How to sharpen a chainsaw chain at home

When learning how to adjust your chainsaw, be very careful, because faulty settings are the first cause of rapid chain failure and tooth abrasion. Usually the chain gets blunt for the following reasons:

- The use of low-quality or inadequate oil that does not meet the parameters specified in the manual;

- Improper setting of the clearances between the lip and the limiter;

- Lack of lubrication in the system;

- poor chain tension.

Also, be careful when sawing old boards, because there are nails in them, which also dull the sharpness of the teeth. Incorrect handling, frequent contact with hard objects like stones, bricks, heavy use of the chain, etc. are also considered to be important factors of the element’s wear.

How you know when it’s time to sharpen your chain

If you have already studied the information on how to sharpen a chainsaw chain with your own hands, you need to know exactly the characteristics that indicate the gradual failure of the cutting elements. The main ones are:

- you notice that you are putting much more effort into your work;

- Finer sawdust has appeared;

- noticeable vibration or jerking occurs during operation;

- The cuts are not even and are characterized by a great number of jagged and sharp edges.

Information about how to sharpen the chain of a chainsaw is necessary to know for everyone who does not want to eliminate more serious damage to the device in the future. For example, the tight movement of the links puts additional strain on the engine, thereby stimulating a rapid wear and tear.

Ways to solve current problems

Inexpensive chainsaws are equipped with relatively short-lived budget level chainsaws. In the long run, such bars and chains will be replaced by more prestigious and durable models.

Practitioners offer an original way to improve the strength and durability of budget devices, known as stabilizing the internal structure of the metal.

To do this, the new bar is warmed up in an oil bath for a week and a half to two weeks at 55 to 65°C. The effectiveness of this technology is confirmed by the positive feedback from the owners of domestic models.

Timely repair of the saw chain

Postponing chain repair indefinitely is highly undesirable. A saw chain with blunted cutting edges practically halves the chainsaw‘s output, wastes fuel and wastes working time.

The problem can be solved by taking it to a specialized service center, which is inevitably accompanied by additional costs. In another variant the owners of chainsaws practice sharpening the chain of a chainsaw with their own hands. There is no fixed interval for maintaining a saw chain.

How to sharpen the chain on a chainsaw with your own hands

A person who has a chainsaw in his or her household should know how to sharpen a chainsaw chain with his or her own hands. There are several ways to sharpen:

- Resharpening with a file (the most common way to sharpen, t.к. allows you to sharpen the tool, directly at the place of sawing work.)

- Sharpening with a special machine (this method is used in service centers, but can also be used in the private household)

- Sharpen with an angle grinder. To sharpen using this method, you need to have certain skills. Not a very common way to sharpen, t.к. It is difficult enough to sharpen with an angle grinder correctly.

In this video, you can get acquainted with the sharpening process, the most popular ways and tools used for this.

File sharpening

The first thing you need in order to sharpen the chain or tweak it a little is a special file.

File

Two kinds of files are used for sharpening and dressing saw chains. First, it is a round file with the diameter corresponding to the diameter of the rounding of the working edge of the saw tooth.

For sharpening saw chains of household tools, circular files with diameter of 4, 4.8 mm, because they have a small tooth. For professional models stronger chains with more teeth are used, and consequently files with diameter of 5.2, 5.5 mm.

In order to sharpen properly, it is not enough to sharpen only the cutting edges of the tooth, it is also necessary to make adjustments to the depth of cut limiter. If it is not done, the chain will not cut into material to required depth that will significantly reduce speed of work and the same as in a situation with a blunt chain can lead to overheating of saw’s engine because of insufficient load on the engine. This job is done with the help of a flat file.

A description of sharpening with files

The first thing to start with when dressing a saw chain is to place the tool on a flat surface or table. In forest conditions, a large-diameter piece of wood will work well for this purpose. Then the chain must be inspected for any defects, it can be cracks, completely broken off teeth. After the inspection, it is necessary to set the brake to the working position, thus blocking its movement on the bar.

