We make a drink at 45 degrees

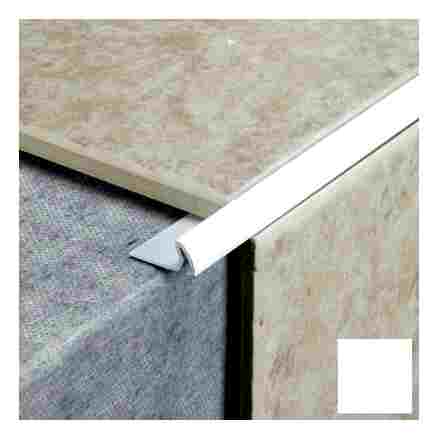

Ceramic pencil skirting is best for protecting the sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45-degree angle on the tile bevel, but not everyone has such a tool. It is easy to make such an angle on your own using the same angle grinder “by eye”. The disc is guided along the line of the cut, with the disc tilted slightly inward.

Undercut tiles at 45 degrees

Electric tile cutter

If you have a large amount of work, then the fastest and highest quality cut comes from an electric tile cutter. They use a diamond wheel and supply water to the cutting site to cool and remove dust. The cheapest types of amateur class can be found on sale for 3-4 thousand rubles.

How to cut porcelain stoneware

It is believed that porcelain stoneware is the hardest material from which floor tiles are made. You can trim it in the same way as a regular tile..

Sometimes simple floor tiles are more difficult to cut than porcelain stoneware. There is a hardened tile, on which, after cutting with a tile cutter, the notch on the glaze is almost invisible. And even a diamond disc does not take it on an angle grinder – the incision turns out to be torn, like after a tractor. In such cases, you need to use an angle grinder, and file a groove 2-3 mm from the back side to mark the place of the fracture..

Cutting tiles with a manual tile cutter

How a manual tile cutter works

- The tile is inserted into the tile cutter, and the markings on it are aligned with a special mark.

- The handle is lowered and held away from you. It must be driven at the same speed and even pressure so that the roller cuts the glaze to the same depth. It will be enough to run the roller once. If you drive several times, the breakage may turn out to be of poor quality..

- Next to the roller there are special paws that lower and break the tiles into 2 parts, after a sharp push on the lever. In this case, all tile cutters have a metal tubercle on their platform, and soft pads along the edges. When you press on the edges of the tile with your paws, maximum stress will be created at the notch, if correctly aligned with the backing, and it will evenly break off..

It is difficult to explain this in words, so it is easier to watch a video that shows how to cut tiles correctly with a tile cutter:

High-quality tile cutters allow you to cut even tiles with a thickness of 10 mm without problems. It doesn’t matter at what angle you cut it: at least 45 degrees, at least 30.

How to cut a tile with the letter “G”

Since the tile cutter can only cut the tiles straight, many have difficulty with L-shaped cutouts. The easiest option is to divide this tile into 2 rectangular elements, but then you get an extra ugly seam that will catch your eye.

But this can be avoided by trimming the short side with an angle grinder and then cutting the long side with a tile cutter..

Step-by-step instructions on how to make L-shaped cuts on tiles

The second method: by any method available to you, a cut is made on the glaze, and the excess is gradually broken off with pliers. Irregularities are treated with sandpaper. This option will even allow you to get a rounded incision for abutting the risers..

How to choose the right disc by tile

For cutting, metal discs are used with diamond dusting along its edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots on the solder, and will chip when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

Tile cutter tongs

The tile cutter-tongs are the cheapest (200-400 rubles), and it is suitable only for small volumes of work with thin ceramic tiles at home.

After notching, press down on the tile with a cracking pliers

- Make markings taking into account all gaps and seams (-5 mm).

- Attach a metal ruler to the mowing line and run the cutter along the line once. The pressure should be moderate to form a visible streak. Lead him from the far end to you.

