Recommendations on how to properly cut the LED strip: more than 10 tips

In order to understand why the LED strip is warm, you need to consider the conditions of its operation, method of connection and other factors. First of all, you should study the specifications and find out the operating temperature of the product. There are LEDs that during operation are heated to 100 ° or more, it is normal and is a feature of the design. However, such elements are rarely installed on LED tapes. They are generally designed for operation in harsh conditions where excess heat is dispersed into the cold surrounding. There are other factors that should be talked about especially.

Quality

The number of LED strips on the market is huge. New manufacturers appear all the time, and the industrial giants are not lagging behind. The more famous and popular the brand is, the more fakes from South-East Asia. They do not correspond to the stated parameters practically in all points, and the main consequence of this is the excessive heating. It is possible to avoid such mistakes if you do not hesitate to ask the seller for the necessary certificates.

Overload

Many users buy cheap products from unknown manufacturers. Such products rarely match the stated parameters on the packaging. In particular, most of these tapes have excessively high power. This is done in order to use a smaller number of LED elements and get the same brightness as in normal products. When you supply power, the LEDs begin to receive too high a voltage, which becomes the consequence of excessive heating. Simply put, the extra voltages are converted into heat. The solution will either install additional elements or use a lowering resistor.

Other

LED strip is often heated and for other reasons:

- Sometimes the cause of overheating is the use of sealed LED tapes with IP67 degree of protection in warm living areas. The elements are inside a silicone tube, which does not allow excess heat to escape. There is a thermal effect, the LEDs get hot and begin to degrade in an enhanced manner.

- The cause of unnecessary heating is often too tight mounting. The tape is attached in such a way that a large number of elements are concentrated in one place. wound on a pipe, stacked in strips, etc.п. Heat dissipation in such conditions is difficult, and the tape begins to overheat.

- Overheats not only the strip, but also the power supply (driver). This happens if you do not have some power reserve in the source. Over time, its characteristics deteriorate, it begins to work with overloads and gets very warm. The solution to the problem will be to replace the driver with a more powerful device.

Dealing with complex situations: Is it possible to cut the LED strip

With the new LED-materials the situation is more or less clear. It is more complicated when you want to change the configuration of used tape or one that has a non-standard format. As previously stated, it is highly recommended to make sure that there are copper conductors at both ends of the resulting sections. In fact, the above rule is not true in last instance.

There are several situations where a person is able to shorten the LEDs without regard to this recommendation:

- To begin with, it is necessary to make sure that there is a sticky protective layer;

- If this is the case, you need to take a mirror and make a detailed inspection of the junction;

- The task of man. to make sure that the LEDs show no signs of mechanical damage;

- Some help in the work will be the fact that the silicone protective parts will also be intact;

- If one of the above rules is not followed, that you can cut the diode ribbon in a special way;

- Each resulting segment should have at least one copper conductor or 3 connecting points.

There is no need to rush to throw out the LED-tape, if it has signs of damage, wear or factory defect. Firstly, it should be visually inspected for possible defects. If these are insignificant, all that remains is to make a neat separation.

The device of the LED strip

To date, the tape LED type is a printed circuit board, which is reconnected to a thin base of elastic type. On one side of the strip is applied to this type of resistors, which allows you to connect this product to a power source or other device. It is also worth noting that the product has contacts to which, if necessary, you can solder wires connectivity. If you look closely, you can see that there are dashes across the three different elements. That is the point at which it is possible to separate the tape.

There are also tapes that are self-adhesive and with their help, even a high school student can do the installation. In this case, the installation does not need self-tapping screws or any other reinforcing materials, it can be firmly fixed by its base.

Block: 2/9 | Number of characters: 909

Where to cut the LED strip

On the network we found this video, with it you can understand how to do it correctly. Please note that the cut should only be every three diodes. For example, if you cut through one, all the others in the chain will go out at once. Only some strips can be cut through one, here it all depends on the modification, so take it into account.

Note! You should only connect the strip when it is off, otherwise you risk causing a short circuit in your home, and it is not worth it, so be careful.

Also take a look at this video, it’s a different model. All of the tips can be called sensible, so feel free to trust them.

We decided to show you more how the cut of the LED strips can look like, depending on the manufacturer:

Block: 3/4 | Number of characters: 834

How to connect a cut LED strip?

If you have two pieces, you can splice together without much effort. There are two ways to splice a led light:

In the first case, you can connect the individual segments with each other through additional wires, or by soldering directly to each of the contact pads. Consider the wireless splicing method.