The chain should be tensioned while sharpening with a file.

It is desirable to put a support under the bar, it can be a log, a piece of branch of suitable diameter, or producers of sharpening tools have special clamps to hold the bar during the sharpening of the chain.

The chain is sharpened by moving the file from the inside of the tooth to the outside. In doing this the file must be parallel to the special marking on the chain. This mark is applied by the chain manufacturer to indicate the standard sharpening angle.

Sharpened tooth, should be located approximately in the middle of the bar, it is necessary for convenience of work, during sharpening process it is necessary to move a chain on the bar, not forgetting thus each time to establish the brake in working position.

Work on sharpening the chain on a chainsaw, it is necessary to carry out with the use of gloves made of rough material, otherwise it is easy enough to injure yourself, because.к. the tooth contact area is very sharp.

Ideally, the producers suggest to perform the same number of file movements for each tooth, but in practice this is not always possible, because.к. the teeth have different degrees of damage on their cutting edges.

To facilitate the sharpening of the saw chain with a file, special holders with marked angles can be used. The markings are not only made for standard cross-cutting, but also for longitudinal cutting.

Hand files are also handy if you are not experienced in sharpening. Experienced craftsmen do not use holders for sharpening, and can only use special devices that support the file.

Another device designed for sharpening is the manual saw chain dresser. As a sharpening tool it uses a regular file, which can be replaced by yourself. The machine is mounted directly on the bar, it is also equipped with an adjustable sharpening angle and a special stop that holds the sharpened tooth.

Manual sharpening machine, great for beginners. Along with the electric models of sharpening machines, the manual one has its indisputable advantage in the form of a low price. Depending on the manufacturer of the manual machines their appearance can vary, but the working principle is the same for all.

Adjustment of the depth of cut is made with a flat file, so that there is a difference between the upper cutting edge of the tooth and the height limiter.

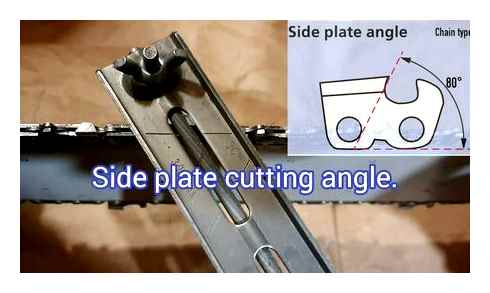

As it can be seen in the figure the depth limiter is adjusted in such a way as to bring the value of the gap to the factory value. In the table below you will find the values for the main angles and clearances for the most common types of chains.

As a rule, the clearance value is corrected using a special die. The electric sharpening machine is mounted on the chain during sharpening and the depth limiter is then ground.

Electric sharpening machines

For sharpening large numbers of chains, electric sharpening machines are usually used in service centers or production plants. Depending on the manufacturer the design of the machines may be different, but the principle is the same.

The saw chain, mounted in a special guide rail, which is mounted on a turntable and has a special latch to hold the tooth to be sharpened. The fixer is able to move in the horizontal plane. Electric chain sharpener with adjustable angle to the sharpening tooth, activated by the operator by pressing the start button. Both the depth of the burr and the angle at which it is sharpened are adjustable. The dive itself is performed by the operator. The chain is dressed with a special grinding wheel that can be changed if needed.

How to correctly sharpen chain on a chain sharpening machine

Sharpening chain on a chain sharpening machine is much faster and more accurate than sharpening it by hand. Many different electric sharpeners are available. Household machines are compact and work from 220 V. They are easy to change abrasive wheels and can be easily adjusted for different chain parameters: tooth pitch, top edge thickness, grinding angle. All machined cutting edges are identical. The process is fast.

Electric chain sharpener for chainsaws

The main part of the machine is an electric motor, on the shaft of which a sharpening disc is mounted. On its handle there are controls. Clamping clamp for securing machine to the chain. Spring clamping device permits to regulate the pressing pressure on the item to be sharpened. Differentiated clamping allows for self-centering of the workpiece in the machine. Hinged safety guard for safe working.

