How to cut a circle out of wood without a jigsaw. How and what to cut curves and circles with

Plywood sheets are seldom used in the same format they are commercially available. Plywood is most often additionally cut. It is often necessary to obtain a workpiece of a certain shape. How to cut a circle out of plywood. even without having at hand a special tool, we will tell you more.

- It is recommended to cut only dry plywood. Moisture increases the resistance of the board and increases the risk of fractures, delamination of the veneer and other defects.

- It is better to replace cutting tools as soon as the first signs of blunting appear.

- When using an electric jigsaw in order to get the cleanest edges of the workpiece, the cutting line for the trimmer should be directed along the fibers, but when using hand tools. across the veneer. In the latter case there may be more chips, but the tool is not likely to leave the cutting line.

- When transferring drawings or other elements to the plywood, try to make sure that the potholes (spots, knots and cracks on the material) go in the waste, not on the plywood workpiece itself.

- If there is a complex, task, for example, cutting a round product, you need to think about the use of a special tool (a disk or ordinary saw will not do) or the original improvised means.

How can a circle be cut out of plywood?

The most difficult to decide how to cut an even circle from plywood. If there are no special tools at hand. But even in this situation there is a way out. improvised means. This is the essence of the method:

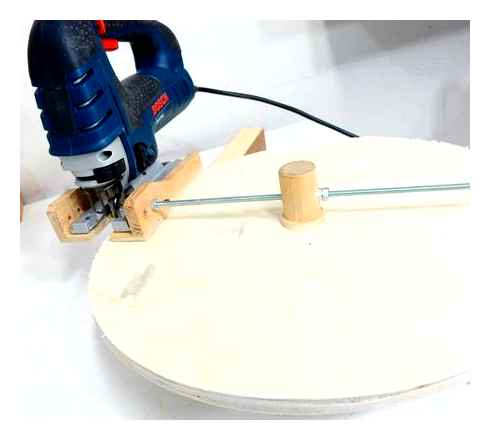

- Main tool. Slat of wood with a pair of nails.

- The first nail must be hammered through the bar, and then placed in the very center of the plywood workpiece.

- The second nail must be as sharp as possible. It is hammered in at a distance that is equal to the radius of the circle, from the first. The nail has to go out of the strip by 5-10 mm or more (depending on the thickness of the plywood sheet).

- Rotating the slat against the first nail, the second nail forms a groove and gradually deepens in the plywood

- The rotations are made until the complete cut of the plywood sheet.

Instead of a ruler, a high-strength cord can be used, but the principles of obtaining a circle do not change.

traditional methods of obtaining a circle from plywood using a suitable tool:

- jigsaw. electric or manual. Initially an outline is made with a pencil (let’s say using a template), then a cut is made along the lines, and the finished part is additionally sanded with a file or emery paper;

- with a router. A great tool for making a circle out of thick plywood. The staff ruler is fixed with a self-tapping screw in the center of the circle. Next, the cutter rotates at a given radius, forming a hole with a regular circular shape.

Articles, Diagrams, Handbooks

Often, when repairing or installing various wooden products, you need to drill a perfectly round hole. In this article, we will try to cover all the ways in which you can cut such a hole. Variants with special tools and without them will be considered. A hacksaw with a very narrow blade, a jigsaw, a boring saw and a circular file. these are the hand tools that can be used to cut through the curve.

Wait for the end of the search in all bases.On completion, there will be a link to access the found materials.

Jump to search results

Watch this video : How to cut a round hole in thin metal without special tools.

How to make a round hole in chipboard?

I have a couple of speakers to make, and did not learn how to saw straight with a jigsaw. The Fiolent is stable in this respect. How to make a hole for a speaker with a diameter of about cm. With a jigsaw with a circular jig!

I don’t know if there is such a device for the Chinese. With a router, with a similar tool if you have a router. Well actually the jigsaw is the easiest. Only take a new saw and without a strong feed to cut. If you have a milling machine, you can use it. It comes with a special lever for circular cuts. And take a small milling cutter with a finger. You mill halfway on one side and then the other. There are also special circular tools for the drill.

For 25 cm is enough. But it needs a good drill stop, preferably a stand. Again, if the chipboard is wide, the depth of the cutter may not be enough. Then you can try on both sides. And actually it’s a great skill to make good columns, in t.

