This angle is measured relative to the sliding plane of the cutting link and, depending on the type of saw chain, ranges from 50 ° to 60 °. The top blade is the main blade and the back corner of the top blade. this is the most important corner. The clearance angle of the upper blade is difficult to measure, the correct value is obtained by observing other prescribed values.

The sharpening angle or entering angle is obtained by measuring from the top cutting edge at right angles to the guide bar.

The sharpening angle can be changed, depending on the application. Rule of thumb: the larger the sharpening angle, the higher the cutting performance when cutting non-frozen softwood. Reducing the sharpening angle when cutting frozen and / or hard wood contributes to a smoother saw blade and less vibration. However, sharpening angles greater than 35 ° and less than 25 ° should be avoided (except for rip chains where this angle is 10 °).

The rake angle, sharpening angle and upper blade angle change when sharpening. These angles have a decisive influence on the cutting performance of the chain. Be sure to observe the prescribed values.

A depth gauge is located on each cutting link in front of the tooth scapula. The difference in height between the top edge of the depth gauge and the front edge of the back of the tooth is defined as the distance of the depth gauge.

The depth of penetration of the upper blade into the wood (chip thickness) and thus productivity depends on the distance of the depth gauge. The distance of the depth gauge is set depending on the chain pitch and the type of execution. How to properly sharpen a saw attachment for. Normally, it should be 0.5-0.8 mm, more often 0.6 mm. High values will lead to an increased tendency of the chainsaw to kickback, too much grip and chain vibration. Low values lead to a drop in performance. You can sharpen a chainsaw chain by hand or how to sharpen a chainsaw chain with a file. Since the distance of the depth gauge decreases with each sharpening of the saw due to a decrease in the upper edge of the tooth, the depth gauge also needs to be filed periodically. after 5-10 chain sharpenings.

Assistive devices

Another device that makes sharpening easier is the so-called saw chain teeth straightener. The device is fixed to the chain bar with special clamps included in the device design. The guide is set at an angle that determines the degree of sharpening. It can be adjusted by changing the parameter.

The sharpened tooth is secured with a special stop, on which the file is also placed. A machine of this type is produced by a large number of different manufacturers. Outwardly, the tools may differ, but structurally they are all the same.

Please note that the working edges of the teeth are first sharpened manually, and only then the depth gauge is trimmed. In this case, it is necessary to strictly maintain the difference in the height of the edge of the tooth and the upper plane of the limiter.

PowerSharp System

This system allows the chain to be sharpened in seconds without even removing it from the bar. Includes PowerSharp chain, abrasive bar, guide bar and sharpener. In order to sharpen the chain with them, you will need to take the following 3 steps:

- install the PowerSharp bus and chain;

- fix the bar inside the sharpening device, after which it is installed on the tire;

- the end of the chainsaw is pressed against an object and started for a couple of seconds.

The video below shows in more detail how to sharpen a chainsaw chain with your own hands using this system:

How and how to sharpen the chain teeth

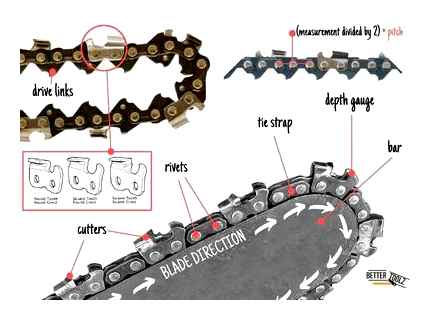

The saw chain teeth are irregularly shaped. They consist of a base, a blade and a depth gauge. At the same time, the blade has a vertical blade and a horizontal blade that falls at an angle. It is thanks to these blades that the chainsaw cuts wood. They work on the principle of a plane, cutting off pieces, and the limiter adjusts their thickness (the difference in height between it and the horizontal blade will be the thickness of the chips). You can sharpen the chainsaw chain manually or using a machine.

How to sharpen a chainsaw chain manually without removing it from the tire with a round file. How to sharpen a chainsaw chain with a file, what subtleties you need to know. oral and video advice! STIHL. do it yourself

Many do not know how to sharpen the teeth on a chainsaw chain, but it’s quite simple. round file 4.8 mm and everything in

Manual and electric machines

If the teeth are severely worn and the cutting blade has lost its shape, it will take a long time to align them by hand. In this case, a manual machine or an electric one with a sharpening wheel is usually used. The first type of device is in the form of a bow saw with a round file. The machines are stationary and mobile, which can be installed directly on the tire.