- Place the tongs with their feet along the mowing line of the crowbar near the edge. The sponges should be on top of the glaze and the straight part on the bottom. the line of the break should go right in the middle between the edges of the upper jaw.

- Press gently on the handles to break off the tiles. At the same time, do not raise it high, otherwise after falling it will break..

How to cut tiles without a tile cutter

If you only need to cut a few tiles, it doesn’t have to be spent on a tile cutter. You can use the tools at hand:

- Glass cutter.

- Drill. It should preferably be with a victorious tip, as it will scratch the tile better..

- Nail.

- Construction knife.

Attach a metal ruler to the notch and draw once with a glass cutter or drill. A deep scratch should remain on the enamel. If you use a knife, but you will need to carry out several times.

Place the tile with the cut at the corner and press down on its edges with a sharp motion. The cut will not turn out perfectly even, unlike the tile cutter, but you will not have to spend additional money.

To make cutting ceramic tiles easier, many craftsmen soak them in water for about 1 hour..

Why do you need to fasten the corners to the slopes

Let’s start with the most important – why is it necessary? What role do the corners play – only decorative or do they have more serious functions? Let’s not argue with the fact that if you frame the slopes of doors or windows with special decorative elements that fit perfectly into the design of the room, then the interior will immediately change for the better..

Corners protect slopes from damage

But besides this, they also perform a very important protective function. Sooner or later, you have to carry bulky things through the opening, which is fraught with damage to the corners, and you can simply accidentally touch the outer corner and damage it. There can be a lot of situations, most importantly, the result is the same – a damaged surface and, accordingly, a view. In addition, as practice shows, most often the wallpaper begins to flake off precisely in these places. So it is best to protect the outer corner of the slope with a decorative element that will also transform the interior..

Corners are not only protection, but also a neat aesthetic appearance

What glue to use?

One of the most effective options is polyurethane glue. It is possible to use both a special adhesive for plastic corners, and any other composition suitable for the installation of PVC products.

A silicone based sealant can be used for finishing light traffic areas..

This adhesive is also used for fixing corners to ceramic tiles in the kitchen or bathroom..

Another option is liquid nails. When installing light products, it is better to use a colorless composition, and for dark products, any option is suitable.

Types and sizes

PVC corners can be divided according to two criteria: application and type of finish. Below will be considered the main types.

By the nature of the purpose, the products are divided into the following types:

- Equilateral. This type is used mainly to give strength to slopes. Available in sizes from 20×20 to 50×50 mm.

- Not equilateral. With their help, they decorate arched openings. Dimensions – 5×17 and 20×25 mm.

- T-shaped products. Most often used to hide the joints between wall cladding and slope.

- Removable (with a latch). Allows to carry out repair work without resorting to dismantling the profile. If necessary, it is enough just to bend it, and at the end of the repair, return the shelves to their place.

According to the type of finish, the corners are:

- outdoor;

- internal;

Installation of products

Now that all the elements are prepared, the installation of the corners on the window begins..

- Fragments are laid in random order. Although it is recommended to mount clockwise.

- Glue is applied to the seamy side. This should be done closer to the inner corner, given that the excess will protrude over the edge..

- The workpiece is immediately pressed against the selected area. Excess adhesive is erased.

- Each element is additionally fixed. To do this, use masking tape..

- Thus, following the described procedures, the entire perimeter of the opening is covered.

- The scotch tape is removed after a day, making sure that all parts are securely glued.

After mounting the corners on glue, you must additionally fix them with masking tape

Installing plastic corners is a simple undertaking. The main thing is to be accurate and observe the accuracy of calculations when trimming..

In order to properly take care of the interior decoration, it is important to pay attention to every detail. Decorating windows and doorways is no exception in this regard. Decorate openings and give them an aesthetic appearance with a decorative plastic corner.

It will not only emphasize the clarity of the lines of the corners, but also hide the imperfections of the plaster, if it was used as a finishing material..