I meant what you said. “and a jigsaw straight sawing and did not learn. Making for myself, so any will be good. No router. Where to find them, the approximate cost. Such circulars are called “Fixture for cutting holes of large diameter,” or conductor for drilling holes of large diameter. In short, it’s a special bushing with a shank for the drill and a cone for alignment.

There’s a through hole across the sleeve where you put the long rod. At the end of this rod is a rectangular hole for a chisel with a screw to tighten. The diameter of the hole is regulated by the position of the rod in the sleeve. You set it and fix the pin in the sleeve with the clamping screw.

And then you actually drill. We have seen such devices at construction markets many times. That’s where you should look. It’s not homemade, someone makes them on an industrial scale. If you need to make a neat recess for the head flange recessing, that is correct, and for HF it is even obligatory. it’s probably only with a router. As for the front panel, take good advice from Nickel. Also, in the body itself you could use a spacer.ki. especially if it’s big and the walls are thin, and cover it with vibration and sound absorbers.

I tried it with a jigsaw and it turned out awful. Took a router, made a fixture in 20 minutes, and cut through. With the flange recess. Thanks again!! And when this circular for the drill rotates, it doesn’t hit it? Because I’m not going to buy a 2 Nickel woodchip board. There is particle board. I was thinking of putting together a box. Put some “anti-noise, etc.” on the front of it and glue another sheet on top. But then the speaker will “sink”. And about the jigsaw, for some reason the jigsaw‘s going like this and it’s Røbir. that you have to pull the jigsaw hard to the left.

It turns out on the line, but the saw bends and gets a chamfer of 40 degrees. Tavrovod wrote: And about the jigsaw, for some reason the saw is so and it Røbir. I have to pull the jigsaw hard to the left. Desti wrote : Don’t. It’s all right?? Or all the Calibers and other Chinese? Or chipboard is a thick material? I’ve never noticed that with my jigsaw! IMHO A good jigsaw and good saws is the key to success! On a non-thick board, yes. But try your jigsaw to cut a piece of 4 cm. And if the saw is already running and a bit worn, you don’t even have to try.

Desti wrote: On a non-thick board, yes. Beech is mm, I will try with a saw DP. But if it’s always to the left, it’s always to one side. the material probably has nothing to do with it! I don’t think Tavrovod always saws 50mm oak or beech. I have an 18mm front wall of a column glued. I’ve been practicing on scraps, I have not been able to get an even cut, the saw moves away instantly. To make a jigsaw stem absolutely without backlash, and a saw with a strictly symmetrical sharpening, unreal.

When put together, these two factors, plus the unevenness of the density of the material, different density layers or the structure of the layers of wood and lead to sagging. Desti wrote : I have an 18mm headstock front wall glued together. Tried a green bosch, philantom, skeleton, makita, different saws in the neighbors collected all for this case. I ended up buying a router as no one else had one and I needed to make a hole.

Desti wrote : I’ve tried it with a green bosch, philantom, skeel, makita, different saws. I sawed wood chipboard Soviet 15 mm and plywood. about 8. Mine takes it away. No Fiolent. That is, I can feel with my hand, how the jigsaw wants to go sideways.

Check the geometry of the jigsaw. Maybe the jigsaw is facing sideways from the beginning. Try getting a new coarse-cutting saw. it has a larger angle of departure, making it easier for the jigsaw to follow the arc. Well, and the feed e. And the drill of course beats, you can’t hold it in your hand, especially with such a thickness. All you need here is a prop. I wonder if the panel will fit under the stand? The milling machine, of course, the ideal option Made a quarter-circle shelves in the corner of oak with the milling machine.

The Chinese 6mm finger mill broke, the splinter flew out and caused a lot of unpleasant impressions. After that went this way.

First I use a router with a compass to get a mm groove. Then I cut the required contour with the jigsaw, the saw goes inside the groove with a reserve, t.

Then a router with a bearing goes over the edge of the finished piece, the bearing rolls over the former edge of the groove. Desti wrote : To make a jigsaw stem absolutely without backlash, and a saw with a strictly symmetrical sharpening, is unreal. When I made a sub in the car, I easily made a hole in plywood 18mm for a 12″ speaker or something like that with a jigsaw with a tool a la scraper.

And when I did the same thing for the mm speakers, there was a slippage. The plywood was even 12mm thicker, but the jigsaw and saws are the same. But now for the speakers in my home I’m going to use 25mm Fiberboard and a router. For a quality round hole, only a router. And the sinking. Forum Blogs Video Market Ranking Masters.