Electric chain sharpening machine

The saw chain is fitted into a special rail mounted on a turntable. A clamp holds the tooth to be sharpened and an electric emery is mounted at a preset angle. The operator switches on the motor and controls the plunge disc

Machines with manual drive

There are devices designed for sharpening, but without electric drive. These are manual machines for straightening saw chains. A regular file is used as a sharpening tool. The machine is mounted directly on the bar. Special stop, that holds the tooth to be sharpened. Sharpening angle is adjustable.

Stationary unit shown in the picture, with the sharpening disk rotated by a crank via a gear unit. The saw chain itself is clamped in the machine bench vice. The machine has a frame that can be bolted to the table.

Manual chain saw sharpener

Machine for sharpening chainsaw chains: selection criteria, design features, technical and operational characteristics of the equipment, the principle of operation of manual and automatic devices, review of popular models of sharpening machines.

Additional recommendations on how to sharpen a chainsaw chain with your own hands

Safety regulations must be strictly observed at all times. Always wear coarse gloves to protect your hands, because the cutting surface of the tines is very sharp.

If the sharpening technology requires dismantling the chain, do not apply excessive force to the threaded fastener when reinstalling it. To tighten the screws fixing the bar, it is best to use an electric screwdriver calibrated to the limb.

Experts recommend a method of increasing the strength and wear resistance of chains, which is known as “stabilizing the internal structure of the metal”. To do this, the new tire is warmed up in an oil bath for a week and a half to two weeks at 55 to 65 degrees Celsius. Operation confirms the effectiveness of this technology.

How to sharpen a chainsaw chain

Chainsaw chain sharpening is a procedure that gardeners and professional woodcutters regularly face with. In this article, the master plumber will tell you how to restore the damaged teeth of the saw bar, and quickly return it to its previous working condition.

To understand how to properly sharpen a chain, it is necessary to understand the basic principles of its construction and operation. You cannot just sharpen a chain by eye, you need to know the basic characteristics of the chain and its parts.

A chainsaw chain consists of three types of links made of high-alloy steel:

- Cutters are essential elements of the chain. A distinction is made between right-handed and left-handed, which are arranged alternately, with their cutting edges above the plane of the bar. Tooth design includes cut depth limiter.

- Drives (shanks). serve to transmit torque from the gasoline engine to the chain via the drive sprocket. This feature extends sprocket life and gives the chain a firmer hold on the bar.

- Coupling. connects the chain shanks and cutters.

One of the main elements of the chain is the cutting tooth, which plunges into the wood and removes chips. The tooth depth limiter determines the thickness of the wood chip and limits the depth of penetration into the wood.

the recommended settings relative to the limiter are 0.025″ (0.65 mm) or 0.030″ (0.75 mm), depending on the chain type.

The long life of any chainsaw depends on proper care and use, including the chainsaw. Good performance of the latter affects the performance of the device and the productivity parameters. Incorrect sharpening can cause some problems with the saw itself. Most often it is:

- Curved cuts;

- Heavy loads on the saw, resulting in increased wear and tear on the parts of the device, and therefore a reduction in the life of the entire device;

- Increased fuel consumption.

If the cut produces fine dust chips and the saw plunges into the cut with great force, it means that the target has blunted.

There are other signs of a dull chain:

- The speed of the tool has decreased;

- Uneven and sharp sawdust is produced;

- It is necessary to apply more force to cut the wood;

- The chain is stretched or has become slack.

A chainsaw chain can quickly become blunt for the following reasons:

- If you work with the saw too often;

- When the operator presses hard on the saw while sawing;

- If the chain is made of bad quality metal or if the steel is not properly heat-treated;

- When sawing raw or resinous wood frequently;

- When sawing hardwood trees such as: oak, birch, cherry, acacia, elm, ash and others;

- If the chain encounters an obstacle in the form of sand or rocks;

- If the chain is not properly sharpened or has insufficient tension when working.