Various types of products

There are different types of corners, which are divided according to their size and scope. The following varieties are distinguished:

- Standard. They differ in the same size of the sides. Used to give strength to slopes. There are two main sizes: 22 and 55 cm.

- Non-standard. Their sides are asymmetrical. They are used for work with slopes, which are installed on curved or arched openings. The most common size: 1020 mm.

- F or T – shaped. Hides the spaces that are created when slopes and wall material dock.

- On the latch. They are characterized by a removable design, which allows work to be carried out much faster.

Types of plastic corners

Preparatory activities

- In the case of installing the hardware on an untreated surface, carry out a preliminary check for protrusions, potholes, protruding nails. For maximum adhesion, a flat surface must be achieved..

- When working with some surfaces, before installation, it is necessary to degrease, wipe the corner from dirt.

- Measure the window opening. When measuring, take into account small gaps so that gaps do not form when cutting the connection. Recommended overlap length – 1 – 5 mm.

- When cutting off parts, you do not need to cut corners at once, it is better to do it in place.

- By overlapping each other. The resulting difference is covered with a sealant to match the color of the material.

- Undercutting the corner joint. Looks prettier, requires skill.

The plastic is cut with a clerical knife. A blunt instrument may damage the product.

Installation of corners and plastic profiles on window slopes

After the PVC windows are installed, it is necessary to install a corner on the window for the slope. This will give the window opening a decorative finished look. If plaster was chosen as the material for finishing the slope, then the PVC corner will allow you to create clear mowing lines for the window frame.

How to choose corners for window slopes

The quality of the final result is influenced by the correct choice of material that will be used during its direct installation. There are a large number of products in various colors with pictures. Plain and imitating metal, marble, wood materials.

Depending on the scope of application, several types are produced:

- standard – U-shaped, used for finishing openings on windows and doors at the beginning of installation;

- versatile – have the shape of the letter L, flexible, angle of 90 degrees, used for curly, arched openings;

- T.-shaped – are fixed on different surfaces, form an even border of joints, used when laying tiles;

- F-shaped – used for fastening to the ends of the panels using a special jumper, which can be removed if necessary. Acts as a platband, framing window or doorways;

- removable – plastic, with a latch, the edges are easily folded back;

- self-adhesive – flexible, easy to install, available in rolls.

Designed not only for internal but also external corners (90 and 105 degrees). An angle of 90 degrees is fixed so that one strip is on the outside as an edging, and 105 degrees – with shelves up. Length of one strip of material 2.6 – 3.0 meters.

The dimensions of the raw material for finishing plastic windows can be 10×10 mm or 15×15 mm. For corner surfaces, in order to strengthen them, material with a size of 20×20 mm to 50×50 mm is used. Before purchasing, you can see a photo with samples of plastic corners.

How to Cut Corner Tiles – Quick Tips

How to properly cut a corner on a ceiling plinth

Ceiling plinth, also known as fillet, frieze or baguette, is a finishing material that is used at the final stage of the renovation of the premises. At the same time, it not only masks possible irregularities of the upper edge of the wallpaper or peeling of plaster near the ceiling, but also acts as a decorative element, giving completeness and uniqueness to the space..

Ceiling plinth with internal and external corners

Many people install the ceiling frieze in their apartment on their own, without involving masters. This job is not that difficult if you know how to choose the tools and cut the corner correctly on the skirting board. The main thing when working with a ceiling molding:

- take into account the peculiarity of the material from which the fillet is made;

- have the right tools and use them correctly;

- know the intricacies of step-by-step work.

h2 1,0,0,0,0.-

Fillet cutting for inner corner

Internal corners are always present in rooms – so you will definitely have to deal with them when installing skirting boards on the ceiling. In this case, when cutting a baguette, we follow the algorithm:

- we measure the required length of the workpiece by attaching it to the ceiling at the place of future installation;

- we place the bar in the miter box along the near wall so that its location coincides with how it will be mounted on the ceiling;

- holding the plinth, we put the cutting tool in the groove with an inclination of 45 ° and cut the workpiece without unnecessary pressure;

- we do the same actions in a mirror image for the second, adjacent bar. For the convenience of cutting, you can turn the miter box with the bar installed in it to the desired hand.

