How to correctly adjust saw teeth

Blades of wood hacksaws are made of corrosion-resistant alloyed steel with hardness of 40-50 HRC units. Thanks to such material the tool retains its qualities even if it has not been used for several tens of years. In order to bring even an old rusty blade back into operation it is enough to correctly sharpen and set the teeth, but for this you will need some tools and equipment. Let’s say right away that modern cutters with hardened serrated edge (where you can see the colors of discoloration) are not sharpened and set, but only after the annealing of the blade.

Securely fasten the hacksaw by means of a piece of board, on the end of which a cut is made parallel to the wide side. The cut has to be made with the same hacksaw that is being worked on, the depth is about 70-80mm. The blade must be inserted into the kerf with the bevel downwards, so that the teeth protrude from the kerf to a height of at least 50 mm. The wooden plier itself should be clamped in a vice, or fixed to any stationary object, immobilizing the blade with a wide and thin wedge

As a further enhancement to the saw blade, a similar holder can be used to secure the saw blade quickly

Processing of metals of this hardness is possible manually and mechanically. In the first case you can use files with 60 or 65 HRC hardness, or diamond escapement files. While machining, electric grinder with white electro-corundum stone on a vulcanite binding installed on it is used. Optimal diameter of the wheel is 120160 mm, the thickness should not exceed 8 mm, otherwise the face has to be set to a disk-shaped profile. Grit size of abrasive particles should be P 120-140 or higher.

A tool called a setter is required to set the teeth. It is a thin plate on the handle, with one or more cross cuts of different widths. The edge of the hacksaw should enter one of the cuts so tightly that the slope of the handle relative to the blade was at a right angle /. 2 °. To make the setting even and symmetrical in both directions, an adjustable angle stop in the form of a metal arc is attached to the setting.

Mans Reading

Like any tool, hand saws and hacksaws require care and maintenance. High accuracy and cleanness of cut is possible only if the teeth are properly sharpened and set. No need for special tools, just a basic understanding and some basic knowledge.

National Encyclopedia of Building ProfiDom.com.ua tells in this publication, how to properly sharpen and set up a saw

Theoretical To get a good cut, you need to understand how the saw’s cutting edges interact with the material you are cutting. Unlike steel and plastic, wood. the material is not homogeneous, precisely because of its properties, and several types of saws have been developed, differing in the profile of the teeth, the angle of their sharpening and the degree of separation.

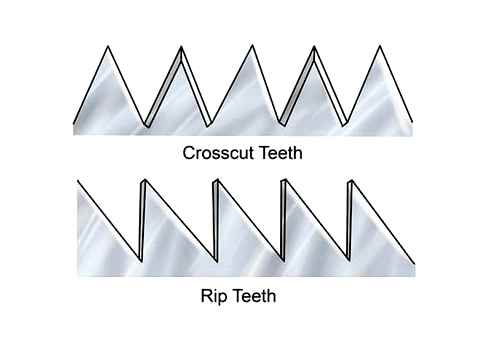

Basic types of wood hacksaw teeth. 1. cross-cutting type 1; 2. cross-cutting type 2; 3. longitudinal type 1; 4. longitudinal type 2; 5. universal sawing

There are three types of sabre saws: cross, rip and universal. The main difference lies in the cutting principle: when sawing wood across the grain, the teeth encounter fragments of different densities. This fact, on the one hand, is advantageous: the chips generated are smaller and easily removed from the contact zone, allowing the presence of the blade on both sides of the tooth for sawing, both in forward and reverse feed direction.

On the other hand, cross-cutting cuts are partly impact cuts, so blunter angles of the cutting edges are required.

Sawing wood along the fibers can be characterized as repetitive micro planing cycles. the force on the tooth is uniform, so the teeth are asymmetrical and point in the direction of cutting. In this case, the edge formed at the apex of the tooth is directed strictly perpendicular to the plane of the blade. Cutting along fibers creates elongated chips that are difficult to remove from the contact area.

Also, during longitudinal cutting, more moisture, resins and adhesive substances are released, which, in combination with the first factor, prevents sawing in both directions. chip evacuation occurs when the tool is moved straight: the perpendicular cutting edge direction causes swarf to be ejected in the sawing direction. The reverse movement removes chip residues and cleans the edges.