To adjust the necessary parameters, start with the smallest tooth. After all the teeth are sharpened and aligned, the round file is replaced with a flat file to sharpen the stops.

The advantage of electric machines is that the disc is fed directly under the blade to be sharpened. In addition, the quality of sharpening in this case is guaranteed and all teeth will be the same size.

The video below shows an example of sharpening a chainsaw with your own hands using an electric machine.

The blades are always sharpened first, and only then the stops.

The sharpening angle can be changed. it depends on the purpose of the application. A smaller angle is used for cutting hardwood, and a larger one for soft. In any case, it should be between 25 ° and 35 °. 10 ° angle is used for chains intended for longitudinal cutting.

Electric and chainsaws are included in the arsenal of many owners of private houses, along with such devices as a drill, hammer drill and others. This tool has one negative side. from time to time the chain becomes blunt. You can sharpen it with your own hands, if you know how to do it correctly.

Sharpening kits

One of the most common methods is with a set of round and flat files, a holder, a stop template and a hook used to remove sawdust. For the correct positioning of the holder, special markings are applied to it, allowing you to determine the correct angle for sharpening. It is installed on the upper part of the tooth and the stop, while the round file remains under it and is located just next to the blade. Thanks to the holder, the file is at the correct height, or more precisely, protrudes 1/5 above the blade. For sharpening the cutting tooth, only round files are used, since the contour of the tooth has a rounded shape.

Kits must be purchased based on the chain pitch. You cannot use the same sharpening kit for different chains.

Before you start sharpening the chainsaw chain at home, the tire must be secured in a vice or with a clamp, the main thing is that the saw does not move during processing. Having installed the holder according to the markings, begin smoothly and without too much pressure, move the file strictly away from you 2-3 times. Similar actions are repeated with all other teeth. The file must be turned over from time to time so that there is no one-sided wear. The force of pressure and the number of movements for all should be the same, this is necessary for uniform sharpening of all teeth. If they are different, then cracks may form in the chain, which will lead to its breakage.

To make it easier to work, the teeth are first sharpened on one side, and after them the saw is turned over and the teeth are aligned on the other.

They start sharpening from the smallest tooth so that the length of all the others is the same with it. After the work on the processing of the blades is finished, proceed to the limiters. A template from the kit is installed on top of the chain in such a position that the stopper is in the hole. The protruding part is grinded with a flat file.

The video shows an example of how to sharpen a chainsaw chain with a file:

How To Identify Your Chainsaw Chain

There is another set, which, instead of a holder, has one template, both for sharpening the blade and for grinding the stop. Install it so that the chain falls into the holes. Then the round file is placed on top of the rollers and fed under the blade. During sharpening, you need to ensure that it is always parallel to the lateral edges of the template.

There are 2 separate holes for the stopper, labeled Soft for soft wood and Hard for hard wood. The protruding part from the slot, grind with a flat file.

Sharpening is carried out only from oneself and with smooth movements, the number of the latter should be the same for all teeth.

The tooth of the chain planes the wood like a plane, and the thickness of the shavings is adjusted by the height of the stopper.

The heavy work of the saw leads to a playful dullness of the chain. How to sharpen a chainsaw chain with your own hands. Several sharpenings may be required within 1 day. The problem is also aggravated by the fact that the tooth rapidly becomes blunt when it meets the ground. How to sharpen a chainsaw correctly. It is enough to hook the soil with the tire once or twice, and the work can be stopped. the shavings become small and the saw stops going deep into the wood.

The earlier the blunt teeth are sharpened, the less material needs to be removed during sharpening, as a result. the service life of the saw chain is longer. Finding the moment when sharpening is already required is quite easy. The main feature is the feed force. A properly sharpened chain is pulled into the cut with just a little pressure. If, on the contrary, the chainsaw is forced to cut by an increased feed force, then the teeth are dull. A dull chain can also be recognized if, instead of large, thick chips, only small chips fly out of the cut.

In this situation, the chainsaw must be sharpened urgently. Do not cut with a dull or defective saw chain. the result is a strong tension in the body, a large repetitive load, poor cutting results. How to sharpen a chainsaw chain with a file yourself. How to sharpen with a file before sharpening a chainsaw chain. In addition, this means a decrease in productivity, high fuel consumption and overestimated wear of all chainsaw units.