Knowing how to correctly cut out the inner corner on the ceiling plinth with a miter box, you can easily arrange more complex ones – outer corners.

Position of the left bar for the inner corner with the direction of pressure when cutting Right bar position for the inner corner with rotation for easy cutting Cutting the left inner bar Cutting the right inner bar h3 2,0,0,0,0.-

Trim skirting in miter box

The miter box is one of the most important tools when processing a baguette, allowing you to make cuts on the skirting board with the desired slope for an even joint. Consider the features of working with fillets using this device.

To correctly and evenly cut the ceiling plinth using a miter box in the corners, you must follow certain rules.

- Cutting workpieces with a miter box is only suitable for 90 ° right angles.

- When cutting a baguette intended for the ceiling, it is applied and sawn on the inner side of the miter box closest to you.

- The workpiece is installed in such a position as it will be mounted later on the ceiling.

- Cutting is carried out on the front side of the baguette.

- The side that is subsequently glued to the ceiling must press firmly against the bottom of the tray when cutting.

- It is recommended to use a specific cutting tool for each type of material: a hacksaw or knives are good for cutting soft materials such as foam, a saw is preferable for wood.

Ceiling corners can be internal and external, or external, therefore there are differences in the preparation of the baguette, which consist in the methods of joining the planks and the different inclination of the cuts. To make it easier to work with the miter box, it is useful to make visual prompts on it in the form of small stickers with inscriptions, as shown below.

Miter box with tips for easier work Angle types

The main attention should be paid to the accuracy of cutting workpieces at the desired angle. It is recommended to start working from the inner corner and then work to the outer corner. Otherwise, it is possible that the length of the baguette will not be enough. Schematically, the cutting steps look like the figures below..

Scheme for trimming adjacent skirting boards for inner corners Scheme for trimming adjacent skirting boards for outer corners h3 1,0,0,0,0.-

Materials for ceiling plinths

Ceiling moldings can be of different widths, have a convex pattern on the front side and special recesses for engineering systems on the back side. Fillets are made in a specialized production from polystyrene, its varieties – expanded polystyrene, polyurethane and wood.

Polyfoam is the most affordable finishing material. Its positive qualities: light weight, ease of cutting and processing, the possibility of finishing by painting in any color. Negative point – granularity and low strength – even a slight mechanical damage can violate the integrity of the foam surface.

Varieties of foam plinth Foam plinth on the ceiling

Expanded polystyrene is a more durable type of foam. It is also light in weight and in processing, but it has a higher density and a smooth surface, is more resistant to mechanical damage, and lends itself well to staining. These two materials, due to their low weight, have little stress on the load-bearing walls..

Ceiling plinth made of expanded polystyrene Baguette painted to match the wall

Wood is the hardest and most impact-resistant of all fillet materials. Products made from it retain their appearance longer and are able to withstand significant mechanical stress. In the style of some interiors, it is wooden friezes that are most applicable. Wood ennobles the room and fills it with warmth. However, it has a higher price than previous materials.

Different types of baguettes made of wood Wooden fillet in the interior

Products made of polystyrene, as well as expanded polystyrene, have an advantage over wood. The softness of the material makes it possible to press the baguette as tightly as possible against the wall, ceiling and each other – therefore, there are no gaps. It is possible to achieve excellent joining of the plinth on not perfectly flat walls if you use a not wide foam or expanded polystyrene fillet.

Skirting tools

When installing friezes, you need to prepare the necessary tools to perfectly cut the skirting board and fit the ceiling frieze to the corners of the room. To trim the baguette, a miter box and cutting tools are used: knives (carpentry and ordinary), hacksaws, saws. When handling each of them, it is necessary to take into account the features of the device and the subtleties of application..