Teeth of all types of hacksaws are set, they are alternately tilted in different directions from the longitudinal axis of the blade. Due to this, in the longitudinal profile of the row of teeth of the hacksaw a kind of dovetail is formed. two sets of cutting wedges formed by the tips of the cutting edges of the teeth. Accordingly, two grooves are created in the saw blade at the bottom of the kerf, thus assuring evenly stepped removal and efficient chip evacuation.

Tools and equipment, preparation for work Wood hacksaw blades are made of corrosion-resistant alloy steels with hardness of 40-50 HRC. Thanks to this material, the tool retains its qualities even if it has not been used for several decades. To bring even an old rusty blade back into operation, all that is needed is to properly sharpen and set the teeth, and this requires some tools and tooling. Let us mention right away that modern hacksaw blades with hardened serrated edge (where you can see the tarnishing color) are not adjustable and not sharpened, but only after the annealing of the blade.

Securely clamp the hacksaw using a piece of board with a kerf cut parallel to the width of the hacksaw. The cut should be made with the same hacksaw that is being worked on, the depth is about 70-80 mm. The blade should be inserted into the kerf with the butt downwards, so that the teeth protrude from the kerf to a height of at least 50 mm. The wooden plier itself should be clamped in a vice, or fixed to any stationary object, immobilizing the blade with a wide and thin wedge

As a further improvement of the jigsaw, it is possible to use a similar holder to fix the saw blade quickly

Machining of metals of this hardness is possible both manually and mechanized way. In the first case you may use files with 60 or 65 HRC hardness or diamond escapement files. When machining, an electric grinder with a white electro-corundum stone on a vulcanite binder mounted on it is used. Optimal diameter of the wheel. 120 160 mm, it is desirable that the thickness does not exceed 8 mm, otherwise it will be necessary to tuck the face to the disk profile. Grit size of abrasive particles should be P 120-140 or higher.

To set your saw’s teeth, you will need a tool called a setting tool. This is a thin plate on the handle that has one or more cross-cuts of different widths. The edge of the hacksaw must enter one of the cuts so tightly that the tilt of the handle relative to the blade is at a right angle /. 2°. To make the set even and symmetrical in both directions, an adjustable angle stop in the form of a metal arc is fastened to the set.

How to set the saw teeth Hacksaw teeth are set before sharpening. The blade should be clamped firmly in a vice and the tines cleaned of resin and fine wood dust. The tool must be calibrated before setting the teeth. You will need a set of feelers and a metal ruler for this. The amount by which the teeth must be bent is set in the standard and averages 1/10th of the pitch or distance between the tips. Measuring the pitch of the teeth, you need to pick up the appropriate set of styli or pads, the total thickness of which is equal to the distance of the pitch.

First choose an arbitrary tooth and bend it by a certain amount, by eye, achieving the correct amount of bend. After that a set of spacer blocks is pressed to the blade plane, and their total thickness is equivalent to the setting. The metal ruler should be pressed by the edge to the shim and make sure that when you pass by the top of the tooth, it will provide only a light touch.

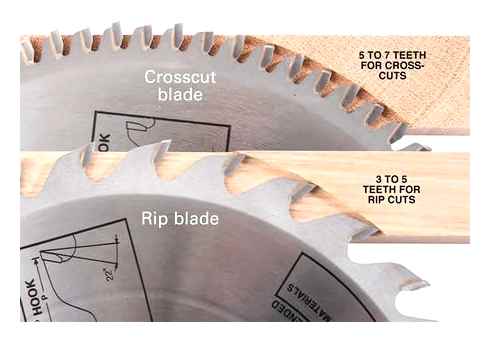

Basic grinding angles of circular saws

The circular saw tooth, which is usually made of carbide metal, has a complex structure. It has three cutting edges as standard, so it is important to sharpen the teeth to sharpen these edges. But the main thing when sharpening is to observe the angles at which the tooth planes diverge from the edges, and the angles of attack between the tooth plane and the workpiece. The last point is important for maintaining the performance of a circular saw blade.

the leading edge, the one that first cuts into the workpiece as the saw moves along, forms the main cutting edge with the trailing edge. The angle at which the leading edge meets the material is called the leading angle Y (angle of attack). The angle between the back face and the front face is the angle of sharpening. If we subtract the anterior angle and the angle of sharpening from 90 degrees, we get the posterior angle.

