Stencil cutting

The method is recommended for cutting products intended for installation in non-standard-shaped rooms with angles that differ from the standard 90-degree mark. Stencils for the desired angle can be made from paper or thin cardboard. First, strips are cut from the rough material, which have exactly the same width as the skirting board. Then they are applied to the corner and fixed, after which they are cut to the shape of the corner. Then, according to the stencils received, the plinth itself is cut at the desired angle.

Stencil cutting of plastic skirting boards

How to cut a plastic skirting board

If the angle in the room where it is planned to finish the joints of the walls and the floor with a plinth is 90 degrees, which happens extremely rarely, then the cuts of the plinths should have an angle of 45 degrees each. Such a cut is the easiest to make, especially with the use of a miter box. It is enough to insert the plinth into the miter box, then select a groove at 45 degrees and make a cut.

However, such angles of 90 degrees in rooms are extremely rare, usually they differ by several values in one direction or another. And in some rooms, the corners may even be larger. Then the cutting is done differently: a marking is drawn on the floor with a pencil, where the border of the location of the plinth is drawn on one and the other side of the corner. You will get a small diamond. The diagonal of this rhombus will be the very cutting line of the product. Next, a plinth is applied to the markings, on which the markings are made in accordance with the diagonal of the rhombus. If you draw a straight line from this mark to the corner of the plinth, then you get the very necessary cutting line.

Cutting the corner to the plinth

The outer corners of the skirting boards are formed a little differently, or rather, in a room with ideal geometry, you can also cut products at an angle of 45 degrees (but in a different direction) and, after joining, close the edges with a plug. Non-standard corners are cut like this: one of the skirting boards is applied to one of the walls, its borders are marked with a pencil. The same procedure is carried out with the other product. Again, a rhombus flaunts on the floor, the diagonal of which will become a guideline for cutting products.

Decoration of the outer corner of the plastic skirting board

How to properly trim the corners of the skirting board

Since it is hard plastic skirting boards that are increasingly used during repairs, it is in them that the speech will go. Their installation is inevitably associated with the need to cut and form beautiful joints in the corners. This is how the skirting board will be joined, in general, the quality of all work and the appearance of the room where the repair is being made will depend.

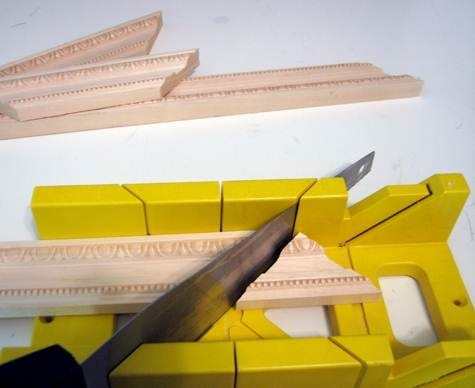

Cutting the skirting board with a miter box

For the correct trimming of the plinth, a special device was invented, which was called a miter box. It is a small block with a notch for the skirting board and with gaps located at different angles. For cutting tools.

With the help of a miter box, you can get neat and even cuts. The plinth is fixed inside the product, then the angle and direction of cut required in a particular case are selected.

We make a miter box with our own hands

When working with a miter box, it is important to make sure that the edges of the skirting board protrude a short distance beyond the edges of the selected slots. If the trimming tool is wider than the skirting board itself, it is recommended to securely fix the product inside with a miter box before trimming. Otherwise, the plinth can move inside, the cut angle will constantly change, because of which it (cut) will turn out to be incorrect and incorrect.

Making cuts for joining skirting boards using a miter box

Cutting with a rotary miter

The main types of floor skirting boards

Wooden plinth. It’s a classic. It is a natural product, as it is made from solid wood. This type is characterized by high strength and durability. Skirting boards, installed back in the times of the USSR, still serve faithfully in some apartments and houses. Now they are made mainly of pine wood, but there are also products from walnut, oak, ash and other species. However, this increases the cost of products. Such skirting boards are not affordable for everyone.

Wooden floor plinth

Because of this, veneered skirting boards appeared on the market. Their are much lower. However, outwardly, they practically DO NOT differ from products made of expensive wood. The fact is that their upper part, which plays a decorative role, is just made of a thin layer of expensive wood. Without certain knowledge and experience, it is almost impossible to distinguish veneered skirting from ordinary wood.