The structure of the teeth of the tool chain

If we consider the structure of the chain teeth using an example as a template for the “Friendship” chainsaw, then we can observe several important points:

- teeth have a pair of edges: top and side;

- the upper edge has an angular bevel in the direction of blade movement;

- cutting links are represented by a base, a tooth blade and a penetration stop;

- the scapula has a horizontal, angled blade and an end vertical blade;

- the thickness of the chips is determined by the difference, which is represented by the upper boundary line and the front line on the back of the teeth;

- under standard conditions, the indicators of the difference can be in the range of 0.5-0.8 mm, but the optimal parameter is 0.6 mm;

- each subsequent sharpening reduces the distance due to a decrease in the size of the upper edges of the teeth;

- control notches are made every six to eight sharpenings;

- for ensuring the cutting properties of the chain, the angle of the upper edge of 50-60 ° and the clearance angle on the end blade are responsible;

- the front corner is formed by the edge of the end blade and can be of the order of 60-85 °.

Sturm BG60016

Our TOP is completed by Sturm BG60016. Users like this machine for its high precision and easy operation. With its help, it is possible not only to return the former sharpness to the teeth of the chains of petrol and electric saws, but also to align the links. The machine is suitable for sharpening saw chains with different pitch, height of the cutting element and angle of the cutting edge. Presetting the sharpening depth allows you to achieve a uniform cutting tooth size on all links of the sharpened chain to evenly distribute the load along its entire length when cutting wood, which prevents it from sudden breakage in a weak area and ensures operator safety. And the cast metal base of the machine provides precise fixation of the chain and the correct angle of inclination of the sharpening module for a high-quality sharpening result. Well, the tilt angle limiter ensures that the same cutting edge of the teeth is obtained on all links of the sharpened chain. The engine power of this machine is 160 watts. Thanks to this power, an even and high-quality processing of the tooth elements is ensured. In addition, the engine of this machine is notable for its low noise level and low vibration, which does not affect the quality of sharpening. Also in this machine it is worth noting the clamping mechanism. It adopts double wedge and screw chain retention, which effectively prevents the chain from slipping and slipping out of the working stream. And the presence of a rotary regulator in the clamping mechanism reduces to a minimum the number of resetting of the processed chain and the time for sharpening. Other features of this machine are its compact size and low weight, which makes it easy to move. And for the safety of the operator, the device has a protective casing of the abrasive disc and a plastic screen that will protect against flying sparks. In general, such a chain sharpening machine will be an excellent purchase for both personal use and professionals, guaranteeing high sharpening accuracy.

- Power: 160W.

- Speed: 3000 rpm.

- Landing D: 10 mm.

- Circle size: 100mm.

- Weight: 2.5KG.

How to sharpen a saw chain with a file

The use of such a tool is convenient in that a special landmark is applied to it, which allows sharpening the chain as correctly as possible. The insert will rest on the depth stop and on the top line of the cutting teeth, allowing the file to sit under the cutting edges.

So, for the correct sharpening of the chainsaw chain, you need to watch an educational video and adhere to a certain sequence of work.

- A neat but reliable fastening of the tire is carried out and the correct files are selected.

- Start sharpening so that the round file protrudes no more than 1/5 above the cutting edge of the tooth.

- File movement must be in one direction.

- After performing several sharpenings, the kerf stop must be adjusted.

If we consider the general sequence of saw sharpening, then it consists in the following actions:

- chain brake installation;

- installation of the tool according to the template;

- mark the initial tooth so as not to perform circular sharpening;

- direct sharpening.

How to sharpen with an angle grinder

When sharpening a chainsaw with an angle grinder, it is necessary to constantly monitor the level of chain sharpness, treat the drive sprocket with machine oil. At the same time, this method has one significant advantage. it is not necessary to remove the chain set from the saw, you can visually select the sharpening angle.

Although many owners of chainsaws and chainsaws believe that this tool can damage the cutting teeth of the chain, if the work is done by an experienced specialist, then the risk is minimal.

Only a special disc is suitable for working with metal. Its diameter must be at least 2.5 mm. It is recommended to select an already used disc with rounded edges.

