a loss of power;

- Increased fuel consumption;

- The chain saw does not reach its maximum rpm.

- Stops at revs.

This list can go on for a long time, but the main reasons we have identified. Before you start adjusting, you need to know what the carburetor on your STIHL 180 chain saw consists of, and who makes it.

Cost of repair work and carburetor replacement

If there is no experience in repairing parts of STIHL chain saws, it is better to entrust it to professionals. Price depends on complexity of repair and region. The average values are as follows:

- Diagnosis of the gasoline chainsaw. 300;

- carburetor replacement. 300;

- comprehensive service (the complex includes flushing, installation and adjustment). 1000;

- external cleaning without disassembly. 300;

- adjustment. 300;

- Reassembly of the carburetor and engine. 2000;

- sealing of the nozzle. 200.

See ” Top 2 reliable and comfortable models of American chainsaws Poulan

Regular carburetor tune-ups are a great way to improve your chainsaw’s performance and lower your fuel costs. We recommend following the exact procedure or having the handle removed by a specialist.

Removing the handle

To disassemble the STIHL 180 the handle must be removed. It is fastened to the frame with three rubber buffers. To remove the rubber buffers it is necessary to remove plastic plugs from the inside cavity of the buffers, and then using a strong screwdriver to first press out the upper shock absorber and then the one closest to the rear handle.

There is an throttle trigger at the back of the handlebar which is connected to carburetor through a wire tie. To disconnect it from the throttle trigger you should unscrew two screws and dismantle the handle.

When the handle remains on one shock absorber, it is necessary to unscrew the chainsaw body from the inside of the handle and, breaking to the side, remove the body from the last rubber.

Malfunctions of the pump and the system as a whole

As you know, nothing in this world is permanent and over time everything has to be repaired. The STIHL oil system in the mc 180 is no exception, and has its own specific faults. Let us consider them in detail.

There are two ways to tell if the lubrication system is malfunctioning:

- The chain is absolutely dry and is not shiny;

- Oil won’t come out of the oil tank;

- The chain is getting stretched fast and constantly;

- The guide bar moves sideways when sawing;

- The bar is warm and around the drive sprocket, the paint is melted.

All of these signs are an indication, either directly or indirectly, that there is a problem with the chain lubrication system of the chain saw.

The first thing to do after you suspect the chain lubrication oil is not coming in is to check the oil flow. There are two ways to do this. The first one is described in detail in the instruction to the tool and consists in the following: start up the chainsaw, increase gas pressure as much as possible and direct it towards some obstacle.

If the lubrication system is working properly, oil will fly off the tip of the tire and a streak of oil droplets will appear on the surface where the tire is pointing. If there are irregularities in the system, the surface should be clean.

The second way is to remove the bar from the chainsaw and start it. When the engine speed increases, at the place where the bar shank is installed, oil will flow from the oil channel, if this does not happen, it is necessary to look for the cause of the malfunction.

Diagnosis

To diagnose the problem first check the STIHL 180 oil receiver (filter) and make an inspection. As a rule, if the filter is heavily contaminated, the oil supply may stop.

To save money, a clogged filter, you may try to clean it out by giving it a good wash in gasoline.

Next, you must remove the sprocket drum, and check the condition of the drive pinion. The threads on it should be well pronounced, not nicked or have any other defects, also with the gear removed, you should check the wire lever. It must crimp the pinion tightly and not turn, otherwise, the pinion stands still and does not transmit power to the pump, causing the oil supply to stop.

If all these remedies didn’t help you to find the problem you have to take extreme measures. е. Dismantle the pump.

How to Remove the Pump

The oil pump is installed on the right side of the bottom of the body, in the same place it is connected to the oil pipe that comes from the gasoline tank. To remove the pump, you must first loosen the saw from the handle by unscrewing the back handle of the unit and disconnecting the throttle control rod. In the next step you need to take out the handle shock absorber plugs and with the help of a strong slotted screwdriver press them out of their places on the handle.

After the handle has been removed, the chainsaw body should be turned upside down. The hose that goes from oil tank to pump is immediately visible. It must be removed from the seat.