The miter box is a device that guides the cutting tool blade with the required inclination. It is specially designed for cutting materials that are then mounted at a specific angle. Structurally, it can be conventional and tilt-rotary, or precision. They are visually different, but the principle of operation is the same..

Different types of miter boxes Plastic miter boxes with clamps

An ordinary miter box is a U-shaped tray made most often of plastic. It also comes in metal or wood. There are slots in its walls for guiding the cutting tool at a given angle to the base. This variety has a template type and cannot be adjusted: the material is cut at standard angles (normal or negative), which are structurally embedded in the grooves. When choosing a miter box, you need to look so that it should be wider than the workpiece for cutting. To fix the material in the device, a clamp or special pins can be used – if the structure has perforations for their installation. Usually, the workpieces in it are simply held by the free hand..

Plain plastic miter box Plain wooden miter box

Swivel, or precision miter box – by adjusting to any angle of inclination, it allows you to cut at an angle and get a simultaneous cut in two planes at once. It is a professional tool that is rarely used under normal conditions..

Swivel miter box with hacksaw Precision (swivel) miter box

Saw – Recommended mainly for hard wood skirting boards. Using the saw on soft materials such as styrofoam and polystyrene is not always a good idea. The cut from the saw turns out to be rough and requires additional grinding with sandpaper or a file.

A hacksaw is a widely used cutting tool for cutting a baguette. It is necessary to carefully approach its choice: the canvas must correspond to the size of the slots in the miter box – be of sufficient thickness and width. When working with a hacksaw, it is necessary to observe the inclination of the tool so as not to damage the miter box and observe the correct direction. At the same time, the cut of the part often turns out to be not very smooth and sometimes requires alignment and grinding..

Construction knife – makes it easy to cut soft foam fillet. It is not difficult for them to work, and the cut turns out to be even and smooth. Instead of a construction knife, it is permissible to use an ordinary knife – the main thing is that it is of sufficient sharpness and length.

Cutting tool h2 3.0.0.0.0.-

Fillet cutting for outer corner

Outside corners in a room are not so common, but they require particularly careful cutting of fillets and precise joining of their sides. Unlike the internal ones, small gaps in the external ones are more noticeable and difficult to hide. You also need to take into account some peculiarities when working with external corners. It’s easy to do, following certain rules:

- parts of the frieze should protrude slightly from the edge of the wall, forming a small margin;

- we measure the bar by attaching it to the ceiling as it will be glued in the future;

- we place the frieze in the miter box, pressing it against the wall closest to you;

- we insert a hacksaw or other suitable cutting tool into a groove with an angle of 45 °, and cut off the workpiece without unnecessary pressure;

The location of the left outer strap in the miter box

- we put the adjacent bar to the nearest wall of the miter box and, holding it, insert a hacksaw or other tool into the groove at an angle of 45 °. For the convenience of work, we unfold the miter box with the workpiece “under the arm”;

- we act in the same way as in the previous case – carefully and evenly cut the fillet.

Position of the right outer plank in the miter box with rotation for easy cutting Cutting the left outer plank Cutting the right outer plank

It remains to join the cut baguette strips and check the cutting accuracy. Taking the cut pieces of the baguette in pairs, we join them, forming an inner or outer corner. If the cutting of the planks was carried out accurately and accurately, then the edges of the adjacent planks will ideally coincide with each other..

Fitting the skirting board for the inner corner Fitting the skirting board for the outer corner

In the presence of small irregularities and roughness, it is allowed to work on them with a sharp knife, clean them with a file or emery paper fixed on a bar.

Precise baguette fit

The layout shows how a properly cut and mounted fillet will look in finished form on the inner and outer corners..