Before applying rosin to the contacts, make sure they are not oxidized.

Apply rosin to contact pads that have not been oxidized. In this case, treatment should be amenable to both the site on which the LEDs are located, and the surface under the protective film on the back side of the tape. For quality splicing of the segments, the thickness of solder must be at least 3 mm on each segment of the backlight.

The total length of the spliced ribbon must not exceed 5 meters.

The incoming voltage is designed by the manufacturer only for illumination of limited parameters. Its value will decrease with the formation of printed tracks of greater length to the end of the strip.

This will cause the LEDs at the end of the backlight to burn less brightly than those closer to the power source.

The easiest connection method is to use a special connector. To connect an additional segment, the following algorithm should be followed

How to cut the LED strip 220 volts?

Unlike a low-voltage strip, a 220V strip has a more rigid shell. It can be divided into segments only in specially designated areas. In the carrier board for the cut by the manufacturer provided gaps. conductive rails. Their length can vary within 1.5-2 cm. The frequency of special breaks in silicone depends on the manufacturer and may vary in the values of 0.5-2 meters. For example, in ecola 220v LED strips the sections for cutting are located at a distance of 1 meter.

The cut should be made strictly in the middle of the gap with sharp scissors.

As a result, you get several light sources independent of each other. Between two bars can be from 30 to 120 LEDs.

If you do not make the cut in the torn area, the separated portion of the led-tape will not work, or it will cause a short circuit.

How to cut correctly

Each Led strip has many short blocks, which have a number of chips and resistors, depending on the model. LEDs are clear or white, current limiters are black. Between the blocks, most often there is a mark (dotted line for trimmer and a picture of scissors) along which the strip can be cut.

Warning! If there are no marks on the front side, you should look at the back side.

On a thin strip, it is more convenient to make the cut with sharp scissors. Exception: boards mounted in silicone tube. Cut between the two contact pads. When offset, it is difficult to solder wires to connect to other sections or the power supply.

The LED strip has joints every 50 cm, where individual blocks are soldered overlapping. It is not advisable to cut the strip in these places (the contact pads are too small). If it is still necessary to cut, you must replace the scissors with a soldering iron (solder the joint).

A normal 12-volt LED strip

12 V LED strip consists of blocks with 3 diodes (in products for 24 V. 6 diodes). This means it can be cut into very short pieces. The product is cut strictly along the dotted lines with sharp scissors.

Important! If this condition is not met, the individual units will not light up, and it will not be possible to connect them. Spoiled section will have to cut off and throw.

Cut off from the board of SMD 335 and DIP can be in pieces consisting of 3 diodes.

LED strip 220 volts

LED Strip 220 volt LEDs are made from SMD LED 3528, 2835, 3014, 5050, 5630, and come in several varieties, different in the scheme of chips. The main difference from 220 V products is the cutting capacity of 0.5, 1 or 2 metres. Number of diodes on one piece varies from 30 to 120 pieces. A piece of this tape can be cut with scissors along the dotted lines.

VLUU L100, M100 / Samsung L100, M100

Colored RGB strip

The design of RGB and RGBW LED cards do not differ much from the design of one-color LED strip. The difference lies in the number of tracks that conduct current (on the multicolor strip there are four or five). The contact pads are marked with “R”, “G”, “B” and “-” (on the RGBW strip “R”, “G”, “B”, “W” and “-“). You can cut off a piece from such a strip in the same way as you cut off a monochrome strip. with dotted lines.

When connecting to the power supply and connecting the pieces it is important to connect each channel to the corresponding colored pin. If this condition is violated, the light source will fail because of the different power parameters of each color.

Block: 2/7 | Number of characters: 2517

What to do if there is no line on the LED

It also happens that the manufacturers do not mark where to cut the strip correctly. In this case look at the photo above. Scissors put between pairs of diodes strictly on the center, then there should be no problems.

buy a fuelless generator or turn on your head.

Block: 4/4 | Number of characters: 290

To sum up

As you can see, having a certain knowledge base, cut the LED strip is not difficult. For lighting in the home it is advisable to use led strip with a voltage of 12 volts. They do not cause difficulties when installing and are safer in contrast to the high-voltage.

In the process of working with LED types of tapes often need to cut off a certain length. This is due to the fact that the minimum unit sold is one meter tape. Often these or other ideas are not standard, and the length required is arbitrary. Many consumers from time to time the question arises, whether it is possible to cut the LED strip? In this article we will explain how to do it correctly.

