How to cut a log on your own along a chainsaw

Boards and timber are one of the main building materials. But not everyone has financial opportunities for buying ready.made boards. In such situations, one of the outputs is to independently harvest wood on a plot taken in forestry.

You can cut the log using sawmills, benzo or electric saws and additional devices. When choosing one of these tools, the volume of upcoming work should be taken into account. The cost of the cheapest stationary sawmill along with all components is 150 thousand. Chainsaws are much cheaper. It is more convenient for electric saws for the following reasons:

- Electricity is not required to bring the tool. this makes it possible to use a chainsaw on the plots.

- Is more powerful compared to a saw with an electric drive.

- It starts smoothly and allows you to conveniently adjust the speed, which reduces the likelihood of a circuit gap.

- The operation of the inertial brake is faster than that of the electric saw.

- A long time without a break. up to one hour.

- Can be used in conditions of high humidity.

Types of working nozzles

When sawing logs of a chainsaw, various nozzles are used.

- Dry.cutting nozzle. Used to saw the logs along, the process takes place in a horizontal position. After work, the master receives the same thickness from the product. Ready.made materials are subjected to the drying process, after which the boards are used in construction. In appearance, the device is a small frame, it is attached to the bus on each side.

- Drum debarker (fascin). With the help of such a nozzle, it is easy to dissolve the log, it works due to the cuneiform transmission. Attached to belts on both sides, for this special pulleys are used. The speed of rotation of the shaft depends on the size of the pulleys, so the operability of the nozzle is easy to change. This technology forces the master to carefully monitor each stage of the process, some experts use an assistant during this cut. But this option requires increased safety measures.

- Slinging a lightweight nozzle. The method is not highly performance, but is used quite often. The element is mounted on one side, but the blanks are a little uneven. Such materials are necessary for the construction of sheds or fences.

Advantages of using this option

First of all, we will figure out what advantages this method of cutting has:

| The ability to work in any conditions | Unlike electrical equipment, which is afraid of high humidity, a chainsaw is able to work in the most unfavorable conditions, and no harm to the design will be caused, because all the nodes in the chainsaw are adapted to the open air and even under the atmospheric precipitation |

| Performance | If you are going to work for a long time, then you will need equipment with a capacity of about 7 horsepower or more, it can withstand significant loads, while the quality of the work will be invariably high |

| Autonomy | Since the device works on gasoline, you are not dependent on electricity and you can build a cutting structure in any convenient place. This is especially convenient when working in places where there are no power lines |

| Convenience | The inertial brake in the chainsaws works faster than in electrical systems, and the smooth start and adjustment of the speed of rotation of the chain provide high quality work, even if you do not have such experience |

Important! In addition to all of the above factors, the low cost of the design should not be forgotten, the acquisition of a stationary sawmill will cost several times more expensive.

Another plus can be considered the mobility of the device, you can easily transport it to the right place

Review of some options

We will talk about the two most popular designs that provide the best quality during work, and you yourself will determine which is more convenient and preferable in your case.

Homemade option

First, consider how to make a device for cutting logs of a chainsaw with your own hands.

The work on the work has the following view:

SpongeBob Loses Gary IRL �� “Gary Come Home” Music Video | SpongeBob IRL

- It is best to use a frame from an old school desk or a square of a square section with a side of 20×20 or a little more.

- First of all, two clamps are made, these are elements with a length of 50-60 cm, on one end of which the crossbar with two holes for the fitting bolts and a small protrusion in the middle for the clamp clamp clasp is welded, the element of the same configuration is attached from above, the photos below are shown ready-made elements, As you can see, everything is quite simple, and having a welding machine at hand, you can make them very quickly.

The clamps should be of such a size that the width of the location of the bolts is slightly larger than the tire height

- To produce longitudinal sawing of a chainsaw log, a support frame is needed, the width of which should be 7-8 centimeters less than the length, two elements 10 cm long perpendicular to two of the sides, they should be slightly larger so that clips come in, they need Install two fixing bolts, a hole is drilled for this and nuts are welded to tighten the fasteners in them, a handle is welded in the middle for the convenience of moving.