New posts New topic Albums Popular tags Specials. Join the Mastergrade community Sign up. Tools & Power Equipment Forum Power tools: instructions, repair, operation What to make a round hole in a chipboard?

How to make a wooden beer mug without a lathe

The manufacture of wooden utensils has long since passed into the category of exotic activities. And if earlier in almost every village you could find a master of lathe art, but now such a rare skill possesses a few.

At such a rate, the production of wooden dishes at home will soon disappear into oblivion, but you agree that we would not want to let this happen.

However, there are a few methods of producing tableware without using a lathe. They are commonly used on an industrial scale.

Meanwhile, let’s determine what materials and tools you will need to make your own hands a beer mug without using a lathe.

How to make a circle out of wood?

Often, when repairing or installing various wooden products, you need to drill a perfectly round hole. In this article we will try to highlight all the ways in which you can cut such a hole. Variants with and without special tools will be considered.

A hacksaw with a very narrow blade, a jigsaw, a boring saw, and a circular file are the hand tools with which to saw along a curve.

It is the narrow blade that gives the hacksaw its maneuverability, but for the same reason it is extremely difficult to drive. You have to have a steady hand and a keen eye to make sure there are no deviations from the markings. At the same time do not try to work quickly. On the contrary, it is better to advance in small jerks. This will help to hold the handle of the saw more confidently and guide it precisely along a given line.

Saw small round or oval holes and “narrow” curves it is better to use special tools. a saw and a circular file, which can also be used to deburr roundings.

However, the most suitable tool for sawing rounded parts and holes should recognize electric sabre saw. Its advantage is not only in the fact that it saves time and effort. Included set of interchangeable blades with different teeth allows you to pick up a blade for sawing blanks of almost any type, whether wood, plywood or chipboard. In other words, an electric hacksaw can be rightly called a universal tool.

How to make a scratching post out of wood with your own hands

What you need

- Sisal rope or jute;

- liquid fabric dye. optional;

- wooden bar;

- A round wooden workpiece;

- felt-tip pen, pencil, or pen;

- drill;

- paint for wood. optional;

- Brush. optional;

- screws;

- A hot gun;

- construction stapler;

- pompoms and yarn. optional;

- bar top. optional; and.

How to make a scratching post

If you wish, give a different color to the nail, using the instructions on the dye package. In this master class, the pieces of rope are painted in three different shades.

Place the bar in the center of the round workpiece and trace.

Divide the rectangle thus drawn with two perpendicular lines. You will have four identical smaller figures inside. Divide them diagonally. at the intersection of the lines will be the points where the screws need to be screwed in. Place the same marks on the base of the bar.

Drill four holes in place of these dots on each piece.

The round base can be painted without affecting the center of the workpiece.

Screw the timber to the round piece with screws on the back side.

Place the future scratching post on the base. Glue the sisal rope or jute at the bottom and secure the end with a construction stapler. You can screw in a screw instead.

Wrap the rope around the bar, gluing it to the wood on all sides. If you change differently colored pieces, additionally fix the tip of each piece with a stapler.

When the surface for sharpening is done, you can still attach pom-poms on strings and a nice top.

What other options are there?

This cat scratcher is similar to the previous one. Only the base is additionally trimmed with cloth, and a simple house from a small shelf is set on top:

How you can cut a circle out of plywood

The most difficult thing to decide how to cut an even circle from plywood

, If there is no special tool at hand. But even in such a situation there is a way out. improvised means. What is the essence of the method:

- The basic tool is a slat of wood with a couple of nails.

- The first nail should be hammered through the bar, and then placed in the very center of the plywood workpiece.

- The second nail should be as sharp as possible. It is hammered in at a distance, which is equal to the radius of the circle, from the first. The edge should protrude from the strip by 5-10 mm or more (depending on the thickness of the plywood sheet).

- Turning the slat against the first nail forms a groove with the second one, and gradually deepens it in the plywood

- Rotations are made until the plywood sheet is completely cut.

A high-strength cord can be used instead of the plank, but the principles of making a circle do not change.

traditional methods of getting a circle out of plywood using the right tool:

How to cut a circle out of plywood

The most difficult thing to decide how to cut an even circle from plywood

, If there is no special tool at hand. But even in such a situation there is a way out. improvised means. What is the essence of the method:

- The basic tool is a slat of wood with a pair of nails.

- The first nail should be hammered through the slat, and then placed in the very center of the plywood workpiece.