The design of all chain saws is similar, so the algorithm for removing the chain will be the same:

- First, protective cotton gloves should be put on to avoid cuts from the cutting teeth.

- Remove the protective cover from the chain saw’s working part and lay it on a flat surface on its side.

- Using a socket wrench of the correct diameter, unscrew the securing nuts that hold the body and bar and remove the top cover of the body.

- Now slide the bar all the way down to the sprocket, loosen the chain, and remove the operating elements from the mounting bolts.

- Disconnect the chain from the bar.

How to properly sharpen a chainsaw chain with your own hands

A sharp blade on a chainsaw not only saves strength and equipment from wear, but also makes it safer to use. In addition, blunt chains will not cut straight. Here are a few tips for sharpening your own chainsaw chain.

Determine the chain size of your chainsaw. You need to buy a special tool. Or a sharpening stone or saw chain file that will align the teeth. Since there are several different tooth sizes, the sharpening stone or file you choose should be of the right diameter. Standard sizes are 3/16, 5/32 and 7/32 inches in diameter.

Clean the chain thoroughly. You can use white spirit or a technical degreasing cleaner to remove oil, dirt and debris. Do not apply excessive amounts of cleaner to the motor or other components, as some of these products can cause damage to the plastic housing or other parts.

Check the chain for damaged or severely worn links and teeth. An individual prong may be chipped, broken, or bent, making the chainsaw dangerous to use. There is a rule of thumb: The tooth blade (the flat surface on top of the cutting teeth) should be at least 1/4 inch long. If they are worn so much that they are shorter than this length, there is a risk of breakage during operation. Any chain that is damaged, loose, or badly worn should not be used.

Set the saw on a firm surface or clamp the blade in a vise. The saw must be positioned steadily and the blade must be firmly secured to ensure safety and accuracy of machining. The best option is to clamp the blade in a vise so that the chain can rotate freely.

Select the lead cutter as the starting point. It will be the shortest cutter in the chain. If all the picks are the same length, you can start at any point. The key is that you file each cutter so that the blade of the tooth on top of each cutter is essentially the same in length. Then each will cut the same amount of wood as they pass through the kerf. It may also be helpful to mark the first tooth with a little paint or a permanent marker to know the location of the first point.

Place the file in the notch at the front of the cutter. This is an angled tooth on the front of the flat surface of the chain link. It must fit perfectly to the face of the cutting plate, and the top 20% of the file diameter must protrude over the tooth.

Hold the file at the same angle at which the cutter was sharpened to begin with. The angle should be 25 or 30 degrees (check the chain saw’s specifications). Some chains may have a flatter angle. In either case, it is important to adjust the chain angle to that which was originally set. Some of the teeth are marked as tips.

Use a moderate twist on the face of the file to remove metal shavings. There are different opinions on what direction to go with the file, but usually you will be working from the short side of the angle toward the long side. This should make the cutting surface smooth.

Work every other tooth from the starting point along the chain in a similar fashion. As you go from prong to prong, rotate the chain by hand so the prong you’re working on is on top of the bar.

Turn the saw over and continue working the unaffected tilted prongs in the opposite direction. Watch the length of each flat tip of the cutter. Some manufacturers suggest taking measurements with a caliper so that the saw “bites off” equal pieces during the cut, but if you have a good eye, this will be enough to achieve a good result.

Check the clearance of the depth limiters, the curved hook that forms the links between the cutters. The cutting edge of the depth stops should be lower, about one-tenth of an inch than the cutter. These can be used to control the amount of wood the cutter removes with each pass. A special tool that is placed over the blade can be found at chainsaw suppliers or construction stores. If the limiter is too high and needs to be filed, this tool will protect adjacent teeth while you mill the limiter.

Grind away any stops that interfere with the cutter (in other words, those that are too high) using a flat draught file (may not be necessary, except when working with a defective chain).