How to cut a normal LED strip 12?

LED tapes are referred to as devices led. At its base this system has only an electrical circuit. 12 V tape is not only flexible, but also elastic. It, like other counterparts, consists of individual segments, which usually contain three LEDs each. You can verify this fact yourself by removing a certain part of the strip and look closely. Along the backlight between the individual segments is the distribution of voltage across the strip.

Due to the fact that the coating has a thin layer, the tape can be cut, clearly controlling where there is a line for the trimmer. This is easily accomplished with a letter opener. If you cut this type of product, break the rules and do not do it on the right line, it will lead to the fact that one of the parties will stop its work.

When producing these tapes, the manufacturer himself clearly distributes the lines with dotted lines, where you want to make the cut.

How to cut a conventional LED 12 V tape?

LED tapes refer to the so called led devices. At its base this system has only an electrical circuit. 12 V tape is not only flexible, but also elastic. Like its counterparts, it consists of individual segments, which usually contain three LEDs each. Verify this fact you can yourself, removing a portion of the tape and look closely. Along the backlight between the individual segments is the distribution of voltage on the strip.

Due to the fact that the coating has a thin layer, the tape can be cut while clearly controlling where the trimmer line is. This is accomplished simply by using a letter opener. If you, cutting a product of this type, break the rules and do it not on the right line, it will lead to the fact that one of the parties will stop its work.

When producing such tapes, the manufacturer himself clearly distributes the lines with dotted lines, where you need to make the cut.

How to connect one-color LED strip with connectors to the power supply

With this connector we can easily connect one end of the LED strip with the power supply.

Ribbon is cut only by segments, multiples of three LEDs. It is easy to see where to cut by the lines on the front side of the strip. Keep in mind that this specific distribution of diodes on the ribbon will not allow you to cut the exact size you want “tit for tat” and will always be either a larger size or a smaller size.

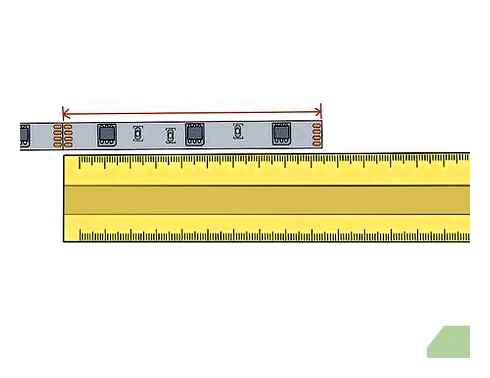

With scissors we cut so that the copper nickels on the line of the cut remain on both sides of the strip. In the photo the nickels can be seen as small round copper pads.

Taking the connector for quick installation of the ribbon. Place it as you see in the photo. A white, wide stripe upwards. Next, without much effort pull the ends of the second plastic clip. When performing these operations, never hold on to the wires, otherwise you will have to work with a soldering iron.

Inserting the LED strip in the connector check polarity. Not always the color of the wires can match the “” and “-“. This is especially true of those who buy cheap Chinese connectors. Let me reassure everyone. There is nothing wrong with Chinese connectors. 99% of them come to Russia from there. Someone just buys them in Russian stores, and someone else is smarter and buys them at Chinese sites.

After the tape will be inserted into the connector, you must return the latch in place. And without making serious efforts to check the reliability of fastening. If everything is in order. connect the wires to the power supply and check the functionality of the tape.

How to cut a colored (RGB) LED strip?

RGB ribbon has a slightly different separation process. The device is also divided into parts, but each part has several contact pads.

Under this condition, it is extremely important that the color channel, which has been cut, connects with the same name, so that the color that has been conceived burns. Each color has its own immediate parameters, in case of violation of which there may be extremely negative consequences.

Design Features

Regardless of power and type of LEDs used, all strips are designed for power from 12V to 24V (220V private version is not taken into account).

How to cut?

At the end of each segment there are connecting pads, between which there is a line for trimmer of potential separation.

Any strip is a set of segments consisting of three LEDs and one to three current-limiting resistors. The number of resistors depends on how many light-emitting crystals in the LED.

LED 3528 consists of a single crystal, so one resistor is enough for each section.

Each LED 5050 element has three independent LEDs, each connected through its own resistor. Note that there can be from two to six contact pads. In fact, to supply these LEDs is enough to two wires, but some particularly pedantic manufacturers for each group of diodes make a separate channel of power, as in the RGB elements.