- The system is assembled in the following way: first, the clamps are inserted into the grooves, after which the chainsaw tire is inserted and carefully fixed. The distance is selected depending on the thickness of the sawing. To understand how this is done, look at the photo where the design is shown, the price of the issue is several metal elements and renting welding for an hour.

Now let’s tell you how to cut a log onto the boards of a chainsaw using this design:

- You will need two goats that will serve as supports, they should be so height to ensure the convenience of work.

- As a guide, a reliable metal rail or durable board is best suited. You can make this element from the corner or other metal products.

- A log is placed from below, which must be put to the desired height, after which you can start work. After the first passage, the log is raised to the desired height, and the process is repeated.

The work is carried out quite simply, the main thing is to put everything accurately and fix it reliably

Important! Do not forget that a chain for the longitudinal cutting of wooden products should be installed to work on the chainsaw, this will provide high speed and high.quality sawing.

Ready decision

The option Big Mill Timbergzhig is very popular, this is a special kit for mining mines. Slinging logs on a chainsaw boards using this device is simple and effective.

By purchasing this option, you get everything you need, we will talk about how to organize the cutting of logs:

The design is very thought out and is simplicity and reliability

- First you need to connect two durable and even boards among themselves. As a result, you should get a T-shaped design. It will be a stubborn ruler.

- Next, make two r-shaped stops. There are corners that are designed specifically for these purposes in the supply set.

- Roll up the log and place it on comfortable and reliable bars. To its ends with self.tapping screws to attach supports, you should not use nails, since it is much more difficult to remove them later.

- Further, the ruler is attached to the installed wooden supports. This is done through clamps that also come in the kit, while remembering that the cutting fishing line for the cutting is not on the edge of the guide, but 10 millimeters higher.

- Before carrying the cut on the boards of a chainsaw, we recommend lifting one side by about 30 degrees. it will be much more convenient to work like that. Fix this position using two supports, if you do not understand something in the description, look at the photo, everything is shown clearly, in addition, instructions are always included with detailed schemes.

How to dissolve a log onto the boards of a chainsaw? This device allows you to do this easily and quickly

Features of sawing logs when using a chainsaw

Creating additional equipment for sawing logs is quite simple:

- To create a support, a frame is used, which can be created from school desk legs. The most suitable pipes with a square section of 20 × 20 mm are.

- When building a frame, it is necessary to create 2 clamps, and on one end, fix the cross. This element should have holes for solid bolts. In the middle, a ledge is created for the tire.

- In order to cut the log along, it is necessary to construct a support frame, the width of which should be no less than a length of 8 cm.

- For ease of work, the handle should be welded on the frame.

- Before carrying out work, it is necessary to carefully check whether the frame is securely fixed on the tire.

Use a homemade tool is quite simple. Before sawing, it is necessary to install 2 goats. they will be used as a log for logs. In addition, a metal rail or a flat board is prepared, which will serve as a guide element.

The technique of sawing along

The most difficult stage of the process is to make the first saw. For this you need:

- install the leading ruler, which consists of two boards that are fastened to each other at an angle of 90 degrees;

- After that, place the sawn log on the supports and fix it;

- Then it is important to check whether the log is located exactly;

- At the next stage, it is necessary to fix the leading line on the supports using self.tapping screws;

- After that, you can start creating the first saw.

Consider the two ways suitable for us: cut the logs along and across

- And the longitudinal method is used to dissolve logs on boards, beams, rails. For this, many devices are used in production. We will consider how you can cut a log at home, yourself.

So, we have already removed the bark from the log, so we proceed to the following steps:

- We fix the log on the guides or bed

- We saw off the hump on one side to get a flat surface

- We turn the log by the flat side to the bed and remove the second horseman

- Next, we dissolve the log onto the boards

How to cut a log on flat boards and bars

It is quite difficult to smoothly cut wood along the logs. After all, along the entire length you need to withstand the same thickness. For this there is a special equipment that is mounted on a log.

Many, for sawing logs at home, make a sawmill with their own hands

How to make a home sawmill with your own hands

Consider the two most used options for the manufacture of sawmills.