In practice, it is important to maintain these angles for each disc type when sharpening. It is by the front angle that saws are divided into types:

- Longitudinally cutting, where the leading angle must not go beyond 15-25 degrees.

- Transversal cutting, where it is allowable to sharpen the leading edge of the tooth at an angle of 5 to 10 degrees.

- Universal disks, which can quite easily handle both longitudinal and transverse cuts, have a front angle of about 15 degrees.

Bevel angle of the back and front planes is also important: the sharper it is, the easier it is for the saw to get into material, but the wear is faster.

Follow the rules! When sawing hard wood sharpening of saws has to be done in such a way that the angle of sharpening and the angle of bevel are as small as possible (in permissible limits). This increases blade life before the next sharpening.

How and what is a saw set-up?

Sharpening a hacksaw is an uncomplicated procedure that starts with a process called Tooth Sharpening. This procedure is performed with one simple purpose. to give a free move of the blade when working with the tool. Lack of setting leads to the fact that the tool will get stuck in the thickness of the workpiece to be sawn, which will cause inconvenience in work.

Sharpening the tines of a hacksaw is a procedure that involves unbending the tines in different directions. The most important thing is that each tooth should be bent exactly the same distance as the previous one. The greater the amount of tooth deflection from the plane of the blade, the greater the width of the cut. The greater the kerf width, the higher the process of removing chips from the kerf, and thus, the faster the useful work is done.

The width of the tines depends on the possibility of the blade jamming. The wider the setting, the less chance that the blade will bind inside the workpiece that is being sawn. How much should be the set value of the tooth set, not many people know. But this parameter should be taken into account, because the quality of the tool depends on it. The degree of set to the teeth depends primarily on the thickness of the blade steel. This value is usually from 0,5 to 2 mm. It also depends on the type of wood (dry or wet) with which you plan to work:

- For raw wood, the value of the bend should be in the range from 0,5 to 1 mm. The thicker the blade, the greater the set should be

- For dry wood the setting value is between 0.3 and 0.5 mm

To determine the amount of camber, use a special device. a template that can be made your own from a piece of wood. Picture of such a device in the image below.

Number 1 shows the template, while 2 is the tooth pitch, and 3 is the hacksaw blade.

When you know the value to which you need to set the teeth, you can get down to business. To implement the action, special devices are used. It is not necessary to use these devices, as a common screwdriver with a wide sting will do. The disadvantage of a special device for sawtooth deburring is that the price of such a device in the form of pincers is quite high.

Instead of special pincers, you can use divider plates. The design of this tool has a manual adjustment and a stop. The unbending process begins with the fact that the blade must be fixed in the jaws of the vice, and then get down to business. First you need to go over one side, and then repeat the process with the other. It is not necessary to bend the teeth by the incisor itself (base or sharp part), but from the middle.

This is interesting! Once the tines are straightened out at the same distance, you still need to perform a height alignment procedure on the cutting parts. To find out which teeth are higher in height than the others, press the blade with its cutting part against a sheet of paper. A piece of paper will show a print on which it is not difficult to identify which teeth need sharpening. You can use a flat file to shorten them.

Sharpening properly

In sharpening wood hacksaws there is nothing complicated, but it is important to follow the sequence of work and take into account some subtleties:

- A great role in the sharpening process is played by a firm grip on the hacksaw. Sharpening the tool “on your knee” you will never get a good result, so before you start, clamp the blade in a vise.

- The quality of the tool used in the saw is of paramount importance. A file is used for sharpening, and it is advisable not to use it for other types of work. Final fine tuning of the cutting edges is done with the finest velvet chisel.

- Tool technique. Hold the file with your right hand while your left hand rests on top of the file and guides it. The file should only touch the metal while moving forward. It should be returned without touching any of the teeth. Do not press the file too hard.

- Quality of work. Even if the sharpening is done very carefully, burrs may remain on the metal. This phenomenon accelerates the wear of the blade, leading to a chipping of the working part of the tooth. Minor sharpening defects should be carefully removed using the finest file.