Before you start sharpening, you need to insert a wedge of wood between the chain and the bottom of the bar to prevent the headset from moving.

Electric sharpeners

To maintain the angle of inclination and correctly sharpen the teeth, a template must be installed on the machine. Equipped with a tilt angle tool, the sharpener will sharpen your chain faster. Such a device, fixed on the machine, can be a wooden block, a small ruler. It is necessary to make a template with the ability to change the angle, because you will need to sharpen one element with two angular parameters.

A small grinding wheel or emery tape, started up instead of a belt drive. two ways, among which you can choose a priority sharpening option for yourself.

How to identify and measure a chainsaw chain

Technical features of the grinding process

If a person is the owner of a professional tool, then it is extremely undesirable to constantly sharpen his chain with his own hands. Such events are permissible only if absolutely necessary.

In other cases, it is better to entrust the work to professionals or use a special machine. But if a person took up a file, then it is advisable to watch a video on how to sharpen a chainsaw chain with your own hands, and also follow the recommendations of professionals:

It is not necessary to apply a lot of effort to the file.

It is important to do all movements smoothly and accurately. It is necessary to carry out constant turning of the file. This allows not only to sharpen the teeth more evenly, but also to reduce the wear of the file. The chain teeth must be sharpened consistently. It is convenient to sharpen the teeth first in one direction and then in the opposite direction. For each cutting element of the chain, the same pressure and the same number of file movements are important.

This will keep the chain sharpened evenly. If the teeth of the chain are ground unevenly, then the element with the minimum height is the reference point.

The presence of teeth of different sizes in the chainsaw chain will lead to rapid wear and frequent breakdowns of all parts of the tool.

Chainsaw chain sharpening templates and accessories

It is much easier to work with greater confidence to get the right result, if the master has provided himself with a set of accessories, which includes a template. It maintains the correct values for all sharpening angles of the tooth. The angle of the leading edge is recorded in the instructions, usually its value is 65º. 80º. The value of the clearance angle of the upper blade can only be estimated from the template. Its value should be in the range from 50º to 60º.

The clearance angle of the saw decreases with increasing wood hardness. The optimal value for longitudinal cutting is considered to be the value of the angle 10º… 12º, and 25º… 30º. for cross cutting.

Saw tooth configuration template

How to sharpen a chainsaw chain on a machine

Sharpening a chain on a lathe is much faster and more accurate than with your hands. There are many different electric sharpeners on the market. Household units are compact, operate on a 220 V network. Abrasive wheels are easily replaced on them, they can be easily rebuilt to different chain parameters: tooth pitch, upper edge thickness, sharpening angle. All machined cutting edges are the same. The process is going fast.

Tooth configuration and sharpening angle of the chainsaw chain

Chainsaw teeth have a complex configuration, which depends on the direction of movement of the chain. The tooth has two working edges: the lateral one, located perpendicular to the axis of movement of the links, and the upper one, which is at a certain angle to the direction of movement of the chain. Each tooth has a cutting depth stop. It determines the height of the chips to be removed. The main cutting force falls on the cutting edge. The sharpening angle of the tooth determines the quality of the tool.

Important! The configuration of the tooth should be checked regularly, especially before starting long-term work.

Each saw model has its own cutting edge pitch, the value of which for household and semi-professional models is associated with the power of the unit and the drive torque. For rip sawing, the pitch is taken less (eg 0.325 inch). In this case, the work performance will decrease, but the required effort will also decrease. When felling trees with a large trunk diameter, the engine power does not exceed 2500 W. The thickness of the cutting edge for most chainsaws is set to 1.3 mm.

The height of the chain profile is either 0.625 mm or 0.762 mm, and a low profile is used for household saws. At the same time, the vibration of the saw increases slightly.

The edge of the tooth for longitudinal cutting should be very sharp and have an angle in the range of 6º… 12º, for transverse. up to 25º… 30º.

In the first case, sharpening should be done more often, since an unacceptably small angle of inclination of the tooth contributes to its rapid chipping. This is especially noticeable in links that are made of structural alloy steels containing silicon and manganese, for example, 40KhGS or 35KhGSA.

Hand-operated machines

There are devices designed for sharpening, but without an electric drive. These are manual saw chain straighteners. A regular file is used as a sharpening tool. The machine is attached directly to the rail. Special stop that holds the sharpened tooth. The sharpening angle can be adjusted.