Lubricate the chain, check the tension and then you can use the chainsaw again.

Pro tips

Before starting work, it is advisable to work out a sequence of operations and get some skills on sharpening a discarded chain. A small loss of time is compensated for by fewer common errors.

The design of the saw headset is perfect in principle, the manufacturer has already considered all the nuances, so attempts to improve anything are likely to end in vain. Before the first attempt at self-sharpening it is recommended to understand the design of the saw link.

Its uncomplicated configuration includes two cutting edges, a side and a beveled top. the height of the chip breaker determines the thickness of the cuttings that can be removed. Excessively low-cut stops initiate additional loads on the engine, not excluding the possibility of an injury-prone chain break.

Useful tips

You can increase the service life by alternating between manual sharpening and a sharpening machine. The latter allows for the most accurate alignment of the sharpening angles on the machine. The depth of grinding should not be too great.

Safety precautions should be taken to ensure that wood of all sizes is sawn with maximum efficiency and minimum risk to personnel:

- Before assembling the chain tool and fitting the headset, it is advisable to familiarize yourself with the. This is because each tool has its own characteristics.

- Wear gloves and safety glasses when sawing.

- For work, it is recommended to choose close-fitting clothes made of natural dense materials and the most reliable shoes.

- It is necessary to cut wood with a chainsaw in a stable and safe position, and to position the material as stably as possible. The installation of a toothed stop on the log can help guarantee stability.

- It is necessary to hold the saw with both hands while working and constantly monitor the sawing process.

Modern chainsaws are used in domestic and industrial applications. It is important to maintain the performance and high efficiency of the tool, which is directly related to the condition of the sharpened chainring.

Expert Advice

There are helpful tips for sharpening your chainsaw quickly and efficiently. General recommendations:

- at the beginning it is necessary to run in the headset at a low speed, this allows the lubricant to get on each element of the bar;

- The chain must be energized, looseness can lead to injury, especially when using an electric machine;

- it is recommended that the headset be dressed after each continuous operation of the tool, checking the teeth carefully before starting to saw;

- timely lubricate every element of the bar, which not only improves the process of working with wood, but also reduces the load on the rotor, the motor.

Depth of cut, condition of cutting edge and limiter should be checked after 3-4 sharpenings. It is recommended to check with a template for a specific model of headset.

Sharpening chainsaw chain. an essential part of working with this tool. Tooth sharpness influences performance and safety during cutting. To straighten the cutting edge of the bar you can use an electric or manual machine, at home it is easier to use a file. It is necessary to take into account the peculiarities of a particular model of the headset, measure each element with a template.

How to choose a machine for sharpening chainsaw chains?

To choose a chain sharpening machine for chainsaws you need to study several important features. These include:

- Power. each electric machine is equipped with a motor that receives power from the electric network. It is best to buy machines with higher capacity. These devices have a solid working life and are easier to handle heavy loads;

- Speed of standard spindle. the speed of recovery depends on this parameter. In practice, the higher this characteristic, the faster the sharpening will be. For infrequent but regular use, a machine with a spindle speed of about 3 thousand is suitable. rpm. For continuous intensive use, it is better to choose machines in which the spindle is capable of rotating at speeds ranging from 4800 to 7500 rpm;

- Diameter of the wheel for sharpening the headset. the range of applications depends on this parameter. Machine for sharpening chainsaw chains, in which the standard wheel has a diameter of up to 105 mm, can be used in the household. there are also machines that are equipped with a disc with a diameter of up to 400 mm. This equipment is used mainly in large machine-building enterprises;

- Additional options. among them, the ability to rotate the standard head for grinding stands out. By turning the part in different directions, and changing the sharpening angle, the saw owner gets an opportunity to evenly process the blunted teeth of the saw headset.

Having studied all these characteristics, the chainsaw owner will be able to buy a suitable machine, which will give an opportunity to quickly restore the worn headset at home.