Option one

- We weld the frame from the channel and the profile pipe

- We attach a saw with an electric or gasoline drive on a carriage with a vertical feed

- Attach the ruler to the vertical rack so that the dissolution on the boards is more accurate as much as possible

- Use the polished pipe or rod as a guide carriage, they are needed to make the carriage vertically.

- We install the screw in the bearing in order to move the carriage when moving

At the same time, the saw is given in the movement on a specially attached frame, and the log remains in place. The chain saw in this case will quickly cope with the task. If you plan to use a saber’s saw, then the process will delay, since it works in one direction.

How To Use A Chainsaw to Clear Fallen Trees | Severe Weather Guide

Circular to help you!

One of the most used tools that use to solve this problem is the circular! Just need to know a few fundamental rules. Firstly, it is necessary to ensure the longitudinal movement of the tree.

It is clear that this is almost impossible to do on an ordinary horizontal table, because it will also roll from place to place during the cut, which is very inconvenient and can threaten the injury! What we would not like perfectly.

But what to do you ask? There is one cunning that is known to all professionals under the code name “fin”.

The fin is such a device, the thickness of which corresponds to the width of the cut. But you need to install this thing in such a way that it is possible to correct, adjust its position. It is very important!

The log is dissolved on the boards together, this happens according to the following technology: first they saw it along, that is, the work is carried out according to the usual methodology. Then, when the fin is completely entered, the spacer is inserted, which should slightly exceed the width of the cut. Install a string-handle, which will perform two functions at once, one of which is holding, and the other will be needed in order to conveniently pull it.

File-the spacer at this moment will not allow the board to deviate somewhere, which is very convenient! Then you will need to act like this: the first employee will pull the object by the clamp, and the other is pressed to the ruler, which is used in this case in order to determine the width of the board!

Work, thus, in the hands of the masters argues! Things go uphill! And the speed of action surprises them themselves!

Chainsaw. multifunctional tool!

In order to perform this type of work using a chainsaw, a lot of actions do not need to be taken at all! But this is not for beginners. For those who begin to perform this type of work! And you have to do this from almost scratch, it will be best to purchase a machine. About how to make it can be read in my article here.

You will need it in order to fix the logs, you still need a guide for cutting and nozzle frames. all this is used for the same purpose! No, of course, you can try to make all these products yourself, with your own hands, but remember that the equipment will be under heavy loads, so at the most important point with home-made devices, some kind of trouble can happen that can threaten your life and health.

First of all, it will be necessary to make the guides: we fold two neat boards and fasten in the form of a half.tanker. Then, from various pieces, we create stops for a semi.tank guide! It seems so far everything is clear and simple!

We lay the log onto an even platform, which we will prepare in advance, then we roll the object from place to place, it can be done quickly and conveniently with the help of the tank. We fix the frame on the tire with nuts very strongly, so that it does not fly away even in the case of an earthquake. We fasten the supports, they are needed in order to press the ruler to the ends of the logs!

The line itself is needed to see the width of the board employee. We fix all the fasteners with self-tapping screws, so that something does not fly away at you at the most crucial moment! Then the most interesting part of the work begins, because all preparations, for the most part, are already completed.

It remains only to check the fishing line for the trimmer of the cut, it should pass 10 millimeters above the ruler! So, holding your breath, start the saw and make the first cut. Then you have to free the log from all kinds of iron. stops and rearrange the structure to the next cut line, but this must be done as carefully and accurately so that the first cut is perpendicular to the first saw!

Then we turn the log again and fix the boards to the stops that are on the ground! Run the unit and saw saw. sawing, enjoying our work.

Yes, cutting at home is hard work, but you will do everything efficiently and yourself! Just remember, for this case you need more than one device, it is better to make a right angle on the barrel, and then you can harvest boards of any width.

The technological process of cutting logs

There are several ways to work:

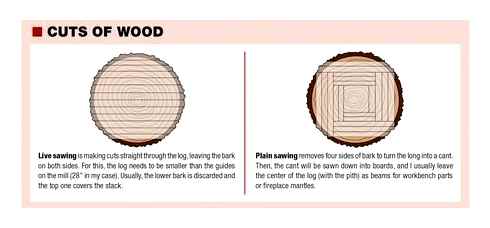

- Collapse. Rectoline cut with a lack of rotation to obtain non.wiped boards. Minus in low quality of raw materials. Subject to additional circumcision;

- Around the circle. The first cut is carried out, then a coup is carried out. About five coups are needed standardly. As a result, the waste is minimal. Lack of low speed;

- Bar. Around the circle. The center is sawn. Using large logs.