Inner skirting board on the layout Outer skirting board on the layout

Following all the rules and principles of working with special tools when preparing fillets, you can easily independently install any ceiling skirting boards.

How to cut tiles with a tile cutter. Step by step and with photos.

How to cut tiles with a mechanical tile cutter. has already been briefly described and shown on this site.

At first glance, there is nothing complicated about this. But in any business, there are details. The hell is known to be in the details.

Cutting in a straight line is not particularly difficult. Having to cut the tiles with the letter “G” is somewhat confusing.

So usually you have to cut tiles on slopes and near various hatches, doors.

Step-by-step cutting of a piece of tile.

Previously, using a square and a marker, it is necessary to mark 3 corner points of the cut piece. Sometimes a short wedge and a pencil are enough for marking. (VIDEO AT THE END OF THE ARTICLE).

Run the cutting wheel of the tile cutter along two lines, according to the markings.

Cut the short line of the cut with the angle grinder. The cut-off wheel must be designed for cutting ceramic tiles (this is always indicated on the disc packaging). The cut-off wheel, when cutting, should not be located along the mowing line indicated by the tile cutter, but along the edge, on the side of the cut (unnecessary) piece.

All these difficulties are needed so that the cutting wheel does not leave chips on the enamel..

If the tile is “very budget-friendly”, as in the picture, the enamel will bounce off even when cutting with a new wheel and an expensive tile cutter.

Part of the cut made by an “angle grinder”

After a short cut of the angle grinder has been made, the tile must be installed with the long side on the tile cutter, exactly along the line previously drawn with the wheel, and broken off with the handle-lever of the tile cutter.

Lever (with cut-off roller) for breaking tiles, it must be installed at the beginning or at the end of the tile, stepping back from the edge of the tile 2-3 cm.

setting the lever of the tile cutter when pressing on the cutting line

In this way, tiles up to 12-15mm thick can be cut. But not every tile cutter.

Cheap tile cutters, with two pipe guides, bend and cannot break, often, ordinary porcelain stoneware. The tool shown in the photo can cut tiles up to 18mm. Only in this case, it is necessary to make cuts on both sides of the tile..

After a piece of tile is broken off, it is necessary to refine the corner with a cutting wheel.

The whole process is completed by sanding the cut edges with a float with emery paper. This operation is especially important when the cut part of the tile is not covered with anything..

processing of the cut end of the tile

When it is not possible to install a tile cutter on a table or workbench, then they work directly on the floor. With a significant amount of undercutting, the knees begin to hurt. This can be avoided by placing a 5 cm sheet of styrofoam next to the tool. This will not only create comfort for the knees, but also help to trim large tiles..

“LITTLE TIPS” when cutting tiles with a tile cutter

A short video on how to mark and cut a tile with the letter “G”

Questions from letters and consultations on Skype:

How to cut corrugated tiles?

An electric tile cutter is most suitable for trimming corrugated tiles. This is the case when it is superior to mechanical (my opinion).

With a slight tuberosity of the tile, the last version of the tool is also quite suitable..

But the more relief the tile has, the more difficult it is to break with the lever along the mowing line of the roller cut. Therefore, the cutting wheel should draw as much line as possible for all irregularities. Then there is a chance that the tile will break along the cut line..

And the smaller the cut piece, the less chance for a successful cut. The video below shows that half of the tile always breaks successfully..

Polyurethane

Polyurethane foam (in common parlance – just polyurethane) is a very good material for ceiling plinths. Due to their good flexibility, they adhere exactly to the base (the junction of the wall and ceiling), even if the walls and ceiling are uneven due to construction errors. In addition, polyurethane is easy to clean and therefore can serve for a long time. Low load resistance is not a problem here: there are almost no loads on the ceiling plinth. We also have a separate article, where the question of how to make a plasterboard ceiling and suspended plasterboard ceilings is discussed in more detail..

Cut the polyurethane plinth with a miter box as follows:

- Measure the wall and ceiling in the junction area.