The pump itself can be removed by means of a screw with M5 thread and a wide washer. Length of the screw should be approx. 45-50mm. A washer is put on the screw and screwed into the pump (pump is threaded on the inside). Next, as the screw is screwed in, a stop made from a washer will force the oil pump up the threads. thereby the pump is removed from its seat. Before you start, we recommend that you read about how to disassemble the STIHL 180.

To understand the removal process better you can watch the video below. In the video the master chain saw operator shows in detail how to remove the oil pump from the chain saw and describes the main faults in the feeding system.

The STIHL oil pump 180 is a high-quality and robust piece of equipment, so it should only be replaced if all other system components have been checked.

After the pump has been removed you should clean and flush it out. As a rule, the main breakdown of an oil pump is its clogging. After it is fixed, the pump can be put back in its place.

The pump only needs to be replaced if a blockage cannot be removed.

The cause of oil leakage on the underside of the chain saw

The STIHL 180 chain saw has a defect in that the oil hose is not properly sealed in the chain saw and leaks in the oil tank. To fix it, simply remove the STIHL MS 180 saw handle, disconnect the hose, rinse and degrease the seat in the housing and the hose shank, then apply sealant and put the hose back in place. This simple procedure reliably prevents the oil from leaking.

How the STIHL 180 works: design, principle of operation

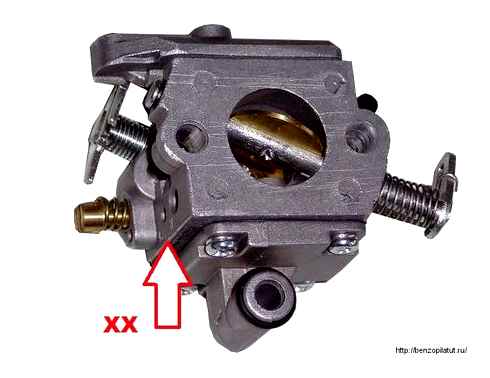

The major components of the STIHL 180 chain saw carburetor include the following:

- fuel pump (with internal diaphragm);

- Main (diaphragm) chamber;

- diffuser;

- Throttle and air valves;

- Needle valve;

- fuel injectors;

- nozzle and valve;

- idle speed adjustment screw.

Operating principle is as follows. The chainsaw crankcase is connected to the fuel pump in the carburetor by a special channel. Alternating piston stroke creates vacuum in the engine crankcase. The diaphragm in the fuel pump is lifted and the valve opens to deliver fuel to the carburetor.

Fuel goes through the filtering element (sieve) and through a special channel gets into the main chamber. In this chamber, the control diaphragm is installed, which regulates the flow of fuel by pressing the rocker arm, which in turn lowers the needle valve.

For raising the control diaphragm, the vacuum produced in the carburettor diffuser by turning the air valve, throttle valve. As soon as the engine is running, the mixture is thinned. We lower the choke, the vacuum in the diffuser is minimal, the diaphragm falls into place.

Fuel flows from the main chamber to the nozzle and nozzle with check valve or through the nozzles at idle speed (when the throttle is closed). There, it mixes with the intake air and the ready mixture enters the engine cylinder. Check valve prevents air from the diffuser to the main chamber.

Throttle flap

Tuning a STIHL saw carburetor Tuning a chainsaw carburetor. Or how not to pay repairmen! Owning a chainsaw makes life a lot easier, even for the amateur, and in some professions this tool is virtually indispensable. But like any relatively complex appliance, chainsaws require periodic maintenance. Because of untimely or poorly maintained.

How to Adjust the Carburetor on a STIHL Petrol Saw 3 The adjustment of the carburetor of a lawn mower make in home conditions lawn mowers, as well as all gasoline tools for the garden, is not difficult in service technique. Repair, adjustment without the aid of others is possible and necessary. For example, adjusting a lawn mower’s carburetor at home is a five-minute affair. The carburetor from the lawnmower is a node in the power system.

How to Adjust the Carburetor Lawn Mower STIHL Fs 3 lawn mowers, as well as all gasoline tools for the garden, is not difficult in service technique. It can and should be repaired and tuned without the aid of others. For example, adjusting the lawnmower carburetor yourself is a matter of 5 minutes. The lawnmower carburetor is the hub in the power system. In a personal computer, as well as all carburetors, goes.