It is convenient to cut wooden skirting boards with a hacksaw for metal

The most popular now is the plastic skirting board, that is, made of PVC. It has partially displaced conventional wood products from the market, as it has a number of advantages:

- It looks nice and neat. Able to imitate natural wood products;

- Easy to install, flexible and very easy to cut;

- Can serve as a cable channel for laying wires;

- NOT afraid of exposure to water, and also does not rot, mold does not start on it;

- Inexpensive compared to wood or veneer.

Plastic skirting board is made of polyvinyl chloride, which is passed through special forms under high pressure. After the mass has solidified, a neat plastic product is obtained.

Plastic skirting board

Plastic skirting boards are of several types. For example, used for carpet (have a special shape in the shape of the letter G, fix the material) or for linoleum. There are also universal products that can be installed on any kind of flooring. They can be classified and depending on the hardness.

Table. Types of plastic skirting boards depending on hardness.

Flexible plastic skirting boards

Using a ruler and pencil without a miter box

If you have a miter box at hand, and you don’t want to make stencils, then you can try to apply the required markings on the plinth with a pencil. In the case of the formation of an inner corner, the width of the product is measured with a ruler, then the obtained value is deposited on the end of the plinth, but its angle is drawn to this marked point with a pencil, along which the cut will be made. The second plinth, which will form a corner together with the first, is simply cut off according to the first attached to it.

Floor plinth in non-standard corners

How to cut the skirting board in the inner corners: action plan step by step

Begin installing the skirting boards in one of the corners. If this is your first experience, choose the part of the room in which there will be something. Not always, it’s over, the first pancake is lumpy, but it’s still better to insure yourself. To make the corner of the plinth neatly, I work without haste. One sawed off, checked, adjusted. Let’s move on to the next one. It is better to fix it after two adjacent corners are assembled. But it’s not worth it to postpone the assembly too much.

Trimming skirting boards in corners requires some skill. But by making several joints yourself, you can beautifully design complex corners.

How to use a miter box to cut skirting boards? Placing the device in front of you, preferably on a table, but also on the floor. Whichever side it is returned it does not matter, it is SYMMETRICAL. A bar is inserted into the profile, turn it so that it will stand in the walls. When washed down the floor plinth in the miter box, wall the wall farther from you also appears. Once again: it firmly presses the skirting board against the back wall in the position in which it will be installed. Insert a hacksaw into the desired slots. You can start getting dusty.

Miter box for skirting boards

Carpentry miter box. This is a device for cutting at a certain angle. It is used with a hacksaw. In principle, you can make a miter box yourself by collecting a guide from the boards and making cuts in the walls. There are various models on sale ranging from 15 to several hundred dollars. They differ in capabilities, materials, although they are all called miter box. Professional models are made on the basis of a good hacksaw, have a scale that allows you to set the dust as needed. With such a tool, it is not a problem to set any desired cutting angle in order to properly cut the skirting board for perfect joining.

Professional carpentry miter box. Wide range tool

The simplest miter box is a plastic U-shaped profile, in the walls of which they are formed by slots. These slots are used as a hacksaw guide. They DO NOT allow the web to deflect. In any case, there are two cuts. Straight and 45 degrees. Some may have a couple more options.

How did you wash down the plinth at 45 degrees? One of the methods. Use a miter box

Sometimes a hacksaw is included, sometimes not. Usually what’s included, not too good. You can use any hacksaw, picking up the blade for the material you plan to cut. It is important that the canvas moves freely into the slot.

Making an external joint

In apartments or houses, there are not only internal corners, but also external ones. In this case, the nearest inner corner is first trimmed and modified. When ready, you can make an outside corner to the baseboard. We put the bar in the corner, as it should be. In the place of the outer corner with a pencil, we make a mark exactly at the place of rotation.

How to make the outer corner of the skirting board

Then we transfer the bar to the miter box, choose the appropriate position. In order not to be mistaken, all the time imagine how the plinth stands against the walls and what you should get.

We cut the second segment at 45 degrees so that it joins the finished one. To do this, change the position of the saw to the opposite and start the plinth on the other side.

Types of corners in rooms

When installing the skirting boards, you need to somehow arrange the corners. By their appearance, the corners are external (which protrude forward) and internal (for example, corners in a room). In rooms with normal geometry, the corners are straight, i.e. 90. When joining two pieces of plinth strip in the corner, they are cut so that each has an angle of 45.

To arrange the outer and inner corner, the skirting board must be cut

But how to make an angle on the plinth so that it is exactly forty-five degrees? For this, a special carpentry tool is used. Miter box.

How and what to cut a plastic skirting board

All of the above applies to MDF skirting boards and wood. Cutting them with an ordinary hacksaw is not a problem. It is advisable to take a blade for metal, since it has a smaller tooth and a saw cut is smoother, you will have to work less with sandpaper. This is not the case with plastic. When trying to cut a piece, some thin-walled skirting boards crumble and break.