Rotation

After reaching the required value, the trunk is turned over.

- Non.sawed raw materials are carried out, it is necessary to calculate for further use.

- Then the log is turned over 90 degrees, repetitions of measurements.

When calculating the calculation, it should be remembered about the passes for the saw.

Sawed

There are several options for initial sawing:

- Bad site. The tilt of the barrel is not recorded. The results are obtaining boards with a small length, but a large number of non.cut raw materials;

- The best area. Logs are installed so that sawing equipment is parallel to the bark.

Turning

The procedure requires a log of logs. It is carried out in accordance with the scheme. Perhaps apply two ways:

Step.by.step instructions for cutting logs

To cut the logs along, you need to take the following steps:

- Make a leading ruler. To do this, you need to fix 2 straight elongated boards at an angle of 90 degrees;

- The log is placed on the supports, fixing in this way its position;

- The nozzle is fixed;

- Due to the screws, supports are attached to log ends on both sides. The horizon is checked using the level;

- The leading ruler is fixed with screws to the supports;

- Another supporting board is translated transversely, it should rest in the soil and raise a log slightly;

- Using a chainsaw with a nozzle for horizontal sawing, the first section of the log is cut off;

- The guide ruler moves, then fastened;

- 2 cuts are carried out orthogonal to the first;

- Further, the leading line can not be used. The guide will serve as a formed board;

- A thickening of the sawing is installed on the frame;

- Further sawing of orthogonal to the second is carried out. As a result, there is a segment of a tree, the bottom of which is covered with a bark;

- 4 cuts are carried out to divide the remaining section of the wood, which is with the bark. A very even, wooden block will come out;

- Next, the bar of the bar is carried out to the earlier;

- It turns on to the back and the saw is carried out to the end.

Когда утолщение досок не играет роли, обрезать края с корой не нужно. Here you can use the nozzle and make a cut of boards from the beginning of the procedure.

Slinging logs on the boards of a chainsaw: what will be needed for this

Some people have the opportunity to take a certain area for logging in the forest to dissolve the trunks, but as a chainsaw to dissolve the log onto the boards, if you never had to face it? Those who have been engaged in logging for a long time can do this without any devices. it is enough for them to beat off on the trunk a longitudinal fishing line for a trimmer and with its help cut a beam or board.

But if you have never done this, then you will need certain devices that we will talk about now, and also show the thematic video in this article.

Cut the logs onto the boards of the chainsaw on the forested

We dissolve the barrel on the boards

Note. For cutting the barrel on logs, you may need a sawmill or electric or chainsaw with easel devices.

What will be needed for this

The chainsaw is the most affordable tool, in addition, there are a number of reasons:

- Sawing of trunks can be done directly for logging. This does not require any stationary or autonomous power sources, only one tool;

- Compared to an electric saw, gasoline has a much greater power. What is the key moment in the longitudinal dissolution of logs;

- It has a smooth start and soft speed adjustment. This means that the risk of rupture of the chain during operation comes down almost to zero (it, of course, is possible, but for this you need to try very hard);

- Compared to sawmill, the price of a tool operating on gasoline is several orders of magnitude lower;

- Compared to an electric unit, inertial inhibition is much faster here;

- intensive use time allows the operating instructions to stretch up to 1 hour;

- It is possible to carry out work with high humidity (rain, fog)

As we have already said, experienced sawmen can dissolve a log without any devices, but for beginners you will definitely have to purchase or make a machine for fixing a log, a nozzle frame for a saw and guide for a flat cut.

We should not forget that with this work the tool experiences very large loads. Therefore, if you want to do this professionally, then, of course, you will need the corresponding model, that is, as powerful as possible.

Professionals call the most popular and best options, these are Stihl MS-660 or Stihl MS-880. Such units give out more than 7 horsepower, which ensures uninterrupted operation at large loads.