The throttle valve, installed in the carburetor body and is responsible for increasing the flow of fuel consistency specifically in the cylinder of the motor. At the moment of pressing the gas, throttle plate opens, thus increasing the capacity of the channel and the fuel from the cavity of the carburetor, rushes into the cylinder in a larger volume.

Combustion of larger quantities of fuel increases the amount of energy available, which in turn influences the power and speed of the processes. The choke is mounted on a shaft extending all the way through the carburetor body. At the outlet of the shaft from the body, there is a mount for the throttle cable, next to it is a tapered adjusting screw, which is responsible for adjusting the idle speed. By tightening the screw of course slightly to adjust the position of the shaft and the choke attached to it, thus increasing or otherwise decrease the idle stroke, opening or otherwise closing the choke.

Particulars of carburetor cleaning on STIHL and Husqvarna chain saws

It does not matter if you have a STIHL, Husqvarna, Partner, or other brands. On all models the carburettors can be cleaned in the same manner as described above. The only difference is in some design features. On STIHL chain saws the carburettor jets have copper-plated or brass jets and must be removed for cleaning.

To adjust the mechanism on Husqvarna chain saws the same way. Only the design is different, but the adjustment principle is the same as described above.

Removing and disassembling the engine

The engine is held in place by 4 screws on the bottom of the STIHL 180. To remove it is necessary to unscrew them, and then carefully remove the engine from the seat and the rubber spigot of the carburetor.

To disassemble the engine unscrew the 4 screws of the crankcase and remove it, then you can remove the crankshaft complete with oil seals, bearings and piston rings.

Removing bearings and oil seals normally requires no tools

, but if the bearings have been pressed on the shaft with force, a special puller is needed for disassembly.

To remove the piston from the connecting rod, you need to remove the retaining ring from the seat with a thin screwdriver, then from the opposite side press out the piston pin, after which the piston is removed to the side.

Adjusting the carburetor of a chainsaw with your own hands

To adjust the regular carburetor yourself, the owner of the chainsaw will need a Phillips-head or flat-blade screwdriver. as well as a manual tachometer.

To adjust the carburetor of a chainsaw. There are spring-loaded adjusting screws in the carburetor’s basic design.

Depending on the brand-manufacturer of the chainsaw, the marking of its adjusting screws may vary. Nevertheless, in order to properly adjust the carburetor on a chainsaw initially. you can always act on the same algorithm:

- First, the operator must find in the instruction manual of the saw the exact angles of gradual turning of the spring-loaded adjusting screws. Immediately after that on the used saw with the motor turned off they must be turned according to the instructions in the manual. If this is not done, the operator risks breaking the engine of the tool;

- Then the chainsaw used in the household must be set firmly on a flat, stable surface. At the same time, the bar and the factory chain should initially point away from the operator;

- Then you need to start the saw’s engine and give it at least 10 minutes to warm up;

- After that it is necessary to find the correct position of screw L. To do this, the operator should slowly turn it clockwise and counterclockwise until the engine is quiet and without dips;

- If this causes the chain to start rotating, then you need to find the position of the T screw where the chain will stop in place:

- Next, connect a tachometer to the cylinder of the internal combustion engine. Then you should start turning the H screw. As soon as the tachometer reading is in agreement with the instructions in the manual, you can let go of the thumbscrew.

To check the carburetor and the chainsaw engine you need to start the engine again and slowly pull the throttle lever. If the engine is gaining speed smoothly, it means that the adjustment was performed correctly. If not, you will need to turn the L screw 1/8 turn counterclockwise and check the motor again.

What to flush the carburetor of a chainsaw?

You should think about cleaning the fuel unit of a gasoline tool in the following cases:

- when the engine is difficult to start;

- When the engine is unstable at short idle;

- in the case of a lag when the regular throttle trigger is pressed smoothly;

- in case of a considerable increase in the consumption of refueled fuel.

Most often, to flush the built-in carburetor of a chainsaw, liquids are used, which are available in almost every garage:

Modern gardeners, who use powerful professional saws, use more effective and gentle means:

- Mannol Vergaser Reiniger, a cleaner commercially available as an aerosol. It quickly and easily breaks down even the oldest formations of tar, carbon deposits, oily plaque and other types of dirt;

- Hi-Gear. this cleaner stands out for its high dissolving properties. It can remove old dried-on stains, oily encrustations and the first signs of rust without damaging the fuel system parts;

- Jet 100 Ultra is a high-tech spray designed for fast cleaning of chainsaw carburetors. Shows a high rate of dissolving the oldest oil stains.

Cleaning the carburetor on the chainsaw is performed in this sequence:

- First you need to clean the outside of the saw’s engine and remove and thoroughly wash the factory air filter housing;

- Then you can move on to disassembling your power tool. To do this, you need to remove the filter housing and also unscrew the fasteners that hold the carburetor together with the engine;

- Then you will need to carefully disconnect the pull rod and throttle cables from the carburetor. The springs available in the structure must be removed so as not to stretch them;

- After that, you must carefully pull the fuel hoses off the factory fuel fittings of the fuel assembly;

- To clean the carburetor on a chainsaw. You need to remove it from the brand-name mounting studs. It is important to maintain the integrity of the gasket installed between the engine cylinder and the fuel assembly;

- The next step is to clean the outer walls of the carburetor. To do this, they can be treated with a liquid cleaner or gasoline. At the same time it is necessary to try that the dust and debris did not get inside the unit or the motor cylinder;

- Next, you will need to unscrew the screws fixing the carburetor diaphragm, remove its cover and wash the internal cavity with an aerosol cleaner;

- After that, it is necessary to dismantle the fuel filter of preliminary fine cleaning, as well as to disassemble the part of the assembly, to which the fuel is supplied. All internal parts of the carburetor should be thoroughly washed with a spray cleaner. If the first cleaning did not yield results, then the flushing should be repeated.

After the final drying of all the internal parts of the regular carburetor, it is necessary to assemble the fuel assembly in reverse order, and install it in place in the construction of the utility chainsaw.

Troubleshoot the carburetor

If, as a result of pressure on the gas, the chainsaw begins to stall, the problem is in the carburetor. Also a sign of carburetor malfunction can be a delayed start of the chainsaw and the inability to gain revolutions.

Most often such a malfunction occurs as a result of wear of the rubber sleeve, which is placed on the piston of the fuel gas pedal. This results in an air leak when starting the tool. In general, such a breakdown occurs after several years of use of the chainsaw.

The elimination of this malfunction is carried out in the following sequence:

- Remove carburetor. Unscrew the screw that holds the cover with the diaphragm. Turn the carburettor so that the pin is visible. It is necessary to remove the retaining ring and disconnect the spring of the choke. After that the choke. To do this, you need to unscrew the screw that holds it. The next step is to remove the choke axle.

- Pull the gas pedal with spring. It has a collar. Wear of this very element leads to air suction and engine stalling after a recent start. The piston and cuff must be replaced.

- Assemble the carburetor in reverse order and install it on the chainsaw.

This is interesting: if there is no spare gas pedal on hand or it is impossible to buy it in the store, you can use an alternative repair. In this case, a plug is installed instead of a piston. This prevents air infiltration. After this repair, the chainsaw will work properly. The difference will be that it will take a little longer to start.

Now you know how to eliminate the frequent failure of the carburetor. Observing all the rules, you can easily perform these works with your own hands.

Read also: Changing blades on an Interskol planer

Advantages and disadvantages

Zama carburetors are very reliable and easy to use. The STIHL 180 chain saw has a carburetor that doesn’t have the sand quality and quantity settings we are accustomed to. One screw makes adjustment much easier.

The diaphragm carburetor has no major disadvantages. With a carburetor like this the chain saw works in any position. When sawing from the side, upright, etc.д.

Despite the aforementioned advantages, the carburetor is sensitive to fuel quality. In addition to clean air from the air filter, the carburetor needs to be fed with cleaned fuel from the gas tank. But it is not always possible, so it must be cleaned and blown out at least once every six months.

How to clean a chainsaw carburetor with your hands

Several signs can indicate that a carburetor needs cleaning. For example:

- It’s hard to start the engine.