Cutting plastic is NOT very convenient because of the thin walls

To cut normal quality plastic skirting boards you can use:

- Hacksaw for metal.

- Angle grinder (angle grinder) with diamond disc.

- A revolving miter saw. Before cutting, overclocking the disc and only then start cutting.

- Jigsaw and fine tooth pollen. Here you have to try. Pick up speed and pollen.

- Sharp knife.

- Scissors for metal. In any case, it is not difficult to make straight cuts with them.

Only personal experience will help you decide how it is more convenient for you to cut a plastic floor plinth. If you have a miter saw, try using it. It is not a problem to try an angle grinder with a diamond disc a couple of times. If all this doesn’t work well, try a hacksaw, jigsaw, or knife. There are, of course, special scissors for plastic, but they are too expensive to buy for a single use.

Accessories for the design of corners and joints of PVC skirting boards

In plastic skirting boards you can arrange corners and joints using special fittings. There are external and internal corners, plugs and connectors. In principle, they allow you to assemble the desired configuration. Each manufacturer makes its own fittings. For your own profile, colors. But the principle of their use is the same.

How to arrange the corners of a plastic skirting board

First rule. All cuts are made straight. Strictly perpendicular. The marks in the corners are set at a distance of 1-1.5 mm from the corner. The fact is that the rigidity hardware has its own jumpers. For them, it is necessary to retreat a couple of millimeters, but no more. Otherwise, a gap will appear or plinths will pop out of THESE corners.

This is the result of the assembly

I must say that not everyone likes the look of plastic corners. You can make a corner on a PVC skirting board in the same way as described for wood or MDF. The only difficulty is that you have to be careful with plastic. It breaks down from excessive effort. There is one trick. Before cutting the plastic skirting board, add a little polyurethane foam on the back side and wait for the polymerization to begin. It will be tougher, easier to cut, less deformation. If the foam subsequently interferes, it is not a problem to remove it, but to cut it is, indeed, easier.

How to make a skirting angle more or less than 90

Not all angles are exactly 90 degrees. If the deviation is small, the gaps can be removed with sandpaper. In the second cases, you will have to mark and cut taking into account the real degree. The main task in this case is to find a point on the floor where two plinths will join.

Let’s start by explaining how to properly slice the outside corner if it’s not 90 degrees. We take the bar, put it to the corner from one side, and press it tightly against the wall. Since she should be standing. Draw a line on the floor with a pencil along the bottom edge of the plinth. We apply the bar to the other side of the corner, do the same. The intersection of two lines will be the point of joining of two skirting boards.

How to join a skirting board if the angle is less than or more than 90 degrees

Now put the plinth strip again, set it how it will be attached. We make two marks: at the top at the turn itself, at the bottom in the place where the lines we have drawn intersect. Now an important task: you need to make a cut along these marks. If you have a miter saw or a miter box with an adjustable saw blade. We expose it and cut it. If not, carefully cut with a hacksaw. In order not to get lost, you can use a pencil to apply the fishing line on which you need to dust. Similarly mark and cut off the second part. Modifying the connection of the skirting boards with sandpaper.

With a custom-sized inner corner, everything is exactly the same. We put a plinth in the corner, draw a straight line on the floor. Do it on the other side. Transfer the intersection point to the planks.

How to cut the corners of a skirting board

The acquired plinth must be cut according to the perimeter of the room. To make this process faster and easier, you can draw a diagram of it on a sheet of paper, marking all the outer and inner corners.

Cutting skirting boards at non-standard angles

Modern design solutions in interior decoration often consist in the use of original forms. In this case, it is quite difficult to carry out the installation of a floor plinth in non-standard corners. After all, they are often both internal and external at the same time. Sometimes the corners are completely rounded. That is why the above docking methods are not suitable.

If you are dealing with a round corner, then you need to cut the skirting board into 4-5 pieces. Using the connection plugs, carefully lay out the entire corner in small pieces. Do not forget to fix them with glue or putty. This will create a neat rounded corner.

If you have an inside-outside corner in the room, then you should take the following steps:

- On one side, we apply a plinth and draw its border on the floor.

Now we apply the other half and make two marks: one. Intersection with drawn border, second. With a wall.

Connect the resulting points and spray.

- We carefully close the ends with plugs.

- If you use wooden skirting boards for finishing non-standard corners, then instead of plugs you will have to use putty. After hardening, the resulting surface must be carefully sanded with sandpaper. And the principle of how to cut corners for a wooden plinth remains the same.