- The second nail should be as sharp as possible. It is hammered in at a distance, which is equal to the radius of the circle, from the first. The nail head should protrude from the slat by 5-10mm or more (depending on the thickness of the plywood sheet).

- The second one, rotating it against the first nail, makes a furrow and gradually deepens it in the veneer

- Rotations are made until the veneer sheet is completely cut.

It is possible to use a high-strength cord instead of the plank, but the principles of obtaining a circle do not change.

traditional methods of making a circle out of plywood using a suitable tool:

Key rules

For the process of sawing to be simple and fast, it is necessary to observe the basic key rules of work:

To make the edges of the veneer flat, it is better to saw along the blade.

- Work only with dry material, as moisture increases the resistance of the material, which can cause the veneer to begin to delaminate;

- It is necessary to change the cutting blade as soon as the first signs of blunting of the teeth appear;

- Electric jigsaw is better to work along the fibers of the material, so the edges will be more even;

- with a hand jigsaw should be cut across the fibers of the veneer.

To work safely, it is necessary to adhere to the following recommendations:

- securely fasten the sawing table and jigsaw in the frame;

- The jigsaw should have serviceable and well-fitted handles;

- do not press too hard on the jigsaw, trying to “help” him, this will only lead to an acceleration of blunting of the working blade;

- straight and long cuts are best made with a wide blade, so the process of sawing will go faster;

- you must always see the markings, so sawdust from the material you are sawing should be removed by hand, never blowing it off, as it could get into your eyes.

Following these simple rules will help the beginner learn how to cut circles with a jigsaw and facilitate his work.

Power tools or hand tools?

Cutting a circle in plywood is possible with the following tools and materials:

- electric jigsaw;

- drill;

- hand jigsaw;

- nails;

- milling machine;

- chisel;

- rope;

- A box cutter;

- hammer;

- compass;

- sandpaper.

The most popular option is to cut a circle in the plywood with an electric jigsaw. Besides circles, all other possible geometric shapes can also be cut with this tool. Its only disadvantage is the need to form additional grooves where there are curves, but in the case of the circle this is not noticed. Choosing the right file is important. They are divided into three kinds: ripping on the left, ripping on the right and ripping on both sides. After selecting the blade, you can cut a circle, which can have any size. This is worth knowing for anyone who wants to buy plywood.

You can also use a normal hand saw. Before cutting a plywood circle with this tool, you must make sure that the process can be carried out. The main difficulty is the limitation (up to 0,3 m) because of the physical construction. Thus, it is not possible to work at recesses. In the case where the work starts not from the edge, but from the center, the file is tucked in last. Everyone who asks the question “where to buy plywood” should know this?”

Another popular and convenient option is the use of a milling machine. This implies a firm grip with the surface, so in the central part of the circle is screwed a self-tapping screw. The circle can have any diameter and is cut rather quickly. It happens that the working handle is not enough, so you have to create improvised brackets from a profile, channel, board, bar or even rope, but with a rigid coupling is much more convenient. This tool allows you to make a very wide hole, so before starting work, it is necessary to make careful measurements of the structure.

How do you cut a circle out of plywood

The hardest part is deciding how to cut an even circle out of plywood. If you do not have a special tool at hand. But even in such a situation, there is a way out. improvised means. What is the essence of the method:

- Basic tool. A wooden plank with a pair of nails.

- The first nail must be driven through the slat and then placed in the very center of the plywood workpiece.

- The second nail should be as sharp as possible. It is hammered in at a distance which is equal to the radius of the circle, from the first. The edge has to protrude from the strip on about 5-10 mm or more (depending on the thickness of the plywood sheet).

- Rotating the slat against the first nail, the second nail forms a furrow, and gradually deepens it into the plywood

- The rotations are performed until the plywood sheet is completely cut.

A high-strength cord can be used instead of the plank, but the principles of making a circle do not change.

traditional methods of making a circle out of plywood using a suitable tool:

- jigsaw. With an electric or a handheld tool. Initially an outline is made with a pencil (we assume according to the template), then a kerf is made along the lines, and the finished part is additionally ground with a file or emery paper;

- with the cutter. Great tool for getting a circle out of thick plywood. The regular ruler is fixed with a self-tapping screw in the center of the circle. Next, the cutter rotates at a given radius, forming a hole of the correct circular shape.

Why do you need a plywood circle?