- Choose a suitable template on the cutting table.

DIY installation

Once the corner is properly cut, it must be attached to the wall. This can be done in the following ways:

-

Thin carnations. This method is suitable for wooden skirting boards attached to wooden walls. You can’t drive a nail into a concrete or brick partition.

Using a miter box at home

The easiest way to adjust the strips of the skirting board is to cut it with a miter box. This device is a U-shaped structure (something like a box without one of the walls). In the sidewalls of the miter box, cuts are made in advance, which are later used as a template for cutting both the plinth and other materials.

Cutting the plinth at an angle using a miter box, see this video.

The miter box has the following advantages:

- It allows you to accurately cut the edges of the skirting board according to the finished template..

- It is easy to do it yourself using four planks, a square and a saw. At the same time, you can cut through the template grooves for every taste, depending on the required type of work..

- It makes it easy to form both inner and outer corners..

The only drawback of this method concerns only those cases when the miter box is made by hand: it is necessary to be extremely careful, in advance to outline the mowing line for template slots using a protractor, without deviating by a degree.

Cutting a corner on a ceiling plinth using a miter box has its own characteristics. You may also be interested in reading an article on the topic, plastering walls with your own hands, types of plaster.

Wood

Wooden skirting boards are not common and are expensive, so you need to be extremely responsible in their processing. Cutting technology looks like this:

- The cut end is fixed in the miter box.

- The cut is made. This can be done with an ordinary wood hacksaw, but it is better to use a special saw or metal saw to avoid cutting too wide..

Asterisk IMPORTANT: when adjusting, you need to be extremely careful; it is better to close the uneven cut with a decorative overlay or wood filler than to chise out too large an array of wood.

A plinth made of plastic (polyvinyl chloride, PVC) is now widespread. It’s convenient because:

- Easy to cut with any tool.

- Flexible, can be used even in uneven corners.

- Usually it has internal cavities, which means it can be used as a cable channel for laying electrical wiring or fiber-optic lines for the Internet.

PVC skirting boards are cut in the same way as polyurethane. However, one must take into account: the best tool, a hacksaw for metal with fine teeth, is suitable only for thick skirting boards, in thin ones it can pull out pieces. Therefore, the best option for thin products is a stationery or construction cutter or a sharpened knife. To use it, you need a certain skill, so it is better to practice in advance on scraps or sheets of thin plastic.

External

For the outer corner – the plinth is applied to the right side of the miter box (or to the one closest to you, if the template is placed across the desktop), aligned along the plane and the wall, and then cut off or sawed off using the template.

Interior

For the internal – the same, but in the opposite order: the attachment occurs on the left or far side of the miter box.

Both trimmed skirting boards are applied in place without gluing. If there are gaps, the fragments are fitted to each other with a knife. Small defects can later be covered with putty. It will also be useful to read the article on how to make do-it-yourself wall putty.

Hand Right IMPORTANT: Even when using a template, trimming corners requires some skill. Therefore, for the finisher doing this for the first time, it is recommended to first practice on the unnecessary remnants of the baseboard, cutting them off, and trying to dock without gaps.

How to cut tiles that are in corners or difficult to cut

Styrofoam

Polyfoam is also often found as an element of the decoration of rooms. Its characteristic feature is increased fragility, therefore, it must be adjusted in place very accurately, the foam does not tolerate any deformations.

You need to cut it with a miter box as follows:

- Plinth plates are stacked in the miter box.

- An incision is made. Unlike polyurethane, foam is a soft material, and you can even cut it with a knife or, better, with a stationery or construction cutter. Here it is better to use a small, but even piece of wood, a metal plate or a ruler. As a last resort, you can make pencil marks corresponding to the slots of the miter box, connect them with a ruler – and lead the slot.

Asterisk IMPORTANT: Styrofoam is a brittle material, so the cutting tool should be sharpened as best as possible.