What and how to cut a plastic skirting board

The skirting board is an element that gives the finish look. The joining of the walls with the ceiling and floor must be done very neatly and beautifully. To choose the right baseboards, coordinate them with the walls, floor and ceiling, mount the corners. you need to know how to.

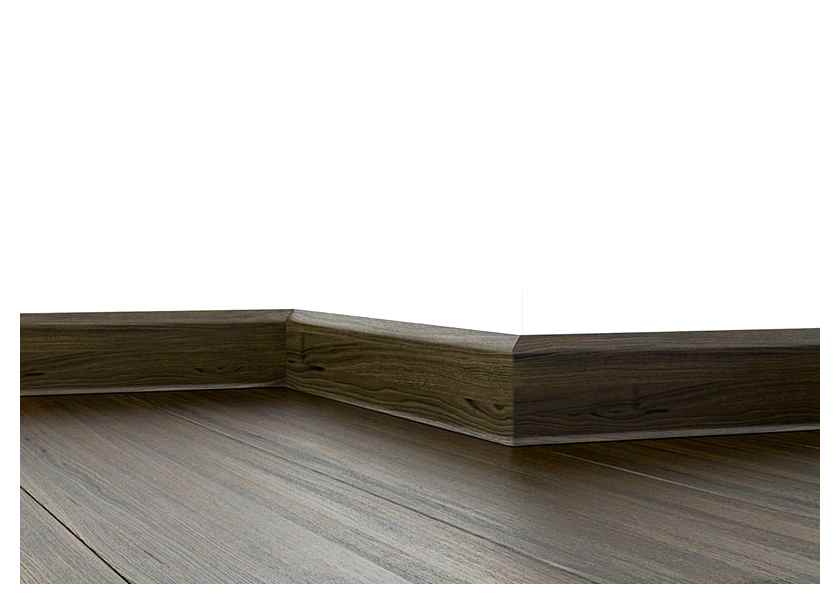

Plastic skirting boards have replaced the wooden ones used in previous years. They have a number of advantages. They are made of polyvinylchloride (PVC), a material that is widely used in industry and construction. Their appearance imitates any type of wood. They are easy to process, easy to assemble. They are immune to mold, mildew and damp, they are easy to clean. They are much cheaper than wood.

Plastic skirting boards come in different shapes and colors. Various manufacturers’ skirting boards differ from each other. To each specific product it is necessary to apply the appropriate technology to him.

There are types of plastic skirting boards aimed at a particular floor covering. carpet, linoleum or parquet.

Ceiling skirting boards are usually made of dense foam.

How to choose the right tool for trimming plastic baseboard

To work with plastic skirting boards, you need the most common tool, which is available to any craftsman and even many men of the household.

Hand tools

Of hand tools for work will come in handy hacksaw for wood with a fine cross-cutting tooth, a hacksaw for metal, hand drill, screwdrivers, sharp knives, scissors. All tools must be sharp, otherwise you can simply crush the edges of the cut. If you do not have skills, you should practice on scraps of material with different tools.

Power tools

Of the power tools in the work can use an electric jigsaw, power drill, angle grinder.

Skirting materials

Before cutting ceiling plinth, it is worth getting acquainted with the materials for their manufacture, which differ in the density of the components used. This also determines the way the elements are cut.

Features of materials for ceiling plinths are presented in the table:

- Fade resistance and high durability.

- Flexibility.

- Moisture resistance.

- Different sizes and ornaments, which allows you to choose for any interior.

- Can be painted.

- High weight.

- Relatively high price.

- Low weight.

- Low cost.

- Soft edges.

- Varied design.

- Easy to cut and mount.

- Fragile. Not used on curved surfaces.

- The grain structure of the material and the rough edges require additional treatment. trimming, painting.

Tip: Buying polystyrene ceiling mouldings, you should give preference to denser materials, made by extrusion.

- An abundance of colors.

- Low cost.

- Resistance to moisture.

- Easy to work with.

- Not subject to repainting.

- It is easy to crack.

- The corners of the baguette are not rigid at connection, it is necessary to use in addition the glue composition.

- Environmental friendliness.

- High-end material. Used for decorating rooms, styled like the old times (see the photo). ).

- Hygroscopicity, which can lead to changes in the size and geometry of products due to moisture absorption.

- Expensive.

- Can rot.

- Burns.

- Can be difficult to cut to size.

Tip: When cutting any of these materials, a fine toothed hacksaw should be used. Otherwise, it may result in an uneven edge of the part. The large tooth of the tool will bite into the material.

Before installing the baguette on the ceiling with his hands, you need to determine how to cut it. The main difficulty is to maintain the required angle of joining the elements. Only then is it possible to achieve a butt joint without a visible gap.

Tip: If gaps are formed after the installation of the beams, they need to be sealed with a special glue, silicone or sealant in white.

Tools for cutting the baseboard

A quality and properly selected tool, will allow you to perfectly dock the baseboard at all corners. To trim the baguette for the ceiling, various tools are used, which have their own peculiarities of use.

This is a special box with several holes. When performing the operation, a workpiece is inserted inside the device, and then the baguette is cut with a hacksaw. The work is done quite simply, but the edge of the part turns out quite rough, sometimes the product, especially foam plastic, even spoiled by the impact of an ordinary hacksaw.

Tip: After trimming plastic or wood baguettes in the jigsaw, the cut areas should be sanded with sandpaper or a file.

With this tool, the cut is as good as possible. When cutting an electric tool, the blade is lowered onto the baseboard and the desired result is obtained.

Such a tool is very convenient to trim a skirting board made of wood, as seen in the photo, plastic and other products at an angle. The peculiarity of cutting is the exact drawing of markings on the workpiece, and then the smooth lowering of the working saw on the baseboard.

Electric jigsaw creates cuts in different directions, at the desired angle. The advantage of the tool is the efficiency and accuracy of the work.

It is easy to cut foam products with such a tool. After pre-marking the part with a knife, the skirting board is carefully trimmed at the right angle.

Despite the simplicity of cutting, in order not to spoil the new skirting board, it is better to use scraps of material and determine the technology of the process, before obtaining the desired result.

- To measure correctly, the plank is measured between the two corners. In this case, for internal corners, the length is measured from the elements. And the distance from the outer corners is measured from a point that is away from the inner.

- When installing foam baseboards at the junction between the wall and the stretch ceiling, adhesive is applied to the part of the product that is in contact with the surface.

- The final fixing of the skirting board is carried out after adjusting the angle of the adjacent plank.

- If the wall, ceiling and floor have a right angle, it is easier to fit the strips at the bottom, laying out the details on the floor or on a prepared table.

- Small gaps remaining in the corners should be puttyed.

- Particular attention should be paid to the installation of ceiling plinths made of wood of rare species. In this case, puttying the gaps expected result, most likely will not give. On the background of the texture will appear a bright spot.

- High-class ceiling skirting boards, in addition to the main planks, have special inserts for right angles. Such inserts will greatly simplify installation and improve the quality of the work performed.

Peculiarities of cutting and joining baguette elements

Before you start the work, it is worth watching the video.

- It is necessary to cut the skirting board from the front side and along the outer edges.

- When cutting an inside corner this way, both sides of the baguette must be machined.

- When performing the work it is better to use a trim saw, but in the home you can do with a simple pliers.

- For the foam baguette requires its edges to cut at an angle of 45 °.

- The cut on the right is made on the baseboard, glued to the left. And vice versa.

- The lower part of the baguette should protrude over the upper, in order to obtain an optimal internal angle.

Cutting the skirting boards with the plinth cutter

The chair is a device that can be made of:

In appearance it is a tray, on the sides of which there are grooves at different angles.

- To cut the corner on the skirting board, the element is mounted in the position in which it will be positioned on the ceiling plane.

- The part should be properly placed and pressed tightly to the base.

- Carefully aligned flat on the ceiling.

Tip: The skirting board should be tried on dry before installation, and then put a pencil mark. This will not allow you to mix up the direction of the cut.

- For a skirting board made of hard material, it may be necessary to adjust the element with a file.

- Do not use a lot of force when making the cut. Otherwise soft materials can deform and crumble.

Cutting baseboard corners without a chisel

Cutting the corners of ceiling plinth can be performed without a pitchfork, or make it yourself.

It’s easy enough, using several options:

- With the help of improvised materials:

- is made a form of three planks or thick plywood;

- Use a 45° notch in the sidewalls of the appliance. A protractor or angle piece should be used for marking.

- If there are no materials to make, or you need to cut a little, then:

- The paper is bent at the desired angle. It is laid on a bar and a line for a trimmer, along which a cut is made;

- the element is placed under the bar and the cut is made according to the template.

- Determines the cutting angle of the ceiling plinth and decides how best to cut the part. At the same time:

Cutting rules

In order to safely carry out the work it is necessary to clearly follow the following rules:

- When working with panels that have been brought in from the cold, it is necessary to wait a short period of time. This is necessary in order to warm the material. If you do not listen to the advice, then the plastic panels in the process of cutting will break, thereby losing their neat appearance. It is not uncommon for cracks to appear on a surface that is cut lengthwise.

- In order to obtain several slats of the same length, it is necessary to lay them on at least 2 supports. This protects against sagging or shifting. It is recommended to place the edge of the element, which is not to be trimmed, against the wall. Thanks to this action it is possible to secure them from shifting.

- You can facilitate the process by making a marking with a pencil or marker.

- Correctly make the cut should be the underside of the panel down, because during processing under the influence of the load the profile of the slat changes and causes some inconvenience in the process of installation. Often there are microcracks on the face surface, which appear in the future.

- When using a power tool you need to use protective goggles and gloves that can protect from splinters and sawdust, flying in different directions in the process of cutting.

What to cut the plastic panel at home?

What to cut plastic panels at home? This question is very relevant to thrifty homeowners who have decided to cover the walls of the toilet and bathroom with decorative PVC panels.

The material is practical and can fully replace ceramic tiles, when there is a lack of time or money for a full repair.

In this article we will find out what to cut the plastic panel, so as not to damage the material and make a neat edge.

What is the best way to cut plastic panels?

Plastic panels have long been loved by owners of apartments and private homes, because their installation can be carried out independently without much difficulty, they are not affected by moisture, are materials of low flammability, resistant to mechanical damage, and also have a long service life and are relatively cheap.

But often there is a need to cut the panel, because its standard length is 3 meters, which often exceeds the standard ceiling height in apartment buildings and private constructions. In this regard, inexperienced craftsmen are faced with the question of what to cut the PVC panel with. In fact, there are several answers. Let’s consider each suitable option in detail.

A clerical knife

An ordinary office knife can also be used for this purpose. First of all a straight notch is made on the surface of the panel with a ruler, after which the plastic is simply broken.

Important! It is better not to use a common knife to cut PVC panels. If the panel has a cellular structure, then it is not recommended to use a knife at all.

The power tool

For the most impatient people, the answer to the question of how to cut plastic PVC panels is the power tool. You can use any machine that you have at hand. This method will save time, because the sawing will be carried out in a matter of seconds.

So what is the best way to cut PVC?? For this purpose, the most commonly used:

Important! When using an electric jigsaw, you should choose a saw blade with a fine tooth and switch off the pendulum stroke. It is also better to start by trying to make a cut on an unnecessary piece of panel to see which side will have a neat edge.

Important ! After cutting with an angle grinder plastic corners will need to grind with a special machine. If you do not have such a tool available, it is better to look for another option for cutting plastic.

Important! It is recommended to cut plastic panels at low speed because if the speed is too high the material will start to melt and emit toxic fumes, and the cut will be torn.

How to cut a PVC panel? Basic rules:

- If the panel has been outdoors before cutting, especially in case of low ambient temperatures, you should not start working immediately. You need to let the plastic warm up, because when it is cold it becomes more brittle and the chance of damaging it increases.

- Before sawing plastic panels, you need to mark the line for the trimmer notch. For this purpose a felt-tip pen is best suited. It is clearly visible, and if necessary, traces can be easily erased.

- The master must be vigilant and observe all safety precautions. Working, you must wear protective goggles and gloves, so that the sharp splinters that are formed as a result of cutting, do not hurt you.

- Since the material is quite fragile, you should work with it very carefully and carefully, taking your time.

material

As you can see, there are several answers to the question of how to cut a plastic panel. Each master himself can choose from the proposed options the best for himself, because some tools you will find at home, and some. will have to buy or make. In any case, working with such a fragile material, you should be careful and take safety measures.

What to cut plastic panels at home?

What to cut plastic panels at home? This question is very relevant to thrifty homeowners who have decided to cover the walls of the toilet and bathroom with decorative PVC panels.

The material is practical and may well replace ceramic tiles, when there is a lack of time or money for a full repair.

In this article we will find out how to cut plastic panels, so as not to damage the material and make a neat edge.

What is the best way to cut plastic panels?

Panels of plastic loved by owners of apartments and private homes for a long time, because they can be installed on their own without much difficulty, they are not affected by moisture, are materials of low flammability, resistant to mechanical damage, and also have a long service life and are relatively cheap.

However, the need to trim the panel often arises, because its standard length of 3 m, which often exceeds the standard height of the ceilings in apartment buildings and private constructions. Therefore, inexperienced craftsmen are faced with the question of how to cut the PVC panel. There are actually several answers. Let’s consider each option in detail.

A box cutter

An ordinary office knife can also be used for this purpose. First a straight cut is made on the surface of the panel with a ruler and then the plastic is simply broken.

Important! It is better not to use an ordinary knife to cut PVC. If the panel has a cellular structure, then it is not recommended to use a knife at all.

Power tools

For the most impatient ones, the answer to the question of how to cut plastic PVC panels is a power tool. You can use any machine that is at hand. This method will save time, because the sawing will be carried out in seconds.

So what is the best way to cut PVC? For this purpose, it is most often used:

Important! Using an electric jigsaw, you should choose a saw with a fine tooth and turn off the pendulum stroke. It is also better to try cutting on an unnecessary piece of panel to see which side will have a neat edge.

Important! After cutting with an angle grinder plastic corners will need to grind with a special machine. If you do not have such a tool, it is better to look for another option for sawing plastic.

Important! It is recommended to cut plastic panels at low speed because if the speed is too high the material will start to melt and emit toxic fumes, and the cut will be torn.

How to cut a PVC panel? Basic rules:

- If the panel before the moment of cutting was on the street, especially important in the case of low ambient temperatures, then immediately begin to work can not. You need to let the plastic warm up, because when cold, it becomes more brittle and the chance of damaging it increases.

- Before sawing plastic panels, it is necessary to mark the trimmer line for the notch. The best way to do this is with a felt-tip pen. It is well visible, and if you do not need it, it is easy to erase traces.

- The master must be vigilant and observe all safety precautions. Working, you must wear protective goggles and gloves, so that the sharp splinters that are formed as a result of cutting will not hurt you.

- Since the material is quite fragile, you should work with it very carefully and carefully, taking your time.

the material

As you can see, there are several answers to the question of how to cut a plastic panel. Each master himself can choose from the proposed options the best for themselves, because some tools you can find at home, and some. will have to buy or make. In any case, when working with such a fragile material, care and safety precautions should be taken.

Cutter

This tool has proved itself perfectly because of its low cost. It is excellent for work at home.

The tool has excellent performance, and the surface that can be cut looks flat. It is also worth highlighting the fact that no special physical effort is required to perform the cutting. A great advantage is also its compactness, which does not take up much space for storage.

The disadvantage of the tool is that it can only cut in a straight line, it will not be possible to round the edges.

Saws

practical in use is considered a hacksaw, and it does not matter whether it is metal or wood. The only requirement when using a wood hacksaw is the presence of small teeth, which should not be bifurcated, because this destroys the surface of the material to be sawed into pieces. This tool is often used for crosscutting.

Cutting a baseboard with a wire and plinth saw

The angle of connection of two planes in a room corresponds to 90 degrees, accordingly each panel should have a 45-degree angle of cut to form the necessary value at connection. To carry out the process of sawing you will need a cutting tool, a jig saw, and a simple pencil.

- The tray in the middle of the jig is designed to hold the skirting board. The panel is placed against the device with the rough surface, because if it is placed the other way around, the front part of the product can be damaged when cutting;

- The diagonal slots on the jigsaw are placed so that the piece cut along them has a certain degree. they play the role of guides for the cutting tool. Choosing the necessary angle, you should make sure that the edge of the panel went beyond the edge of the guide slot by a small distance, to get a perfect cut across the width of the skirting board;

- If the width of the baseboard is narrower than the jigsaw tray. you need to press the panel evenly to one side of the groove and in this form to carry out the sawing. This way, the corner you cut will have the exact value. It is inadmissible to place the panel in the tray at different angles. this will cause the resulting cut shapes to not be identical to each other;

Cutting the skirting board at an angle by means of a jig saw

- The cutting tool blade is inserted into the guide slots and the panel is cut evenly. Polyvinylchloride has an elastic structure. when sawing, you can not put pressure on the tool, otherwise the cut can be uneven. Also, you can not saw too quickly, as this will cause heating of the edges and deformation of the edge;

- After one side of the corner is sawn off, proceed to form its second part. The sawing process is carried out as in the previous case, with the difference that the second corner is the mirror opposite of the original workpiece. In order to get a mirrored corner, you need to put the panel in the chair on the other side and cut it on the appropriate guide;

- To make straight cuts, the machine also has perpendicular cutouts that can be used to cut the panel vertically. Carrying out the cut the only thing you should constantly monitor. the uniform position of the panel in the tray, so that the cut turns out as evenly as possible;

This method is suitable only if during masonry and wall covering the corners were carefully aligned and correspond to the value of 90 degrees, but sometimes it happens that they may have other parameters, since the construction of the house does not always comply with building regulations. The perfect angle formed by means of a jigsaw will be inappropriate. in this case the stencil cutting method is used.

Cutting with a stencil

If the corners of the walls do not meet the necessary parameters. the stencil method of cutting is used. For this you will need strips of thick paper or thin cardboard, which will serve as material for making a stencil. On the basis of the received details the marking of the cut on the baseboard is carried out. Given the fact that each corner can have a different degree, for each need to make an individual stencil.

The use of connectors will not everyone’s taste, as their presence in the interior is not always appropriate. the formation of joints is more time-consuming, but at the same time more aesthetic approach. Proper sawing is the key to good appearance of the corner in general and the baseboard in particular (also read about the properties of flexible baseboards).