Before you think about how to cut a circle in plywood with a jigsaw. It must be clearly understood what it is for. Use in the subsequent can be both the resulting billet round shape itself, and plywood sheet with a hole of the right shape.

- for the manufacture of various crafts and templates for them;

- be used as a base for a wall clock;

- To be used for subsequent shape cutting or decoupage;

- act as the seat of a stool, the tabletop of a kitchen or coffee table, etc.д.

- To create various souvenirs, for example, caskets, etc.д.

It may also be necessary to cut a right circle out of plywood for the subsequent use of a sheet with a hole:

- installing a recessed sink in the countertop;

- Obtaining a ceiling with a cutout for round light fixtures (spotlights or a single chandelier);

- for the production of furniture with decorative fronts and other elements, etc.д.

When working with different types of wood it is always necessary to know the detailed variations. Before you cut a circle in plywood, you need to know all the options, because often you have to adjust to the situation. There are many options for performing such a venture, and they differ dramatically.

To cut a circle out of plywood, you can use both professional tools and improvised means.

Electric appliances or hand tools?

When determining the diameter of the future wheel, you need to consider the dimensions of the cutter.

The most popular option among all is an electric jigsaw. This tool allows you to cut not only circles, but also any other geometric shapes. The only disadvantage of it is the need to form additional grooves in the places of turns (corners), but when creating a circle it is unnoticeable. It is very important to choose the right file, t.к. they come in 3 types: rips on the left, rips on the right, rips on 2 sides. Once the blade is selected, cut a circle of any size.

An ordinary hand jigsaw. Before you cut a circle out of plywood with this tool, you need to make sure that the workflow is accessible. The main difficulty is the limitation (usually up to 30 cm) due to the physical structure, t.е. it is not possible to work in deep places. When you start working not from the edge, but directly from the center of the file is set in the last place.

milling machine. A very convenient option, but requiring a rigid adhesion to the surface, for which a self-tapping screw is screwed into the center of the circle. The circle is made of any diameter, and very quickly. Sometimes there is not enough working handle, so you have to make all sorts of improvised brackets, which can be a channel, profile, bar, board and even rope, but on a rigid hitch is much more convenient. This tool makes quite a wide hole, so before starting the work, you need to carefully measure the future structure.

It is necessary to choose only sharp nails, and the edges of the resulting billet are processed with coarse sandpaper.

Nails. A very popular method in cases where the work must be done “yesterday” and the tools will not be soon. It is worth noting right away that the resulting work is quite rough, so it is used in the most extreme case. Only a hammer, 2 nails and a rope will be needed. One nail is hammered into the center of the hole, and the other nail is stretched on a rope for the required length (radius), after which the circle is carried out with a firm movement. Such circles with pressure continue until the circle is finally cut out. At the very end, the nail is removed from the hole, turned over and carefully hammered to achieve a neater seam.

Chisel and office knife. Here everything is much easier, because first you need to draw a circle with a compass (pencil), then this circle is circled several times with a paper knife under pressure. The peculiarity of the outlining is the movement not of the knife, but of the sheet of plywood, so as not to break the metal, and such action is repeated on two sides. Then a chisel is applied to the prepared seam and with gentle strokes brought to the opposite seam (2-3 strokes are usually enough). At the very end we hammer out a circle, like in the nailing variant.

Usually, in order to saw out of a piece of plywood or board an even circle, craftsmen resort to all kinds of routers, use manual or electric jigsaws, and, at the worst, take a hacksaw. And meanwhile, with a simple device to cut absolutely flat circle can be and circular saw. How to do it in practice, read and see in the detailed step-by-step instructions.

Before you cut a straight circle with a circular saw, make sure you have the right materials. You don’t need much of the latter:

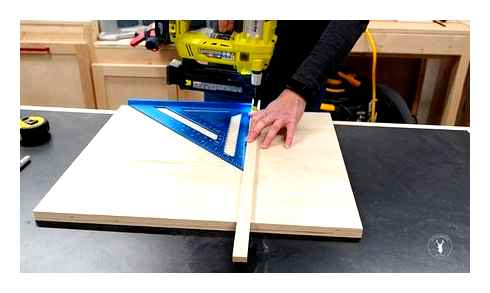

Step 1. Take a meter and measure the depth, length and width of the gutter on the work table of the circular saw. Using these measurements, cut a suitable thickness out of a piece of plywood.

Step 2. Insert the timber into the gutter, and trim the edges if necessary. The bar should slide easily along the trough without catching it.