To adjust the thickness of the sawn board, a special steel frame is put on the tire, which can adjust the distance from itself to the tire.

In order to make such a corner, you can buy a square steel tubular profile of 20 × 20 mm, but you can use itching material. For example, duralumin legs from the old school desk are best suited here as possible.

A thick board was used as a guide

As a guide, to do something like a stationary machine, you will need any hard metal, most likely steel, profile, or a thick flat board under the log, as shown in the upper photo. In fact, it looks the same as in the picture. two goats are installed and they put a guide (board or profile) on them.

But at the same time, it should be borne in mind that such a device can only be used for short logs, since if it is increased (the distance depends on the thickness of the guide), then there will be a deflection, which will lead to a different thickness of the manufactured material.

The thickness of the board or cut will be even if any template is used to maintain a chainsaw-a leading ruler or a guide. It is very convenient to use the Swedish machine Big Mill Timbergit, which you see above-it costs about 9-10 thousand.

Here you already decide whether you need such a device, but having spent once, you will get a compact device, which, together with the saw, can be delivered to the site on a motorcycle.

In order to get to work, you will need a two.stroke saw and a tire with two nuts. With this device, you will get the opportunity to dissolve logs up to 60 cm in diameter. Keep in mind that in this situation you will have to get a chain for the longitudinal cut of the barrel, but if you purchase it for some reason, then rewind the usual chain at an angle of 10⁰.

The Big Mill Timbergit has a variety of details that will help to install and fix the wooden guide. It turns out that when the chainsaws are conducted along this guide, the frame glides, and the tire does not go to the side.

Note. Whatever the wood breed you process, in any case the chain is stupid, and in order for your cutting process to occur without problems, it should be periodically tightened.

Gapling of a chainsaw. process

Now let’s see how to cut a log onto the boards of a chainsaw:

- First, we make the guide. we take two even cut wooden boards and fasten them together in the form of a half.tanker;

- Of the pieces of the same boards, we make stops for a semi.tank guide. the fixtures for fasteners are included;

- Roll up the log using the knife and put it on a pre.prepared convenient basis;

- We fix the frame on the tire with nuts;

- After that we fasten the support. which hold the ruler to the ends of the log, checking its horizontal level;

- We fix all the fasteners with self.tapping screws. since the nails at the end of work will be extremely difficult to pull out;

- We check that the fishing line for the cutting trimmer passes not in the ruler, but 10 mm above;

- run the saw and make the first cut;

- We free the log from stops and rearrange the structure to the next cut line so that it turns out perpendicularly (90⁰) to the finished cut;

- Now we turn the log again and fix it with boards to the stop on the ground. the ruler will not come in handy for you, it will be replaced by a previously made cut.

Cut the logs onto the boards of a chainsaw according to the marks

As shown in the video of the YouTube channel “Capercaillie. The second channel “, before the cut in this way, the log is cleaned of the bark, laid on the gaskets and attached with two screws.

Log mounting on screws

The level is made. Apply two vertical lines on the ends of the logs.

Marking the end of the log

The marking is pulled by the marking or set the marks, and then connect them with a ruler.

Using a marking cord

Marking logs with a ruler

The first drank logs are made by marking.

The first drank logs

The in.depth drank logs

The final drank logs

Before the last passage to the log, a stray is put on for insurance, only after which fasteners are removed.

Removing fasteners

A log sawn into two parts

Estimated exit in varieties

In varieties the situation is quite interesting. It turns out that the percentage of the output of the highest varieties depends on the following factors:

- Circular pilot production coefficient. The grade does not depend directly, but indirectly. The fact is that after some kind of golden mean, the more plank we get from a cubic meter, the higher the amount of low.grade wood with a review;

- The larger the diameter, the higher the probability of getting more high.quality board;

- The presence of wood defects such as curvature, rot, blue and others, the less they are, the higher the percentage of obtaining a high.quality board;

- The shorter the finished products, the higher the percentage of obtaining a high.quality board.

And now let’s estimate in the diameter the percentage of producing first.grade pilot products from the total volume of the resulting board. For this I did everything in the form of a small table.