How to cut a color (RGB) LED strip

With RGB a little different situation, each section of such tape has four pads.

It is important that when you later connect the pieces, each color channel is connected to the corresponding pad. Each color has its own power parameters, and if you break the connection, they can fail.

How to cut the 12 V LED strip without marking

Some manufacturers do not apply separation markings on the bearing surface.

Even when there is no separation markings, between each piece of tape there will be contact pads between which the cut should be made. As an exception, there are samples with the location of the contact pads on the side of the substrate.

Design Features

Regardless of power and type of LEDs used, all the strips are designed for power from 12V to 24V (220V private version is not taken into account).

How to cut?

At the end of each segment is the connection pads, between which is a line for trimmer potential separation.

Each strip is a set of segments consisting of three LEDs and one or three current-limiting resistors. The number of resistors depends on how many light-emitting crystals are in the LED.

LED 3528 consists of one crystal, so one resistor is enough for each site.

Each LED 5050 element has three independent LEDs, each connected via its own resistor. Note there can be from two to six contact pads. In fact, to feed these LEDs is enough two wires, but some particularly pedantic manufacturers for each group of diodes make a separate channel of power, as in the RGB elements.

How to cut a colored (RGB) LED strip

In RGB the situation is somewhat different, each section of this strip has four pads.

It is important that when you later connect the pieces, each color channel is connected to the corresponding pad. Each color has its own power parameters and if the connection is broken, it can fail.

How to cut the LED strip 12V without marking

Some manufacturers do not put a separating mark on the bearing surface.

Even when there is no separation marking, there will be contact pads between each piece of tape and a cut should be made between them. As an exception, there are samples with the location of the contact pads on the side of the substrate.

Cutting the LED tape for repair

It should be understood that damage of the mechanical type can occur even during the installation of the strip. For example, because of its excessive bending. It is important to know that the maximum radius to which you can bend this tape is five centimeters, no more. If you want to wrap this tape object, which has a small size, the probability of long life of the tape is not great.

It should be noted that malfunctions of this type can be easily and simply eliminated. In this case, the part that has ceased to carry out the work is cut out. Next, we pick up a section of the same parameter and with the use of the connector put everything in its place. If soldering is possible, it is better to make the connection in this way.

But this type of repair has its own direct nuances. For example, if the breakage is located in a place where the cord is too clearly visible. In this case, you need to have a cord, the length of which will allow you to hide such moments.

How to connect the cut LED tape?

If you have two sections, you can connect between them without much effort. There are two ways of splicing a led light:

In the first case, you can connect the individual segments with each other through additional wires, or by soldering directly to the contact pads of each of the segments. Let’s look at the wireless splicing method.

Before applying rosin to the pins, you should make sure that they are not oxidized.

Apply rosin to pads that have not been oxidized. In this case, both the pad on which the LEDs are located and the surface under the protective film on the back of the strip must be treated. For quality splices, the thickness of solder should be at least 3 mm on each section of the backlight.

The total length of the spliced tape must not exceed 5 meters.

The incoming voltage is designed by the manufacturer only for illumination of limited parameters. Its value will decrease as printed tracks of greater length are formed towards the end of the belt.

This will lead to the fact that the LEDs at the end of the light will burn less brightly than those that are located closer to the power source.

The easiest way to connect is using a special connector. To connect an additional section should follow the following algorithm:

Block: 5/6 | Number of characters: 1529

To summarize

As you can see, having a certain baggage of knowledge, cut the LED strip is not difficult. For backlighting at home it is advisable to use led lighting with 12 volts. They do not cause difficulties in installation and are safer in contrast to the high-voltage.

If necessary to lengthen or shorten the LED strip requires cutting into blocks that can act as separate light sources.

Problems can arise if there are no dotted line and scissor marks on the strip. If they are not present on the back side, you have to refer to the width of the strip on the edges of the tape.

Silicone is easier to cut with a knife, the board. with sharp scissors.

Home masters install LED strips in different ways. If you have experience in cutting LED strips, share your experience in the Комментарии и мнения владельцев.

LEDsHow to choose the right LED flashlight by type and purpose

LEDsHow to get the white glow of LEDs

Block: 7/7 | Number of characters: 833

Number of blocks: 13 | Total number of characters: 15583Number of donors used: 3Information on each donor: