How to cut a pipe profile at an angle

In the course of installation and plumbing work is often required to cut blanks at a certain angle. Changing the direction of the cut line is necessary for further joining and welding to other pipes of the same configuration, or for the installation of shut-off and control valves.

It is worth bearing in mind that the accuracy of cutting at the right angle is necessary to obtain a high density connection of rolled metal. To do this, you need to have the necessary tools, a quality pipe cutter and possess the appropriate experience in the processing of pipes.

In this article we will consider techniques of cutting pipes at different angles.

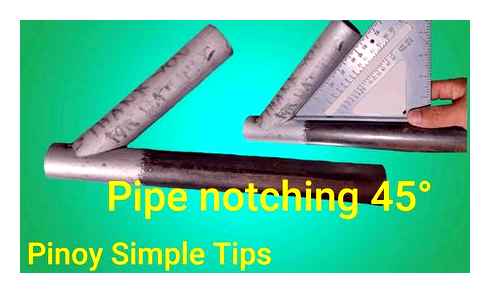

Methods of marking pipes at a 45 degree angle

Cutting pipe blanks at an angle of 45 ° is most in demand at the installation of heating mains, sewerage networks, gas pipelines. For this purpose black and stainless steel pipes with cylindrical cross-section and small and medium diameter are used. 20-500 mm.

One of the main tasks when cutting pipes at an angle of 45 degrees is the accuracy of angle measurement and flatness of the cut pipe, so that when joining the joined elements coincide with the accuracy of a millimeter. This is especially true for thin-walled pipes. with the slightest cutting error, the walls of the connected pipes will not be able to connect in the desired configuration. That is why great attention must be paid to cutting accuracy.

If you do not have a production template, you can use a mold from a square sheet of paper. To perform the marking of the pipe perform the following actions:

- Fold a square plate strictly diagonally, aligning the opposite corners. The length of the pattern diagonal should be equal to the circumference of the workpiece.

- Wrap the folded sheet around the pipe. It is important to ensure that the side of the template closest to the face of the billet is strictly perpendicular to the central axis.

- A dotted line is made at the future cutting point.

- Then the pipe is cut.

Marking square and rectangular pipes

To make a template for marking the profile pipe it is advisable to use a similar billet with a larger cross section. Markings on the workpiece are made once with an engineering ruler or protractor. A profile is inserted into the hollow of the prepared template, and then it is marked and further cut.

Marking pipes at 90 degrees

It is easy enough to execute 90 degree angle marking of the pipe. If necessary, you can use a sheet of paper: the sheet is wrapped around the pipe, fastened, and the marks are made. It is important to ensure that the edges of the sheet coincide around the circumference, then the cut will be even.

How to cut a profile pipe at a 90 degree angle?

For cutting a square or rectangular cross-section pipe, it is preferable to use a triangle. Using this machine, mark each side of the profile in turn with a marker. After marking the cut line the pipe is cut.

Marking pipes at other angles

For cutting the pipe at other angles you will need templates with the corresponding values. The template can be prepared using Excel or other computer programs by entering the pipe diameter, desired angle, etc in the appropriate window.д.

Any pipe diameter and angle can be calculated by means of any calculation program. But more often this method is used to create a template for cutting small and medium diameter pipes. Programmable cutting machines are preferred for cutting large-diameter and high-volume pipes.

How to cut pipe with a “collar cutter?

Often when installing water supply networks, pipe blanks with a triangular cut at the end are required. This pipe configuration is necessary to connect with another pipe of circular cross-section at right angles.

To perform a collar cut proceed as follows:

- Measure the circumference of the pipe.

- Cutting of the pipe at an angle of 90 degrees is performed.

- Mark equidistant points on the end of the pipe which are in relation to each other at angles of 90 and 180 degrees.

- Calculate: the diameter of the pipe divided by three.

- From these two diametrically located points the measurement is detached and marked.

- These points are connected to other points by smooth arcs.

- After cutting, the pipe cutting tool separates the semicircular segments, which are ready for subsequent welding work.

How to order tools for pipe cutting

For consultations on selection of equipment for pipe cutting please contact our managers:

When carrying out work on the installation of gas or water mains, it is often necessary to change the direction of the line, whereby the pipeline is cut and then welded at the desired angle. Most often the direction changes to 90 degrees, and the question arises. how to cut the pipe at 45 degrees to accurately connect the joints when welding.

To cope with the problem at angles of 45 or 90 degrees of the cut edge is possible with the appropriate knowledge and techniques that will help save not only time but also materials when carrying out the work. At other angles of turn to solve the problem with a ruler and a sheet of paper is impossible. you will have to call in computer technology to help.

How to properly cut tubes of different metals at 45 degrees and 90 degrees

How to cut a pipe at a specific angle? It has already been said about the straight cut. Next, let’s look at techniques for separating tubular blanks from different metals using a metal locksmith’s chair. In addition to the ease of cutting, the wire cutter minimizes the amount of sawdust, which is important if you are working at home.

The Locksmithing Jigsaw consists of two assemblies:

- Handheld hacksaw, which has upper tubular guides that keep the tool strictly perpendicular to the cutting direction;

- A channel-like body in which holes. slots on both sides are made in advance to help the worker make precise angular cuts (usually 90 ° and 45 °, but there are some saws with an angle meter, which can perform angular cuts in the range of angles from 100 to 1150).

A distinction is made between cast and pressed jars. The first ones, although cheaper, do not work well under the conditions of periodic bending stresses.

It is important to choose the right design of the hacksaw. Only precision tools with top rails which are additionally secured against bending by spring stops are suitable for making right-angled cuts.

Selection of the size of the locksmith’s jigsaw is made according to the following parameters:

- The width of the jig, which determines the maximum diameter of the workpiece.

- Length of the jigsaw, with the increase of which the accuracy of the cut increases.

- Angle gauge.

- Depth and width of through cuts in the side walls of the channel: the deeper they are, the less sensitive the machine is to changing cutting conditions. the state of lubrication, the increase in temperature of the hacksaw blade and workpiece. On the other hand, when sawing large-diameter pipes, increased kerf width will have a negative impact on accuracy.

- body material: steel (cast or stamped) chisels are clearly preferable to plastic chisels, even though the latter are lighter.

How to cut a pipe at a 45 degree angle? When working with a metal pliers, you first need to file the material, and then, making sure the wall is perpendicular, gradually increase the pressure on the hacksaw blade.

How to cut a profile pipe evenly

Saw a profile pipe can be roughly the same way, but it is easier to use the angle piece. The device is applied in turn to each side, for which cutting element will need to be rotated, and a marking is made. Next, the pipe must be fixed and you can begin the work. Any suitable tool can be used for sawing. But if you have to cut a lot of pipe, it makes sense to make full-fledged templates from offcuts. In this case one has to measure and measure only once.

When you need to cut a large-diameter pipe, you can use a number of special tools and appliances. This may be necessary if, for example, a pipeline needs to be repaired.

- angle grinder. The use of an angle grinder is justified in terms of the availability of tools and comparative cheapness of the work. However, you should not count on high productivity in this case, in addition, carrying out work in this way is associated with considerable risk.

- Roller grinder. Such devices are also often called pipe cutters. In fact, such a device is the same angle grinder, but more adapted for this type of work. The machine includes a special base, where the element to be cut is fixed, and a cage with mounted cutting rollers, which do the actual work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. The cut is made with a high intensity flame, and the waste produced is blown out with a gas pressure. The method can be considered the most practical and effective.

Gas cutting in this case is the fastest option

SEE the gas cutter on AliExpress →

There are other options for carrying out the task, such as the use of plasma, hydro-abrasive or laser cutting, but in private use, they are practically not used.

How to cut a profile pipe evenly

Saw a profile tube can be approximately the same way, but here it will be easier to use an angle piece. The device is applied in turn to each side, for which the element to be cut will need to be rotated, and a mark is applied. Then the pipe must be fixed and the work can begin. Any suitable tool can be used for sawing. If you have to cut a lot of pipe, it is advisable to make full templates from scraps. In this case it only needs to be done once.

When large diameter pipe must be cut, a variety of special tools and appliances can be used. This may be necessary if, for example, a pipeline needs to be repaired.

- angle grinder. The use of an angle grinder is justified in terms of tool availability and comparative cheapness of the work. However, in this case you should not count on high productivity, in addition, to carry out the work in this way involves considerable risk.

- Rolling machine. Such devices are also often called pipe cutters. In essence, such a device is the same as an angle grinder, but more adapted for this type of work. The machine includes a special base, where the element to be cut off is fixed, and a cage with installed cutting rollers, which perform the actual work. It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

- Gas cutting. This option is most often used when working with large diameters. The cut is made with a high intensity flame and the waste products are blown out by the gas pressure. The method can be considered the most practical and efficient.

Gas cutting is the fastest method here

SEE the gas cutter on AliExpress →

There are other options for carrying out the task, such as the use of plasma, waterjet or laser cutting, but in private use, they are practically not used.

How to cut a cast iron pipe

If the pipe is made of cast iron, then in order to cut it accurately it is necessary to apply a certain knowledge. The fact is that this material is characterized by high fragility, which means that before you cut such a pipe, you need to determine the algorithm of actions.

- We mark it the same way as with steel pipes.

- At the place where the sawing is carried out, you need to put a wooden bar as a support.

- Next, it is necessary to make a cut of a few millimeters around the circumference.

- After that, a chisel is inserted into the groove and a sharp and strong blow with a hammer must be made.

As a result, it will split along the line, forming a fairly even cut, which, if necessary, can be further processed.

View the steel pipe cutter on AliExpress →

Other tools for cutting plastic pipes

They are rarely used when there is no pipe cutter at hand:

- Angle grinder. for cutting pipes you will need a cutting disc for metal. The main point when working with an angle grinder is the precise regulation of the force, too much pressure on the tool is impossible.

- Electric jigsaw. this is the most convenient way in the absence of special scissors. There is a high probability of getting an oblique cut here, so for greater accuracy the pipe must be turned several times during the work.

What categorically not recommended to cut pipes:

- Band saw. its blade moves too slowly and if it is not de-toothed enough there is a high probability of damaging the inside diameter of the pipe that leads to chips and cracks.

- Circular machine. Because plastic pipes are flexible, pushing them into the machine often causes the pipe to shift and bump, which is dangerous for the person making the cut.

Cutting a pipe at a 45 degree angle

This is most often done when installing plumbing and heating and assembling frame structures. Cut the pipe under 45 degrees angular grinder can be on the markings, which make or sheet of paper of the same format A4, or use the usual school (drawing) isosceles angle.

Use a sheet of paper or cardboard

You will have to do several operations with the sheet to get the right angle. If you do not want to get tangled in the folds, just make it square and fold it diagonally. you get the right angle. You can do the same with any sheet, as long as its sides are equal to each other. The method is convenient because it can be applied to a large-diameter pipe as well as to [square and rectangular profile pipes].

IMPORTANT: Gas and water pipes

Marking with a square

If you have a square at hand, you must first determine the exact line to trim the end of the pipe, including the profile. Applying the tool and moving it smoothly over the surface, we get a 45-degree cut trimmer line. The same technique is used with a 30-degree angle.

Helpful computer program

Computer program

I would also like to consider the method of marking with a computer program. This is quite a complicated method for those who are not used to working with a computer. It requires knowledge of PC, availability of programs for reaming and drawings. Begin the work by making a drawing with the size of the circumference and the slope. We make a so-called virtual template.

Virtual cut

Then use a printer to print the image on a sheet of paper. The larger the diameter of the pipe, the more sheets with markings will be. Cut out all the parts of the drawing with scissors, and glue them together with masking tape. The ready template is attached to the pipe and we make a marking on the edge of the paper. This is considered one of the most accurate methods of marking. If your computer does not have such programs, you can use the Internet. The template for the marking can be downloaded from the Internet. It also must be printed on the printer and cut out. Wrap the ready template around the pipe and mark it.

If the pipe is profiled

We cut at an angle profile tube according to the marking

And here, for example, we have a profile pipe, not a round one. Manual marking of a profile pipe can lead to a large error. The best way out of this situation, would be to make a template of the same profile of a larger diameter. Let’s take a small piece of profile pipe and mark the angle of 45 degrees with the help of an angle gauge. We cut off on the marking with an angle grinder and grind the edges, so we don’t injure ourselves on the burrs while working. Next, all we need to do is to insert the profile of a smaller diameter into the template and, having made a marking, cut it off.

Cut at an angle profile tube in a homemade device

In this article, we looked at how to cut the pipe at a 45 degree angle. Using one of the above methods, make a marking and perform the cut. For a flatter cut it is best to use an angle grinder. You will need experience when cutting with a welder, or the cuts will be uneven. As a last resort, you can use a metal hacksaw. Nowadays there are many different devices for cutting pipes at an angle on the market, but buying them requires unnecessary expense. It is easier and cheaper to make yourself a template once, and use it as needed.

Marking the corner with a paper sheet

Marking with a paper sheet is one of the easiest ways to accomplish the task. A square sheet of paper is needed. It is folded exactly diagonally. The resulting template for cutting pipes should be wrapped around the product so that the long side went parallel to its cross section.

Then a 45 degree angle is formed on the smaller side. It remains to mark the line for the cut trimmer with a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with a narrow adhesive tape so as not to accidentally erase it. This method is great for long, large pipes with a cut approximately in the middle of the product.

Marking method with a bowl of water instead of a template

This method of marking is suitable for pipes of small diameters that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of slope is marked on it. Now it is necessary to carefully dip the end of the product into the liquid, tilt it towards the mark, and then pull it out.

As a result of such actions, a clear line for the trimmer contact with water will appear on it, it must be highlighted. According to it, the pipe is cut at an angle. This method is best for work where multiple markings are required.

Marking out a corner with a paper sheet

The paper sheet marking is one of the simplest ways to perform the task. A square sheet is needed. It is folded exactly diagonally. The resulting template for cutting pipes must be wrapped around the product so that the long side runs parallel to its cross section.

Then a 45 degree angle is formed on the smaller side. It remains to mark the line for the trimmer cut with a construction pencil or marker on a sheet of paper.

It is recommended to wrap the marking area with a narrow adhesive tape so as not to accidentally erase it. This method is great for long, large pipes with a cut approximately in the middle of the product.

The method of marking with a container of water instead of a template

This method of marking is suitable for small diameter pipes that are planned to be cut at a certain angle close to the edge. First you need to prepare a deep container of water. The planned angle of inclination is marked on it. Now you need to carefully immerse the end of the product in the liquid, bend it to the mark, and then pull out.

As a result of such actions, a clear line for trimmer contact with water will appear on it, it must be highlighted. According to it, the pipe is cut at an angle. This method is best suited for works where multiple markings are needed.

How to cut thin-walled pipes

Another type of pipe is thin-walled. These are usually made of nonferrous metals such as aluminum or copper. Cutting thin-walled pipes is characterized by greater complexity, as there is a high probability of deformation of the element. In this case it is possible to use some kind of filler, such as sifted sand.

As a tool you can use an angle grinder, a metal saw or a special machine. It depends on the situation.

Cutting metal pipes is quite time consuming, but quite feasible by one’s own hands. In this case, the work with round tubes, are not fundamentally different from the cutting of profile pipe. The main thing to remember is that when carrying out the work it is necessary to observe the safety rules.

Mechanical methods

To simplify the cutting of tubular products is widely used thermal effect on the metal and mechanized methods.

angle grinder. Using an angle grinder with an abrasive disc. the most accessible of the mechanized methods. It is used not only in everyday life, but also in industry. However, work with an angle grinder requires the performer to be as careful and attentive as possible. A slight misalignment can cause the disc to become jammed or even destroyed. Therefore, personal protective equipment should not be neglected. And, of course, it is necessary to adhere to the following rules:

- To perform cutting, using an angle grinder, should the performer who has skills to work with it, and no one else;

- The pipes must be clamped in a vise as securely as possible;

- It is forbidden to cut concrete, stone or other materials with a disc designed to work with metal;

- to prevent uncontrolled release of the disk from the slot, the direction of motion of the angle grinder should be the same as the direction of rotation of the abrasive disk itself;

- Before starting work, always wear a face mask or safety goggles;

- It is strictly forbidden to work with an angle grinder without a safety guard.

Cutting thick-walled pipe to size is also possible with the angle grinder. True, in this case there will be a significant consumption of abrasive discs.

Cutting metal pipe with an angle grinder is the most affordable and cheapest method

Roller tube cutter. Here the main working components are one or several rollers. Moving along the surface of the pipe, they remove the metal in the cutting zone. Moving cutting rollers on a special cage guide, which is installed in the place of cutting before the work begins. Their clamping force on the pipe is adjusted by means of screwed mechanical devices. Cutting is rocking up and down in a downward/upward movement combined with a gradual pulling-in of the rollers.

It is worth noting that cutting large-diameter steel pipes with a pipe cutter does not significantly simplify and speed up the process.