- the engine can not get the maximum speed.

- The chainsaw stalls when idling.

- Increase in rpm and you can stop the engine.

- Muffler emits black smoke when in operation.

- Fuel consumption increases.

- Engine stops while warming up.

If you see one or more signs of chain saw malfunction you need to clean the equipment. To do this, experts recommend following this sequence of actions:

- Get a cleaner. It is also possible to use WD-40 solvent.

- Dismantle the carburetor.

- Disassemble the unit, starting with the place where fuel is pumped. the diaphragm pump. For this purpose just unscrew the fastening screw.

- Remove the top cover. The diaphragm pump can be accessed by removing the cap.

- The membrane should be clean, elastic and soft. If it is stiff and clogged, it must be replaced.

- Now it is time to assess the condition of the fuel filter screen. If you find clogging on its surface, they must be removed. To do this, the mesh is removed and cleaned with a soft brush.

- After that, you need to turn the carburetor to yourself with the back side and unscrew the fastening screws that fix the plate.

- Under the plate there is a second diaphragm that controls the needle, closing and opening the hole through which the fuel enters.

- It must also be clean and elastic. Otherwise the second diaphragm must also be replaced.

- A small foot is connected to the needle, if it has a bent look, it can be carefully bent towards yourself by 0.5-1.0 mm. If this is not done, the needle will not be able to open fully, reducing the power output of the chainsaw motor.

- Now you can clean the inside of the device and blow out the ducts with a cleaner. On its spout is a long tube with an atomizer, which makes it easy to work with.

After cleaning is complete, the equipment is assembled in the reverse order of disassembly.

Cleaning the carburetors on STIHL and Husqvarna chain saws

Cleaning process does not depend on the brand of chainsaw. The only difference is in the design. STIHL and Husqvarna carburetors, for example, have additional jets. Can be made of brass or copper. When cleaning the carburetors of these models jets also need to be dismantled and clean.

Timely cleaning of the chainsaw carburetor the unit will work efficiently and without interruptions.

How to clean a chainsaw carburetor with your own hands

There are a number of signs that a carburetor needs cleaning. For example:

- The engine does not start easily.

- Engine cannot reach maximum rpm.

- Your chain saw stops when idling.

- RPM increases and the engine stops.

- There is black smoke coming out of the muffler when operating.

- Fuel consumption increases.

- Engine stops when warming up.

If you see one or more signs of chain saw malfunction you need to clean it. To do this, experts recommend adhering to the following sequence of actions:

- Purchase a cleaner. Do not exclude the possibility of using WD-40 thinner.

- Perform removal of the carburetor.

- Disassemble the device starting from the place where the fuel is pumped. membrane pump. To do this, it is enough to unscrew the fastening bolt.

- Remove the top cover. By removing the cover you can get access to the diaphragm pump.

- The membrane should be clean, elastic and soft. If it is stiff and clogged, it must be replaced.

- Now it is time to evaluate the condition of the fuel filter mesh. If there are clogs on its surface, they must be removed. For this purpose remove the mesh and clean it with a soft brush.

- After that you need to turn the carburetor to yourself with the back side and unscrew the fixing screws that fix the plate.

- Under the plate there is a second diaphragm that controls the needle, closing and opening the hole through which the fuel enters.

- It must also be clean and elastic. Otherwise the second diaphragm will also have to be replaced.

- A small foot is connected to the needle, if it has a bent appearance, it can be carefully bent to itself by 0.5-1.0 mm. If this is not done, the needle will not be able to open fully, reducing the power output of the chainsaw motor.

- Now you can clean the inside of the device and blow out the ducts with the cleaner. There is a long spray tube on its spout, which makes it easy to work with.

After cleaning is complete, the equipment is assembled in the reverse order of disassembly.

Cleaning the carburetors on STIHL and Husqvarna chain saws

Cleaning process does not depend on the brand of chain saw. The only difference is the design. For example, STIHL and Husqvarna carburetors have additional jets. They can be made of brass or copper. When cleaning the carburetors of such models, the jets also need to be removed and cleaned.

Timely cleaning of the chainsaw carburetor the unit will work efficiently and without interruption.