- Check the quality of the sharpening after use. Well sharpened tooth tips of a hacksaw blade do not shine in good light, but remain dull under any angle of incidence. If you can see the shine it means you need a finish file.

Works on return of sharpness to saw teeth are performed with the help of a triangular file, which has a fine notch and angle between faces of 60 degrees.

Zaagtanden Vijlen, Making Sawteeth

If you have carefully read the recommendations given here, then for sure you will be able to qualitatively sharpen the teeth of a hacksaw for wood. In conclusion we would like to give an important advice: do not wait until the blade stops completely sawing or starts to get stuck in the material. Restoring a very blunt tool is very troublesome, so as soon as you see the first signs of deterioration in the performance of the hacksaw, correct its sharpening.

Question “How to sharpen a hacksaw with your own hands?”remains very popular in spite of modern power tools in every home.

A saw is essential in the home, indispensable on vacation, used for cutting boards, logs, particle board.

It is also indispensable for construction, carpentry and assembly work; in the garden and in the workshop.

In the city, in the cottage or in the garage, everyone has this time-tested tool.

New machine. correcting manufacturing inaccuracies

After reading the above you will be able to check and if possible fix your saw blade. However, it is easier and cheaper to buy a good new one. The only way to test the machine is to check the resulting set. Repeated pressings should result in a maximum two point difference in the indicator. To give you an example let me tell you what we had to do when one of our customers asked us to bring his machine to working condition.

From the outside, the machine looked very nice. But when we tried to set up the band saw on it we found out that almost all knots were made defectively. The variation of the obtained values at repeated pressing was more than ten units, which did not allow to make a high-quality dilution on it.

The moving plate was not perpendicular to the plane of the base (slight vertical and horizontal deviation).

The body of the saw was clamped somewhere in the middle and stronger on the right edge and only part of the plane of the thrust pins ends. The upper part of the saw’s body remained free. Swinging effect.

The springs of thrust pins were long and too rigid, not allowing the pins to move fully into the slots of the moving plate.

Tooth pusher was a cone of non-hardened material.

Flattened out quickly at the tip, making it hard to shank.

Indicator stop is not parallel to the band saw’s plane, the plane of its end is not torn off (the indicator readings varied depending on the place of contact).

Face not hardened. would make a dent very fast, hitting it would also lead to inaccurate set.

Lower, non-adjustable blade back supports. It is not possible to set the desired height of the tooth part. The saw had a radius rather than a polygonal pattern. Instability in the kerf.

No pusher on three teeth with stops for accurate tooth feed. Unable to traverse in one place on each tooth. Inaccurate setting.

And even after we corrected all the manufacturing inaccuracies, only band saws with non-hardened teeth or with hardened teeth, but with weak fixation in the body (about the types of band saws it was told in the previous articles) could be well set on the machine. When breaking other types of saws, the “seesaw” effect appeared immediately.

Tips for sharpening handsaws. How to Sharpen a Hand Hole Saw

The most popular tool for woodworking is probably the saw. Wood hacksaw is used when sawing bars, fiberboard and chipboard, and with a two-handed saw you can “cut” into strips even a log.

This tool is made of special steel. However, despite the softness of the material to be cut (wood), it is necessary to sharpen the hand saw regularly. The main thing is to know how to do it correctly. Similar procedures should also be followed with a chainsaw.

In the absence of special devices, you can sharpen a hand saw with a triangular or diamond-shaped personal file. If the hacksaw has small dimensions, it can be clamped in a vise, the sharpening of a hand-held wood saw is carried out by the progressive movement of the file blade.

Do not apply too much force. It is enough to achieve the appearance of a “fresh” strip on the main rear surface of the tooth.

In a locksmith’s vise you can also produce a hand saw, because if the teeth are on the same line, the cutting process will not be possible. The reason is the probable jamming, and the “culprits” here are sawdust, which is not removed from the narrow slot.

If the teeth of a hacksaw are heat-treated (hardened), then the question “how to sharpen the saw” disappears by itself, such a tool is practically eternal and does not require sharpening. It is important only to protect the cutting edges and the teeth themselves from external influences (dynamic blows). The hardened material, along with its hardness, has a disadvantage. it is fragile.