Step 3. Put a square piece of plywood on top of the block, leaving the block in the groove. Install it so that it does not interfere with the saw itself.

Step 4. Screw the plywood tightly to the joist with self-tapping screws. Pay attention to the length of the fasteners when choosing them. The self-tapping screws must not damage the surface of the work table when screwed in.

Step 5. Get a piece of plywood or board from which you need to cut a straight circle. Adjust it to the shape of the square. Place the plywood on top of the prepared structure and hammer a nail exactly in the middle. Do not hammer the nail all the way in. Plywood, from which to cut a circle, must be free to rotate, and the nail itself at the end of the work will need to be carefully taken out.

Step 6. Rotating the square in a circle, cut off its corners, so you get an octagon.

Step 7. Keep rotating the square further and further, cutting off its sharp corners. At the end of the work carefully grind away the smallest irregularities. So, without unnecessary effort you will get a smooth circle cut from the board with an ordinary circular saw.

Often questions arise about how to cut a circle with a jigsaw, as many craftsmen are faced with only straight cuts of material. But sawing out varying degrees of curvature only seems complicated at first glance.

How to cut plywood with a jigsaw?

Before you cut a circle out of plywood, remember some general tips for working with this material. Sawing can only be done on dry material. Wet plywood has a higher resistance and the veneer will crack when you saw, which can cause damage to the saw blade or even the entire tool in the case of electric models. At the first sign that the teeth are not sharp enough or that some part of the blade is crooked, it is time to replace the saw.

When sawing plywood with the jigsaw, the main cutting lines should be as close as possible to the grain of the veneer.

This will promote clean cut edges. When working with a hand jigsaw, it is easier to cut across the fibers. This will not prevent chipping, but it is less likely that the saw will get pinched or move away from the planned line.

Before you cut a circle, you need to transfer its contours to the plywood. In doing so, you should try to ensure that areas with defects, chips, stains, and knots fall outside of the cut outline. To transfer the outline on the plywood, you can trace it through copy paper, cut a paper outline to trace, or simply draw a circle of the desired radius with a compass. If necessary, the starting hole in the plywood is made with a thin drill.

To cut a circle with the jigsaw, a blade is inserted into the hole. The free end of the hand model is reclamped in its place with a clamp or mounting screw. Workpiece to the workbench is clamped by clamps, the cut is made according to the transferred line. When the circle is closed, the center piece is separated from the sheet and the edges are machined with sandpaper or a file.

Before cutting with an electric motor jigsaw, a narrow saw blade must be placed on it. There is a special improvement for this tool, called a circular cutter, it is set in the center and start the work. No pressure should be applied to the tool when working, it does not make for faster cutting. The pressure can bend and break the jigsaw and even its mounts. If the circle you need to saw has a small radius, it’s best to do the job in several passes, as steep turns can break and bend the blade.

Usually, in order to saw out of a piece of plywood or a board an even circle, masters resort to all kinds of routers, use manual or electric jigsaws, and, at worst, take a hacksaw. And meanwhile, with a simple device to cut a perfectly straight circle is also possible with a circular saw. Read and see how to do it in practice in the detailed step-by-step instructions.

Before you cut a straight circle with a circular saw, take care to have the right materials. You don’t need much of the latter:

Step 1. Take a meter and measure the depth, length and width of the trough on the table part of the circular saw. Based on the parameters obtained, cut a piece of plywood of a suitable thickness.

Step 2. Insert the cant in the trough and trim the edges if necessary. The bar should slide easily along the trough, without catching it.

Step 3. Leaving the bar in the gutter, put a square piece of plywood on top of it. Make sure it does not interfere with the saw itself.

Step 4. Screw the plywood tightly to the block with wood screws. Pay attention to the length of your choice of fasteners. The self-tapping screws must not damage the surface of the worktable as they are screwed in.

Step 5. Take a piece of plywood or board, from which you need to cut a straight circle. Adjust it to the shape of the square. Place the plywood on top of the pre-assembled construction and drive a nail straight down the middle. Do not hammer the nail all the way in. The plywood, from which you are going to cut a circle, should rotate freely, and the nail itself when the work is finished, you need to take it out carefully.

Step 6. Rotating the square in a circle, cut off its corners so that you have an octagon.

Step 7. Continuing to rotate the square further, cut off its sharp corners. At the end of the work carefully grind away any small irregularities. So, without any extra effort you will get an even circle cut out of the board with an ordinary circular saw.