The photo shows a stationary machine in which the grinding disc rotates with a handle through a gearbox. The saw chain itself is clamped in a machine vice. The machine has a base that can be screwed to the table.

Manual Chain Saw Sharpening Machine

A machine for sharpening chainsaw chains: selection criteria, design features, technical and operational characteristics of equipment, the principle of operation of manual and automatic devices, an overview of popular models of sharpening installations.

How to properly sharpen a chainsaw chain with a file

Templates and patterns must be fixed on the area to be treated. They will give the right direction to the file, making the process easier. When all the preparatory work has been done, you can proceed directly to sharpening the chain.

According to the rules, it is necessary to sharpen the teeth in one direction, then in the other. Work begins with light clicks with a file in the direction away from you, the pressure gradually increases. Reverse file movement. without pressing. The circular tool must be continuously rotated along its axis. The chain is sharpened by movements from the inside of the tooth to the outside. In this case, the file must be located parallel to a special mark on the chain, which is applied by the manufacturer to indicate the standard sharpening angle.

The sharpened tooth should be located approximately in the middle of the tire, this is necessary for ease of work. In the process of processing, you need to move the chain along the tire, not forgetting to set the brake to the working position every time.

The angle of inclination of the tool should be right, and the angle of sharpening of the chain of the chainsaw horizontally. sharp, while its changes are allowed in the range from 10º to 30º. The smallest tooth in the row should be taken as a basis. Turn the tire over and do the same job for the teeth that go in the opposite direction. The disadvantage of this sharpening method is the high time consumption.

Sharpening the chain with a file

You can insert a round file with a broken handle into the chuck of an electric drill or screwdriver. You will get a very convenient mechanized sharpening device.

Sharpening the chain with a drill and file

How to sharpen a chainsaw chain at home with a file

A tool with an exceptionally round section will help to properly sharpen the chainsaw chain with a file. File parameters are determined by the dimensions of the saw itself. It is important to know the pitch of the teeth. One round sharpener is not enough. For sharpening and dressing chains, two types of tools are used. The first is a file with a circular cross-section with a diameter corresponding to the diameter of the rounding of the working edge of the saw tooth. A flat file is required to cut the depth gauge on the guide tooth.

Sharpening can be done manually using a round file with a working diameter of 4 5.5 mm. It is extremely important to position the tool correctly in relation to the tooth being sharpened. The upper edge of the working part of the file is approximately one fifth higher than the upper edge of the workpiece. The tool is held perpendicular to the chain axis at an angle of 25º… 30º to the upper edge of the tooth.

For sharpening saw chains of household tools, round files with a diameter of 4 and 4.8 mm are used, since they have a small tooth. For professional models, use more powerful chains with a larger tooth. Therefore, files with a diameter of 5.2 and 5.5 mm are needed.

You will need a flat file to sharpen the limiter, and a hook that removes the resulting sawdust to clean the work area. There are also special holders on the market, on which the mowing line is graduated with the direction of movement of the file relative to the axis of the chain. The holder can be mounted on top of the tooth, resting on its upper edge. Since its height is adapted to a certain chain pitch, this device should be selected in relation to chainsaws of specific models and brands. The minimum required set in order to obtain the correct angle of sharpening the chain by hand is shown in the photo.

A set of sharpening tools and accessories

Manual sharpening saves material resources, allows you to work in the field. First, place the instrument on a level surface. If the work is done in the forest, trimming a large diameter log is a good choice. Next, you need to inspect the saw chain for any defects, it can be cracks, completely broken off teeth. After inspection, you need to set the brake in working condition, thereby blocking the movement along the chain bar, which must be tightened during sharpening with a file.

Do-it-yourself chainsaw sharpening with an angle grinder

Experts strongly recommend not to use this method for inexperienced craftsmen. He’s pretty dangerous.

But if there is no other way out, then you must follow the safety rules. The angle grinder must be installed in a vice and clamped securely. After switching on the tool, bring the edge to be sharpened to the rotating surface of the disc. Since it is impossible to maintain a constant sharpening angle using an angle grinder, a tooth sharpened in this way will differ significantly from a filed one. In addition, there is a risk of the angle grinder’s disc notching the tooth attachment ear.

Sharpening the chain with an angle grinder