The main types of floor skirting boards

To date, skirting boards from the following materials are used for interior decoration. Wood, plastic, MDF.

Skirting boards made of wood. Traditional type of decoration. In old houses, only such were laid on the floor. Wooden skirting boards have a raised surface on the outside and special grooves for mounting wires and cables inside them. They are fixed with self-tapping screws, less often nails. It is allowed to use a sealant to fix them on the floor. If self-tapping screws are used for fastening, then dowels are pre-installed in the walls.

Among the advantages of wooden skirting boards are durability, environmental friendliness, safety for humans and animals, the possibility of reuse.

However, their use does not always hide the wiring. In addition, after installing a wooden skirting board, it must be additionally putty and varnished, paint, stain. Plus a tree. An expensive material, and therefore products from it will be distinguished by a high cost. And before cutting the skirting boards on the floor, you will need to prepare special equipment.

Plastic skirting boards are simple and convenient products for finishing flooring. In them, everything is most often thought out to the smallest detail: the design of the outer and inner corners, pockets for laying cables and wires, end caps, special fasteners for fixing on the wall and floor.

Plastic skirting boards are characterized by quick installation, a variety of colors, no need for putty and painting after installation, the presence of additional elements for sealing joints. This finish goes well with any flooring material: parquet, carpet, tiles, laminate, linoleum. Whatever coverage you have, you can easily match a plastic skirting board to it.

However, plastic. A fragile material, and with a strong impact, chips and holes may appear on its surface. This would require a complete replacement of the entire whip of the product, as a minimum. Despite this drawback, modern builders prefer plastic skirting boards due to the large number of its advantages.

Skirting boards from MDF. Eco-friendly and attractive products. On their front side, paper impregnated with dyes is glued. over, the process is carried out at high temperature and under pressure. This eliminates peeling of the decorative coating during operation.

A melamine coating is applied on top of the paper. It protects skirting boards from moisture and stubborn dirt. Even if exposed to direct sunlight, the product will NOT lose its appearance for many years. Also, the advantages of MDF skirting boards include quick installation, easy maintenance, cost-effectiveness, a wide palette of shades.

Before joining the floor plinth in the corners, remember that MDF is highly fragile. In the process of mounting and cutting such a product, extreme accuracy is important.

Plastic or MDF, from which skirting boards are made. These are lightweight materials, which have a large number of colors. That is why it is quite easy to choose a product for any interior decoration and design solution. Most often, when choosing a color for skirting boards, they are repelled by the shade of the floor covering.

Skirting board installation tools

The procedure for trimming and joining skirting boards from different materials is not much different. The main difference is that wood, plastic and MDF have different hardness and density, and working with wood, for example, is more difficult. If a sharp knife is also suitable for cutting plastic, then a hacksaw is needed for wood.

To work with wooden, plastic or MDF skirting boards you will need:

- Miter box. Special carpenter’s tray for saws, on the sides of which there are slots at different angles.

Roulette and pencil.

A hacksaw, jigsaw, or joiner’s knife. Any of these tools will work for cutting. But only you can decide how to cut the plastic skirting board for the floor. It depends on which tool is easier for you to work with.

Fine-grained sandpaper.

Sealant or putty.

Fasteners (screws, dowel-nails).

How to join the floor plinth in the corners

Docking the floor plinth in the corners. This is a demanding process, which is important to carry out with high quality, since precisely drawn clear angles are pleasing to the eye and give the floor covering a complete look. To connect the products and get a neat Joint, you need to know the technology for cutting them and the existing methods of fixing. Before cutting the floor plinth, read the instructions and recommendations below.

Cutting the plinth for internal corners

Despite the fact that rooms most often look like a regular rectangle, the corners in them are not equal to 90 degrees. Such an angle. The dream of any builder and repairman. If you are still lucky and have a classically correct angle, then to cut the skirting board, you need to do the following:

We find on the side panel a furrow and a mark of 45 degrees;

Focusing on it, we begin to saw the baseboard with a hacksaw;

If you are unlucky and your angles do not have 90 degrees, then you need to do the following steps:

Attached the plinth to the resulting rhombus, mark its diagonal.

Here is the obtained mark in the corner of the plinth, draw a straight line. This is your cut line. Focusing on it, it is sprayed with a hacksaw.

At the end, it is necessary to insert a plug into the resulting joint to form a neat inner corner of the skirting board for the floor. If this is a tree, then the joint should be treated with putty and prepared for further painting.