Among professionals and amateurs, hacksaws with “raw” tooth are the most common, so every owner must know how to sharpen a hand saw. To simplify the sharpening process, you can make a simple device of two boards arranged at a certain angle to each other (optimally 37 degrees).

The hacksaw is fastened with two or three slats to the top board. The sharpening itself is carried out with a file parallel to the ground and backwards. Only in this way the correct cutting angle can be achieved. By turning the saw over, the other side of the hand-held wood saw is sharpened. It is important to have the right tooth geometry, ideally it should be an equilateral triangle.

Setting the teeth of a handsaw with a saw blade

Not only do the teeth get blunt in the process, they also get deformed. That’s why regular setting of wood saw (bending of neighboring teeth in different directions) is a very necessary procedure. The sharpening process is carried out with the help of a special slotted plate, the width of which must correspond to the thickness of the hacksaw blade.

For versatility, several slots can be cut with the angle grinder. It is then possible to make a hand saw of any thickness. The hacksaw is clamped in a vise with two slats, a plate with a slit is “threaded” on the tooth. Only the upper part of the tooth is bent (about one third).

Setting Crosscut Saws | Paul Sellers

Sharpening hand saws is not difficult, you just need the right skills. Just try it once. It is also not difficult to break up a handsaw. A properly sharpened hacksaw will save both effort and time when sawing.

Loading Thank you for adding this article to your site:

How to properly sharpen a wood saw blade

Greetings to all woodworking enthusiasts. The topic before this video was suggested to the author of the channel by a viewer, who asked to talk about how to properly dilute hacksaws.

In front of you lies the tool. Hacksaw, circular saw, and carbide-tipped saw blades. Where do we start?? The topic is not so hot anymore. Its importance is slowly dropping, because the first edged blades appeared a few decades ago. Patterns are 30 years old. They used to saw particle board. You didn’t have to dilute it, thanks to the carbide plates. Serves a long time.

Modern Italian disk with tungsten carbide plates. It’s made more accurately. In order not to deform it during the work, saws are made. Width of 2.5 mm. The resistance of the material is very small. You don’t need a set for these discs. As for the sabre saw with a carbide tooth, there is no need for such an approach either. They are ready to use. But it is impossible to sharpen them with a file. Only on the electric grinder. The question about the tooth setting is still important. Where do I start?? In order to properly deburr the hacksaw, you need to profoundly. After that, cut a mark between the teeth with an angle grinder just a little bit, so that each tooth is the same height. After that, you have to deburr.

What to start with, how to work correctly? Measure the thickness of the blade. You need to consider what kind of wood we are going to saw. If it is wet, loose, or dry and hard, it needs to be set in different ways. For loose, damp wood, a high degree of dilution is required. But not more than 2 thicknesses of the blade. If the blade is 0,8 the pitch should be 1,5 mm. width of the cut. If the wood is dry, it must be cut well, but this should not be more than 1.5 times the thickness of the leaf. Then the resistance of the material will be minimal. The hacksaw will not jam.

How the bulk of the people do the straightening. People used to boast and say that they did it with an axe. This by itself says that the work is supporting, i.e. rough. Teeth should be deflected to the right and left at the same angle. If they dance, i.e. one more, one less, it will be a bad quality of sawing. The front will be hard, it’ll cling. The teeth will be knocked out. The quality will be poor. Watch the continuation on the video from minute five.

Trimming and straightening

The steel from which the hacksaw blade is made is ductile, which can cause burrs to form on the cutting edge. To remove them, it is enough to clean the flat edges of the tooth in the direction from the base to the top. Since it is very difficult to correct a bent tooth with a flat file, it is better to use 80-120 grit abrasive paper rolled into a small tube.

To make precise fitting cuts, many craftsmen recommend blunting the tip of the teeth to form a third cutting edge. It is better to do it with a miniature diamond escapement file, which has at least one flat edge. A nail file is brought to the tooth so that its working surface is perpendicular to the plane of the blade (not the tooth). Then is carried out 1-2 light removals, the movement is carried out from the base of the tooth to the top.